Professional Documents

Culture Documents

Cold Work Tool Steel

Uploaded by

631052Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cold Work Tool Steel

Uploaded by

631052Copyright:

Available Formats

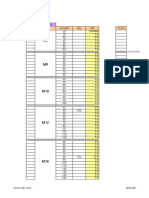

Schematic family tree of the cold work tool steels

for cutting, punching, shearing and comminuting

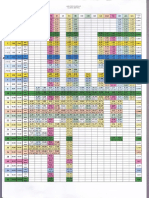

650 58

870 2767 260

50/56 X45NiCrMo4 MHM

AISI 6F3 650 60

C

0.40

Cr

1.20

Mn

0.20

Ni

3.80

S 900 2550 225

0.50 1.50 0.58 4.30 0.030

55/58 60WCrV8 NNH 600 56

앒 AISI S1 XXX 910 2746 295

C Cr Si W S 660 61 50/54 45NiCrMoV16-6 NHM

0.55

0.65

0.90

1.20

0.70

1.00

1.70

2.20 0.030 860 2101 225

57/59 62SiMnCr4 MHM C Cr Mo Ni V

0.41 1.40 0.73 3.80 0.45

0.49 1.60 0.85 4.20 0.55

680 58

660 62 C Cr Mn Si S

890 2249 220

2243

650

2743

61 650 61

53/57 45SiCrV6 NNH

880

56/61 61SiCrV5

220

NNH

0.58

0.66

0.40

0.70

0.90

1.20

0.90

1.20 0.030 870 235 1070 2360 240

XXX 54/59 60NiCrMoV12-4 MHM 56/59 X48CrMoV8-1-1 MHM

C Cr Si V S 680 64

C Cr Si V S C

0.40

0.50

1.30

1.60

1.30

1.60

0.07

0.12 0.035 0.57

0.65

1.00

1.30

0.70

1.00

0.07

0.12 0.035

820 2510 230 0.55

Cr

1.00

Mo

0.30 0.07

V Ni

2.70

C

0.45

Cr

7.30

Mo

1.30

V

1.30

S

56/62 100MnCrW4 MNH 0.60 1.30 0.40 0.12 3.00 0.50 7.80 1.50 1.50 0.005

Increasing toughness

AISI O1 XXX

650 64

C Cr Mn W S

0.90

1.05

0.50

0.70

1.00

1.20

0.50

0.70 0.035

860 2067 225

57/61 102Cr6 MNM 650 Thyrodur 64

600 56

970 2357 248 C Cr Mn Si S

1080

58/62

2990 250

HHM

50/57 50CrMoV13-14 MMH 0.95 1.35 0.25 0.15 X100CrMoV8-1-1

1.10 1.65 0.45 0.35 0.030 XXX

AISI S7 XXX C Si Cr Mo V

680 66

C Cr Mo V S

0.45

0.55

3.00

3.50

1.30

1.70

0.15

0.25 0.020

820 2516 230

0.95

1.10

0.85

1.05

7.40

8.30

1.00

1.65

1.50

1.70

58/62 100WV4 MHM

XXX

C Cr W V S

1.15 0.15 0.90 0.07

1.25 0.25 1.10 0.12 0.035

650 64

820 2842 220 650 63 700 63

57/62 90MnCrV8 MNH 970 2363

231 1050 2379

250

AISI O2 XXX 58/63 X100CrMoV5 MMM 58/62 X153CrMoV12 HHN

C Cr Mn V S AISI A2 XXX AISI D2 XXX

0.85 0.20 1.20 0.05 C Cr Mo Si S C Cr Mo V S

0.95 0.50 2.20 0.20 0.030

0.95 4.80 0.90 0.15 1.45 11.0 0.70 0.70

1.05 5.50 1.20 0.35 0.030 1.60 13.0 1.00 1.00 0.030

650 64

980 2080 250

58/62 X210Cr12 HMN

AISI D3 XXX

a. Max. annealing temperature (°C) a f f. Max. hardness (HRC) C Cr Mn Si S

b. Max. hardening temperature (°C)

c. Rec. service hardness min / max (HRC)

b 1.DDDD g g. Max. annealed hardness (HB) 1.90

2.10

680

11.0

13.0

0.20

0.60

0.10

0.60 0.030

64

c eeeeeeeee h(123) h. Properties 1- Tensile strength

D. German material number AISI designation XXX XXX = Available from stock 2- Through hardening

980 2436 250

rev. 02;022007

e. Abbreviated name C Si Mo V S 3- Machinabilty H: High / good 59/63 X210CrW12 HMN

min. M: Moderate AISI D6 XXX

max.

N: Low C Si Cr W S

2.00 0.10 11.00 0.60

2.30 0.40 13.00 0.80 0.030

no responsibility is taken for

www.dew-stahl.com Increasing abrasion wear resistance the correctness of this information

Schematic family tree of the cold work tool steels

for coining, pressing and bending

600 59

870 2721 250

52/57 50NiCr13 NHH

C Cr Mn Ni S

0.45 0.90 0.40 3.00

0.55 1.20 0.60 3.50 0.035

650 58

870 2767 260

50/56 X45NiCrMo4 NHH

AISI 6F3

C Cr Mo Ni S

0.40 1.20 0.15 3.80 650 61

0.50 1.50 0.35 4.30 0.030 1070 2360

240

56/59 X48CrMoV8-1-1 MMM

680 64

C Cr Mo V S

820 2510 230 0.45

0.50

7.30

7.80

1.30

1.50

1.30

1.50 0.005

56/62 100MnCrW4 MNH

Increasing toughness

AISI O1 XXX

C Cr Mn W S 650 Thyrodur64

0.90

1.05

0.50

0.70

1.00

1.20

0.50

0.70 0.035

1080

58/62

2990 250

HNM

X100CrMoV8-1-1

600 56 XXX

970 2357 248 C

0.95

Si

0.85

Cr Mo

7.40

V

1.00 1.50

50/57 50CrMoV13-14 MHH 1.10 1.05 8.30 1.65 1.70

AISI S7 XXX

C Cr Mo V S

0.45 3.00 1.30 0.15

0.55 3.50 1.70 0.35 0.020

650 64

820 2842 220 650 60

57/62 90MnCrV8

AISI O2

NMH 900 2550 225

XXX 55/58 60WCrV8 NMH

C Cr Mn V S 앒 AISI S1 XXX

0.85 0.20 1.20 0.05

0.95 0.50 2.20 0.20 0.030 C Cr Mn W S

0.55 0.90 0.15 1.70

0.65 1.20 0.45 2.20 0.030

650 51

870 2312 235 700 63

48/49 40CrMnMoS8-6 NNH

AISI P20 + S XXX

1050 2379 250

58/62 X153CrMoV12 HNN

C Cr Mn Mo S AISI D2 XXX

0.35 1.80 1.30 0.15 0.05

0.45 2.10 1.60 0.25 0.10 C Cr Mo V S

1.45 11.0 0.70 0.70

1.60 13.0 1.00 1.00 0.030 650 66

a. Max. annealing temperature (°C) a f f. Max. hardness (HRC)

b. Max. hardening temperature (°C) b 1.DDDD g g. Max. annealed hardness (HB)

1230 3343 269

c. Rec. service hardness min / max (HRC) c

62/65 HS6-5-3 HNN

eeeeeeeee h(123) h. Properties 1- Compression strength

D. German material number AISI M3 Typ2 XXX

AISI designation XXX XXX = Available from stock 2- Polishability

rev. 02;022007

e. Abbreviated name C Cr Mo W V

C Si Mo V S 3- Machinabilty H: High / good

0.86 3.80 4.70 5.90 1.70

min. M: Moderate 0.94 4.50 5.20 6.70 2.10

max.

N: Low

no responsibility is taken for

www.dew-stahl.com Increasing abrasion wear resistance the correctness of this information

You might also like

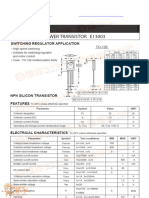

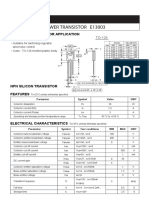

- Power Transistor E13003: Switching Regulator ApplicationDocument2 pagesPower Transistor E13003: Switching Regulator Applicationblancodaniel00000No ratings yet

- Materi 5 Selectivitas BioleachingDocument8 pagesMateri 5 Selectivitas BioleachingemiaNo ratings yet

- Ejercicio 4Document4 pagesEjercicio 4Ivan galarza avilaNo ratings yet

- 1.10 B Kitchen VentilationDocument1 page1.10 B Kitchen VentilationMiguel Alberto Llanos XoloNo ratings yet

- CaffeieneDocument8 pagesCaffeieneHawta AbdullaNo ratings yet

- Multi TopDocument1 pageMulti TopTậpTrungNo ratings yet

- ASTM A240 - A240M (Page 3)Document1 pageASTM A240 - A240M (Page 3)Yusuf KhoirNo ratings yet

- Grating Excel SheetDocument7 pagesGrating Excel SheetS S HARISHNo ratings yet

- Coefficients v1 1cDocument6 pagesCoefficients v1 1cRekha PandeyNo ratings yet

- ThicknessDocument1 pageThicknessMaged Lotfy Abdel-aalNo ratings yet

- Common Cast Steel Material Comparison ChartDocument3 pagesCommon Cast Steel Material Comparison ChartJose Marval RodriguezNo ratings yet

- CALIBRATION COLUMN 150 & 500 ML-ModelDocument1 pageCALIBRATION COLUMN 150 & 500 ML-ModelsindoroprintNo ratings yet

- Agua-Amoniaco Grupo 1oDocument13 pagesAgua-Amoniaco Grupo 1oXimena Ramos QuispeNo ratings yet

- Datos 0 LabmodernaDocument2 pagesDatos 0 LabmodernaRafaNo ratings yet

- Estimated Vee Curves: 0.500 SCR 350 Volts Excitation 2 Pole 3000 RPM 162000 kVA 15000 Volts 0.850 PFDocument1 pageEstimated Vee Curves: 0.500 SCR 350 Volts Excitation 2 Pole 3000 RPM 162000 kVA 15000 Volts 0.850 PFXiangdongNo ratings yet

- Bearing - Pressures For SR20Document1 pageBearing - Pressures For SR20Giri WakshanNo ratings yet

- EDocument1 pageEkcr zones243No ratings yet

- Convert or SDocument9 pagesConvert or SFatima Muhammad SaleemNo ratings yet

- N:Muhuud A I 3htar Pe: O, So, O12% 0, BD 0,190Document2 pagesN:Muhuud A I 3htar Pe: O, So, O12% 0, BD 0,190Muhammad A'isy Syahrur RajabNo ratings yet

- COCINADocument7 pagesCOCINAChristell Burquez AncoNo ratings yet

- Caracteristicas Motor1Document12 pagesCaracteristicas Motor1OmarPDomInguezNo ratings yet

- Distancia Adicional Total Poste A Caja 8 0.15 8.15 Caja A Tablero 1.8 0.15 1.95Document41 pagesDistancia Adicional Total Poste A Caja 8 0.15 8.15 Caja A Tablero 1.8 0.15 1.95Lisset Soto CabelloNo ratings yet

- UnderlyingDocument1 pageUnderlyington carolinoNo ratings yet

- Is 1030 GR340-570WDocument2 pagesIs 1030 GR340-570WAnkit Singh100% (1)

- Operation Breakdown: Style # Department Customer Desc. Season Fall 14Document18 pagesOperation Breakdown: Style # Department Customer Desc. Season Fall 14Saint's saintNo ratings yet

- TRUCKHUYUDocument1 pageTRUCKHUYUNgoc NguyenNo ratings yet

- Taha Associates - Blade Ejector PinDocument2 pagesTaha Associates - Blade Ejector PinTaha AssociatesNo ratings yet

- Torsi Terhadap Beban Konsumsi Bahan Bakar Spesifik Terhadap BebanDocument5 pagesTorsi Terhadap Beban Konsumsi Bahan Bakar Spesifik Terhadap BebanZay Rmouf VananyNo ratings yet

- Dn027b Led6cw l100 SQDocument1 pageDn027b Led6cw l100 SQHaianh PhamNo ratings yet

- Plastic Packages For Integrated CircuitsDocument1 pagePlastic Packages For Integrated CircuitsShakti SinghNo ratings yet

- Tablas de Practica de Ley de HookeDocument3 pagesTablas de Practica de Ley de HookeRafael HernandezNo ratings yet

- جارتات 03 - Spontaneous - potentialDocument7 pagesجارتات 03 - Spontaneous - potentialيا ابا صالح المهديNo ratings yet

- 90° T-Pieces, Galvanised: Duct SystemsDocument1 page90° T-Pieces, Galvanised: Duct SystemsMd NohNo ratings yet

- 90 T Pieces PDFDocument1 page90 T Pieces PDFbeemasundarNo ratings yet

- 90 T Pieces PDFDocument1 page90 T Pieces PDFbeemasundarNo ratings yet

- 3.03 Mce - Calculo de MurosDocument46 pages3.03 Mce - Calculo de MurosArmando J. Medina PalaciosNo ratings yet

- Data Analisis ArchimedesDocument6 pagesData Analisis ArchimedesAkhmd RdlNo ratings yet

- Characteristics DF Pipingmateriais SteelpipeDocument4 pagesCharacteristics DF Pipingmateriais SteelpipeMauricio RodriguesNo ratings yet

- Tubos Redondos SAPA AlumínioDocument10 pagesTubos Redondos SAPA AlumínioSérgio MartinsNo ratings yet

- Asam Mefenamat Chart Title: t (menit) Abs Pengenceran C obat (μg/ml) Faktor koreksi (Cp x Vol samplingDocument4 pagesAsam Mefenamat Chart Title: t (menit) Abs Pengenceran C obat (μg/ml) Faktor koreksi (Cp x Vol samplingMrtNo ratings yet

- Truss DetailDocument1 pageTruss DetailJezzrel SumalinogNo ratings yet

- Machining Conditions: APKT 100308 PDTR LT 3130 M0004470 MetricDocument2 pagesMachining Conditions: APKT 100308 PDTR LT 3130 M0004470 MetricDedik HandokoNo ratings yet

- Din 8557Document1 pageDin 8557behzad mohammadiNo ratings yet

- Alloy Steel ChartDocument4 pagesAlloy Steel Chartmodi_mihirNo ratings yet

- LMTD Correction Factor ChartsDocument1 pageLMTD Correction Factor ChartsTifano KhristiyantoNo ratings yet

- Structural Use Concrete: Règles Et EtDocument60 pagesStructural Use Concrete: Règles Et EtSimone Ferraris100% (1)

- Registros Sismicos en El PeruDocument17 pagesRegistros Sismicos en El PeruDey TorviscoNo ratings yet

- D2 KNLDocument1 pageD2 KNLmini p shendeNo ratings yet

- GRAFICASDocument19 pagesGRAFICASAlfredo TlapaleNo ratings yet

- Vapour Liquid Equilibrium Data CollectionDocument51 pagesVapour Liquid Equilibrium Data CollectionMirsoNo ratings yet

- E13003 PDFDocument2 pagesE13003 PDFLuis VivasNo ratings yet

- Datasheet PDFDocument2 pagesDatasheet PDFCalixto Milla EsauNo ratings yet

- Admittance Parameters CircuitDocument1 pageAdmittance Parameters CircuitsaiNo ratings yet

- Ecuacion Van LaarDocument8 pagesEcuacion Van LaarAvj ParceroNo ratings yet

- Casa CapasDocument1 pageCasa CapaschrisNo ratings yet

- Final Col Terrece Floor Floting Pour - 1Document28 pagesFinal Col Terrece Floor Floting Pour - 1sanjeevNo ratings yet

- West Nomogram-Body Surface Area: Ppendix MDocument2 pagesWest Nomogram-Body Surface Area: Ppendix MLisaNo ratings yet

- Nomogram PDFDocument2 pagesNomogram PDFMuhammad AdeelNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- ASSAB Tool Steel Performance Chart A4 enDocument2 pagesASSAB Tool Steel Performance Chart A4 en631052No ratings yet

- Processing Arnite PBTDocument21 pagesProcessing Arnite PBT631052No ratings yet

- Mould MaintenanceDocument8 pagesMould Maintenance631052No ratings yet

- Checklist For Mold RemediationDocument2 pagesChecklist For Mold Remediation631052No ratings yet

- COMPREHENSIVE Mold Design and Processing ConditionsDocument24 pagesCOMPREHENSIVE Mold Design and Processing Conditions631052No ratings yet

- Microsoft Dynamics Ax 2012 Trade and Logistics Training OnlineDocument2 pagesMicrosoft Dynamics Ax 2012 Trade and Logistics Training Online631052No ratings yet

- Arburg 520S Technical DataDocument1 pageArburg 520S Technical Data631052No ratings yet

- Installation Procedure NX-6Document1 pageInstallation Procedure NX-6631052No ratings yet

- Midi Basics en V10a PDFDocument4 pagesMidi Basics en V10a PDFcatisacNo ratings yet

- 100 Ways To Save The EnvironmentDocument3 pages100 Ways To Save The EnvironmentSarvesh JaiswalNo ratings yet

- Electronics Y2 PDFDocument237 pagesElectronics Y2 PDFNebuchadnezzar Buggy Andamon SaysonNo ratings yet

- Camapana de Humo Sin DuctosDocument4 pagesCamapana de Humo Sin DuctosBRIAN JULIAN GARCIA ALFONSONo ratings yet

- 14 Disperse Systems With AnswersDocument5 pages14 Disperse Systems With AnswersPatricia Camryne Ambida100% (2)

- Bemco BrochureDocument19 pagesBemco BrochurelightsonsNo ratings yet

- T-4.896.425 - C01 - MS ITP For Hot Cold Insulation WorksDocument20 pagesT-4.896.425 - C01 - MS ITP For Hot Cold Insulation Worksshahid imamNo ratings yet

- Workshop Manual - Daihatsu 3 Cyl 993cc Wiring DiagramDocument41 pagesWorkshop Manual - Daihatsu 3 Cyl 993cc Wiring Diagramโจ้ สแปร์แร็ค80% (5)

- Rubber DurabilityDocument19 pagesRubber DurabilityZelzozo Zel ZozoNo ratings yet

- ABS Under 90m - Part 4Document356 pagesABS Under 90m - Part 4blindstrom42No ratings yet

- Working Stress DesignDocument4 pagesWorking Stress DesignUopEmptyNo ratings yet

- Changing The Pump Seals: (All Pumps Except The G1361A Preparative Pump)Document2 pagesChanging The Pump Seals: (All Pumps Except The G1361A Preparative Pump)sarasaNo ratings yet

- New Company ProfileDocument14 pagesNew Company Profileanamika tripathiNo ratings yet

- IGCSE Chemistry DefinitionsDocument5 pagesIGCSE Chemistry DefinitionsTanmay Karur100% (1)

- BS 4514 2001 PDFDocument18 pagesBS 4514 2001 PDFanas shehabi100% (1)

- Continuous Distillation Diagram ProcessDocument1 pageContinuous Distillation Diagram ProcessSebastianNo ratings yet

- Kinetic Molecular Theory and States of MatterDocument25 pagesKinetic Molecular Theory and States of MatterjunnaNo ratings yet

- Quality Requirements New Format-06.04.13Document1 pageQuality Requirements New Format-06.04.13beeyesyemNo ratings yet

- RF Series-Catalog 3800 - SectionADocument3 pagesRF Series-Catalog 3800 - SectionAStefan DinuNo ratings yet

- Mechanical Design Calculation of Pipe Rack Under Pass 1Document7 pagesMechanical Design Calculation of Pipe Rack Under Pass 1tobeeprassNo ratings yet

- Method Statement For Insulation of Ducting SystemDocument11 pagesMethod Statement For Insulation of Ducting SystemSaijon chandyNo ratings yet

- Microcontrollers: Digitally Addressable Lighting Interface (DALI) Unit Using The MC68HC908KX8Document162 pagesMicrocontrollers: Digitally Addressable Lighting Interface (DALI) Unit Using The MC68HC908KX8alexwongks6118No ratings yet

- Ansi C84.1Document24 pagesAnsi C84.1jojagucaNo ratings yet

- Argillon ICA DeNOx EnglishDocument2 pagesArgillon ICA DeNOx Englishukhfulajif;gNo ratings yet

- Bible Saintgobain PamDocument742 pagesBible Saintgobain PamfrankytgNo ratings yet

- Experiment 4 CombustionDocument8 pagesExperiment 4 CombustionJof RomanNo ratings yet

- PuneDocument564 pagesPuneANSHUMANNo ratings yet

- ACADIA 2019 Papers BUGA WOOD NocoverDocument11 pagesACADIA 2019 Papers BUGA WOOD NocoverBarbiPetőNo ratings yet

- Neeraj PrefaceDocument64 pagesNeeraj PrefaceAnimesh TiwariNo ratings yet

- Engine Control System: SectionDocument1,924 pagesEngine Control System: SectionMihai IavorschiNo ratings yet

- PSA Nitrogen PlantsDocument4 pagesPSA Nitrogen PlantsIdo Aprilian TariganNo ratings yet