Professional Documents

Culture Documents

4M Change Procedure

Uploaded by

KRISHAN KUMAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4M Change Procedure

Uploaded by

KRISHAN KUMARCopyright:

Available Formats

Ratan Aluminum Recycling Pvt. Ltd.

INTEGRATED MANAGEMENT SYSTEM PROCEDURE DOC. NO. : IMSP/PRD/02

Issue NO. : 01

DATE : 20.01.2018

4M Change Management

Rev. No./Date: 00/20.01.2018

PAGE : 1 of 2

ISSUED BY: APPROVED BY :

1. OBJECTIVE:

This procedure defines the control of 4 M on shop floor.

2. SCOPE:

This is applicable in shop floor for Planned change / Unplanned change/ Abnormal situation handling.

3. ROLES & RESPONSIBILITY:

1)Quality Engineer

2)Production Incharge

4. Procedure/ Flow:

S. Reference

Activity Responsibility

No / Format

1 Identification of Change Point in Process. …..

4M Change sheet will be filled by Operator on Daily basis. 4M Change

Production In-

2 Point Control to be Display on each M/C and it should be filled daily F/PRD/03

charge

by the Operator/production In charge.

If there is any Change in 4M than Fill Daily 4M Change Sheet& to be Quality

3

display on 4M Change Control Board. Incharge

If there is any planned / unplanned / Abnormal change then follow 4 Production

4 M change control standard and communication about changes as per

Work Instruction for Communication. In-charge

Ratan Aluminum Recycling Pvt. Ltd.

INTEGRATED MANAGEMENT SYSTEM PROCEDURE DOC. NO. : IMSP/PRD/02

Issue NO. : 01

DATE : 20.01.2018

4M Change Management

Rev. No./Date: 00/20.01.2018

PAGE : 2 of 2

ISSUED BY: APPROVED BY :

For all Unplanned Change All the parts produced before 4M Change

Quality

5 will be kept in HOLD area & to be Inspected as per 4M Change

Incharge

Instruction.

4M Change point Control Sheet to be filled when a change occurs in Production

MONITORING

process. In-charge

5. Reference Documents:

F/PRD/03 4M Change Record.

F/PRD/09 4M Change History Card

You might also like

- 4 M Change ProcedureDocument2 pages4 M Change ProcedureManasi shindeNo ratings yet

- Training on 4M Change Management ProcessDocument28 pagesTraining on 4M Change Management Processsunil kumar90% (10)

- 4M Change Procedure - PED 02Document2 pages4M Change Procedure - PED 02sathyabalaraman87% (23)

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (4)

- Procedure for PFMEA Analysis and ImprovementDocument3 pagesProcedure for PFMEA Analysis and ImprovementPk Nimiwal100% (3)

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- 4M Change MatrixDocument1 page4M Change MatrixAnkit SainiNo ratings yet

- Change Control Management Matrix for Vendors (M/s Sigma vibracoutic India Pvt. Ltd. A Company of the TrelleborgVibracoustic GroupDocument3 pagesChange Control Management Matrix for Vendors (M/s Sigma vibracoutic India Pvt. Ltd. A Company of the TrelleborgVibracoustic GroupManikandanNo ratings yet

- W.I - Abnormal SituationDocument1 pageW.I - Abnormal Situation25april100% (2)

- Operator Observance ChecklistDocument2 pagesOperator Observance Checklistrajesh sharma100% (1)

- Master List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoDocument6 pagesMaster List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoSafety DeptNo ratings yet

- 1 2 3 - 4M Change Part TagDocument4 pages1 2 3 - 4M Change Part TagIt's me DJNo ratings yet

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDocument1 page14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersNo ratings yet

- 17 4M Change ProcedureDocument3 pages17 4M Change ProcedureKanwar Singh100% (3)

- Supplier 4M Change Request FormatDocument1 pageSupplier 4M Change Request FormatManoj KumarNo ratings yet

- Operator Observance SheetDocument5 pagesOperator Observance SheetEr Avinash Kumar100% (2)

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- 4M Change ManagementDocument2 pages4M Change ManagementManoj KumarNo ratings yet

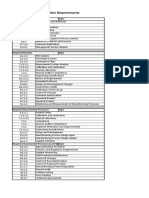

- Inital Flow Management Productivity ProcedureDocument4 pagesInital Flow Management Productivity Procedureshaggyrahul100% (3)

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneNo ratings yet

- IATF 16949 DocumenDocument1 pageIATF 16949 Documenpunitg_2No ratings yet

- Guideline 4M Change MatrixDocument3 pagesGuideline 4M Change MatrixAman JasujaNo ratings yet

- QAF12 Process Audit Rev 09Document4 pagesQAF12 Process Audit Rev 09ukavathekarNo ratings yet

- 4M Change Control Management Work InstructionDocument2 pages4M Change Control Management Work InstructionSameer Saxena100% (2)

- 4M Nissan Criteria For The AuditDocument29 pages4M Nissan Criteria For The AuditGaurav WadhwaNo ratings yet

- Manufacturing Process Audit Report SummaryDocument1 pageManufacturing Process Audit Report SummaryNaresh kumarNo ratings yet

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- 4M Change Management FormatDocument1 page4M Change Management FormatSUBODHH100% (2)

- Change Monitoring SheetDocument1 pageChange Monitoring SheetDINESHCHOUDHARY88No ratings yet

- 4M change management definition docDocument4 pages4M change management definition docManasi shindeNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Procedure For Ppap: Input / Output DiagramDocument5 pagesProcedure For Ppap: Input / Output DiagrammuthuselvanNo ratings yet

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- 4M Change Management July 2016Document14 pages4M Change Management July 2016Hichem ArbiNo ratings yet

- IATF Objective Data Analysis - Quality - ExampleDocument1 pageIATF Objective Data Analysis - Quality - ExampleSachin RamdurgNo ratings yet

- Training Topic Vs Name AnalysisDocument46 pagesTraining Topic Vs Name AnalysisAshish VaidNo ratings yet

- Product Audit Report SummaryDocument44 pagesProduct Audit Report SummaryEnis SirbegovicNo ratings yet

- Procedure For EcnDocument8 pagesProcedure For EcnChintamani GiramkarNo ratings yet

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- QS - F-136 List of (Iatf) Internal AuditorsDocument1 pageQS - F-136 List of (Iatf) Internal AuditorsShaili SharmaNo ratings yet

- IATF Road MapDocument1 pageIATF Road MapGANESH BORUDENo ratings yet

- T2 VSA With RequirementDocument8 pagesT2 VSA With RequirementSandeep K Malhotra100% (3)

- 4M Change FormatDocument1 page4M Change FormatOBSC PerfectionNo ratings yet

- Training Module 4M ChangeDocument13 pagesTraining Module 4M ChangebhawnaNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Operator observation sheet reviewDocument1 pageOperator observation sheet review25aprilNo ratings yet

- 4M Change Tracking SheetDocument1 page4M Change Tracking SheetKanaiya Jha100% (5)

- Attribute MSA 4th EditionDocument4 pagesAttribute MSA 4th EditionSachin RamdurgNo ratings yet

- Sampling plan for elastomer parts inspectionDocument1 pageSampling plan for elastomer parts inspectionLOGANATHAN V100% (1)

- Initial Supply Control ProcessDocument3 pagesInitial Supply Control ProcessKapil Karhana100% (1)

- Change Management Matrix for Vendor Updates in May 2022Document1 pageChange Management Matrix for Vendor Updates in May 2022nitin rathoreNo ratings yet

- QSP-PROD-03 4 M Change ProcedureDocument1 pageQSP-PROD-03 4 M Change ProcedureDeepak KumarNo ratings yet

- Quality System Procedure For Change Point ControlDocument3 pagesQuality System Procedure For Change Point Controlrajesh sharmaNo ratings yet

- SOP - Startup Shutdown and Operation of Coal MillDocument2 pagesSOP - Startup Shutdown and Operation of Coal MillJCSNo ratings yet

- ID Card Generate For Visitor SOPDocument2 pagesID Card Generate For Visitor SOPJaydeep PurohitNo ratings yet

- P 7.2-01 Prosedür - Müşteri İle İlişkili Prosesler Prosedürü - EngDocument4 pagesP 7.2-01 Prosedür - Müşteri İle İlişkili Prosesler Prosedürü - Engfaruk öztürkNo ratings yet

- Mesha Engineering Industry Pvt. Ltd. Unit-Ii: Oee Action Plan (2019)Document4 pagesMesha Engineering Industry Pvt. Ltd. Unit-Ii: Oee Action Plan (2019)Fabian BellNo ratings yet

- Point 1 - B) Procedure For Managemet of ChangeDocument3 pagesPoint 1 - B) Procedure For Managemet of Changemahesh KhatalNo ratings yet

- WgidatasetDocument362 pagesWgidatasetMiranda Rugova-KurteshiNo ratings yet

- History of JS: From Netscape to Modern WebDocument2 pagesHistory of JS: From Netscape to Modern WebJerraldNo ratings yet

- KHOADocument11 pagesKHOAshile9011No ratings yet

- ME6511 Dynamics Lab ExperimentsDocument3 pagesME6511 Dynamics Lab Experimentsraj_klnceNo ratings yet

- Assignment Qualitative and Quantitative Notes 1Document8 pagesAssignment Qualitative and Quantitative Notes 1api-544038337No ratings yet

- Latin Communis Means Common Opinion: EtymologyDocument6 pagesLatin Communis Means Common Opinion: EtymologySchena Dela CruzNo ratings yet

- Ceramics Chap12Document22 pagesCeramics Chap12Amar SheelwantNo ratings yet

- Coding DecodingDocument6 pagesCoding DecodingDeepjyoti BarmanNo ratings yet

- EIU Dropbox WFH Executive SummaryDocument19 pagesEIU Dropbox WFH Executive SummaryЮрий БагничNo ratings yet

- Survey Employer - PEODocument5 pagesSurvey Employer - PEONozie AbdullahNo ratings yet

- Victor MeyerDocument2 pagesVictor MeyerJulian de LaraNo ratings yet

- USAAO 2015 (Second Round)Document18 pagesUSAAO 2015 (Second Round)Science Olympiad Blog100% (4)

- Overview Manajemen RisikoDocument28 pagesOverview Manajemen RisikoSri Shanti WahyuniNo ratings yet

- Pipeline Nomenclature PDFDocument18 pagesPipeline Nomenclature PDFphenkNo ratings yet

- Lec 8 Normalization 2Document54 pagesLec 8 Normalization 2Banda Shravan KumarNo ratings yet

- St. Francis Xavier University - Antigonish, NovaDocument15 pagesSt. Francis Xavier University - Antigonish, Novaapi-26332274No ratings yet

- DDT BiomagnificationDocument2 pagesDDT BiomagnificationZe Rong Yin100% (1)

- Proyecto de inglés III para tercer gradoDocument8 pagesProyecto de inglés III para tercer gradoLauris RiosNo ratings yet

- Air pollution and its effectsDocument65 pagesAir pollution and its effectsDelima Adan100% (1)

- Specimen Aural Test 1 - 3Document40 pagesSpecimen Aural Test 1 - 3EnricNo ratings yet

- Customer Satisfaction Samsung ProjDocument57 pagesCustomer Satisfaction Samsung ProjVikas Gupta MirzapurNo ratings yet

- Daily Lesson Log 11Document5 pagesDaily Lesson Log 11Diane Marr Nicolas DencioNo ratings yet

- Airfield Pavement2Document12 pagesAirfield Pavement2molgarNo ratings yet

- Phraseological Units, Similes, ProverbsDocument13 pagesPhraseological Units, Similes, ProverbsMarietaNo ratings yet

- Chowdhury - The Power of Six Sigma 4AHDocument5 pagesChowdhury - The Power of Six Sigma 4AHHanZan100% (1)

- EndgameDocument2 pagesEndgameJose Jacob Ortiz MoralesNo ratings yet

- TSL Syllabus - Geography 0460 Yr8 (Ver.2)Document12 pagesTSL Syllabus - Geography 0460 Yr8 (Ver.2)Ezra NathanaelNo ratings yet

- SEV320 - Theory of Structures Assignment 1, 2020 Influence Lines & Deflection of Determinate Structures General InformationDocument3 pagesSEV320 - Theory of Structures Assignment 1, 2020 Influence Lines & Deflection of Determinate Structures General Informationhamza awanNo ratings yet

- Art TraceDocument283 pagesArt Tracenddprasanth1No ratings yet