Professional Documents

Culture Documents

Clutch 94 Golf

Uploaded by

pedro.tablet.velosoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clutch 94 Golf

Uploaded by

pedro.tablet.velosoCopyright:

Available Formats

CLUTCH

Article Text

1994 Volkswagen Golf III

This file passed thru Volkswagen Technical Site - http://volkswagen.msk.ru

ARTICLE BEGINNING

1994 Clutch

Golf III, Jetta III

DESCRIPTION

The clutch is a single dry disc type, which uses a diaphragm

spring-type pressure plate. The clutch is operated by a cable.

ADJUSTMENTS

Cable clutch system is automatically adjusted and requires no

manual adjustment.

REMOVAL & INSTALLATION

CLUTCH ASSEMBLY

NOTE: Transaxle may be lowered out of vehicle without removing

engine.

CAUTION: On models with theft protection system, obtain stereo

security code from vehicle owner before disconnecting

battery cable.

Removal

1) Disconnect negative battery cable. Remove upper clutch

housing-to-transaxle bolts. Disconnect right engine mount. Disconnect

back-up light switch wires, speedometer cable and clutch cable at

transaxle. See Fig. 1.

Fig. 1: Identifying Clutch Cable & Related Components

Courtesy of Volkswagen United States, Inc.

2) Disconnect shift linkage at gearshift lever. Disconnect

transaxle mounting brackets. Attach Engine Support (10-222) to engine.

Disconnect front engine support bracket. Remove starter and clutch

shields.

3) Remove exhaust pipe bracket. Support transaxle with floor

jack. Remove rear transaxle mount. Disconnect left and right axle

shafts at transaxle. Turn steering full left and secure axle shafts.

Remove large clutch cover plate bolts (plate remains on engine).

Remove small clutch cover plate bolts and clutch cover plate.

4) Push engine as far to the right as possible. Pull

transaxle away from engine while positioning engine so right drive

flange clears flywheel. Lower and remove transaxle.

5) With transaxle removed, install Flywheel Holder (VW558) on

flywheel. Remove flywheel and clutch disc. Pry retaining ring from

intermediate plate, and lift intermediate plate from pressure plate.

Remove pressure plate-to-crankshaft bolts in a diagonal pattern.

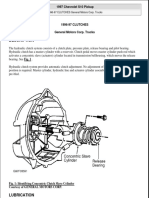

Installation

To install, reverse removal procedure. Clean hub splines of

input shaft and apply a light coat of grease. Ensure that protrusion

on intermediate plate points away from pressure plate. See Fig. 2.

Ensure transaxle oil level is correct.

Fig. 2: Exploded View Of Clutch Assembly

Courtesy of Volkswagen United States, Inc.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Application Ft. Lbs. (N.m)

Axle Shaft-To-Transaxle Bolt ..................... 32 (43)

Engine-To-Transaxle Bolt

10-mm .......................................... 33 (45)

12-mm .......................................... 41 (55)

Flywheel-To-Crankshaft ................ 44 (60) + 1/4 Turn

Pressure Plate Bolt ................... 22 (30) + 1/4 Turn

Starter Bolt ..................................... 44 (60)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

END OF ARTICLE

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Clutch 93 GolfDocument3 pagesClutch 93 Golfpedro.tablet.velosoNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Transmission Removal & Installation - M/T Article TextDocument3 pagesTransmission Removal & Installation - M/T Article TextGatis IvbulisNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Steering Column Switches Article TextDocument8 pagesSteering Column Switches Article TextGatis IvbulisNo ratings yet

- Pitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939From EverandPitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939No ratings yet

- Clutch 95-96 GolfDocument9 pagesClutch 95-96 Golfpedro.tablet.velosoNo ratings yet

- Manual Trans Overhaul - Type 02A Article TextDocument20 pagesManual Trans Overhaul - Type 02A Article TextHakim Ben Abdeljelil100% (1)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Engine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Document19 pagesEngine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Dany Pistiner100% (3)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- 1.6L 4cyl Diesel & Turbo DieselDocument18 pages1.6L 4cyl Diesel & Turbo DieselLeomir BrandaoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 1993 Engines Eurovan - 2.5L 5-CylinderDocument20 pages1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanNo ratings yet

- Suspension - Front Article TextDocument5 pagesSuspension - Front Article TextGatis IvbulisNo ratings yet

- AUTO TRANS - Removal & InstallationDocument42 pagesAUTO TRANS - Removal & InstallationIngenieria MultifuncionalNo ratings yet

- N - Remove/Install/Overhaul - Gasoline Article TextDocument6 pagesN - Remove/Install/Overhaul - Gasoline Article TextgvmarianoNo ratings yet

- MT 02a Overhaul 96Document15 pagesMT 02a Overhaul 96XGACDNo ratings yet

- VW 2.0L 4-cylinder engine guideDocument25 pagesVW 2.0L 4-cylinder engine guideVictor100% (1)

- VW 2.0L 4-cylinder engine guideDocument25 pagesVW 2.0L 4-cylinder engine guideVictorNo ratings yet

- Remove Install Overhaul Turbo PDFDocument3 pagesRemove Install Overhaul Turbo PDFOskars ŠtālsNo ratings yet

- Aba Aeg 2 0Document25 pagesAba Aeg 2 0Diego NunesNo ratings yet

- 1993 VOLKSWAGEN ENGINES 2.5L 5-Cylinder PDFDocument19 pages1993 VOLKSWAGEN ENGINES 2.5L 5-Cylinder PDFlidaNo ratings yet

- Transfer Case 233 Chevrolet S10Document8 pagesTransfer Case 233 Chevrolet S10Maxi SardiNo ratings yet

- Volvo 850 1995 Engine Removal Overhaul InstallDocument3 pagesVolvo 850 1995 Engine Removal Overhaul InstallOskars ŠtālsNo ratings yet

- VW Golf 95-98 2.0 Repair ManualDocument60 pagesVW Golf 95-98 2.0 Repair ManualAales Welding67% (3)

- 4G63 ManualDocument34 pages4G63 Manualfrinliwigo100% (4)

- VW 1.8L 4-Cylinder Turbo Engine GuideDocument71 pagesVW 1.8L 4-Cylinder Turbo Engine GuideJai Bhandari100% (2)

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 InglesDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Inglesjorge Angel LopeNo ratings yet

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFtrastornadojhonNo ratings yet

- Application: 1990 Ford Bronco 1990 Ford BroncoDocument74 pagesApplication: 1990 Ford Bronco 1990 Ford BroncoWin Cardona100% (1)

- 2.4L 5-CYL VIN (55) : 1995 Volvo 850Document25 pages2.4L 5-CYL VIN (55) : 1995 Volvo 850apek1No ratings yet

- 2.0l 4 Cyl Nissan b13Document52 pages2.0l 4 Cyl Nissan b1325912530No ratings yet

- Drive Axle FrontDocument23 pagesDrive Axle Frontcarloslopez85No ratings yet

- Overhaul Transfer Case 231Document9 pagesOverhaul Transfer Case 231Ahmat Juhairi AriffinNo ratings yet

- 7.5L EngineDocument32 pages7.5L EngineSalvador Gasca100% (1)

- Transmission Removal and Installation at PDFDocument4 pagesTransmission Removal and Installation at PDFOskars ŠtālsNo ratings yet

- 4.2L Engine PDFDocument28 pages4.2L Engine PDFIvanov Hernandez Freire67% (3)

- Steering Gear - Power Rack & Pinion Article TextDocument4 pagesSteering Gear - Power Rack & Pinion Article TextGatis IvbulisNo ratings yet

- Series 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelDocument14 pagesSeries 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelJuan RiveraNo ratings yet

- 7.3L TurboDocument60 pages7.3L TurboIsmaelOrdoñez100% (2)

- Engine 1.6L (Steem G16) PDFDocument18 pagesEngine 1.6L (Steem G16) PDFAry Duran0% (1)

- Expo 2.4Document27 pagesExpo 2.4Percy RojasNo ratings yet

- Clutch Chevro S10 1997Document12 pagesClutch Chevro S10 1997roberto galvanNo ratings yet

- Aaf Aet Timing BeltDocument3 pagesAaf Aet Timing BeltAymz100% (1)

- VW 1.9L TURBO DIESELDocument26 pagesVW 1.9L TURBO DIESELfloresf5100% (1)

- 1993 Ford Thunderbird - 3.8L V6-VIN (4) & 3.8L SC V6 - VIN (R)Document46 pages1993 Ford Thunderbird - 3.8L V6-VIN (4) & 3.8L SC V6 - VIN (R)g_garcia_c_996374095100% (2)

- Engine Identification: 1999 Pontiac Grand Am GT 1999 Pontiac Grand Am GTDocument35 pagesEngine Identification: 1999 Pontiac Grand Am GT 1999 Pontiac Grand Am GTRenato GodoyNo ratings yet

- Grabd Am 2.4l EngineDocument61 pagesGrabd Am 2.4l EngineWayneNo ratings yet

- VW Golf Type 020 Manual Transmission Overhaul GuideDocument16 pagesVW Golf Type 020 Manual Transmission Overhaul GuideAndreiNo ratings yet

- Wiper/Washer System Article TextDocument2 pagesWiper/Washer System Article TextGatis IvbulisNo ratings yet

- Brake System PDFDocument9 pagesBrake System PDFOskars ŠtālsNo ratings yet

- 24L FourDocument28 pages24L FourIqbal NugrohoNo ratings yet

- Para DescargarDocument41 pagesPara DescargarTheJomVz PrNo ratings yet

- Manual - de - Servicio - Isuzu - 2.2l (LUV) PDFDocument24 pagesManual - de - Servicio - Isuzu - 2.2l (LUV) PDFLuis ValenzNo ratings yet

- Manual de Servicio Isuzu 2.2lDocument24 pagesManual de Servicio Isuzu 2.2lChino PlagaNo ratings yet

- Steering System Power Rack and Pinion PDFDocument6 pagesSteering System Power Rack and Pinion PDFOskars Štāls0% (1)

- Eh1100 3Document7 pagesEh1100 3Alfonso BerRamNo ratings yet

- Peugot 206 2001 2.0HDi FusesDocument7 pagesPeugot 206 2001 2.0HDi FusesnekonekicNo ratings yet

- RX 60 25 35 en TDDocument10 pagesRX 60 25 35 en TDsuranga yapaNo ratings yet

- BCS Nissan Versa 2011Document20 pagesBCS Nissan Versa 2011Nathalio HuaynocaNo ratings yet

- NIS Universal Joint PDFDocument47 pagesNIS Universal Joint PDFKennyNg100% (1)

- ChassisDocument24 pagesChassisempu pacolNo ratings yet

- Murray Model 405000x8c Lawn Tractor (2004) Parts ListDocument16 pagesMurray Model 405000x8c Lawn Tractor (2004) Parts ListKarloz MedinaNo ratings yet

- Texa Motor Truck 40.0.0 Latest Version Application List en-GBDocument251 pagesTexa Motor Truck 40.0.0 Latest Version Application List en-GBkallatisNo ratings yet

- Indian Economy Demonstrates Resilience Despite Challenges in 2009Document4 pagesIndian Economy Demonstrates Resilience Despite Challenges in 2009GULSHANKUMARVERMANo ratings yet

- Session Plan2 - Drining NCIIDocument49 pagesSession Plan2 - Drining NCIIBoy Lorilla0% (1)

- 1.0 PM (IP) Hilux Price ListDocument1 page1.0 PM (IP) Hilux Price ListChirstty YongNo ratings yet

- Cajas AutomaticasDocument12 pagesCajas AutomaticasREYNALDO COPANo ratings yet

- Geolandar at G015 Brochure PageDocument1 pageGeolandar at G015 Brochure PageemboscaoNo ratings yet

- PETROL,CNG,LPG Three Wheeler Spare Parts CatalogueDocument71 pagesPETROL,CNG,LPG Three Wheeler Spare Parts CatalogueJuan Manuel OrtegaNo ratings yet

- Technical Service Information: THM 4L60-EhdDocument3 pagesTechnical Service Information: THM 4L60-EhdJOSE GARVCVIANo ratings yet

- Tata Aria With 36 Features LatDocument88 pagesTata Aria With 36 Features LatAbhijeet LimayeNo ratings yet

- JA0606O00139ADocument4 pagesJA0606O00139Apulkitymcaust_112907100% (1)

- View Active Fault Codes on Blue Bird School Bus Dash DisplaysDocument7 pagesView Active Fault Codes on Blue Bird School Bus Dash DisplaysJaider Cruz CruzNo ratings yet

- WQP List For WholesaleDocument22 pagesWQP List For WholesaleAbid balouchNo ratings yet

- X100PRO Key Progamming Vehicle List: Programming KeysDocument135 pagesX100PRO Key Progamming Vehicle List: Programming KeysClaudio CurbeloNo ratings yet

- TerraGator Challenger 3244Document4 pagesTerraGator Challenger 3244ForomaquinasNo ratings yet

- Products Catalog: Bosch Common Rail InjectorDocument17 pagesProducts Catalog: Bosch Common Rail InjectorMuhammad Rafique Khan90% (10)

- Laporan Breakdown 28 Maret 2020Document1 pageLaporan Breakdown 28 Maret 2020Rheza IslamsyahNo ratings yet

- Chery A15 Inner Lining ManualDocument7 pagesChery A15 Inner Lining ManualCarlos TecnicNo ratings yet

- Man (Shacman) f2000 f3000 - Fuse Box and RelayDocument11 pagesMan (Shacman) f2000 f3000 - Fuse Box and RelayOroszi Gábor100% (1)

- LPT 2518 Tcic BS Iii Cat PDFDocument317 pagesLPT 2518 Tcic BS Iii Cat PDFYernena Naresh100% (1)

- Automatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElDocument212 pagesAutomatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElVIDAL ALEJANDRO GARCIAVARGASNo ratings yet

- CCR PowerTrain PRINTDocument2 pagesCCR PowerTrain PRINTJean Claude EidNo ratings yet

- How to install a car alarm in a 2004 Opel VivarDocument2 pagesHow to install a car alarm in a 2004 Opel VivarHrvoje HrKyNo ratings yet

- SPFRDDocument2 pagesSPFRDSebastianus Ari YudhantoNo ratings yet