Professional Documents

Culture Documents

Clutch 93 Golf

Uploaded by

pedro.tablet.velosoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clutch 93 Golf

Uploaded by

pedro.tablet.velosoCopyright:

Available Formats

CLUTCH

Article Text

1993 Volkswagen Golf III

This file passed thru Volkswagen Technical Site - http://volkswagen.msk.ru

ARTICLE BEGINNING

1993 Clutch

Cabriolet, Golf, GTI & Jetta

DESCRIPTION

The clutch is a single dry disc type, which uses a diaphragm

spring-type pressure plate. The clutch is operated by a cable.

ADJUSTMENTS

System is automatically adjusted and requires no manual

adjustment.

REMOVAL & INSTALLATION

CLUTCH ASSEMBLY

NOTE: Transaxle may be lowered out of vehicle without removing

engine.

Removal

1) Obtain radio code. Disconnect negative battery cable.

Remove upper clutch housing-to-transaxle bolts. Disconnect right

engine mount. Disconnect back-up light switch wires, speedometer cable

and clutch cable at transaxle. See Fig. 1.

Fig. 1: Identifying Clutch Cable & Related Components

Courtesy of Volkswagen United States, Inc.

2) Disconnect shift linkage at gearshift lever. Disconnect

transaxle mounting brackets. Attach Engine Support (10-222) to engine.

Disconnect front engine support bracket. Remove starter and clutch

shields.

3) Remove exhaust pipe bracket. Support transaxle with floor

jack. Remove rear transaxle mount. Disconnect left and right drive

shafts at transaxle. Turn steering full left and secure axles. Remove

large clutch cover plate bolts (plate remains on engine). Remove small

clutch cover plate bolts and clutch cover plate.

4) Push engine as far to the right as possible. Pull

transaxle away from engine while positioning engine so right drive

flange clears flywheel. Lower and remove transaxle.

5) With transaxle removed, install Flywheel Holder (VW558) on

flywheel. Remove flywheel and clutch disc. Pry retaining ring from

intermediate plate, and lift intermediate plate from pressure plate.

Remove pressure plate-to-crankshaft bolts in a diagonal pattern.

Installation

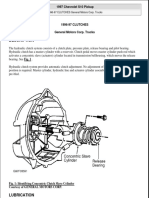

Reverse removal procedure to complete installation. Clean hub

spinnes of input shaft and apply a light coat of grease. Ensure that

protrusion on intermediate plate points away from pressure plate. See

Fig. 2. Ensure transaxle oil level is correct.

Fig. 2: Exploded View Of Clutch Assembly

Courtesy of Volkswagen United States, Inc.

CLUTCH CABLE

NOTE: If installing new cable, compress adjusting mechanism using

same retaining strap used to compress adjusting mechanism of

new cable. Strap is included with new cable.

Removal & Installation

1) Carefully cut 1/2 of retaining strap eyelet. Remove

retaining strap from new clutch cable, being careful not to bend

clutch cable. Depress clutch pedal at least 5 times. Install retaining

strap onto old cable. See Fig. 3.

2) With an assistant, compress adjusting mechanism and hook

retaining strap tabs onto pins of adjusting mechanism. If adjusting

mechanism cannot be compressed, repair or replace adjusting mechanism.

Remove over-center spring and clutch cable. Installation is reverse of

removal. Ensure proper operation by depressing clutch pedal at least 5

times and move clutch release lever approximately 10 mm in direction

opposite of normal travel. Clutch release lever must move freely

during check.

NOTE: Always depress clutch pedal at least 5 times before repeating

operation check.

Fig. 3: Removing Clutch Cable

Courtesy of Volkswagen United States, Inc.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Application Ft. Lbs. (N.m)

Clutch Cover Plate Bolt .......................... 15 (20)

Drive Shaft-To-Transaxle Bolt .................... 32 (43)

Flywheel Bolt .................................... 15 (20)

Pressure Plate Bolt ................... 22 (30) + 1/4 Turn

Starter Bolt ..................................... 44 (60)

Transaxle-To-Engine Bolt ......................... 55 (75)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

END OF ARTICLE

You might also like

- VW 1.8L 4-Cylinder Turbo Engine GuideDocument71 pagesVW 1.8L 4-Cylinder Turbo Engine GuideJai Bhandari100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Series 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelDocument14 pagesSeries 60 - Section 1.11 Gear Case Cover Exhaust Gas Recirculation (EGR) ModelJuan RiveraNo ratings yet

- 3.3L 6-Cyl VinDocument28 pages3.3L 6-Cyl VingypsyshortNo ratings yet

- 7.5L EngineDocument32 pages7.5L EngineSalvador Gasca100% (1)

- Modern Diesel Technology Heavy Equipment Systems.7Document56 pagesModern Diesel Technology Heavy Equipment Systems.7Adrian Troncoso EsquivelNo ratings yet

- Transmission Removal and Installation at PDFDocument4 pagesTransmission Removal and Installation at PDFOskars ŠtālsNo ratings yet

- 1993 Engines Eurovan - 2.5L 5-CylinderDocument20 pages1993 Engines Eurovan - 2.5L 5-Cylinderfrancesco pavanNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Research Seminar on Air Suspension SystemsDocument15 pagesResearch Seminar on Air Suspension SystemsParth SawantNo ratings yet

- VW 1.9L TURBO DIESELDocument26 pagesVW 1.9L TURBO DIESELfloresf5100% (1)

- Manual de Servicio Isuzu 2.2lDocument24 pagesManual de Servicio Isuzu 2.2lChino PlagaNo ratings yet

- 24L FourDocument28 pages24L FourIqbal NugrohoNo ratings yet

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFtrastornadojhonNo ratings yet

- Overhaul Transfer Case 231Document9 pagesOverhaul Transfer Case 231Ahmat Juhairi AriffinNo ratings yet

- 4G63 ManualDocument34 pages4G63 Manualfrinliwigo100% (4)

- The ISO 55000 RevolutionDocument2 pagesThe ISO 55000 RevolutionEduardo_77100% (1)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Engine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Document19 pagesEngine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Dany Pistiner100% (3)

- Manual Trans Overhaul - Type 02A Article TextDocument20 pagesManual Trans Overhaul - Type 02A Article TextHakim Ben Abdeljelil100% (1)

- Aba Aeg 2 0Document25 pagesAba Aeg 2 0Diego NunesNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Steering System Power Rack and Pinion PDFDocument6 pagesSteering System Power Rack and Pinion PDFOskars Štāls0% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Compressor WabcoDocument6 pagesCompressor Wabcoruben_cruz_34No ratings yet

- REC107487 KPA Truck Loading and Unloading Operations V2 1 PDFDocument11 pagesREC107487 KPA Truck Loading and Unloading Operations V2 1 PDFRoni EnjelaniNo ratings yet

- Technical Proposal For Detailed EngineerDocument27 pagesTechnical Proposal For Detailed EngineerJay PanitanNo ratings yet

- SeparatorsDocument140 pagesSeparatorsmatteo2009No ratings yet

- ATPL POF - Principles of Flight Questions BankDocument32 pagesATPL POF - Principles of Flight Questions Bankpilotmo100% (2)

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 InglesDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Inglesjorge Angel LopeNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- Clutch 94 GolfDocument3 pagesClutch 94 Golfpedro.tablet.velosoNo ratings yet

- Clutch 95-96 GolfDocument9 pagesClutch 95-96 Golfpedro.tablet.velosoNo ratings yet

- Transmission Removal & Installation - M/T Article TextDocument3 pagesTransmission Removal & Installation - M/T Article TextGatis IvbulisNo ratings yet

- 1.6L 4cyl Diesel & Turbo DieselDocument18 pages1.6L 4cyl Diesel & Turbo DieselLeomir BrandaoNo ratings yet

- Suspension - Front Article TextDocument5 pagesSuspension - Front Article TextGatis IvbulisNo ratings yet

- Steering Column Switches Article TextDocument8 pagesSteering Column Switches Article TextGatis IvbulisNo ratings yet

- Remove Install Overhaul Turbo PDFDocument3 pagesRemove Install Overhaul Turbo PDFOskars ŠtālsNo ratings yet

- AUTO TRANS - Removal & InstallationDocument42 pagesAUTO TRANS - Removal & InstallationIngenieria MultifuncionalNo ratings yet

- Volvo 850 1995 Engine Removal Overhaul InstallDocument3 pagesVolvo 850 1995 Engine Removal Overhaul InstallOskars ŠtālsNo ratings yet

- N - Remove/Install/Overhaul - Gasoline Article TextDocument6 pagesN - Remove/Install/Overhaul - Gasoline Article TextgvmarianoNo ratings yet

- 2.0l 4 Cyl Nissan b13Document52 pages2.0l 4 Cyl Nissan b1325912530No ratings yet

- Brake System PDFDocument9 pagesBrake System PDFOskars ŠtālsNo ratings yet

- Brake System: 1988 Jeep CherokeeDocument22 pagesBrake System: 1988 Jeep CherokeePreet_Raj_2303No ratings yet

- Transfer Case 233 Chevrolet S10Document8 pagesTransfer Case 233 Chevrolet S10Maxi SardiNo ratings yet

- MT 02a Overhaul 96Document15 pagesMT 02a Overhaul 96XGACDNo ratings yet

- Engine 1.6L (Steem G16) PDFDocument18 pagesEngine 1.6L (Steem G16) PDFAry Duran0% (1)

- Clutch: 1988 Toyota CelicaDocument6 pagesClutch: 1988 Toyota CelicaToua YajNo ratings yet

- Section 10 - Power Take-OffDocument19 pagesSection 10 - Power Take-OffMiller Andres ArocaNo ratings yet

- Manual - de - Servicio - Isuzu - 2.2l (LUV) PDFDocument24 pagesManual - de - Servicio - Isuzu - 2.2l (LUV) PDFLuis ValenzNo ratings yet

- Drive Axle FrontDocument23 pagesDrive Axle Frontcarloslopez85No ratings yet

- Suspension - Rear Article TextDocument4 pagesSuspension - Rear Article TextGatis IvbulisNo ratings yet

- Clutch Chevro S10 1997Document12 pagesClutch Chevro S10 1997roberto galvanNo ratings yet

- VW 2.0L 4-cylinder engine guideDocument25 pagesVW 2.0L 4-cylinder engine guideVictorNo ratings yet

- VW 2.0L 4-cylinder engine guideDocument25 pagesVW 2.0L 4-cylinder engine guideVictor100% (1)

- 2.4L 5-CYL VIN (55) : 1995 Volvo 850Document25 pages2.4L 5-CYL VIN (55) : 1995 Volvo 850apek1No ratings yet

- Luk Clutch Academy Mokka 17 CdtiDocument2 pagesLuk Clutch Academy Mokka 17 CdtiAlanWeissNo ratings yet

- mk2 Golf 90-92front SuspensionDocument5 pagesmk2 Golf 90-92front SuspensionEoin MacEoinNo ratings yet

- Transmission Removal and Installation atDocument8 pagesTransmission Removal and Installation atJeferson SilvaNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- VW Golf Type 020 Manual Transmission Overhaul GuideDocument16 pagesVW Golf Type 020 Manual Transmission Overhaul GuideAndreiNo ratings yet

- Pitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939From EverandPitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Insulin Bio SynthesisDocument12 pagesInsulin Bio SynthesisdrtpkNo ratings yet

- PT INSMART Oil & Gas Speaker Sudibyo ExperienceDocument1 pagePT INSMART Oil & Gas Speaker Sudibyo ExperienceSidik Kunto BNo ratings yet

- Supply Chain Logistics Management 4th Edition Bowersox Solutions ManualDocument4 pagesSupply Chain Logistics Management 4th Edition Bowersox Solutions Manualjohnjohnsondpybkqsfct100% (22)

- MSF2231 - SIB Motor Feb 17Document15 pagesMSF2231 - SIB Motor Feb 17Ibrahim RahmatullahNo ratings yet

- Pigafettas First Voyage Around The WorldDocument31 pagesPigafettas First Voyage Around The WorldSenyorita ArdiNo ratings yet

- Ch11 Global v102Document60 pagesCh11 Global v102Xavier AbainzaNo ratings yet

- Documents Required Onboard Indian AircraftDocument3 pagesDocuments Required Onboard Indian Aircraftnagesh shuklaNo ratings yet

- FAA Drone DataDocument44 pagesFAA Drone DatamacmoonNo ratings yet

- Reading Comprehension-2: False True False True TrueDocument2 pagesReading Comprehension-2: False True False True TrueGamze PişginNo ratings yet

- Volvo opportunity charging system delivers fast, reliable electric bus chargingDocument2 pagesVolvo opportunity charging system delivers fast, reliable electric bus chargingS.KAMBANNo ratings yet

- Tata TruckDocument9 pagesTata Truckbillfrindall7261No ratings yet

- Keywords: Car, Midsize, MumbaiDocument1 pageKeywords: Car, Midsize, Mumbaizulfi66No ratings yet

- Background Information OnDocument30 pagesBackground Information OnfdNo ratings yet

- Terminology OnboardDocument3 pagesTerminology OnboardDavid TurnerNo ratings yet

- NSTL ReportDocument22 pagesNSTL ReportAbel EbinNo ratings yet

- Amelia LiveDocument20 pagesAmelia LiveJelena RodicNo ratings yet

- JM Customs Department export declaration guideDocument2 pagesJM Customs Department export declaration guideFaisal Muhammad100% (1)

- PAL v SAVILLO rules on Warsaw ConventionDocument2 pagesPAL v SAVILLO rules on Warsaw ConventionElaizza ConcepcionNo ratings yet

- New Order Heavy Vehicle Lorries Allowed Time Kothavalchavadi c-5 Police Station LimitDocument3 pagesNew Order Heavy Vehicle Lorries Allowed Time Kothavalchavadi c-5 Police Station LimitLauren WhiteNo ratings yet

- IndigoDocument1 pageIndigoNitin KashyapNo ratings yet

- MdeputaDocument21 pagesMdeputaBryan GonzalesNo ratings yet

- 2010WebCatalog TAMBORESDocument112 pages2010WebCatalog TAMBORESCarlos ReconcoNo ratings yet

- @phinahas Resume@Document2 pages@phinahas Resume@Teena SajiNo ratings yet