Professional Documents

Culture Documents

Customer Part 2 Print Out

Uploaded by

radient.freshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Customer Part 2 Print Out

Uploaded by

radient.freshCopyright:

Available Formats

PRINCIPLE OF WORKING FOR VALVE (NEXT)

Introduction for Manual Operated valve

This valve is designed for LP Gas vapor withdrawal, completed with

safety relief pre-set for start-to-discharge at 26 bar. It should be handled with

H/W for Spin to care, protected to prevent dirt or other outside particle from getting inside, its

Open-Close outlet connection to regulator. Its manual operating valve with handwheel and

spindle to work, Just for principle to work non-different to self-closing valve,

But its work to different with hand to open-close for spin with handwheel and

spindle for valve.

Outlet

Safety Relief

Essential Components of

Manually Operated Valve

Inlet

SCG Thailand Cylinder Valve and Regulator Manufacturer

SAFETY RELIEF VALVES

Safety relief valve will start to

discharge when the pressure inside the

cylinder increased to reach the set start-to-

discharge pressure. Normally, the pressure

inside Propane cylinder is 13 bar. The start-

to-discharge pressure is set at 2 times

pressure or 80% of the test pressure which

is approximate 26 bar (375 psi).

Increased pressure pushes spring to

compress and release pressure out

Relief Valve Cover

Disk for poppet

Poppet

COMPOSITION

OF

SAFETY RELIEF VALVE

Relief Valve Cap

Spring of Safety Relief (Internal Type)

SCG Thailand Cylinder Valve and Regulator Manufacturer

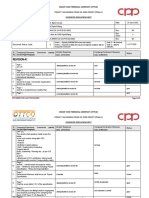

CALCULATION FLOW CAPACITY

OF PRESSURE RELIEF VALVES (REF EN 13953)

The required nominal discharge capacity of the valve can be calculated in accordance with this

formula.

Q = 0.00278PW

Where:

Q = is the required nominal discharge capacity (m3/min of free air)

P = is the flow rating pressure in bar absolute

W = is the water capacity of the cylinder in liters, (W=5 for cylinder of 5 L capacity or less)

Table of Flow Capacity

EXAMPLE Weight of Gas Weight of Cylinder Min. Flow capacity

(kg.) (Liter) (m3/min)

• Calculation for flow capacity

5.5 12.5 1.0

Qa = 0.00278PW

Qa = 0.00278(31.2 bar)(26.6 Liter) 12.5 26.6 2.3

Qa = 2.3 m3/min (Ans.)

35 74 6.4

45 108 9.4

SCG Thailand Cylinder Valve and Regulator Manufacturer

SIZING OF PRESSURE RELIEF VALVES FOR LPG CYLINDERS

PRV 3 m3/min PRV 5 m3/min PRV 10 m3/min PRV 13 m3/min

45 kg.

Weight of Weight of Min. Flow

Gas Cylinder capacity

(kg.) (Liter) (m3/min)

35 kg.

5.5 12.5 1.0

12.5 kg.

12.5 26.6 2.3

35 74 6.4 5.5 kg.

45 108 9.4

SCG Thailand Cylinder Valve and Regulator Manufacturer

OPTIONAL COMPONENTS

• Education tube Sealing Cap

• Fixed liquid level gauge

• Excess flow device

• Liquid level indicator Fixed Liquid

• Sealing cap Level Gauge

• Sediment tube

Liquid Level-Gauge

Education Tube

Excess Flow Device

Sediment tube

SCG Thailand Cylinder Valve and Regulator Manufacturer

PRINCIPLE OF PRODUCTS

Excess Flow

The excess flow device will help to protecting the over pressure into

gas cylinder, Its excess flow will also helping control pressure by

excess flow device will not to exceed 1.5 mm forward of value to

standard.

Excess Flow Device

LPG for Liquid

withdrawal

Smart Hose

SCG Thailand Cylinder Valve and Regulator Manufacturer

PROCESS FOR

LPG CYLINDER VALVE

SCG Thailand Cylinder Valve and Regulator Manufacturer

PRODUCTS

Compact valve Vapour valve (POL) Liquid withdrawal valve

1. MODEL : D-V91-C.8 2. MODEL : D-V9-A.4 3. MODEL : D-V87-AV

SCG Thailand Cylinder Valve and Regulator Manufacturer

CERTIFICATE PRODUCT

SCG Thailand Cylinder Valve and Regulator Manufacturer

DATE: 06/06/2014 F09-MA002

NO.P140046 Issue Status: C

INSTALLATION INSTRUCTION FOR SELF-CLOSING VALVE

Date: 06/06/2014

D14/018

Cylinder Valve Installation Instruction

Product Figure Installation

VALVE INSTALLATION

- Remove packaging and check valve for cleanliness,

abnormality, such as broken threads, bent body or

broken tube.

- Contact local distributor if there is any presence of

abnormality.

- Prepare the cylinder in accordance with the cylinder

manufacturer’s instructions, local legislation or Codes

of Practice.

- Apply a suitable sealant on threads, such as PTFE.

- Use correct size socket or spanner to tighten the valve

onto the cylinder. Avoid damaging the valve during

Product Information

tightening. Recommended torque is 130-170 Nm.

This valve is designed for LP Gas vapor withdrawal,

- Practically, after 110 Nm reached, further torque can be

completed with safety relief pre-set for start-to-discharge at

made in order to orient the safety relief vave to its right

26 Bar. It should be handled with care, protected to prevent

direction, but not exceeding maximum torques.

dirt or other outside particle from getting inside its outlet

- After tightening completed, pressurize air into the

connection or off-taking tube. It should be installed correctly.

cylinder. Apply soapy water onto connection and check

Failure to do so may cause property damage or personal

for leakage.

serious injury.

- Ensure that the valve contains rubber seal inside its

outlet connection.

Valve Type

- Self-closing, compact type (Ref. ISO 14245 Standard)

Warning!

- Ref. Drawing No: D-V91-C.8

- Ensure that only correct couplings are used for

- Outlet connection: Ø22-mm. (Ref G.54, EN 12864)

connecting the valve.

- Inlet connection: 3/4”-14 NGT 1:16, 60° (CGA V-1)

- The cylinder should be 80% filled. Overfilling the

cylinder will result in danger.

Marking & Labeling

- Maintenance of the valve is not recommended, except

SCG: as Manufacturer (SCG-Thailand)

cleaning with soapy water and checking for leakage.

V91: as Model No.

DD-MM-YY-XX: as Manufacturing Date-Month-Year &

Emergency

Lot number

π 0589: as verification of TPED approved, certified by - Close the valve and disconnect regulator or appliance.

- Remove the cylinder to an opened area.

BAM-Germany

SCG Thailand Cylinder Valve and Regulator Manufacturer

PRODUCTS LIABILITY

SCG Thailand Cylinder Valve and Regulator Manufacturer

WARRANTY OF PRODUCTS

Products warranty, Any defect or damage,

for valve its has to contact “Chubb Samaggi

Insurance” by contract information as well

All Claims contact to :

Company : Chubb Samaggi Insurance Public Company Limited

Address : 2/4 Chubb Tower, 12th Fl., Northpark Project, Vibhavadi-Rangsit Rd.,

Thung Song Hong, Laksi, Bangkok 10210 Thailand

Contact person : Jerasak Semmesuk (Mr.), Casualty Claims Adjuster

Contact number: +66 0 2611 4396

Email : jerasak.semmesuk@chubb.com

Please C.c. Email to : Pacharasak Rattarangsi (Mr.), Claims Manager

Pacharasak.Rattarangsi@Chubb.com

: Suchanad Yongvikul (Ms.), Assistant Claims Manager

Suchanad.Yongvikul@Chubb.com

SCG Thailand Cylinder Valve and Regulator Manufacturer

AGEING OF VALVE

Standard Region Description

ADR

European • Equipment shall undergo periodic inspections no later than every 5 - 6 years

• Equipment shall undergo intermediate inspections at least every 2.5 - 3 years

CGA S-1.1

International • Pressure relief valves shall be replaced or requalified within 10 years

• Valve shall be retested on 5 year frequency

LPGA Code of Practice 15

• Valve and its associated equipment are suitable for service life time at least 10 years

AS 2030.5 Australia • LP Gas in cylinder with removable cylinder valves shall periodic inspection intervals 10 years

Japanese Japan • For the LPG Cylinder Valve which is used less than 6.5 years old shall Re-Inspection date after

Regulation

2 year

• For the LPG Cylinder Valve used more than 6.5 years old shall Re-Inspection date after 1 year

• For the Cylinder Valve which is not installed on the Cylinder, it is 2 years after first Maker's

Cylinder Valve Inspection at the factory

SCG Thailand Cylinder Valve and Regulator Manufacturer

Products lifecycle.

VALVES RECYCLE

ENVIRONMENT & RECYCLE

SCG Thailand Cylinder Valve and Regulator Manufacturer

You might also like

- Valvula Reguladora Presion EsterilizadorDocument10 pagesValvula Reguladora Presion Esterilizadortravieso112No ratings yet

- ASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series ValvesDocument1 pageASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series Valvesmohsen fatemiNo ratings yet

- Introduction To ValvesDocument37 pagesIntroduction To ValvesSharmin SumiNo ratings yet

- KL-22 Liner Integrity Test Procedures (Rev JJC)Document7 pagesKL-22 Liner Integrity Test Procedures (Rev JJC)Hamza HamzaNo ratings yet

- OGA Relief Valve Calculations 12-3-12Document31 pagesOGA Relief Valve Calculations 12-3-12penjualgasNo ratings yet

- 1 D27DTPDocument109 pages1 D27DTPatom7-2100% (1)

- AQT Valves CatalogDocument72 pagesAQT Valves CatalogSteve Kevin StephenNo ratings yet

- On-Vehicle Inspection: - RadiatorDocument2 pagesOn-Vehicle Inspection: - RadiatorsalusfrankNo ratings yet

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Outlines: Theory Calculation Conclusion ReferencesDocument31 pagesOutlines: Theory Calculation Conclusion ReferencesYè Paing Oo100% (3)

- Flow Control Valves: Hydraulic ComponentsDocument28 pagesFlow Control Valves: Hydraulic ComponentsMohamed IbrahimNo ratings yet

- Accumulator Tanks & Expansion Tanks in Pressurised Water SystemsDocument7 pagesAccumulator Tanks & Expansion Tanks in Pressurised Water SystemsRajesh KrishnamoorthyNo ratings yet

- Accumulator Tanks & Expansion Tanks in Pressurised Water SystemsDocument7 pagesAccumulator Tanks & Expansion Tanks in Pressurised Water SystemsMohamed HmayenNo ratings yet

- Control ValveDocument23 pagesControl ValveRama ReddyNo ratings yet

- GPSA Control Valve SizingDocument10 pagesGPSA Control Valve SizingsudharshananNo ratings yet

- Control Valves Required DetailsDocument2 pagesControl Valves Required DetailszhangyiliNo ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- AccessoriesDocument31 pagesAccessoriesLuke ArandidNo ratings yet

- Mts - 2013601 Carregador de NitrogenioDocument8 pagesMts - 2013601 Carregador de NitrogenioEduardo CramerNo ratings yet

- Unique SPC-1 ValveDocument8 pagesUnique SPC-1 ValveAngelito_HBKNo ratings yet

- Lecture 4Document30 pagesLecture 4tommy6700No ratings yet

- Gearbox-Mounted Power Take Off: General InstructionsDocument4 pagesGearbox-Mounted Power Take Off: General InstructionsChimuonechi NyirendaNo ratings yet

- Basic Control Valve Sizing and SelectionDocument38 pagesBasic Control Valve Sizing and SelectionmohamedNo ratings yet

- Low Pressure Motor Valves: Applications: CertificationsDocument5 pagesLow Pressure Motor Valves: Applications: CertificationsMuhammad Reza GadranNo ratings yet

- Cameron BOP Control Systems PDFDocument38 pagesCameron BOP Control Systems PDFcarlosorizaba100% (1)

- Capital Controls Series 600 Gas ChlorinatorDocument4 pagesCapital Controls Series 600 Gas ChlorinatorFranco ArellanoNo ratings yet

- Arreglo de Filtros Segun RestekDocument16 pagesArreglo de Filtros Segun RestekAniigiselaNo ratings yet

- Fluid Report Spongbob SquarepantsDocument64 pagesFluid Report Spongbob SquarepantsGehad EssamNo ratings yet

- Dynapak Natural Gas Sampling System: Field-Proven Design, Reliable ResultsDocument2 pagesDynapak Natural Gas Sampling System: Field-Proven Design, Reliable ResultsMoni FraileNo ratings yet

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (1)

- Válvula Reguladora de Pressão - Argos - Eng - 022020Document12 pagesVálvula Reguladora de Pressão - Argos - Eng - 022020EDILSONNo ratings yet

- 7 Screw CompressorsDocument37 pages7 Screw Compressorsalisamir7305No ratings yet

- Control Valve SizingDocument5 pagesControl Valve SizingOwen HennessyNo ratings yet

- Balancing Valve Sizing - TA-1Document11 pagesBalancing Valve Sizing - TA-1ramon duldulaoNo ratings yet

- 13 - SRK S-PlatformDocument46 pages13 - SRK S-PlatformLassané KINDONo ratings yet

- ISA Mentor Program WebEx Best Control Valve Rev0Document44 pagesISA Mentor Program WebEx Best Control Valve Rev0Harold David Gil MuñozNo ratings yet

- GPSA Control Valve SizingDocument10 pagesGPSA Control Valve Sizingbakhtyar21100% (1)

- Catalog Yellow JacketDocument28 pagesCatalog Yellow JacketJohn SuarezNo ratings yet

- ZDM Series Automatic Recirculation Valve - Weilan Flow Control Equipment CoDocument4 pagesZDM Series Automatic Recirculation Valve - Weilan Flow Control Equipment CoEsteban CastellanoNo ratings yet

- LGC Brochure 2013 PageDocument6 pagesLGC Brochure 2013 PageZasaliveNo ratings yet

- Rexroth Flush ValveDocument2 pagesRexroth Flush ValveanandsubbiahNo ratings yet

- 076 - Heating, Ventilation, and Air ConditioningDocument111 pages076 - Heating, Ventilation, and Air ConditioningGedas GvildysNo ratings yet

- Tech - Man ENG 541D20 2007.12Document25 pagesTech - Man ENG 541D20 2007.12eduardoNo ratings yet

- Cost-Effective De-Bottlenecking of Separation Facilities by Use of Inline TechnologyDocument12 pagesCost-Effective De-Bottlenecking of Separation Facilities by Use of Inline TechnologyNaeem HussainNo ratings yet

- Control Valves, Fittings and Accessories: Ws1Ee Twin Alternating Control ValveDocument12 pagesControl Valves, Fittings and Accessories: Ws1Ee Twin Alternating Control ValveHasan AkilNo ratings yet

- On Vehicle Inspection: RadiatorDocument2 pagesOn Vehicle Inspection: RadiatorMiguel ruizNo ratings yet

- CF Sampling Solutions.02Document19 pagesCF Sampling Solutions.02Patrick FoNo ratings yet

- PumptestDocument4 pagesPumptestshwetsovitNo ratings yet

- Condensate Cycle SystemDocument26 pagesCondensate Cycle SystemBhumit Sagathiya100% (2)

- Drone Launcher - Preliminary StudyDocument10 pagesDrone Launcher - Preliminary StudyNaeem KhanNo ratings yet

- 97 Series Pad-Depad Make-Up and Vent: ... World Leader in Tank Blanketing..Document8 pages97 Series Pad-Depad Make-Up and Vent: ... World Leader in Tank Blanketing..Alberto CastellanosNo ratings yet

- Testing Procedure of Dual Plate Check ValveDocument2 pagesTesting Procedure of Dual Plate Check Valverajesh100% (2)

- Preliminary - MITTEN HPU Only Rev DDocument120 pagesPreliminary - MITTEN HPU Only Rev DFabyano BrittoNo ratings yet

- Presentasi Power Pack - Virnando Batu AraDocument17 pagesPresentasi Power Pack - Virnando Batu AraVirnando NainggolanNo ratings yet

- 11 Rotary CompressorsDocument37 pages11 Rotary CompressorshichamNo ratings yet

- EMPDS - First Review Seprator DesignDocument30 pagesEMPDS - First Review Seprator DesignnawarsNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- Centaur Company ProfileDocument12 pagesCentaur Company ProfilePavan Kumar YallaNo ratings yet

- Supplier Quality Development A Review of Literature and Industry PracticesDocument23 pagesSupplier Quality Development A Review of Literature and Industry PracticesAli ZulqarnainNo ratings yet

- NW-FH NW106 GA Drawing R002-1Document2 pagesNW-FH NW106 GA Drawing R002-1Zoran Djurdjevic100% (1)

- 2 Tcds IntroductionDocument9 pages2 Tcds Introductionmczen_associatesNo ratings yet

- Job Sheet - Week 7 Level 5Document4 pagesJob Sheet - Week 7 Level 5Salman Muneer AhmedNo ratings yet

- Dynalog3.4 Update enDocument13 pagesDynalog3.4 Update enMirsad MurticNo ratings yet

- Airbus QTML Test Facilities by Referential1Document30 pagesAirbus QTML Test Facilities by Referential1Namelezz ShadowwNo ratings yet

- Revision-A1: Oman Tank Terminal Company (Ottco)Document5 pagesRevision-A1: Oman Tank Terminal Company (Ottco)ANIL PLAMOOTTILNo ratings yet

- P2-Björn Johansson - What Is Gripen E - 19 March 2013Document12 pagesP2-Björn Johansson - What Is Gripen E - 19 March 2013Mav NTNo ratings yet

- 08 Quite InformativeDocument2 pages08 Quite InformativeQazi BaranNo ratings yet

- Anmol Technical Training Center Corporate Profile FinalDocument11 pagesAnmol Technical Training Center Corporate Profile FinaldelhianmolNo ratings yet

- TFP Fire Products Catalog - 02 19 PDFDocument112 pagesTFP Fire Products Catalog - 02 19 PDFSamiYousifNo ratings yet

- Workflows in BIM 360 and Collaboration For RevitDocument52 pagesWorkflows in BIM 360 and Collaboration For Revitasilva025599No ratings yet

- 3WN1 Circuit-Breakers For AC: Titel - 07.fm Seite 1 Donnerstag, 15. Februar 2001 7:48 07Document54 pages3WN1 Circuit-Breakers For AC: Titel - 07.fm Seite 1 Donnerstag, 15. Februar 2001 7:48 07iyilmaz76No ratings yet

- Heinz Block Recommended Reading List PDFDocument2 pagesHeinz Block Recommended Reading List PDFjeyaselvanmNo ratings yet

- EETAP Fact SheetDocument2 pagesEETAP Fact SheetJaikumar PettikkattilNo ratings yet

- P KroCar GBDocument16 pagesP KroCar GBVlado PetkovskiNo ratings yet

- Itp Bored Pile Rev 1Document10 pagesItp Bored Pile Rev 1Pandar HasibuhanNo ratings yet

- Bright Boipuso Final Presentation-UpdatedDocument27 pagesBright Boipuso Final Presentation-UpdatedBrightNo ratings yet

- Support101 2Document102 pagesSupport101 2Remus BoldeaNo ratings yet

- Otisline Case StudyDocument2 pagesOtisline Case Studynkumar_324No ratings yet

- Member Application Form With Schedule 2018Document11 pagesMember Application Form With Schedule 2018rthomsanNo ratings yet

- Pres 20150608 Roadshow Presentatie Electrabel Final PDFDocument8 pagesPres 20150608 Roadshow Presentatie Electrabel Final PDFfakesasoNo ratings yet

- Case Study Format of KIA MotorsDocument5 pagesCase Study Format of KIA MotorsSujan RoyNo ratings yet

- ZahoorCV (SR Oracle Developer)Document4 pagesZahoorCV (SR Oracle Developer)sabaisNo ratings yet

- Ship MaintananceDocument302 pagesShip MaintananceNur Merah100% (4)

- Certified in Governance Risk and Compliance GuideDocument1 pageCertified in Governance Risk and Compliance GuidekwcnwjrsjtNo ratings yet

- Pumpts PDFDocument273 pagesPumpts PDFRomel LeoNo ratings yet

- Dbms NotesDocument45 pagesDbms NotesKiran KumarNo ratings yet

- 9i DBA Performance Tuning R2 V2 - D37163Document374 pages9i DBA Performance Tuning R2 V2 - D37163avk.oracleNo ratings yet