Professional Documents

Culture Documents

Ae-Qms-P-02 Control of Documented Information

Uploaded by

pankaj66668Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ae-Qms-P-02 Control of Documented Information

Uploaded by

pankaj66668Copyright:

Available Formats

Aashita QUALITY SYSTEM PROCEDURE Rev. No.

: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 1 of 8

Document Distribution

No. Issued To Issue Date Issued By

Master MR 01/05/2019 MR

A Auditor (With MR) 01/05/2019 MR

Revision Record

Page Issue Rev. Change

S. No. Details of Change

No. No. No. Date

1 All 1 0 01/05/19 System Initialized As Per ISO 9001:2015

Abbreviations Used

CAR Corrective Action Report

FH Functional Head

CFT Cross Functional Team

SI Store In-Charge

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 2 of 8

1 Purpose:

To provide updated and correct information to people and to be able to trace the right document for

desired information, while eliminating the use of obsolete documents.

2 Scope:

Quality Manual, Procedures, Formats, Work Instructions, Control Plans, National and International

Standards, Responsibility & Authority Manual and Process Chart etc.

3 Responsibilities:

The responsibilities for preparation, control, review and approval of different documents is as

described on page 5 of this procedure.

4 Details:

4.1 DOCUMENT IDENTIFICATION:

4.1.1 Any document issued for operation of Quality Management Systems is designated by document

number as per scheme given below:

Level I Document - Quality Manual

4.1.1.1 The Quality Manual is designated as:

AE - QM - XX

Serial Number

Stands for Quality Manual

Short Name for Company

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 3 of 8

4.1.2 Level II Document - Procedures

Procedures / Process Approach: AE-P-YY

4.1.3 Level III Documents - (Objectives& Targets, Control Plan, FMEA, PFD, Work Instructions,

Checklist etc.):

The above Documents shall be numbered as per details given below:

Business Plan AE-BP-YY

Objective & Targets: AE -O&T-YY

Control Plan (Customer Wise): AE -CP-YY

Work Instruction: AE -WI-YY

Organization Chart: AE –ORG-YY

PFD: AE –PFD-YY

Responsibility & Authority: AE –RAA-YY

Skill Matrix: AE –SM-YY

Checklist: AE -CL-YY

Master List: AE -ML-YY

Job Description: AE -JD-YY

4.1.4 Level IV Document – Formats

Formats: AE -FT-YY

Where - AE Stands for Aashita Enterprises

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 4 of 8

YY stands for the running sequence number under the department (01 to 99)

4.2 DOCUMENT ISSUE AND CONTROL:

All controlled documents are identified with a stamp placed on them in red ink, reading

“Controlled If Stamped Red”. Currently because of the size only single copy is retained and

that too without any controlled copy stamp. Such documents also contain information about

document holder’s identification, copy number, and date of issue, revision and issue number of

that document and the authority responsible for review, control and approval of such

documents. All authorities sigh revision control page of such documents. For electronic copies

only secured or protected files are treated as controlled copies. The users of such copies must

ensure that their title appears in the attached distribution list of the document. No stamps or

sign appear on electronic copies.

Master copies of all controlled documents are kept and are available with MR. All master

copies are marked with stamp reading “Master Copy”, preferably on the reverse side, on each

page of all the controlled documents. These master copies also provide information about date

of issue and issuing authority.

On the documents, which are not prepared by our organization but defined in the scope

section above (such as national or international standards), only ‘master copy’ stamps are

marked. MR controls these documents. Refer section 4.3 of this document for details

The MR maintains a master list of all controlled documents, indicating the following

information:

Document name

Document identification

Issue No.

Revision No.

Date on which it was revised

Document distribution

When documents are used for Marketing or other similar purposes where non-availability of

latest revision will not affect quality, an uncontrolled copy is issued.

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 5 of 8

4.3 Document and Data Changes

1 All the people using these controlled documents are advised to continually look for

opportunity for improvement and necessary updating in these documents. Based on their

suggestions and usage of the documents, they are revised and updated.

2 For changes required in controlled documents, request is submitted to the MR. the MR reviews

the request, and if changes are required, revisions are made. The MR on issue of new revision

ensures its availability at all pertinent locations and destroying of old documents, this includes

verbal requests submitted. Master lists are used for this purpose and issue and withdrawal of

new and obsolete documents is controlled through them. All relevant master lists are revised

after each revision to reflect the current revision status. The changes made in controlled

documents are also discussed in management review meetings.

3 Master copy of old revisions of revised documents kept by MR for reference as per its retention

period after stamping “Obsolete Copy” on them. If documents are to be kept for a period

beyond their retention time, they are marked as “For Reference Only”.

4 For quality system manual and quality system procedures, when changes are made in

contents of any section, the changes are identified on an attached revision record. Wherever

practical, revised text is put in ‘Italic Text’ to facilitate quick identification of changes made.

5 Changes made in documents are reviewed and approved by the same authority that reviewed

and approved the original document unless otherwise decided.

6 Hand written changes are permissible provided the authorized personnel approve them.

7 To indicate revision status of quality manual and procedures, two numbers are used, namely

Rev. No. and Issue No. The revision no. indicates the revision status of a particular page or

document, whereas the issue number indicates the revision status of entire document. When

maximum 20 changes appear in revision record sheet of quality manual, the entire document

is revised and issued with next higher issue no. For example, when Issue 1 of quality manual

has been revised 20 times, a new issue with issue on 2 is issued in which all sections will have

rev. no.0.

4.4 Control of Documents On Electronic Media:

1 For electronic copies only secured or protected files are treated as controlled copies. The

users of such copies must ensure that their title appears in the attached distribution list of the

document. No stamps or sign appear on electronic copies.

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 6 of 8

2 A back up of all such documents is taken quarterly and on each revision. The entire control of

such documents lies with MR.

4.5 Control of External Documents: (To be read in conjunction with 4.1 Para 3 of this

document)

1 External documents are marked with “Master Copy” stamp. All such documents remain in the

control of MR.

2 International standards are kept updated by visiting the site of relevant issuing authority and

procuring information from there. Records of verification of such international standards will

also be maintained, if such standards from part of our quality system.

3 For other external origin documents, if any, the issuing authority is contacted and the status of

document is obtained.

4 The frequency of such verification is at six months interval and if necessary, it may also be

carried out during determination and review of customer’s requirements.

4.6 Engineering Specifications

1 Customer engineering standards / specification and changes based on customer required

schedule when received are reviewed by the customer representative along with the core

team members as identified in the concerned control plan. If these are for a new component,

the core team is formed in consultation with Proprietor. All engineering specifications are

reviewed as early as possible as but not later than 10 working days.

5 PEFERENCES:

Master Lists of Controlled Documents

File of Obsolete Documents Available with MR

Records of Visit of Web Sites of Organizations Regulating Controlled Documents

Customer’s Part Approval Process

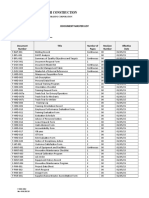

Document Control System:

The Controlling system for different documents is as described below:

Prepared Reviewed Controlled Approved

Document

By By By By

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 7 of 8

Quality Manual MR MR MR Proprietor /MR

Quality System Procedures (QSP) MR MR MR Proprietor /MR

Lab Manual MR MR MR Proprietor /MR

Quality Formats MR & DGM MR & DGM MR Proprietor /MR

Work Instructions MR & DGM MR & DGM MR Proprietor /MR

Master Lists (QM, QSP, R & A Manual W.I.,

MR MR MR Proprietor /MR

External Documents Etc.)

Master List of Approved Suppliers MR MR MR Proprietor /MR

Qualification Criteria / Skill Matrix MR MR MR Proprietor /MR

Responsibility & Authority Manual MR MR MR Proprietor /MR

Internal Audit Checklist MR MR MR Proprietor /MR

Control Plan CFT CFT MR Proprietor /MR

Flow Process Charts CFT CFT MR Proprietor /MR

6 Control Of documented information:

Identification, storage, protection, retrieval, retention and disposition requirements of records

are defined. All records remain legible, readily identifiable and retrievable. Records maintained

on electronic media are properly preserved and protected against change and destruction.

Backup of such records is taken quarterly to avoid chances of loss of data.

Pasting a slip on records, detailing out the location, number, responsibility and retention period

facilitates ready identification and quick retrieval of records. A list of all records maintained is

provided in this document. All storage locations are also numbered and indicated with title of

records.

All records after their retention period are disposed in the month of November and April each

year.

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 8 of 8

All functional heads are responsible for this activity pertaining to their function, whereas the

MR provides suitable framework to achieve the same.

The controlling system of records is defined on subsequent pages.

7 PEFERENCES:

Master Lists of Controlled Documents

File of Obsolete Documents Available with MR

Location &

Record’s Name Responsibility Retention Period

Storage

All Inspection Records Quality Deptt. Quality Head 1 Year

All Production Records Prod. Deptt. Prod. Head 1 Year

Customer Satisfaction, Feedback QMS Deptt. MR 1 Year

Corrective action QMS Deptt. MR 1 Year

Analysis Records QMS Deptt. MR 1 Year

Management Review Meeting QMS Deptt. MR 2 Year

Internal Quality Audits, QMS Records QMS Deptt. MR 2 Year

1 Year & As Per

All customer related records QMS Deptt. MR Customer Requirement

Records of Compliance with statutory

Admin Office Top Management 1 Year

requirements

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

Aashita QUALITY SYSTEM PROCEDURE Rev. No.: 0 01/05/19

AE-QMS-P-02 Issue No.: 1 01/05/19

Enterprises

CONTROL OF DOCUMENTED INFORMATION Page 9 of 8

Machine history records Maint. Deptt Maint. Head 2 Year

Calibration Record Quality Deptt. Quality head 2 Year

Continual Improvement QMS Deptt. MR 1 Year

Skill matrix, Training Record & Other

HR Deptt. HR 2 Year

Employee Related Records

Prepared By MR 01/05/19 Controlled By MR 01/05/19 Issued By MR 01/05/19 Copy No.

Controlled, If

Reviewed By MR 01/05/19 Approved By Proprietor 01/05/19 Issued To 01/05/19 Status

Red

You might also like

- AE-QMS-P-03 Procedure For Corrective ActionDocument4 pagesAE-QMS-P-03 Procedure For Corrective Actionpankaj66668No ratings yet

- AE-QMS-P-07 PROCEDURE FOR MaintenaceDocument3 pagesAE-QMS-P-07 PROCEDURE FOR Maintenacepankaj66668No ratings yet

- Ae-Qms-P-01 Procedure For Competence, Training and AwarenessDocument7 pagesAe-Qms-P-01 Procedure For Competence, Training and Awarenesspankaj66668No ratings yet

- AMM Procedures ManualDocument62 pagesAMM Procedures ManualSyrem RegunaNo ratings yet

- Nonconformity: Corrective Action Request (CAR)Document2 pagesNonconformity: Corrective Action Request (CAR)chandraNo ratings yet

- GP DOC MinDocument307 pagesGP DOC MinVenkatram PailaNo ratings yet

- Customer Related ProcessDocument5 pagesCustomer Related ProcessImtiyaz AkhtarNo ratings yet

- Audit ObservationDocument8 pagesAudit ObservationManoharar RNo ratings yet

- List of Master Formats-Getcert Pvt. LTDDocument20 pagesList of Master Formats-Getcert Pvt. LTDVenkatram PailaNo ratings yet

- Quality Manual - VVRDocument67 pagesQuality Manual - VVRRajamani100% (2)

- AMY-QMP-05 Procedure For External Provider Registration and MonitoringDocument4 pagesAMY-QMP-05 Procedure For External Provider Registration and MonitoringTauseef ShaukatNo ratings yet

- Work Instructionfor MISReports 9980Document1 pageWork Instructionfor MISReports 9980sourajpatelNo ratings yet

- F - 07.03 - Pest - Control - Plan and RecordDocument2 pagesF - 07.03 - Pest - Control - Plan and RecordSAMEER JAVEDNo ratings yet

- 23.sop - HRDDocument4 pages23.sop - HRDrishi gautamNo ratings yet

- Periodic Calibration Card Periodic Calibration CardDocument1 pagePeriodic Calibration Card Periodic Calibration Cardmohamed hamedNo ratings yet

- 4M Change ProcedureDocument2 pages4M Change ProcedureKRISHAN KUMARNo ratings yet

- 01.EXP01 QSC1 ASOYY 12 340001 0001 - Rev00 - Material Selection and Corrosion RepDocument32 pages01.EXP01 QSC1 ASOYY 12 340001 0001 - Rev00 - Material Selection and Corrosion Repksangeeth2000No ratings yet

- Procedure System of Site Qms TrainingDocument9 pagesProcedure System of Site Qms TrainingImtiyaz AkhtarNo ratings yet

- ASPAYE05GuideForEmployersinrespectofEmployeesTax1March2007Document58 pagesASPAYE05GuideForEmployersinrespectofEmployeesTax1March2007erostylesNo ratings yet

- Management System: Please Attach All The Original Invoices/BillsDocument1 pageManagement System: Please Attach All The Original Invoices/BillspvendaraNo ratings yet

- CA-01 Audit ReportDocument2 pagesCA-01 Audit ReportMo ZeroNo ratings yet

- Yash Papers LTD.: Integrated Management System Departmental FormatsDocument1 pageYash Papers LTD.: Integrated Management System Departmental Formatspawan sengatNo ratings yet

- Quality Manual SampleDocument51 pagesQuality Manual SampleFaizy NohNo ratings yet

- WPS+WQP-01 Audit PlanDocument1 pageWPS+WQP-01 Audit PlanMo ZeroNo ratings yet

- 5 QMS Document Master List - Asset Resources Management (Fleet)Document2 pages5 QMS Document Master List - Asset Resources Management (Fleet)Safix YazidNo ratings yet

- 5 QMS Document Master List - Asset Resources Management (Fleet)Document2 pages5 QMS Document Master List - Asset Resources Management (Fleet)Safix YazidNo ratings yet

- Customer Complaint ProcessDocument6 pagesCustomer Complaint ProcessKishan Chauhan100% (1)

- QMP-05 - Corrective ActionDocument5 pagesQMP-05 - Corrective Actionom cnc100% (1)

- Management Manual: 1 2 ContextDocument2 pagesManagement Manual: 1 2 ContextVishesh BabelNo ratings yet

- FT Procedure F1Document10 pagesFT Procedure F1abrayalamNo ratings yet

- Quality Manual - StampedDocument46 pagesQuality Manual - Stampedyogesh pachankarNo ratings yet

- Machine, Equipment and Facilities MaintenanceDocument4 pagesMachine, Equipment and Facilities MaintenanceImtiyaz AkhtarNo ratings yet

- KSH International Pvt. Ltd. Unit-3: Masterlist of Ongoing L3 & L 4 DocumentsDocument50 pagesKSH International Pvt. Ltd. Unit-3: Masterlist of Ongoing L3 & L 4 DocumentsSharad DunghavNo ratings yet

- Poison Test ProcedureDocument2 pagesPoison Test Procedureprashanth92% (13)

- Objective SheetDocument13 pagesObjective SheetNeeraj SinghNo ratings yet

- QMP-01 - Control of DocumentDocument7 pagesQMP-01 - Control of Documentom cncNo ratings yet

- List of of Nat - Int.std - Iatf - R7 - 1.4..2019Document2 pagesList of of Nat - Int.std - Iatf - R7 - 1.4..2019Bhakti MahbubaniNo ratings yet

- Procedure System of Control Procedure For AuditingDocument10 pagesProcedure System of Control Procedure For AuditingImtiyaz AkhtarNo ratings yet

- Car No 05Document1 pageCar No 05Ravi BaghelNo ratings yet

- Quality Manual: Manasota Optics, IncDocument35 pagesQuality Manual: Manasota Optics, IncIsabelle PlourdeNo ratings yet

- FM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Document17 pagesFM 198 Q1 ISO 9001 Audit Report Form Revision 7 20210803Supriya GothwalNo ratings yet

- SMoSB-QM-GEN-xxx-xx-Audit ReportDocument3 pagesSMoSB-QM-GEN-xxx-xx-Audit ReportSyahruulaa RazeehaNo ratings yet

- OH&S Documents ChecklistDocument6 pagesOH&S Documents ChecklistGobinderSinghSidhuNo ratings yet

- Procedure (English)Document13 pagesProcedure (English)Phu ThanhNo ratings yet

- Case Study Manual-Paramount Auto Components-1Document35 pagesCase Study Manual-Paramount Auto Components-1Rakesh SinghNo ratings yet

- Procedure System of Plant & Equipment ManagementDocument19 pagesProcedure System of Plant & Equipment ManagementImtiyaz Akhtar100% (1)

- SOP - Control of Quality RecordsDocument11 pagesSOP - Control of Quality Recordshimawan setyarsoNo ratings yet

- API Audit Planning GuidanceDocument3 pagesAPI Audit Planning GuidanceTasha RamisettiNo ratings yet

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- QSP 06 - Preventive ActionDocument5 pagesQSP 06 - Preventive ActionVivek VNo ratings yet

- Procedure 03 - Control of Non-Conformance and Corrective ActionDocument3 pagesProcedure 03 - Control of Non-Conformance and Corrective Actionsuhara hussainNo ratings yet

- LMP ManualDocument63 pagesLMP ManualAndrey PonomarevNo ratings yet

- Business Processes Master List Financial Accounting & ControllingDocument21 pagesBusiness Processes Master List Financial Accounting & ControllingPrathamesh ParkerNo ratings yet

- Monitoring and MeasurementDocument5 pagesMonitoring and MeasurementImtiyaz AkhtarNo ratings yet

- PH IMS SP12 Procurement Procedures1111111111111111111Document8 pagesPH IMS SP12 Procurement Procedures1111111111111111111Mohamed HamedNo ratings yet

- 5a Sample Supplier Verification Program TemplateDocument1 page5a Sample Supplier Verification Program TemplateJulius MuhimboNo ratings yet

- 26-20-04 Engine FIREXDocument82 pages26-20-04 Engine FIREXEdwar Zulmi100% (1)

- CA-01 Audit PlanDocument1 pageCA-01 Audit PlanMo ZeroNo ratings yet

- 01 Document MasterlistDocument3 pages01 Document MasterlistHorhe SmithNo ratings yet

- Abstract - HR ManagementDocument6 pagesAbstract - HR Managementfinal yearNo ratings yet

- Human Resource Management Practices of AB Bank LimitedDocument67 pagesHuman Resource Management Practices of AB Bank Limitedজয়ন্ত দেবনাথ জয়0% (1)

- MBA - Unit 1 - MB20107 - Managerial Skills and CommunicationDocument21 pagesMBA - Unit 1 - MB20107 - Managerial Skills and CommunicationBalaji DNo ratings yet

- MGT 2 HBO Activity 1Document26 pagesMGT 2 HBO Activity 1Jomari RealesNo ratings yet

- GoogleDocument8 pagesGoogleinfo.bharatfabsNo ratings yet

- EntrepreneurshipDocument19 pagesEntrepreneurshipmathew00785% (27)

- Management InformationDocument10 pagesManagement InformationTanjil AhmedNo ratings yet

- All Units Ppts Walker RoyceDocument110 pagesAll Units Ppts Walker RoyceRahul100% (1)

- HRBP 2 0 - tcm21 44040Document4 pagesHRBP 2 0 - tcm21 44040fernNo ratings yet

- IACS Cyber Security Incident Response Playbook PDF 1694299982Document47 pagesIACS Cyber Security Incident Response Playbook PDF 1694299982Senadin AlisicNo ratings yet

- Event Operation & Quality ManagementDocument15 pagesEvent Operation & Quality Managementuma jainNo ratings yet

- Chapter 10 Positioning The Market Offering Through The Product Life CycleDocument15 pagesChapter 10 Positioning The Market Offering Through The Product Life CycleMandy00011123322No ratings yet

- Glints Ebook - Employer Branding For Emerging Enterprises - in Collaboration With Samuel RayDocument35 pagesGlints Ebook - Employer Branding For Emerging Enterprises - in Collaboration With Samuel RaySyafinaNo ratings yet

- Automatic Model Transformation On Multi-Platform System Development With Model Driven Architecture ApproachDocument12 pagesAutomatic Model Transformation On Multi-Platform System Development With Model Driven Architecture ApproachCSIT iaesprimeNo ratings yet

- Information Deck: 24/7 Roadside Assistance - Tech EnabledDocument25 pagesInformation Deck: 24/7 Roadside Assistance - Tech EnabledAastha Bansal100% (1)

- SP18Document74 pagesSP18bbNo ratings yet

- Satisfying Customer NeedsDocument19 pagesSatisfying Customer NeedsHariton FloreaNo ratings yet

- Exida IEC 61508 Overview ReportDocument12 pagesExida IEC 61508 Overview ReportEmmanu MakembaNo ratings yet

- Sucofindo - Certification RolesDocument10 pagesSucofindo - Certification RolesiskandarfsmsNo ratings yet

- Module 5: Data Management: RequiredDocument7 pagesModule 5: Data Management: RequiredasimNo ratings yet

- 03 Indzara Small Business Product Catalog v1 3Document18 pages03 Indzara Small Business Product Catalog v1 3vijay sainiNo ratings yet

- Final Exam Spring 2021 - Hikmet - IsgenderovDocument15 pagesFinal Exam Spring 2021 - Hikmet - IsgenderovAydin NajafovNo ratings yet

- 5A. Consultants Professionals A4S Essential Guide To Management Information - Pdf.downloadassetDocument56 pages5A. Consultants Professionals A4S Essential Guide To Management Information - Pdf.downloadassetsdfgvbnhjvNo ratings yet

- List of Institutions OfferingDocument13 pagesList of Institutions OfferingPawan Rohilla PhysioNo ratings yet

- In The Modern Business World, Specialist Human Resource Management Skills Are Critical To Organisational Survival and Successes'Document12 pagesIn The Modern Business World, Specialist Human Resource Management Skills Are Critical To Organisational Survival and Successes'ninad_sawant_3No ratings yet

- The Review of Management Accounting: Niu Shuo, Du JianDocument3 pagesThe Review of Management Accounting: Niu Shuo, Du JianJannat JavedNo ratings yet

- Bicc White PaperDocument7 pagesBicc White PaperAhmedMuradNo ratings yet

- L4M2 Case Study FINALDocument4 pagesL4M2 Case Study FINALMohamed ElsirNo ratings yet

- Marketing Plan OF: Pratibha Prabin Stores Butwal-20 Rupandehi, NepalDocument7 pagesMarketing Plan OF: Pratibha Prabin Stores Butwal-20 Rupandehi, NepalAman GhimireNo ratings yet

- Kuliah - 2 - Channel StructureDocument44 pagesKuliah - 2 - Channel StructureWildan HakimNo ratings yet