Professional Documents

Culture Documents

3.7 FES20 - Series - Installation - Manual - Fes20 - 7.3.934 - 2010.5.12

Uploaded by

akhonmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.7 FES20 - Series - Installation - Manual - Fes20 - 7.3.934 - 2010.5.12

Uploaded by

akhonmanCopyright:

Available Formats

FES20M / FES20 ELECTRIC STRIKE

DOOR LATCH POSITION:

1mm gap

Keeper

FSH

Door Keeper

Door Latch Front face of

FSH

strike keeper

Door Frame

Figure 1

As drawn above, there should be 1mm gap between the door latch and the front face of strike keeper to

prevent the door from exerting back pressure on the keeper when the door is closed.

The Electric Strike FES20 Series has a 10mm lip as standard. The product kit includes a 5mm extension lip

for applications where a 15mm strike-lip is required.

MOUNTING STEPS OF STRIKE:

1.) When door is closed, make sure there is no back pressure on the keeper strike.

2.) When the above installation is completed, connect the wiring, secure the strike with appropriate

screws and check operation. FES 20 model is not equipped with monitoring sensor.

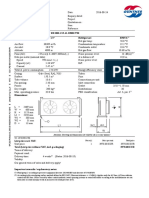

SPECIFICATION:

Power Input 12 VDC – current 220 mA 24 VDC – current 110 mA

Wire output Red (+) Black (-)

LSS (Lock Status Sensor) Black (Common) Yellow (NO-PTO); (NC-PTL) Green (NC- PTO); (NO-PTL)

DSS ( Door Status Sensor) Black (Common) Blue (NO) Orange (NC)

ATS ( Anti– tamper Sensor) Black (Common) Red (NO) White (NC)

LSS Sensor Output DSS Sensor Output Anti-tamper Sensor Output

Sensor Output

3 A, 125 VAC; 2 A, 30 VDC. 3 A, 125 VAC; 2 A, 30 VDC. 5 A, 125 VAC; 3 A, 250 VAC.

Note: The control circuit for the door strike is protected against reverse polarity connection.

INSTALLATION ON METAL FRAMES:

140

123

Depth of lip cutout will vary

39

due to width of door frame

and mounting technique Keeper

14.7

Area

FSH

29.4

162

9.6 x 6

178 C.Sink 2 places

25 212.8

FSH

Remove rubber plug prior to assembly of

extension lips (2 places).

5mm,15mm, 25mm, 50mm, 75mm

extension lips are available options Figure 2

POWER TO LOCK (PTL) <=> POWER TO OPEN (PTO) CONVERSION:

Figure3 Figure4

Procedures to convert PTO (Power to open) to PTL (Power to lock)

Step 1: Remove the rubber cap to expose the capstan wheel. See (Figure 3).

Step 2: Slacken the capstan release screws two full revolutions, DO NOT REMOVE. See (Figure 3).

Step 3: Insert the “tool pin” through the cover end opening hole and operate the solenoid hold it in

position and at the same time insert the “tool” thru the cover plate opening hole and turn the

capstan gear in the direction of the keeper to the stop. See (Figure 4).

Step 4: The strike is now in the Power to Lock mode.

Step 5: Tighten the two capstan releasing screws and replace the rubber cap. See (Figure 5).

Figure5 Figure6

Procedures to convert PTL (Power to lock) to PTO (Power to open)

Step 1: Remove the rubber cap to expose the capstan wheel. See (Figure 3).

Step 2: Slacken the capstan release screws two full revolutions, DO NOT REMOVE. See (Figure 3).

Step 3: Insert the “tool pin” through the cover end opening hole and operate the solenoid hold it in

position and at the same time insert the “tool” thru the cover plate opening hole and turn the

capstan gear in the direction of the release screw to the stop. See (Figure 6).

Step 4: The strike is now in the Power to Open mode.

Step 5: Tighten the two capstan releasing screws and replace the rubber cap. See (Figure 5).

TEMPLATE

26.8mm 123.1mm 26.8mm

Depth of cut-out will vary dependant on width of door frame

1

5

m

m

L

i

p

5 sizes of extension lips are available

Depth

5mm,10mm, 25mm, 50mm and 75mm

1S

0t

ma

md

L

i

pd

n

a

r

TEMPLATE cut thru outline

L

i

p

l

e

s

s

162mm

45mm

Position this line to

your marking.1mm

29.5mm

NOT TO SCALE Latch front face clearance has been

added.

40mm

V1.0 2010

You might also like

- Svpro1 Installation InstructionsDocument4 pagesSvpro1 Installation InstructionsHenry CanalesNo ratings yet

- A/fs-1, A/fs-1a, A/fs-2, A/fs-2aDocument3 pagesA/fs-1, A/fs-1a, A/fs-2, A/fs-2aBachar RennyNo ratings yet

- AGI 4xx Installation Instructions 4189341102 UKDocument2 pagesAGI 4xx Installation Instructions 4189341102 UKrodruren01No ratings yet

- Load Schedule and Single Line Engr GorospeDocument1 pageLoad Schedule and Single Line Engr GorospeMichael Pepz DatuinNo ratings yet

- Top PlugDocument2 pagesTop Plugwar10ckjupiNo ratings yet

- Onkyo - C 701 ADocument21 pagesOnkyo - C 701 Anyoman dundunNo ratings yet

- 05 AMHTC SeriesDocument9 pages05 AMHTC SeriesJair ArmandoNo ratings yet

- Key Fob Signal To TSSM Weak or Fails 3.14: GeneralDocument42 pagesKey Fob Signal To TSSM Weak or Fails 3.14: GeneralKeith ChoiNo ratings yet

- ES2-HB-N ES2-THB-N: Ordering InformationDocument6 pagesES2-HB-N ES2-THB-N: Ordering InformationDiki Permana SNo ratings yet

- Supervisory SwitchDocument1 pageSupervisory SwitchAwais MumtazNo ratings yet

- sl35 Installation InstructionsDocument2 pagessl35 Installation InstructionsHenry CanalesNo ratings yet

- Leslie 2121 InstructionsDocument12 pagesLeslie 2121 InstructionsbjNo ratings yet

- Philips FW-C380Document30 pagesPhilips FW-C380Czcibor KowalcyzkNo ratings yet

- LP2950 Micropower Voltage Regulators: TO-92 Z Suffix Case 29Document16 pagesLP2950 Micropower Voltage Regulators: TO-92 Z Suffix Case 29ejdigger ejNo ratings yet

- ARK E Ssue Owner's Manual: Oogie ESADocument30 pagesARK E Ssue Owner's Manual: Oogie ESAyorgoNo ratings yet

- M2 Antenna Systems, Inc. Model No: 10M7-125: SpecificationsDocument9 pagesM2 Antenna Systems, Inc. Model No: 10M7-125: Specificationsadel agustiNo ratings yet

- Tlm-1903 Service ManualDocument40 pagesTlm-1903 Service ManualdaldoggyNo ratings yet

- Relay and Fuse Arrangement: Edition 06.04Document9 pagesRelay and Fuse Arrangement: Edition 06.04Alexandru CraiovanNo ratings yet

- En40c-1030 ADocument16 pagesEn40c-1030 AIgnacio Jesus Prado MellaNo ratings yet

- LP2950, LP2951, NCV2951 100 Ma, Low Power Low Dropout Voltage RegulatorDocument22 pagesLP2950, LP2951, NCV2951 100 Ma, Low Power Low Dropout Voltage RegulatorLeonardo SantanaNo ratings yet

- ZBK enDocument14 pagesZBK enDragan M.No ratings yet

- 3-13. Slim Low Static Ducted Type (Type M1) 8. Slim Low Static Ducted Type (M1 Type)Document1 page3-13. Slim Low Static Ducted Type (Type M1) 8. Slim Low Static Ducted Type (M1 Type)Loc DoNo ratings yet

- Final ECCO 1Document18 pagesFinal ECCO 1Suraj MitraNo ratings yet

- Circ BreakDocument2 pagesCirc Breakjurica_2006No ratings yet

- Compressor Cutoff ControllerDocument3 pagesCompressor Cutoff Controllerprado01No ratings yet

- F534a-Brosure Alm WM CDocument32 pagesF534a-Brosure Alm WM CNada ZhafirahNo ratings yet

- Pi E-931-S35rrq 171215Document1 pagePi E-931-S35rrq 171215Nataly MedinaNo ratings yet

- Power AmplifierDocument20 pagesPower AmplifierHansBautistaNo ratings yet

- Superior Plasma 90 HF PDFDocument28 pagesSuperior Plasma 90 HF PDFсергей васяновичNo ratings yet

- Moog DINBufferAmplifier G123825001 TechnicalNote enDocument4 pagesMoog DINBufferAmplifier G123825001 TechnicalNote enMauricio GuanellaNo ratings yet

- Fuseclips For A480r5r-1 and A480t2eDocument2 pagesFuseclips For A480r5r-1 and A480t2eM. Taufik HidayatNo ratings yet

- AC Axial FanDocument20 pagesAC Axial FansunhuynhNo ratings yet

- Caution: EG21 and EGS21 Series Electric Gage and Swichgage InstallationDocument2 pagesCaution: EG21 and EGS21 Series Electric Gage and Swichgage InstallationAndres CelyNo ratings yet

- Strada ExDocument12 pagesStrada ExVaibhav DafaleNo ratings yet

- SB-14-12-001 Power Folding Mirror Installation R1Document11 pagesSB-14-12-001 Power Folding Mirror Installation R1Conrad Aixart ForesNo ratings yet

- Megmeet PartsDocument2 pagesMegmeet Partsnugraha1805No ratings yet

- (TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 301-400Document100 pages(TM) Ssangyong Manual de Taller Ssangyong Actyon 2013 en Ingles (1) - 301-400LUIS HERNANDONo ratings yet

- TXTFront HalfDocument4 pagesTXTFront HalfAnonymous v9es4eABNo ratings yet

- 17 Hpl2010-En PDFDocument180 pages17 Hpl2010-En PDFconsultachNo ratings yet

- F50 ManualDocument34 pagesF50 Manualtritoneb5No ratings yet

- Denon Stereo CD Player DCD-485-DCD-685 Parts and Service ManualDocument45 pagesDenon Stereo CD Player DCD-485-DCD-685 Parts and Service Manualpippo2378793No ratings yet

- ManualDocument2 pagesManualFernando Tsuyoshi KikuchiNo ratings yet

- Plitstr250 Rev F SS741MGDocument20 pagesPlitstr250 Rev F SS741MGArc HieNo ratings yet

- 20947Document30 pages20947paco37No ratings yet

- Srs z1Document8 pagesSrs z1TrentungcaysoBombodealopNo ratings yet

- Medidor Murphy EGS21 P y TDocument5 pagesMedidor Murphy EGS21 P y TmemocritoNo ratings yet

- Quick Installation Guide: Microflex E150Document74 pagesQuick Installation Guide: Microflex E150home madeNo ratings yet

- Swing Gate Opener Sw28O Series: User'S Mi/NualDocument10 pagesSwing Gate Opener Sw28O Series: User'S Mi/NualIliescu CristianNo ratings yet

- Acdb 17 in 1 Out - Groung PDFDocument7 pagesAcdb 17 in 1 Out - Groung PDFSumit TyagiNo ratings yet

- Load Sched LES: Project: Proposed Metro Manila New Warehouse Location: Panelboard:Lp-Aux LocationDocument8 pagesLoad Sched LES: Project: Proposed Metro Manila New Warehouse Location: Panelboard:Lp-Aux LocationGilbertNo ratings yet

- ACET Door EntryDocument28 pagesACET Door EntryDave BrittonNo ratings yet

- Yamaha Ystms201 Speaker System Service ManualDocument12 pagesYamaha Ystms201 Speaker System Service ManualttnaingNo ratings yet

- Enterprise Plasma 160 HF PDFDocument20 pagesEnterprise Plasma 160 HF PDFсергей васяновичNo ratings yet

- Service Manual TV Lg42px4rvh EnglishDocument37 pagesService Manual TV Lg42px4rvh EnglishRc Uno UnoNo ratings yet

- Installation and Operating Instructions: DC Fuse Monitor, OFDDocument8 pagesInstallation and Operating Instructions: DC Fuse Monitor, OFDTrường NguyenNo ratings yet

- S.No. Device Sheet No. / Location S.No. Device Sheet No. / LocationDocument14 pagesS.No. Device Sheet No. / Location S.No. Device Sheet No. / LocationKewin CasstroNo ratings yet

- Sony XM7547 CarampDocument28 pagesSony XM7547 CaramproskobyNo ratings yet

- Automation - Series 83 Valve Position MonitorDocument2 pagesAutomation - Series 83 Valve Position MonitorJair MargaritocNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- LC300 - Online Brochure 202110291Document30 pagesLC300 - Online Brochure 202110291JORGE LUIS TRIANA RODRIGUEZNo ratings yet

- Plug in Time Delay Relays C System PDFDocument4 pagesPlug in Time Delay Relays C System PDFAndré CrowleyNo ratings yet

- ZM400 ZM600 Service Manual 14207L-004Document580 pagesZM400 ZM600 Service Manual 14207L-004Rafał Krzysztof KowalskiNo ratings yet

- RS1117Document10 pagesRS1117asismamenNo ratings yet

- Door Close Lock Defect: Meaning)Document1 pageDoor Close Lock Defect: Meaning)Ace Noah SomintacNo ratings yet

- Inversor PV1800 VHM (220V) SPECSDocument4 pagesInversor PV1800 VHM (220V) SPECSwilliam andres pena castanoNo ratings yet

- Summary Inspection Reports PT. SMSE Kupang - Rev. 01Document9 pagesSummary Inspection Reports PT. SMSE Kupang - Rev. 01Muhammad ZakiNo ratings yet

- Everdigm EHB30Document28 pagesEverdigm EHB30ALI RAZAVI100% (1)

- RF Inductance MeterDocument5 pagesRF Inductance MeterTibor NemethNo ratings yet

- CCTV QuotDocument2 pagesCCTV QuotkollidrNo ratings yet

- Digger Cal UTSDocument61 pagesDigger Cal UTSConnor TabainNo ratings yet

- Power Supplies For Photomultiplier Tube Modules: Type No. C10709 C7169 UnitDocument2 pagesPower Supplies For Photomultiplier Tube Modules: Type No. C10709 C7169 UnitCaver VelasquezNo ratings yet

- Aeron Systems: Inertial Sensors and Navigation SystemsDocument7 pagesAeron Systems: Inertial Sensors and Navigation SystemsBhagavad GitaNo ratings yet

- DashDocument2 pagesDashJesse Alonso100% (1)

- Introduction To Computers and Programming Languages: Animated VersionDocument9 pagesIntroduction To Computers and Programming Languages: Animated VersionJuan Del AngelNo ratings yet

- Price List 2010-11 PDFDocument34 pagesPrice List 2010-11 PDFGuddu ChaurasiyaNo ratings yet

- Module4 TransformerDocument47 pagesModule4 Transformeranvay.shirsatNo ratings yet

- Food Saver FM3000 Series 2 1 Vacuum Sealer ManualDocument13 pagesFood Saver FM3000 Series 2 1 Vacuum Sealer ManualMartin CerdaNo ratings yet

- GTU MechatronicsDocument2 pagesGTU MechatronicspmagrawalNo ratings yet

- O-Ring - NOK AS568 SeriesDocument4 pagesO-Ring - NOK AS568 SeriestungNo ratings yet

- Invertec 135S, 150S & 170SDocument7 pagesInvertec 135S, 150S & 170SDiegoNo ratings yet

- Epson EB-S18: Larger Than Life - Proven PerformanceDocument2 pagesEpson EB-S18: Larger Than Life - Proven Performanceapi-313872361No ratings yet

- Flexi Edge Bts SystemDocument25 pagesFlexi Edge Bts SystemMuty Koma67% (3)

- Ficha Tecnica CONDENSADORDocument2 pagesFicha Tecnica CONDENSADORGustavo HidalgoNo ratings yet

- AUG 05 Automotive EnginesDocument16 pagesAUG 05 Automotive EnginesHarishNo ratings yet

- Datasheet - HK Mb90m408apf 4289720Document64 pagesDatasheet - HK Mb90m408apf 4289720Sebastian CorreaNo ratings yet

- Tpi of Bobcut PDFDocument1 pageTpi of Bobcut PDFSanu RajNo ratings yet

- UNIT 2 A Typical PCDocument8 pagesUNIT 2 A Typical PCNurul Fadilah Nainanda Putri Chaniago100% (1)

- CD13001 TRANSISTOR Datasheet PDFDocument3 pagesCD13001 TRANSISTOR Datasheet PDFmikcomiNo ratings yet

- 37xr MetermanDocument2 pages37xr MetermanGatoBeckerNo ratings yet