Professional Documents

Culture Documents

SECTION 2.30: Lubrication System Description

Uploaded by

Nestor OyagaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SECTION 2.30: Lubrication System Description

Uploaded by

Nestor OyagaCopyright:

Available Formats

SECTION 2.

30

LUBRICATION SYSTEM DESCRIPTION

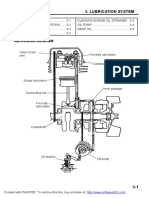

LUBRICATION SYSTEM DESCRIPTION The flow of oil passes from the main bearing journals

into the T-drilled crankshaft and then up through drilled

The lubrication system consists of the following com- passages in the connecting rods. After lubricating the

ponents: connecting rod bearing, piston pin bushing, and piston

• Oil Pan And Pickup Screen pin, the pressurized oil passes through an opening in

the top of the rod. The oil spray exiting the rod cools

• Oil Pump the underside of the piston crown and drains back to

• Oil Cooler the oil pan.

• Temperature Control Valve Oil supply tubes tapped off of the internal oil passage

leading to the front main bearing, supply a continuous

• Pressure Regulating Valve spray of oil to the gear train.

• Full-Flow Oil Filter Internal passages in the crankcase casting also direct

• Filter Relief Valve(s) the flow of pressurized oil to the camshaft bearing sad-

dles to provide lubrication of the main camshaft bear-

• Oil Strainer ings (bushings). Oil flows through holes in the cam

• External Piping (Customer-Supplied) bearing caps and down passageways in the valve lifter

housing. Oil lubricates the roller followers and cam

PRELUBE SYSTEM COMPONENTS lobes, after which it drops back to the oil pan.

• Prelube Pump/Motor An external oil supply line off the main oil header car-

• Prelube Operation ries oil to a separate external rocker arm oil header.

Supply tubes from the rocker arm oil header direct the

• Pilot-Operated Prelube Valve flow of oil to the rocker arm assemblies and valves.

• Inline Lubricator Excess oil drains down a cored passage in the cylinder

• Oil Pressure Gauge head and runs down the outside of the pushrod tubes

to a drainage passage in the valve lifter guides. The

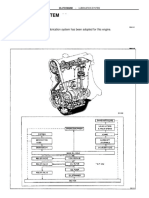

INTERNAL OIL CONTROL passage directs the flow of oil to a drainage hole in the

The main oil header is an integral part of the crank- valve lifter housing, where it flows back to the oil pan

case casting (see Figure 2.30-1). Internal passages in via the camshaft recess.

the crankcase direct the flow of pressurized oil to the The flow of pressurized oil through the fixed valve lifter

main bearings via drillings in the main bearing sad- screws of the rocker arm assemblies also supplies oil

dles. to the lifters, where the excess oil joins the flow from

the cored passage in the cylinder head.

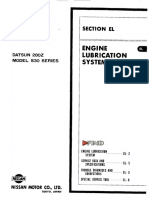

The flow of pressurized oil through the external system

is depicted in Figure 2.30-2.

FORM 6300 2.30-1

LUBRICATION SYSTEM DESCRIPTION

TURBOCHARGER

CORED

PASSAGE

CYLINDER

HEAD

PUSHROD

TUBE

TO SUMP

ROCKER ARM CAMSHAFT

OIL HEADER

TO SUMP

MAGNETIC

PLUG

CHECK

VALVE

SPRAY

NOZZLE(S)

GEAR

TRAIN

OIL

STRAINER

INTERNAL

OIL HEADER MAIN

CRANKSHAFT BEARING FRONT MAIN

BEARING CAP

Figure 2.30-1 Internal Oil Flow System

2.30-2 FORM 6300

LUBRICATION SYSTEM DESCRIPTION

CUSTOMER

FINAL OIL

SUPPLIED PIPING

STRAINER

OIL PUMP

DISCHARGE HOUSING

OIL PUMP

RELIEF VALVE

ENGINE

ENGINE OIL

PUMP

OIL PRESSURE

CONTROL VALVE

ADJUST IN FIELD

AT OPERATING

TEMPERATURE

PRELUBE PUMP

CHECK VALVE

TEMPERATURE

CONTROL VALVE

A

C B

OIL

FILTER

OIL COOLER

Figure 2.30-2 External Oil System Schematic

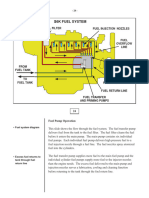

OIL PAN AND PICKUP SCREEN

The bottom of the crankcase is enclosed by the oil

pan. The oil pump draws oil from the lowest point in

the oil pan and delivers it to the oil cooler. The oil

pickup screen (see Figure 2.30-3) prevents foreign

material in the oil pan from entering the oil circuit.

FORM 6300 2.30-3

LUBRICATION SYSTEM DESCRIPTION

OIL PUMP

OIL PAN AND PICKUP

SCREEN ASSEMBLY

Figure 2.30-4 Engine Oil Pump –

(With Guards Removed For Clarity) 12 Cylinder

OIL COOLER

The oil cooler (see Figure 2.30-5 and Figure 2.30-6) is

a tube and baffle type assembly. The auxiliary water

pump circulates coolant through the oil cooler tube

bundle. The oil circulates around the tube bundle. Heat

from the oil passes through the tubes to the coolant,

which then carries it to a heat transfer device for dissi-

pation.

OIL COOLER

Figure 2.30-3 Oil Pan And

Pickup Screen Assembly – 6 Cylinder

OIL PUMP

The gear-driven oil pump is externally mounted. On

VHP Series Four engines the oil pump is located on

the front of the engine, below the crankshaft (see

Figure 2.30-4).

Figure 2.30-5 Engine Mounted Oil Cooler – 12 Cylinder

The thermostat is enclosed in a housing mounted at

the oil cooler outlet (see Figure 2.30-6).

2.30-4 FORM 6300

LUBRICATION SYSTEM DESCRIPTION

assembly develops a force that exceeds 2000G’s,

PRESSURE THERMOSTAT which compacts the contaminants against the turbine’s

REGULATING VALVE

housing. The centrifuge will remove oil contaminating

particles as small as 0.5 microns. The cleanable filter

elements remove remaining particles as small as

25 microns absolute. The Microspin system is more

environmentally friendly than systems that utilize dis-

posable elements. Cleaning the elements eliminates

the expense of replacement elements and the cost of

hazardous waste disposal. See Section 4.30 Lubrica-

tion System Description for information.

OIL COOLER

Figure 2.30-6 Oil Cooler – 6 Cylinder

NOTE: An optional oil cooler assembly is shipped

loose for 12 cylinder engines, and must be either skid

or remote mounted by the customer. The assembly

consists of the oil cooler, temperature control valve,

and pressure regulating valve. Figure 2.30-8 Optional Cleanable Oil Filter Elements

OIL STRAINER

The oil strainer contains one bypass pressure relief

valve. A pressure differential of 15 psi (103 kPa) opens

the valve and allows the oil flow to bypass the strainer

element enroute to the main oil header (see

Figure 2.30-7).

ENGINE MOUNTED

MICROSPIN

Figure 2.30-9 Microspin Centrifuge Assembly

PRELUBE OPERATION

Oil drains back into the

OIL STRAINER

CAUTION oil sump after engine

shutdown, leaving a minimal amount of oil at key

Figure 2.30-7 Oil Strainer wear points. Since the crankshaft starts to turn

before the oil pump begins to circulate oil, failure

MICROSPIN CLEANABLE OIL FILTERING SYSTEM to prelube the engine will result in “dry” starts,

resulting in bearing damage and an accelerated

The Microspin system consists of two major compo-

wear rate.

nents, cleanable oil filter elements (see Figure 2.30-8)

and centrifuge (see Figure 2.30-9). The Microspin sys- The ESM system manages the start, stop, and emer-

tem filter elements are installed in the existing oil filtra- gency stop sequences of the engine including pre- and

tion canister. The centrifuge is installed as a bypass post-lube. Logic to start and stop the engine is built

system, working in conjunction with the filter elements. into the ECU, but the customer supplies the user inter-

The centrifuge is driven by the engine’s oil pressure. face (control panel buttons, switches, touch screen) to

The spinning action of the centrifuge’s internal turbine the ESM system.

FORM 6300 2.30-5

LUBRICATION SYSTEM DESCRIPTION

PRELUBE PUMP/MOTOR INLINE LUBRICATOR

The function of the prelube pump/motor is to purge the

lubrication system of air and to ensure that all moving WARNING

parts, especially the turbochargers, are properly lubri-

If high pressure gas is used to drive the air/gas

cated before the engine is started (see

prelube pump motor, vent the motor exhaust to a

Figure 2.30-10).

safe area in conformance with all applicable

codes. Improper venting may result in severe per-

INLINE sonal injury or death.

LUBRICATOR

The inline lubricator injects oil into a stream of com-

pressed air/gas to automatically provide the proper

internal lubrication for the vanes of the air/gas oper-

ated prelube pump motor (see Figure 2.30-12). The

air/gas starting system also has a lubrication reser-

voir. See Section 4.45 Starting System Maintenance

for information.

PRELUBE AIR/GAS VENT INLINE

PUMP (CUSTOMER LUBRICATOR

PRELUBE PRELUBE CONNECTION)

PUMP MOTOR

Figure 2.30-10 Prelube Motor/Pump Assembly

PRELUBE VALVE

The prelube valve opens to admit air from a branch of

the main air/gas supply line, which turns the prelube

pump air motor to activate the prelube pump (see

Figure 2.30-11).

PRELUBE

PRELUBE MOTOR

VALVE

Figure 2.30-12 Inline Lubricator, Prelube Pump, And

Motor – 12 Cylinder

OIL LEVEL REGULATOR – OPTIONAL

The regulator is mounted on the left lower side of the

engine (see Figure 2.30-13). The regulator maintains

the engine crankcase oil at the correct level. Makeup

oil from an elevated tank is supplied at the regulator

inlet.

NOTE: The regulator should be adjusted so that when

MOUNTING the engine oil is at the proper level, the regulator sight

BRACKET

glass is full to the midpoint.

Figure 2.30-11 Prelube Valve – 6 Cylinder To prevent the regula-

CAUTION tor from malfunction-

ing, the inlet screen to the regulator should be

cleaned regularly.

2.30-6 FORM 6300

LUBRICATION SYSTEM DESCRIPTION

OIL LEVEL

REGULATOR

Figure 2.30-13 Optional Oil Level Regulator

If the oil level should drop for any reason, the float will

also drop, opening the float valve and allowing make-

up oil to be added to the crankcase. A contact is avail-

able for a customer-supplied low oil warning or shut-

down system.

FORM 6300 2.30-7

LUBRICATION SYSTEM DESCRIPTION

2.30-8 FORM 6300

You might also like

- Teves MK 20 Service Manual PDFDocument78 pagesTeves MK 20 Service Manual PDFColin RobertsNo ratings yet

- Yanmar Excavator B7 Electrical Wiring Diagrams + Parts Catalog PDFDocument198 pagesYanmar Excavator B7 Electrical Wiring Diagrams + Parts Catalog PDFthanhhai31100% (2)

- 1 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (001-086)Document86 pages1 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (001-086)Lala Céspedes100% (2)

- Tillotson HD & HR Service ManualDocument11 pagesTillotson HD & HR Service ManualBeckyNo ratings yet

- Compreesed Air Engine Project ReportDocument52 pagesCompreesed Air Engine Project ReportPrints BindingsNo ratings yet

- Read & Reset ECUDocument2 pagesRead & Reset ECUKároly Dávid NyulasiNo ratings yet

- Ficha Tecnica Con Curva Myers Bomba Tipo CampanaDocument4 pagesFicha Tecnica Con Curva Myers Bomba Tipo CampanaRonald FranciaNo ratings yet

- 4700 Operatior's ManualDocument74 pages4700 Operatior's ManualRidwan Praditya100% (1)

- Lube Oil System - Alco & HHP - 2Document43 pagesLube Oil System - Alco & HHP - 2kiran kumarNo ratings yet

- 3 Lubrication SystemDocument7 pages3 Lubrication SystemedwinNo ratings yet

- Bomb Oil AisinDocument38 pagesBomb Oil AisinMAURICIONo ratings yet

- SECTION 5.30: Lubrication SystemDocument54 pagesSECTION 5.30: Lubrication SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- AISIN Oil PumpsDocument36 pagesAISIN Oil PumpsGreicy guzmán ayalaNo ratings yet

- Engine Lubrication System: Section ElDocument8 pagesEngine Lubrication System: Section ElmarkoNo ratings yet

- Lubrication System MR479QDocument11 pagesLubrication System MR479QAdi WidiantoNo ratings yet

- Seal Oil SystemDocument38 pagesSeal Oil Systemnaresh977977100% (1)

- Valve Mechanism 1. General: Engine - 2Tr-Fe Engine Eg-13Document3 pagesValve Mechanism 1. General: Engine - 2Tr-Fe Engine Eg-13Maxi SardiNo ratings yet

- S6K Fuel System: Fuel Filter Fuel Injection NozzlesDocument9 pagesS6K Fuel System: Fuel Filter Fuel Injection NozzlesAr ChuNo ratings yet

- A-Engine 6060Document77 pagesA-Engine 6060Lucas LancioniNo ratings yet

- .E.mfix - , R - SuffixDocument2 pages.E.mfix - , R - Suffixoscar bastidasNo ratings yet

- Lubrication and Cooling SystemDocument23 pagesLubrication and Cooling Systemhellovers600% (1)

- Lub Oil System and Lub Oil PropertiesDocument31 pagesLub Oil System and Lub Oil PropertiestfdfurkananNo ratings yet

- Sym 3. Lubrication System: Mechanism DiagramDocument7 pagesSym 3. Lubrication System: Mechanism DiagramLuis Carlos Barrera IdarragaNo ratings yet

- 02.engine SystemDocument128 pages02.engine SystemYoga Miftahul Sofandy100% (1)

- Section 2 EngineDocument18 pagesSection 2 EngineJoseph EspinozaNo ratings yet

- Bomba de Lubricacion CBF150Document7 pagesBomba de Lubricacion CBF150lau cv 97No ratings yet

- Honda BF 2.3 D Maintenance InfoDocument1 pageHonda BF 2.3 D Maintenance InfoTonyNo ratings yet

- SECTION 5.40: Crankcase Breather SystemDocument24 pagesSECTION 5.40: Crankcase Breather SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- F004-P006-Gfpi Guia de ApreDocument165 pagesF004-P006-Gfpi Guia de Aprejuan perezNo ratings yet

- Ford Shop Manual 2Document300 pagesFord Shop Manual 2flNo ratings yet

- Turbine Lube Oil System AND GENERATOR SealingDocument32 pagesTurbine Lube Oil System AND GENERATOR SealingNishant ChaudharyNo ratings yet

- Lubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Document2 pagesLubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Maxi SardiNo ratings yet

- Toyota 7M Manual LubricatioDocument20 pagesToyota 7M Manual LubricatioBerny GarciaNo ratings yet

- 03 Lubrication System AbwtDocument12 pages03 Lubrication System Abwtcarlos melendez morenoNo ratings yet

- SECTION 5.05: Fuel SystemDocument30 pagesSECTION 5.05: Fuel SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Oil Pump System: Operation Diagram Structure and ComponentsDocument2 pagesOil Pump System: Operation Diagram Structure and ComponentsRadamirNo ratings yet

- QSC, L 5 FlowsDocument20 pagesQSC, L 5 FlowsLuong Nguyen Danh100% (1)

- Ford 6.0 Power Stroke Engine Lubrication SystemDocument7 pagesFord 6.0 Power Stroke Engine Lubrication SystemKevin RuedaNo ratings yet

- RX Do Motor de FuscaDocument1 pageRX Do Motor de FuscatorrescravoNo ratings yet

- Bomba de Aceite MazdaDocument2 pagesBomba de Aceite MazdaWillian Jose Navarro ZepedaNo ratings yet

- 04 - Lubrication SystemDocument10 pages04 - Lubrication SystemMarcos Mo CatalanNo ratings yet

- Lubrication System Diagram: CamshaftsDocument12 pagesLubrication System Diagram: CamshaftsgenuineswedeNo ratings yet

- MXU250 Cap04 (Lubrificazione)Document7 pagesMXU250 Cap04 (Lubrificazione)Alcycles FernandezNo ratings yet

- Lube Oil System Instruction 141A.000.2SM (B) - 5Document32 pagesLube Oil System Instruction 141A.000.2SM (B) - 5anbarasan0% (1)

- Cylinder LubricationDocument21 pagesCylinder LubricationnareshNo ratings yet

- Lec 4-Sounding SystemDocument38 pagesLec 4-Sounding SystemArwa Hussein100% (3)

- Hyundai Model d4b Shop ManualDocument10 pagesHyundai Model d4b Shop Manualcathy100% (31)

- HTMT Power Generation SeminarDocument144 pagesHTMT Power Generation SeminarVhic Estefani100% (1)

- Generator Seal Oil SystemDocument40 pagesGenerator Seal Oil Systembanukiran samboju100% (4)

- Ariel J. Lubrication System-03 04 04Document43 pagesAriel J. Lubrication System-03 04 04Manuel LiñeiroNo ratings yet

- p5 5S-FE+ENGINE+REPAIR+MANUALDocument23 pagesp5 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- KXR50 Cap 04 (Lubrificazione)Document13 pagesKXR50 Cap 04 (Lubrificazione)tutifruti649No ratings yet

- B&W Alpha LubricationDocument4 pagesB&W Alpha Lubricationimmyself94% (17)

- 11 Rotary CompressorsDocument37 pages11 Rotary CompressorshichamNo ratings yet

- Groz ZGPK Instruction ManualDocument20 pagesGroz ZGPK Instruction ManualCarlos OlivaNo ratings yet

- TU-FLO 700 CompressorDocument36 pagesTU-FLO 700 CompressorВладислав ВиршинитNo ratings yet

- Cat 24H Motorgrader Implement and SteeringDocument30 pagesCat 24H Motorgrader Implement and SteeringMiguel Angel Sancho100% (1)

- Lub of Bolero SLXDocument21 pagesLub of Bolero SLXRohit PantNo ratings yet

- GW491QE Petrol Engine Service Manual Lubrication+systemDocument7 pagesGW491QE Petrol Engine Service Manual Lubrication+systemAlbert BriceñoNo ratings yet

- GX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureDocument8 pagesGX610K1 - GX620K1 - GX670 GXV610K1 - GXV620K1 - GXV670 Low Oil PressureRussell JohnNo ratings yet

- PM PumpDocument46 pagesPM PumpDiyaNegi100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- The Role of Engine Oil Viscosity in Low Temperature Cranking and Starting: Prepared Under the Auspices of the SAE Fuels and Lubricants ActivityFrom EverandThe Role of Engine Oil Viscosity in Low Temperature Cranking and Starting: Prepared Under the Auspices of the SAE Fuels and Lubricants ActivityNo ratings yet

- SECTION 1.10: Rigging and Lifting EnginesDocument4 pagesSECTION 1.10: Rigging and Lifting EnginesNestor OyagaNo ratings yet

- SECTION 2.45: Esm Starting System DescriptionDocument2 pagesSECTION 2.45: Esm Starting System DescriptionNestor OyagaNo ratings yet

- SECTION 2.20: Turbocharger System DescriptionDocument2 pagesSECTION 2.20: Turbocharger System DescriptionNestor OyagaNo ratings yet

- SECTION 2.25: Cooling System DescriptionDocument4 pagesSECTION 2.25: Cooling System DescriptionNestor OyagaNo ratings yet

- 6277 Engine InfoDocument1 page6277 Engine InfoNestor OyagaNo ratings yet

- SECTION 2.15: Air Intake System DescriptionDocument2 pagesSECTION 2.15: Air Intake System DescriptionNestor OyagaNo ratings yet

- 6277 TocDocument6 pages6277 TocNestor OyagaNo ratings yet

- SECTION 1.00: Warning Tags and Decal LocationsDocument12 pagesSECTION 1.00: Warning Tags and Decal LocationsNestor OyagaNo ratings yet

- SECTION 1.15: General InformationDocument22 pagesSECTION 1.15: General InformationNestor OyagaNo ratings yet

- SECTION 1.15: General InformationDocument22 pagesSECTION 1.15: General InformationNestor OyagaNo ratings yet

- 6277 Engine InfoDocument1 page6277 Engine InfoNestor OyagaNo ratings yet

- 6277 Tables FinalDocument2 pages6277 Tables FinalNestor OyagaNo ratings yet

- Waukesha EnginesDocument32 pagesWaukesha EnginesAnonymous 5PGSwX5No ratings yet

- PN Compresor Ariel F-14233Document142 pagesPN Compresor Ariel F-14233Nestor OyagaNo ratings yet

- UntitledDocument2 pagesUntitledNestor OyagaNo ratings yet

- Shandong Wonway Machinery Co., Ltd. +8615587344559 +8615587344559Document1 pageShandong Wonway Machinery Co., Ltd. +8615587344559 +8615587344559Nestor OyagaNo ratings yet

- G3 Revision Sheet 2 Model AnswersDocument6 pagesG3 Revision Sheet 2 Model AnswersDiaa GobranNo ratings yet

- Ingersoll Rand AC185D Operators ManualDocument284 pagesIngersoll Rand AC185D Operators ManualAntonio Carrion100% (2)

- Kinematics of MachineryDocument8 pagesKinematics of MachinerySri RNo ratings yet

- Audi A1 SportbackDocument92 pagesAudi A1 SportbackSinue SeguraNo ratings yet

- Service: Crafter 2006Document44 pagesService: Crafter 2006Jan Svein HammerNo ratings yet

- Normally Closed Solenoid Valve by DungsDocument6 pagesNormally Closed Solenoid Valve by DungsM.H.No ratings yet

- How Do Hydraulic Brake Boosters WorkDocument2 pagesHow Do Hydraulic Brake Boosters WorkMilion dugumaNo ratings yet

- TbauxDocument24 pagesTbauxaal_shurafaNo ratings yet

- 06.DBR JUNI 2023 New Rev0Document42 pages06.DBR JUNI 2023 New Rev0Muhammad FatahillahNo ratings yet

- 571775-571180 Towing Winch .: Harbour Acceptance TestsDocument8 pages571775-571180 Towing Winch .: Harbour Acceptance Testsphankhoa83-1No ratings yet

- Trouble Shooting of Gear BoxDocument9 pagesTrouble Shooting of Gear BoxkgkadhiravanNo ratings yet

- Centifugal+Chiller+ (1000+ +10000+kW) MideaDocument35 pagesCentifugal+Chiller+ (1000+ +10000+kW) MideaevrimkNo ratings yet

- ISBUprateDocument3 pagesISBUpratehandoko pocaNo ratings yet

- Turbo PlusDocument27 pagesTurbo PlusAnonymous iDJw3bDEW2No ratings yet

- Spare Parts List: Z-No Mat-No. Change Master Quantity Unit Description Specification Order Type StatusDocument9 pagesSpare Parts List: Z-No Mat-No. Change Master Quantity Unit Description Specification Order Type Statusblinkesku0% (1)

- Ilovepdf MergedDocument15 pagesIlovepdf MergedDeb Sankar MukhopadhyayNo ratings yet

- Matehan Catalog 06 PDFDocument92 pagesMatehan Catalog 06 PDFNAMRAJ SHARMANo ratings yet

- Bacharach Stinger 2000 2000Document2 pagesBacharach Stinger 2000 2000Chethaka Lankara SilvaNo ratings yet

- A4VSODocument64 pagesA4VSORock Saybolt100% (1)

- D4B802C6D8D-1 6 66 77 81 85 2 0 105 110 135 KW TDI CR EngineDocument665 pagesD4B802C6D8D-1 6 66 77 81 85 2 0 105 110 135 KW TDI CR EngineAndrei BaluseNo ratings yet

- Printed in Japan (H) HR-E551T Mar. 2008: Distributed byDocument8 pagesPrinted in Japan (H) HR-E551T Mar. 2008: Distributed byAsari Dear SNo ratings yet

- Sample Questions: Answer Key: 1-C, 2-B, 3-C, 4-B, 5-A, 6-BDocument2 pagesSample Questions: Answer Key: 1-C, 2-B, 3-C, 4-B, 5-A, 6-BAntaryami Singh GoondiNo ratings yet

- RR Avon 1534 2Document3 pagesRR Avon 1534 2frdn100% (1)

- Thread Size CalulationDocument4 pagesThread Size CalulationSandip JadhavNo ratings yet