100% found this document useful (1 vote)

312 views39 pagesOverburden Systems

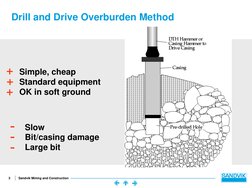

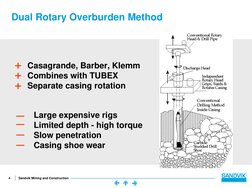

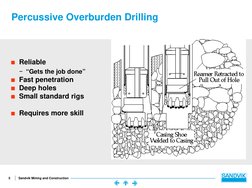

The document discusses different overburden drilling methods including tubex, dual rotary, percussive, and drill and drive methods. It provides details on the tubex system including components, features of the Tubex XL system, part numbering conventions, and an example project installing piles for an underground parking garage through difficult ground conditions.

Uploaded by

Gerardo HernandezCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

312 views39 pagesOverburden Systems

The document discusses different overburden drilling methods including tubex, dual rotary, percussive, and drill and drive methods. It provides details on the tubex system including components, features of the Tubex XL system, part numbering conventions, and an example project installing piles for an underground parking garage through difficult ground conditions.

Uploaded by

Gerardo HernandezCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction to Overburden Drilling Systems

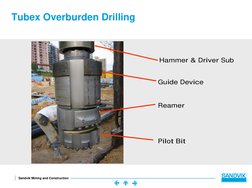

- Tubex Overburden Drilling

- Drilling Methods

- Components and Features of Tubex Systems

- Historical Development of Sandvik Drilling Techniques

- Overburden Drilling Products

- Simultaneous Casing and Tubex Features

- Tubex System Benefits and Part Numbers

- Comparative Analysis of Competitor Systems

- Case Study: TUBEX Drilling in Turin, Italy