Professional Documents

Culture Documents

Melatonin Oral Drop

Melatonin Oral Drop

Uploaded by

Zeyad A Abdullah0 ratings0% found this document useful (0 votes)

6 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesMelatonin Oral Drop

Melatonin Oral Drop

Uploaded by

Zeyad A AbdullahCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

WO 2016/0S8985 PCT/EP2015/073852

Teach unknown Impurity | = 0. 201% 201% = 01%

Total related substances | = 1.0% < 1.0% < 1.0% < 1.0%

7 Microbiology Sterile serie fo serie

& Endotoxins = 30 EU ym | complies | ==

9. Assay LC (melatonin) | 95.0 105.0% | 100.2% | 99.8% | 99.3% | 99.7% | 99.1%

Example 8

Preparation of 2000 ml of oral solution of melatonin (25 mg MLT/ml)..

Materials:

MLT (assay 99.1%) commercial batch n. 194343002;

Polyoxyl 40 hydrogenated castor oil commercial batch n. 23660956P0;

Ethanol 96% commercial batch n. 14073-02.

Auxiliary ingredients:

Glycerol (£422) commercial product: 10.0 %;

Xylitol (E967) commercial product: 7.0 %;

Sodium saccharinate (E054) commercial product: 0.15 %;

Cherry essence commercial product: 4.0 %;

Purified water commercial product.

Glassware as necessary; ingredients, container (38 ml amber glass bottle)

and stopper are from qualified manufacturers and additionally tested by the

quality control. All quantities are reported to 100% assay.

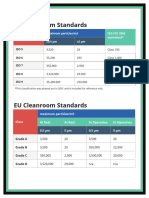

Cleanroom B equipped with dosing machine for bottles (temperature 21°C;

lightening system with UV filters).

Preparation of 500 mi of bulk solution (Solution A)

Step 1 - 50.45 g MLT (assay 99.1%) and 50.0 g polyoxyl 40 hydrogenated

castor oil, both accurately weighed with a precision balance, were placed in

a laboratory scale stainless steel mixer and thoroughly kneaded to yleld an

homogeneous pasty mass (about 15 minutes);

Step 2 - 500.0 ml of ethanol 96 per cent were added to pasty mass inside

the mixer (before under vacuum and then using nitrogen as a purge gas)

and stirred slowly to complete dissolution while a clear and transparent

solution is obtained (about 15 minutes). The resulting bulk solution is

62

WO 2016/0S8985 PCT/EP2015/073852

placed into a 3000 ml amber glass bottle that is well closed with a suitable

stopper, protected from light (about 465 ml; step yield 93.0%).

Step 3 - 3.0 mi sample of the above bulk solution withdrawn from the

bottle was sent to the laboratory for analysis (MLT assay: 98.8 mg/ml)

Step 4 - Preparation of 1500 ml of auxiliary ingredients (Solution B)

In a 5 litres laboratory stirring tank (stainless steel) the following auxiliary

ingredients (calculated to yield 2000 mi final oral concentrated solution)

glycerol 200 g, xylitol 140 g, sodium saccharinate 3.0 g were thoroughly

mixed in 1500 ml purified water until complete dissolution.

Step 5 - Preparation oral concentrated solution (theoretical 2000 ml).

465 ml bulk solution (melatonin assay correction factor of 98.8/100=459 ml

of 100% melatonin) was placed into a laboratory stirring tank from stainless

steel and the cherry essence (8.0 g) was firstly dissolved into bulk solution

A and stirred to complete dissolution. Thereafter 1395 ml of bulk solution B

(by weight), representing the 75% of the final solution, were added and

admixed to yield the final volume of 1854.0 mi of oral concentrated

solution.

Step 6 - 3.0 mi sample of the diluted solution withdrawn from the bottle

was sent to the laboratory for analysis (MLT assay : 24.95 mg/ml).

Step 7 - Once the oral concentrated solution received approval, it was

passed through a membrane filter and the filtrate was collected directly into

a suitable amber glass bottle. The bottle containing the diluted solution was

passed to the Cleanroom B where the solution was apportioned by means of

a dosing machine into amber glass bottles (38 ml capacity) from glass Type

I (Ph. Eur.). A total 51 glass bottles filled with 30.0 mi diluted solution

dosed at 25 mg MLT/mi were obtained; bottles were automatically closed by

a suitable child proof anti-pilfer cap. The bottles were then labelled and

transferred into a dark box protected from light.

Two complete bottles were sent to quality control; solution passed physico-

chemical tests (clear and transparent), melatonin assay (24.90 mg/ml),

complied with pH range (6.5-7.5), filling volume and with microbiological

enumeration test (TAMC max 107 CFU/g; TYMC max 10 CFU/g). The

63

WO 2016/0S8985 PCT/EP2015/073852

product was packed in a folding box along with a dosing plastic device to

adapt the solution dosage according to its use.

The released product (n. 49 bottles; cumulative yield 74%) were partially

used for the programmed stability tests.

Example 9

Stability studies of pharmacy and industrial bulk solution package of

melatonin for oral use of Example 8 of the invention - 30,0 ml multidose

bottle.

Study protocol

Pharmaceutical form : 30.0 ml (25 mg MLT/ml) amber glass bottle

(multidose)

Batch n.° : bottle from Example 8

(A) Type of stability : accelerated

Conditions : 40°C + 2°C / RH. 75% + 5% (climatic monitored

storage)

Duration : 6 months

Intervals : 0 (initial), 3 and 6 months.

Tests Specifications | TimeO | Smonths | 6 months

T. Appearance Free of particles | conform | conform [conform

2. Clarity Clear solution cear_| dear clear

3. Colour Corourless colourless | colourless | colourless

% Mean volume (vial) | 30.0- 31.5 ml sizmt | =

5. pH 60-75 69 70 65

@ Related Substances

=5-methoxytryptamine | < 0.5% <05% | <05% | 0.3%

= each unknown impurity | s 0.1% <0.1% | <0.1% | 0.2%

Total related substances | = 1.0% <1o0% | <10% | 05%

7. Microbiology (CFU)

Tame $10? 10? = 107

TMC 510 10 10

&, Assay LG (melatonin) | 95.0 - 105.0% 3.7% | 993% | 99.2%

(B) Type of stability : long term

64

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Unit 1 Topic ICHDocument10 pagesUnit 1 Topic ICHZeyad A AbdullahNo ratings yet

- QA - Market Complaint Unit 4Document2 pagesQA - Market Complaint Unit 4Zeyad A AbdullahNo ratings yet

- Form 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingDocument8 pagesForm 160 Example - Line - Clearance Opening and Cleaning Form For Tablet PackingZeyad A AbdullahNo ratings yet

- Pharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanDocument16 pagesPharmacognosy Unit 4 5th Short Important Questions Shahruddin KhanZeyad A AbdullahNo ratings yet

- Form 400 Employee Signature RegisterDocument1 pageForm 400 Employee Signature RegisterZeyad A AbdullahNo ratings yet

- Form 085 Released StickersDocument1 pageForm 085 Released StickersZeyad A AbdullahNo ratings yet

- U 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Document7 pagesU 1 PP 2 4th Sem B Pharm Pharmacy Wala Shahruddin Khan 18811494Zeyad A AbdullahNo ratings yet

- Form 125 Example Batch Reconciliation Sheet For Tablet PackingDocument4 pagesForm 125 Example Batch Reconciliation Sheet For Tablet PackingZeyad A AbdullahNo ratings yet

- QMS 035 Deviation Report System SampleDocument6 pagesQMS 035 Deviation Report System SampleZeyad A AbdullahNo ratings yet

- Vol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Document7 pagesVol. 3, Issue 3, March 2015, PharmaTutor, Paper-4Zeyad A AbdullahNo ratings yet

- List of Glassware Used in Pharmaceuticals - PharmaguidelineDocument4 pagesList of Glassware Used in Pharmaceuticals - PharmaguidelineZeyad A AbdullahNo ratings yet

- Form 140 Visitor Entry Into The FactoryDocument1 pageForm 140 Visitor Entry Into The FactoryZeyad A AbdullahNo ratings yet

- Us Cleanroom Standards CompliancewireDocument1 pageUs Cleanroom Standards CompliancewireZeyad A AbdullahNo ratings yet

- RRT - DB - Mat WND enDocument2 pagesRRT - DB - Mat WND enZeyad A AbdullahNo ratings yet

- Project 1 7/5/2021Document1 pageProject 1 7/5/2021Zeyad A AbdullahNo ratings yet

- Catalogue Tablet-Press 2019 V3Document16 pagesCatalogue Tablet-Press 2019 V3Zeyad A AbdullahNo ratings yet

- PortaFab Mezzanine BrochureDocument2 pagesPortaFab Mezzanine BrochureZeyad A AbdullahNo ratings yet

- GMP Clearance GuidanceDocument84 pagesGMP Clearance GuidanceZeyad A AbdullahNo ratings yet

- Tube Filling and Sealing Machine Lab ModelDocument5 pagesTube Filling and Sealing Machine Lab ModelZeyad A AbdullahNo ratings yet

- IndJPhaEdRes 54 3s s473Document12 pagesIndJPhaEdRes 54 3s s473Zeyad A AbdullahNo ratings yet

- Ludipress Technical InformationDocument8 pagesLudipress Technical InformationZeyad A AbdullahNo ratings yet

- Product MonographDocument31 pagesProduct MonographZeyad A AbdullahNo ratings yet

- Tech Bulletin - Suglets - More Than MonographDocument2 pagesTech Bulletin - Suglets - More Than MonographZeyad A AbdullahNo ratings yet

- Sodium Stearyl Fumarate Excipient Pubchem 1559559385Document2 pagesSodium Stearyl Fumarate Excipient Pubchem 1559559385Zeyad A AbdullahNo ratings yet

- Crosslinked Povidone Pubchem 1482747992Document4 pagesCrosslinked Povidone Pubchem 1482747992Zeyad A AbdullahNo ratings yet

- S 065 LBLDocument10 pagesS 065 LBLZeyad A AbdullahNo ratings yet

- 09 Nov 2016 180959770P8GWIJNEANNEXUREDocument2 pages09 Nov 2016 180959770P8GWIJNEANNEXUREZeyad A AbdullahNo ratings yet

- 0Document1 page0Zeyad A AbdullahNo ratings yet

- What Is Environmental Monitoring in Pharmaceutical IndustryDocument12 pagesWhat Is Environmental Monitoring in Pharmaceutical IndustryZeyad A AbdullahNo ratings yet

- Good Practice Manufacturing Operation SampleDocument21 pagesGood Practice Manufacturing Operation SampleZeyad A AbdullahNo ratings yet