Professional Documents

Culture Documents

4 Cylinder Diesel Engine 2.0L Common Rail - VW Amarok 10-16 - PDF Download

4 Cylinder Diesel Engine 2.0L Common Rail - VW Amarok 10-16 - PDF Download

Uploaded by

Haji Rashid0 ratings0% found this document useful (0 votes)

23 views419 pagesOriginal Title

4 Cylinder Diesel Engine 2.0L Common Rail - VW Amarok 10-16 _ PDF Download

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views419 pages4 Cylinder Diesel Engine 2.0L Common Rail - VW Amarok 10-16 - PDF Download

4 Cylinder Diesel Engine 2.0L Common Rail - VW Amarok 10-16 - PDF Download

Uploaded by

Haji RashidCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 419

Service

Workshop Manual

Amarok 2011 >

Edition 04.2013

Service Department. Technical Information

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Repair Group

00 - Technical data

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

20 - Fuel supply system

21 - Turbocharging/supercharging

23 - Mixture preparation - injection

26 - Exhaust system

28 - Glow plug system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2013 Volkswagen AG, Wolfsburg D4Be0260554

‘Amarok 2011 >

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Contents

00 - Technical data 1

1 Identification 1

4.1 Engine number, engine data 1

2 Safety instructions 3

24 Safety precautions when working on fuel supply system 3

2.2 Safety precautions when working on injection system, 4

2.3 Safety precautions when working on charge air system 5

2.4 Safety precautions when working on cooling system + 5

25 Safety precautions during road tests in which testing and measuring equipment is used .. 6

7

7

7

8

8

9

3 Repair instructions

3.1. General notes on the lubrication system

3.2 General notes on fuel system

3.3. Rules for cleanliness when working on fuel supply systeminjection system

3.4 — Rules for cleanliness when working on charge air system

3.5 Instructions for working on fuel system

3.6 To avoid any risk of injuries to persons andlor the destruction of the injection and glow plug

system, the following must be noted 10

3.7 Instructions for hose connections with screw-type clips 1“

10 - Removing and installing engine ............ - 12

1. Removing and installing engine 12

1.4 Removing engine 12

1.2 Securing engine on engine and gearbox support VAS 6095 26

1.3 Installing engine 2

2 Assembly mountings .. : 31

24 Removing and installing assembly mountings 3

13 - Crankshaft group GUI PICs eter tenet eee eee . 33

1 Oytinder block (pulley end) 34

1.1. .cAssembly overview - cylinder block % 34

12° Assembly overview - sealing flange, belt pulley.end 36

43 Assembly overview poly V-belt drive .. sees 3?

44 Assembly overview poly V-belt drive, vehicles without AIC system .evssssessevecsss 38

1.5 Removing and installing poly V-belt... ep eee eee : cee 40

4.6 Removing and installing tensioner for poly V-belt ee 42

1.7 Removing and installing ancillary bracket > vets tee 43

1.8 Removing and installing vibration damper .......000jscecvveeeeseee vee 4d

18. Renewing crankshaft oil seal - belt pulley end . 46

1.10 Removing and installing sealing flange on pulley end 48

2 Ancillary drive 5 51

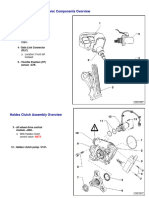

2.1 Assembly everview- ancillary drive 5

2.2 Retrofitting preparation for ancillary drive 8 51

3 ylinder block (gearbox end) 54

3.1 Assembly overview - cylinder block, gearbox end 5a

3.2 Removing and installing dusl-mass flywhee! 55

3.3 Removing and installing sealing flange on gearbox side 57

4 Pistons and conrods 66

4.1 Assembly overview - pistons and conrods 66

42 Checking piston and cylinder bore 68

4.3, Piston and cylinder dimepsions 69

4.4 © Measuring piston projectigy at TOC 70

45 Checking radial clearancktf conrods, a”

contanis i

@

15

17

48

47

5

54

52

53

54

55

1

1.4. Assembly overview - cylinder head

1.2. Assembly overview - cylinder head cover

4.3. Removing and installing cylinder head

4.4 Removing and installing cylinder head cover

4.5 Removing and installing injector seals

1.6 Removing and installing vacuum pump

1.7 Checking compression.

2 Toothed belt drive.

24 Assembly overview - toothed belt drive |

2.2 Removing and installing toothed belt.

3 Fresh air supply system, belt drive

3.1 Assembly overview fresh air supply system

3.2. Removing and instaling blower for fresh air supaly system

3.3. Removing and installing ai filter housing for fresh air supply system

3.4 Removing and installing bracket for fresh air supply system

4 Valvegear . a

4.1 Assembly overview valve gear A

4.2 Measuring axial clearance of camstatt ...

4.3 Measuring radial clearance,of camshafts

4.4 — Removing and installing.éamshafts

4.5 Removing and instalitig camshaft cil seal

4.6 Checking hydraulic'compensation element

4.7 Renewing valve stem seals

5 Inlet and exhaust valves:

5.1 Reworking valve seats

5.2 Checking valve guides

53 Valve dimensions

Lubrication ..5

1 Sump, oil pump

1.1 Assembly everview - sump, el pump.

1.2 Removing and installing oil sump

1.3 Removing ahd installing oil pump

1.4 Removing and installing oil pump, vehicles with balancer shaft module

1.5 Checking engine oil level

1.6 Removing and installing oil level and oil temperature sender G266

1.7 Removing and installing dipstick tube

2 Oilfiter, oil pressure switch

2.1 Assembly overview “i fiter housing with engine oil cooler

2.2 — Removing and installing‘ol fiter housing with enginef@iycooler

2.3 Removing and installing oil‘pressure switch F1

2.4 — Checking cil pressure switch F1%.., 2 oi

2.5 Checking oil pressure

2.6 Measure oll consumption

Amarok 2011 >

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Bearing shells - installation position

‘Separating new conrod

Crankshaft

Assembly overview - crankshaft

Crankshaft dimensions .

Measuring axial clearance of crankshaft

Measuring radial clearance of crankshaft .

Renewing needle bearing in crankshaft

Cylinder head, valve gear .......... :

Cylinder head

1

72

73

73

74

74

75

76

78

78

78

81

85

93

99

- 102

103

- 105

- 105

107

116

116

117

217

118

119

119

121

122

123

129

131

- 132

135,

135

135

136

137

. 137

137

140

148

148

147

147

148

150

150

151

154

- 156

- 157

157

Contents

Amarok 2011

19

20

4-oylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

3 Engine oil cooler 159

3.1 Checking engine oil cooler for leaks 159

4 Balancer shaft module 161

4.1. Assembly overview - balancer shaft module 161

42 Removing balancer shaft module 163

4.3 Installing a new balancer shaft module 165

44 Installing a previously used balancer shaft module again 168

5 Oilcircuit =. 170

5.1 Removing and installing oil supply line to turbocharger, 120 kW and 132 kWengines .... 170

5.2 Removing and installing oil pressure line to turbocharger - 90 kW and 103 kW engine 172

Cooling oe 175

+ Cooling system, coolant . 178

4.1 Coolant hose schematic ciagram 175

1.2. Assembly overview - coolant hoses 178

13. Checking cooling system for leaks 180

14 Draining and filing coolant 182

2 Coolant pump, regulation of cooling system 187

2.1 Assembly overview - coolant pumpiball thermostat (4/2-way valve) 187

2.2 Assembly overview - Continued coolant circulation pump V51 188

2.3 Assembly overview - circulation pump V55 189

2.4 — Removing and installing coolant pump 190

2.5 Removing and installing 4/2-way valve with thermostat 191

2.6 — Removing and installing coolant temperature sender G62 196

2.7 Removing and installing coolant temperature sender at radiator outlet G83 197

28 — Removing and installing continued coolant circulation pump V51 198

2.9 Removing and installing Y-iherméstat .. 199

2.10 Removing and installing récirculation pump V55 s+ 200

3 Radiator, radiator fart’... - 202

3.1 Assembly overviaw- raciator/ radiator fan V7 202

32 Assembly overview - radiator cow and radiator fan V7 2 204

33. Removing and installing radiator... 4, 204

3.4 Removingiand installing radiator cow with radiator fan V7 207

Fuel supply system : -210

+ Procedure when filing with incorect uel 210

4.4 Procedure when filing with incorrect fuel 5 210

1.2. Enging isnot running . 210

13° Engine is running : an

2 Checking low-pressure fuel system. 213

2.1 Checking fuel low-pressure at high-pressure pump .. a... 213

22 Checking flow rate at high-pressure pump ........2eee0e - as 215

2.3. Checking fuel low-pressure ahead of fuel fiter 218

2.4 Checking flow rate ahead of fuel fiter g 222

3 Fuel tenk 226

3.4 Assembly overview - fuel tank 228

32 Assembly ovérview- fuel lines 228

3.3 Removing and installing fuel tank 229

3.4 Removing and installing filler neck + 232

4 Fuel delivery unit, fuel gauge sender » 236

4.4. Removing and installing fuel delivery unit 236

4.2 Removing and installing fuel gauge Sender G 237

5 Fuel fer we 238

5.1 Assembly overview - fuel fiter 238

consents Hii

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

5.2 Removing and installing fuel fiter 230

5.3 Checking fuel fter 239

6 Fuel pump 242

6.1. Checking fuel delivery rate of fuel pump (fuel low pressure) 242

6.2 Checking voltage supply of fuel pump (fuel low pressure) 6... eee eeee 245

7 Accslerator mechanism 248

7.4 Function .... vote tte ett teecteeees 2B

7.2 Assembly overview accelerator mechanism... ceseeeees » 249

21 - Turbocharging/supercharging «250

1 Charge air system covet eee eee sevees 250

11 Assembly overview - charge air system 250

1.2. Removing and installing charge air cooler 251

43 Removing and insaling intake air temperature sender G42 with charge air pressure sender

4.4 Removing and installing exhaist gas fap Valve N20 ree » 255

15. Checking charge alrsystem for leaks 00. geese ee eeeeceeeeeeeeees es 256

2 Turbochargers... cov vveeeeeceee 260

2.1 Assembly overview turbocharger, 120 KW and 132 KW engine, «os... sss es. s+ 280

2.2 Assembly overview - turbocharger, 90 kW and 103 kW engines, cece eee e es 264

2.3 Removing and installing turbocharger - 120 kW and 132 kW engines... . 267

2.4 — Reméving and installing turbocharger - 90 kW and 103 KW engines 272

2.5 Removing and installing charge pressure sender 2. G447 277

2.6 Removing and installing regulating flap potentiometer G584 and vacuum unit for

turbocharger, 120 kW engine 278

2.7 Removing and installing regulating flap potentiometer G584 and vacuum unit for

turbocharger, 132 kW engine 290

2.8 Removing and installing charge pressure control solenoid valve N75... 5............ 300

23 - Mixture preparation - injection ....... 2.6... 0e0eceeee eee wees 302

1 Injection system 302

1.1. Schematic overview - fuel system : 302

1.2 Fitting location overview - injection system 304

1.3. Assembly overview - fuel system att

14 Checking fuel system for leaks ........ 316

1.5 Filinglbleeding fuel system ........... a 316

2 Vacuurm'system . = 318

21 Schematiégiagram- vacuum system . $ 318

2.2 Testing vacuiam system for leaks... see gWOoveeeceereeteeeeeeee 321

3 Injectors and higf-pressure accumulator a6 327

34 Overview of injectors “., soso veces : 327

3.2 Injector delivery calibration voceeteees - 327

3.3. Removing and installing injectors (piezo injectors)... ss. coven 328

3.4 Removing and installing injectors (solenoid valves) 332

3.5 Removing and installing high-pressure lines . _ cece 338

3.6 Removing and installing high-pressure accumulator (ral) 340

3.7 Checking return flow rate of injectors with engine running 343

4 High-pressure pump vote eee cesteeteeeeesneseeees S47

4.1 Removing and instaling high-pressure pump... veveeeeees » 347

4.2 Checking high-pressure pump . : . : + 350

5 Intake manifold Seat eet e ec teteeteeectteeeeeentrceres O54

3.1 Assembly overview intake manifold... ..v.ssssvsessssssvseeierssseveevessss 384

5.2 Removing and installing intake manifold... » 354

5.3. Removing and installing throttle valve module J338 with throtle valve potentiometer G68 and

intake manifold flap motor V157 357

IV contants

26-

28 -

Amarok 2011

cylinder diesel enginié (2.0 | engine, common rail) - Edition 04.2013

6° Senders and sensors

8.1 Removing and installing air mass meter G70

62 Removing and installing exhaust pressure sensor 1 G450

63 Removing and installing fuel pressure regulating valve N276

64 Checking fuel pressure regulating valve N276

65 Removing and installing fuel pressure sender G247

7 Airfiter

7.4 Assembly overview - air fiter Z

7.2, Removing and installing airfiter

8 Engine control unit :

8.1 Removing and installing engine control unit.

8.2 Renewing engine control unit ..

Exhaust system a.

1 Exhaust pipes, silencers

14 Assembly overview silencers

12 Checking exhaust system for leaks

4.3. Aligning exhaust system free of stress

2°, Cleansing exhaust emiss

2.1 ©. Assembly overview - emibgidn control (diese! particulate fiter)

2.2 AsGembly overview - emifgtbn control (catalytic converter)

23 — Removifigrand installing particulate fter

24 — Removing and installing catalytic converter

3 Exhaust gas recirculation

3.1. Assembly overview - exhaust gas recirculation

32 Assembly overview - exhaust gas recirculation, 132 KW engine

3.3. Removing and installing exhaust gas recirculation cooler

34 Removing and installing exhaust gas recirculation cooler, 132 KWW engine

3.5 Removing and installing exhaust gas recirculation valve N18 , 132 kW engine

3.6 Removing and installing changeover valve for exhaust gas recirculation cooler N345

3.7. Checking exhaust gas recirculation cooler for leaks

Glow plug system - :

1 Glow plug system

44 Checking glow plug system

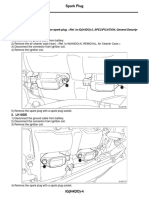

1.2. Removing and installing glow plugs.

1.3 Removing and instaling engine speed sender G28

1.4. Removing and installing Hall sender G40

359

359

360

362

364

365

368

368

370

372

372

372

374

374

374

375

375

377

377

379

381

387

390

390

301

302

308

400

401

402

404

404

404

405

406

407

Contents V

Amarok 2011 >

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Vi_ contons

‘Amarok 2011 >

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

wy) Technical data

1 Identification

(VRLO05497; Edition 04.2013)

= "“1.1 Engine number, engine.data”.page 1

1A Ehgine number, engine data

New.f6ur digit engine codes have been introduced since model

year 2008. The first 3 digits refer to the mechanical configuration

of the engine. They are stamped onto the engine. The fourth digit

denotes the power output of the engine and depends on the.en-

gine control unit. The four digit engine code can be found on the

identification plate, the vehicle data sticker and the engine control

unit

The engine number ("engine code" and “serial number’) can be

found at the joint between engine and gearbox -arrow-.

In addition, there is a sticker attached to the toothed belt guard

showing the "engine code” and “serial number’

‘The engine code is also included on the vehicle data sticker.

‘The engine number consists of up to nine characters (alphanu-

meric). The first part (maximum 4 characters) makes up the

“engine code", and the second part (B characters), the ‘serial

number. If more than 999,989 engines were produced with the

same code letters, the first of the six digits is replaced by a letter.

eae TE

Engine code DCA (DBA CNFA

Manufactured from 01.10

to

mating users” | cuasmeag | euocanaes

U 4 standard EU 4 standard EU 4 standard

EUS: sensors EUS standard EUS standard

Capacity q 20 20

Output kW at sa014000 90/3750 90/3750

rpm|

Torque Nm at} 400/ 340/ 3401

41500 - 2000 1750 - 2250 1600 - 2000

Cepecity 1968 1968 1988

Bore 81.0 81.0 81.0

stroke 95.5 95.5 955

‘Valves per cylinder 4 4 4

Compression ratio 165 165 16.0

Fuel accord- DIN EN 590 DIN EN 590 DIN EN 590

ing to

Firing order 1342 1342 1342

Balancer shaft module no no no,

Catalytic converter yes yes yes

Exhaust gas recirculation yes yes yes

Turbocharging/supercherg- yes yes yes

ing

Charge air cooler yes yes yes

Particulate fiter yes, in the case of EU 5 |yes, in the case of EU 5|yes. in the case of EU 5

\donfcation 1

@ Amarok 2011 >

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

[Engine code ‘Cbca. (CDBA. ‘ONFA

Particulate filter No; on vehicles compli- | No; on vehicles compli-| No; on vehicles compli-

ant with EU 3 and EU 4 | ant with EU 3 and EU 4] ant with EU 3 and EU 4

standards. standards. standards,

Selective catalytic reduction no. no no

(SCR system)

1) Presentin the 6358 of engines compliant with EU 9 standard andiorn conjunction with dual clutch gerboxes.

[Engine codes ‘CNEA CSHA NFB

Manufactured from 01.10

Emissions fulfil EU 4 standard EU 4 standard EU 4 standard

EU 5 standard EU 5 standard EUS standard

Capacity I 20 20 2.0

JOutput kwat] 4132/4000 4132/4000 103/380

rpm|

Torque Nm at 400/ 420/ 3401

rpm| 1500 - 2250 1750 1600 - 2250

(Capacity om] 1968 1968 1968

Bore Smm| 81.0 81.0 81.0

Stroke mm| 95.5 95.5 95.5

‘Valves per cylinder 4 4 4

(Compression ratio 185 460 16.0

Fuel scvore ‘BiweN 590 ‘DIN EN 590 DIN EN 590

ing to|

Firing order 1342 13-42 13-42

Balancer shaft module no yes no

(Catalytic converter yes yes yes

Exhaust gas recirculation yes yes yes

‘Turbocharging/super- yes yes yes

charging

Charge eir cooler yes yes yes

Particulate filter yes, in the case of EU 5 | yes, in the case of EU 5 | yes, in the case of EU 5

Particulate filter No; on vehicles compli- | No; on vehicles compli- | No; on vehicles compli-

ant with EU 3 and EU 4 | ant with EU 3 and EU 4 | ant with EU 3 and EU 4

standards. standards. standards.

Selective cateyte reduc no no no

{SCR system)

2) Present inthe case of engines compliant with EU 5 standard andlor in conjunction wth dual clutch gearboxes.

2 Rep. 07: 00- Technical data

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Can Bus Explained 2021Document22 pagesCan Bus Explained 2021Haji RashidNo ratings yet

- 2.0l Ecoboost I4 Escape Spec SheetDocument2 pages2.0l Ecoboost I4 Escape Spec SheetHaji RashidNo ratings yet

- Wzs bcr142Document8 pagesWzs bcr142Haji RashidNo ratings yet

- Exhaust System - CDCA CDBA CNEA CSHA CNFA CNFB - PDF DownloadDocument30 pagesExhaust System - CDCA CDBA CNEA CSHA CNFA CNFB - PDF DownloadHaji RashidNo ratings yet

- Cars With SRS Table of Contents 1:2, 2:2 Abbreviation How To Use The Wiring Diagram 1:2, 2:2 Electrical Distribution FusesDocument265 pagesCars With SRS Table of Contents 1:2, 2:2 Abbreviation How To Use The Wiring Diagram 1:2, 2:2 Electrical Distribution FusesHaji RashidNo ratings yet

- 4 Drivers Airbag ModuleDocument2 pages4 Drivers Airbag ModuleHaji RashidNo ratings yet

- Shift Point Road TestDocument3 pagesShift Point Road TestHaji RashidNo ratings yet

- Compass: Wiring DiagramDocument2 pagesCompass: Wiring DiagramHaji RashidNo ratings yet

- 3 Inspection Locations After A CollisionDocument9 pages3 Inspection Locations After A CollisionHaji RashidNo ratings yet

- 17238-Touareg 01 07 08Document5 pages17238-Touareg 01 07 08Haji Rashid0% (1)

- Transmission TSBDocument3 pagesTransmission TSBHaji Rashid100% (1)

- 2 Spark PlugDocument5 pages2 Spark PlugHaji RashidNo ratings yet

- DSC 5Document1 pageDSC 5Haji RashidNo ratings yet

- Tou 50-01Document11 pagesTou 50-01Haji RashidNo ratings yet

- GM Tech2 PathsDocument154 pagesGM Tech2 PathsHaji RashidNo ratings yet

- Untitled Spreadsheet - Module ListDocument2 pagesUntitled Spreadsheet - Module ListHaji RashidNo ratings yet

- TouaregDocument18 pagesTouaregHaji RashidNo ratings yet

- VW 5n CL AllWheelDriveDocument1 pageVW 5n CL AllWheelDriveHaji RashidNo ratings yet

- Radio RCD 300: Wiring DiagramDocument6 pagesRadio RCD 300: Wiring DiagramHaji RashidNo ratings yet

- 05 E65-66 Model UpdateDocument46 pages05 E65-66 Model UpdateHaji RashidNo ratings yet

- All ToyotaDocument192 pagesAll ToyotaHaji RashidNo ratings yet

- 1mz-Fe Engine Lubrication SystemDocument27 pages1mz-Fe Engine Lubrication SystemHaji RashidNo ratings yet

- ZF 5HP30 Transmission Repair ManualDocument104 pagesZF 5HP30 Transmission Repair ManualHaji Rashid100% (1)

- Data Link ConnectorDocument35 pagesData Link ConnectorHaji RashidNo ratings yet

- Toyota L 2l 2l T Engine Workshop Service Repair ManualDocument228 pagesToyota L 2l 2l T Engine Workshop Service Repair ManualHaji Rashid100% (1)