Professional Documents

Culture Documents

Exhaust System - CDCA CDBA CNEA CSHA CNFA CNFB - PDF Download

Uploaded by

Haji Rashid0 ratings0% found this document useful (0 votes)

9 views30 pagesOriginal Title

Exhaust system - CDCA CDBA CNEA CSHA CNFA CNFB _ Pdf Download

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views30 pagesExhaust System - CDCA CDBA CNEA CSHA CNFA CNFB - PDF Download

Uploaded by

Haji RashidCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 30

Amarok 2011 >

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

wa Exhaust system

1 Exhaust pipes, silencers

21.4 Assembly overview silencers’, page 374

= "1.2 Checking exhaust system for leaks’, page 375

= 1.3 Aligning exhaust system free of stress”, page 375

44 Assembly overview - silencers

1. Screwstype clip

D_ Note installation posi-

tion,

0 35Nm

2 - Rubber mounting

D_ Note installation posi-

tion > page 375

3 - Front silencer

Removing:

— Remove front propshaft.

— Remove gearbox sup-

port and gearbox

mountings = page 34

= Detach frontirear silenc-

ers at separating point

— Undo bolts holding

hanger

> Item 6 (page 374) on

gearbox cross member.

= Detach front ilencer

from rubber mounting

= Item 2 (page 374) and

completely remove front

sllencer.

4 Rear silencer

Removing:

= Detach front ahd rear si-

lencers at separating

point.

= Detach rear silenéer

from rubber mounting

= Item 2 (page 374) and completely remove rear silencer.

5 - Double clamp Q

Note installation position. a

Installation of double clamp = pagé’37S.

31Nm

6 - Mounting

Fasten mounting on gearbox cross member = page 375

374 ep. o126-- Exhaust systom

cylinder diesel engine (2.0 | engine,

7- Bolt

Q 20Nm

Fasten mounting on gearbox cross member

= Secure mounting -2: to gearbox cross member -1- with bolts

23.

Installation of double clamp

— Mark the distances 39 mm -a and b- at end of pipe of front

silencer -2- and beginning of pipe of rear silencer -1-- 4-.

= Insert front silencer -2- and rear silencer “4"into double clamp

-3- up to dimensions -a and b-

= Align serew-type connection!6f double clamp -3- horizontally

and lightly tighten bot.

— Align front silencer -2and rear silencer -1- horizontally, and

tighten bolts -3- for double clamp.

Installation location of rubber mounting

= Align rubber mounting -1- in such @ way thet the distance -2-

is 8mm,

(Fre

Check entirs installation location of exhaust system.

12 Checking-exhaust system for leaks

Start engine and run at idling speed

g.

Seal end exhaust pipes with dloths or plugs, for exampl

the curation of the leakage test.

Check (by listening) points of connection between exhaust

manifold and cylinder head, and between turbocharger and

front exhaust pipe to make sure there are no leaks.

Reectify any leaks that are found.

13 Aligning exhaust system free of stress

Special tools and workshop equipment required

cose @

common rail) - Edition 04.2013

1. Exhaust pipes. sioncers 375

Amarok 2011 >

# Torque wrench (5...50 Nm) - V.A.G 1331-

+ Exhaust system must be aligned when cold,

Procedure

~ Loosen bolts of double clamp -3-

Tighten bolts hand tight.

Align exhaust system until the marking- 4- is visible.

Align bolts of double clamp -3- horizontally.

Align rubber mountings -1- for front silencer

lencer -1- in such a way that dimension -a- is € mm.

Tighten bolts for double clamp -3..

Specified torques

# 2°11 Assembly overview- silencers’, page 374

4-cylinder diesel engine (2.0 | engine, common rail) . Edition 04.2013

V.A.G 1331

and rear si-

376 ep. o126-- Exhaust systom

Amarok 2011 >

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

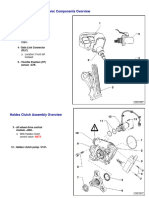

2 Cleansing exhaust emissions

='2.1 Assembly overview - emission control (diesel particulate

filter) page 3:

="2.2 Assembly overview - emission control (catalytic convert

ery page 379

2 in ulate fi a

= "2.4 Removing and installing catalytic converter’, page 387

24 Assembly overview - emission control (diesel particulate filter)

41 - Screw+type clip

Always renewratter re-

moving

Fit screwi-type clip by

hand,

2 When installing, first fit

sctewetype clip on tur-

bbecharger for exhaust

pipe.

2 8Nm

2- Gabket

Renew after removing

Electronic parts cata-

logue (ETKA) must not

Get into the siots on the

probe body.

50Nm|

4-- Control line witK-union nut

Q 20Nm

5 - Exhaust gas temperature

sender 3 - G495-

Grease thread of sender

using high-temperature

aste > Electronic,

arts Catalogue (ET-

KA)

Connector (brown) at

coupling point of air filter

a 45Nm

6 - Exhaust gas temperature sender 4 - G648-

2 Grease thread of sender using high-temperature paste = Electronic Parts Catalogue (ETKA)

Connector (orange) at coupling point of air fiter

2 45Nm

ing exhaust emissions 377

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

7 - Bracket with control lines

8-Clip

9 Control pipe

10 - Union nut

Q 20Nm

11 - Exhaust gas pressure sensor 1 - G450-

Adaptation is necessary after this component has been renewed = Vehicle diagnostic tester.

Removing and installing > page 360

12- Bolt

a 5Nm

13 - Front exhaust pipe

Take into account the fact that there are different types = ETKA (electronic parts catalogue)

O Handle carefully to avoid damage.

+ Transport shock-fres.

+ Do not kink flexible hose,

+ Do not stretch flexible hose.

Q Removing and installing = page 384

14- Particulate fiter

+ Assembly sequence must be adhered to during installation to ensure stress-free installation,

Position particulate fiter with new gasket = Item 2 (page 377) and new screw-type clip

= Item 1 (page 377) .

Tighten serew+type clip > Item 1 (page 377;

Removing and installing = page 381

15 - Bracket

Secured to gearbox on right

O Attaching bracket to gearbox" bage 380

16 - Bolt

Q 20Nm

17 - Bracket

O Fastenedto engine support on right

O Metal type a

Fasten to bracket on engine support = page 380

18-Bott ©

O 20Nm

19 - Mounting 5

378 6p. o126- Exhaust systom

Amarok 2011 >

Accylinde didsél @ngine (2.0 | engine, common rail) - Edition 04.2013

22 Assembly overview - emission control (Catalytic converter)

(B) Note

¢ After working on the exhaust system, ensure that the system is not under stress and that there is sufficient

clearance to the bodywork. Loosen double clamp and cljo if necessary. Align silencer and exhaust pipe so

that sufficient clearance is maintained to the bodywork and the support rings-are evenly loaded.

¢ Renaiv selt-focking nuts,

1- Scremtype clip

Always renew after re-

moving

2 Fit screw-type clip by

hand

2 When installing, frst

fasten the screw-type

clip for the exhaust pipe

on turbocharger

2 8Nm

2- Gasket

Renew after fémoving

Note installation posi.

tion

3 Front exhaust pipe with cat-

alytic converter

Take into account the

fact that there are differ-

enttypes = ETKA (elec

tronic parts catalogue)

Handle carefully to

avoid damage.

When installing, first

fasten the top screw

type clip for the exhaust,

pipe on turbocharger

+ Transport shock-free.

+ Do not kink flexible hose.

+ Donat stretch flexible hose.

Removing and installing

= page 387

4- Bolt

a 20Nm

5 - Bracket

2 Secured to gearbox on right

Attaching bracket to gearbox = page 380

6- Bolt

a 20Nm

7 - Bracket

2 Fastened to engine support on right

Metal type

Attaching bracket to engine support = page 360

ing exhaust emissions 379

@ Amarok 2011 >

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

8 - Bolt

Q 20Nm

9- Bolt

20Nm

Fasten to bracket on gearbox

= Secure bracket -2- to gearbox -1- with bolts -3-

Fasten bracket to engine support

— Secure bracket -2- to engine support -1- with bolts -3..

380 6p. 07.26 Exhaust systom

A-cylindendliedel &iigitié!(20:1engine, common rail) - Edition 04.2013

23 Removing and installing particulate filter

Special tools and workshop

equipment required

.

.

V.A.G 1331

Torque wrench (6...50 Nm)

-VAG 13345

Torque wrefich (40...200

Nm) - V.AG 1332

Hose clip pliers - VAS

636.

VAS 6362

Amarok 2011 >

V.A.G 1332

eS

2. Cleansing exhaust emissions 381

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Removing

ZX warns

Risk of burns.

Parts of the exhaust system may be hot.

Allow exhaust system to coo! before removing.

When doing any repair work, especially in the engine compart-

‘ment, pay attention to the following due to the cramped condi-

tions.

* Route all the various lines (e.g. for fuel, hydraulics, acti-

vated charcoal fiter system, coolant and refrigerant, brake

fluid and vacuum) and electrical wiring in their original po-

sitions.

@ Toavoid damage to lines, ensure sufficient clearance from

all moving or hot components.

'* Cut through cable ties carefully and install new ones in the

same position.

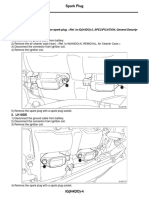

- Detach vacuum hose -2- from upper toothed belt guard -1-.

= Open clips -arrows- and remove toothed belt guard -1-.

= Remove pipe -arrow- from cylinder head cover.

382 pep. o126- Exhaust sysiom

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Detach hoses from intake hose -3- bracket -arrov.

Release and pull off wiring hamess connector -2-. Detach wir-

ing harness -2- from intake hose -2..

Open clips -1- and -4- and remove intake hose -3- together

with pipe -5-

Remove air flter = pave 368 .

Disconnect connectors -1, 2 and 3- for exhaust gas tempera-

ture sender 1 - G235- (black connector), exhaust gas temper-

ature sender 3 - G495- (brown connector) and exhaust gas

temperature sender 4 - G648- (orange connector) at coupling

point (in front of air fier)

Loosen cable ties -3-, free lines -1 and 2- from fittings, and lay

them to one side.

Clamp off coolant hose -2- with hose clamps up to 25 mm =

3094.

Open spring-type clip -1- for coolant hose -2- and pull coolant

hose off.

2. Cleansing exhaust emissions. 383,

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

= Open spring-type clips -1- and pull hoses -2 and 3- off contol

lines for particulate filter.

— Undo and remove bolt -2- for coolant pipe -1- at wheel housing

and tie on coolant hose somewhere at a slightly higher point.

(F) noe

Do not bend coolant pipe.

Undo screw -1- of screwstype clamp -2- between particulate

filter and turbocharger and remove clamp -2..

= Undo and remove bolts -3- for particulate filter bracket ~4.

— Undo screw -1- of clamp -2-

~ Undo and remove fits -3- for exhaust pipe bracket -4-.

384 pep. o126- Exhaust sysiom

eazy @

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

- When removing particulate fiter, push -1- the coolant pipe

-2-allittle to one side,

= Carefully remove particulate filter -1- upwards out of the en-

gine compartment,

Installing

Installation is carried out in the reverse order: note the following:

LX cauion

Ensure particulate fier is not stressed when installed.

The particulate fiter could be damaged.

Follow installation sequence.

Use new clips and gaskets.

+ Assembly sequence for installation of particulate filter must be

adhered to during installation to ensure stress-free installation

2. Cleansing exhaust emissions. 385,

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

4 When installing particulate filter, push -1- the coolant pipe -2-

alittle to one side,

Install particulate fiter -1- carefully.

# Screw ih bolts -3- for particulate filter bracket -4- a few tums

# Position particulate fiter with new gasket

= Item 2(page 377) and new screw-type clip

= Item 14page 377)

Fit exhaust pipe bracket -4- and tighten bolts -3- hand-tight . } c

Fit clamp -22and tighten screw -1- slightly. -

Tighten serew’- for serewstype elip = Item 1 (page 377) -2-

Tighten bolts = itémn 18 (page 378) -3-.

Tighten bolts = Itern 48 (page 378) -3.. a

Tighten screw -1- for clamp2-,

bem J

OS Reas

(Temes

eee eee

= Fasten lines -1 and 2- with new cable ties

386 6p. 01 26- Exhaust systom

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

- Connect connectors -1, 2 and 3- for exhaust gas temperature

sender { - G235- (black connector), exhaust gas temperature

sender 3 - G496- (brown connector) and exhaust gas temper-

ature sender 4 - G648- (orange connector) at coupling point

(in front of air fiter), and make sure they engage securely.

= Install air iter = pace 368

fa Note

‘if new particulate fiter was installed, connect = Vehicle dlag- .

nostic tester and carry out ‘Ash mass comparison’ [eae

Specified torques

2°2,1 Assembly overview emission cont {uibsetartiou,

inte fiter)” page 377

@ 2°71 Assembly overviews air filter”, page 368

24 Removing and installing catalytic con-

verter

Special tools andworkshop equipment required

Torque wrench (6...50 Nm) - V.A.G 1331-

V.A.G 1331

‘¢ Lambda probe open ring spanner set - 3337-

a

2. Cleansing exhaust emissions 387

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Removing

— Remove pipe -arrow- from cylinder head cover.

~ Detach hoses from intake hose -3- bracket -arrows.

Release and pull off wiring harness connector -2-. Detach wir-

ing hamess -2- fromintake hose retainer -3

(Open clips -1- and-4- and remove intake hose -3- together

with pipe 5.

Remove air fter:= page 368

Pull vacuum hose -2- off vacuum unit of exhaust gas recircu-

lation cooler and vacuum hose -1- off regulating flap potenti-

ometer - G584-

= Loosen serew-2- for clamp “4- between exhaust pipe -4-

turbocharger on

cy

A

3 SS

Pires sf sal

~ Loosen clamp -&-on exhaust pipe ~1- and pul exhaust pipe NA we

388 Rep o-26-Exraust system

cylinder diesel engine (2.0 | engine,

Undo and remove bolts -3- holding exhaust pipe -2- on gear-

box bracket -1-.

Release and detach connector -1- of exhaust gas temperature

sender 1 - G235- on front right wheel housing -3- at the cou-

pling point -2.. Then, free wring harass from fitings and lay

tHtoone side

Carefully remove front exhaust pipe upwards out of the engine,

compartment.

Installing

Installation is carried out in the reverse order; note the following:

Use néw clips and gaskets.

Install front exhaust pipe and first fasten the top screw-type

clamp for the exhaust pipe on turbocharger

‘Secure front exhaust pipe with all brackets, and fit screw-type

clip = Item 1 (page 374) at bottom.

Install air filter > pace 368

Specified torques,

.

+

=22.2 Assembly overview - emission control (catalytic con-

Fegan at gremew- emission contol featalitic con:

ge

common rail) - Edition 04.2013

ing exhaust emissions. 38Q

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

3 Exhaust gas recirculation

23.1 Assembly overview - exhaust gas recirculation’,

age 300

2'3.2 Assembly overview - exhaust gas recirculation, 132 kW.

engine’, page 394

2 Install tion

page 392

23.4 Removing and installing exhaust gas recirculation cooler,

132 kW engine’, page 398

=."3.6 Removing and installing exhaust gas recirculation valve

N78, 132 kW engine’, page 400

2"3.6 Removing end installing changeover valve for exhaust gee

Tecirculation cooler N345 ", page 401

402

3.41 Assembly overview= exhaust gas recirculation

1 - Exhaust gas recirculation

valve - N18- with exhaust gas

recirculation potentiometer -

6212.

2 - Vacuum unit for exhaust

flap

3 - Exhaust gas recirculation

cooler

Removing and installing

> page 362

4-- Connection

Coolant hose schematic

diagram = page 175

5 - Bolt

(E) re

For better accessibility

sure the correct torque!

of the exhaust gas reci

cooler on the turbochar

hexagon bolts with par

107 188 Ot« can be usd

First, ft bolts on turbo-

charger side and screw

them in hand-tight.

Q 8Nm

6 - Gasket

Renew after removing

7 - Bolt

20Nm

8 - Lower pipe

9 - Gasket

Renew after removing

390 kop. or 26 - Exhaust systom

eazy @

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

10- Bolt vores s.

@ 20Nm

11- Bolt

a 8Nm

12 - Upper pipe .

13 - Gasket ‘

Renew after removing

14- Bolt

2 Renew after removing g

a 8Nm 5

3.2 Assembly overview - exhaust gas recirculation, 132 kW engine

1 - Exhaust gas recirculation

cooler

Removing and installing

= page 368

2.- Bracket

2 Forexhaust gas recireu-

lation cooler.

3- Bolt

2 Renew after removing

a 8Nm

4 Gasket

5- Connecting pipe

To exhaust gas recircu-

lation valve - N18-

6 - Exhaust gas recirculation

valve - N18-

1 Removing end instaling

5 page 400

7 - Connecting pipe

From exhaust gas recir-

culation cooler

8- Bolt

a 20Nm

8. Exhaust gas recrcuiation 391

3.3

Amarok 2011 >

Special tools and workshop

equipment required

’

+

Torque wrench (5...50 Nm)

-VAG 1331-

Torque wrench (49...200

Nm) - V.AG 1332

Torque wrench - V.AG

131.

Drip tray for workshop hoist

- VAS 6208-

Hose clip pliers - VAS

6340-

Hose clip pliers - VAS

83:

V.A.G 1331

Ss

V.A.G 1410

‘Special tools and workshop equipment required

+ Hose clamps up to 25 mm - 3084-

*

.

Small hand-held mirror

Flexible magnet

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Removing and installing exhaust gas recirculation cooler

V.A.G 1332

NAS 6208

392 kop. or 26- Exhaust systom

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

Removing

(8) note

¢ Exhaust gas recirculation cooler is removed upwards. Conta-

minated areas must be cleaned thoroughly after installing.

© To facilitate removal of the exhaust gas recirculation cooler,

remove the air fiter housing and the exhaust pipe.

© For better accessibility and to ensure the correct torque for the

bolts of the exhaust gas recirculation cooler, hexagon bolts

with part number »N 107 188 Of« can be used.

@ Some connectors are diffcult to see. A small hand-held mirror

(8 required to unscrew and insert the threaded connection.

© Note different bolt lengths for pipes.

¢ Renew gaskets and seals.

— Detach vacuum hose -2- from upper toothed belt guard -1-.

= Open clips -arrows- and remove toothed belt guard -1-.

~ Remove pipe -arrow-,f'om cylinder head cover.

Amarok 2011 >

8. Exhaust as recrcuiton 393

Amarok 2011 >

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

= Detach hoses from intake hose -3- bracket -arrow

Release and pul off wiring harness connector -2-. Detach wir-

ing harness -2- from intake hose retainer -3-.

Open clips -1- and -4- and remove intake hose -3- together

with pipe -5-

Remove air fter > page 368

= Pull vacutiin hose off vacuum unit of exhaust gas recirculation

Coolee-1-and vacuum hose rom regulating lap potentiometer,

- GB84- -2-. ‘

Detach connectors -1- from exhaust gas recirculation valve -

N18--2- and regulating flap for potentiometer - G584- -3.,

Vehicles with particulate filter

me a

= Undo and remove bolt-2- for coolant pipe -1- at wheel housing

and tie on coolant hose somewhere at a slightly higher point.

- Remove particulate fitter = page 381

Vehicles with engines compliant with EU 4 and EU 3 standards

394 Rep o:26- Exraust system

0 —— eS ag Amarok 2011 > @

! 4-oylinder dieséFengine (2.0 engine. common rail) - Edition 04.2013

= Loosen bolt -2- in screwstype clip -1- for front exhatist pipe

<4. at turbocharger. :

= Unserew and remove bolts -3-in bracket for front exhaust Bip

4 :

— Loosen screw-type clip -3- for front exhaust pipe -1-.

. ary

= Undo and remove bolts -3-for front exhaust pipe -2-at bracket

a

— Release and detach connector-1- of exhaust gas temperature

sender 1 - G235- on front right wheel housing -3- at the cou-

pling point -2-. Then, free wiring hamess from fitings and lay

itto one side.

Carefully remove front exhaust pipe upwards out of the engine

‘compartment.

Continuation for all vehicles

8. Exhaust as recrcuiton 395

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

~ Clamp off coolant hose

3094.

= Loosen spring-type clip -3- and remove coolant hose -2- at

‘exhaust gas recirculation cooler -1..

with hose clamps up to 25 mm =

— Undo and remove bolts -2- for pipe -1- and remove pipe from

‘exhaust gas recirculation cooler.

(F me

The bolts -3- for the pipe -4- are not undone.

= Clamp off coolant hose -2- with hose clamps up to 25 mm -

3094.

= Open spring-type clip -1- for coolant hose ~

hose off.

‘and pull coolant

— Undo‘and remove bolts -2- and -3- for pipe -1- and remove

pipe,

(Byte

Bear in mind the differences between the types of bolt!

Ne Win

396 kop. o126- Exhaust systom

Amarok 2011 >

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

= Unclip connector -2- on oil pressure switch - F1-

— Undo and remove bolts -2- at exhaust gas recirculation cooler

on

— Undo and remove bolts -2- at exhaust gas recirculation cooler

ae

= Carefully remove exhaust gas recirculation cooler upwards.

= Clean contaminated areas thoroughly.

Installing

Installation is carried outit the reverse Srtfer:incte the following:

Renew gaskets and seals.

(Fi) v0

For better accessibility and to ensure the correct torque for the

bolts -2- of the exhaust gas recirculation cooler on the turbo-

gharge side, hexagon bots with part number N 107 188 01 can

use

= Replace both bolts -2- at exhaust gas recirculation cooler on

Tight with hexagon bolts (part number »N 107 188 O1«), and

tighten hexagon bolts.

(F) re

& Note different bott lengths for pipes,

¢ Only screw pipe bolts in loosely at first, then tighten.

a

8. Exhaust as recrcuiton 37

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

= Replace screw-type clamp -1- for front exhaust pipe -4-.

— Replenish coolant > page 182

Specified torques

# 23.1 Assembly overview - exhaust gas recirculation

page 390

# > °2.1 Assembly overview - emission control (diesel particu

inte filler’, page 377

* fateh pees °

eden page 7s oven emission contol estate con: SG

ieren) page es

3.4. Removing and installing exhaust gas re-

circulation cooler, 132 kW engine

‘Special tools and workshop equipment required ix

4 Hose clamps up to 25 mm - 3094. =

+ Drip tray for werkhop ho -VAS 6208.

4 Hose clip pliers - VAS 6362-

398 Rep o:26-Exraust system

eazy @

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

[F) Note

The exhaust gas recirculation cooler is removed upwards.

Contaminated areas must be cleaned thoroughly after instal

Jing.

¢ Renew gaskets and seals.

Removing

= Clamp off coolant hose -2. leading to input to exhaust gas re-

circulation cooler -1- with hose clams up to 25 mm - 3094-

— Loosen clamp -3- and pull coolant hose -2- off exhaust gas

recirculation cooler -1-.

= Clamp off coolant hose -1- coming from output of exhaust gas

recirculation cooler -3- with hose clams up to 25 mm - 3094-

= Loosen clamp -2- and pull coolant hose -1- off output of ex-

hhaust gas recirculation cooler -3-.

% Undo and remove bolts -1 and 4- and remove connecting pipe.

a

= Unscrew bolts -3-

8. Exhaust as recrcuiaion 399

Amarok 2011 >

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

~ Unscrew bolts -arrows- and remove bracket -1- of exhaustgas>

recirculation cooler. os"

= Carefully remove exhaust gas recirculation edéler upwards

Installing 4

Installation is carried outin the reverselérder; note the fellowing:

(@) note 7

First, screw in all pipe bolts loosely and then tighten them to

specified torque.

Specified torques 5

@ 23.2 Assembly overview - exhaust gas recirculation, 132 KW

‘engine’, page 391 3

35 Removing and installing exhaust gas re-

circulation valve - N18-, 132 KW engine

Removing *

= Loosen clip -2-and pull pressure Hose off throttle valve control

module - J338-

— Remove bolt -1- for dipstick guide tubé,

= Detach connector -3- from throttle valve céntrol module ~

J338-

Undo and remove bolts -2 and 3- and remove pressure pipe

a.

400 Rep. o:26- Exraust system

eazy @

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

=~ Release oil dipstick again. To this, force expanding clip -2- off,

using removal lever - 80 - 200- .

= Remove throttle valve module - J338- > page 357

— Undo and remove bolts -1 and 3- from connecting pipe -2-.

— Remove connecting pipe -2..

= Undo and remove bolts -arrows- and remove exhaust gas re-

ulation vaive - N18- -1- from intake manifold:

Installing

Installation is carried out in the reverse order; note the following!

Specified torques

@ 23.2 Assembly overview exhadst gas recirculation, 132 KW

engine’, page 391

oo 1y overview P

3.6 Removing and installing changeover 3

valve for exhaust gas recirculation cool- ;

er-N345-

Special tools and workshop equipment required

8. Exhaust gas recrcuiation 401

4-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

# Torque wrench - V.AG 1410-

# Socket set 1/4", 22-piece - VAS §526-

Removing,

= Pull connector -3- and vacuum lines and oull off changeover

valve for exhaust gas recirculation cooler - N345- -1-.

7 Unetp locking lug for changeover valve for exhaust gas recir-

culation cooler - N345- -1- and remove changeover valve for

‘exhaust gas recirculation cooler - N345-

Installing

Installation is carried out in the reverse order; note the following:

A Caution

Do not kink, twist or crush the vacuum lines when routing. This

may cause breakdowns.

‘Connect all hoses to stop or at least 10 mm on the relevant

‘connection piece.

‘cooler for leaks

+ Exhaust gas rédireulation cooler is.

3.7 Checking exhaust i oe

ved pele 308

VAG 1410

eg

VAS 5528

402 Rep o:26- Exraust system

cose @

A-cylinder diesel engine (2.0 | engine, common rail) - Edition 04.2013

= The cooler connection which wil be immersed in the water

must be sealed watertight.

Using a clamp, secure a hose to the cooler connection at which

compressed air is supplied

‘The exhaust gas recirculation coolers ow ready to be immersed

in the water.

(F re

© Supply compressed air at conection where coolant is sup-

plied.

¢ The cooler should remain immersed in the water for at least

30 minutes in order to obtain a significant result.

¢ Using a commercially available immersion heater, heat water

fo approx. 60-80 °C.

© Perform the pressure test with the cooler in vertical position.

¢ The pressure must not exceed 3 bar.

Immerse cooler in water as shown in illustration, Hose

-arrow- must protrude from water in order to perform pressure

test.

8. Exhaust as recrcuiton 403

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GM Tech2 PathsDocument154 pagesGM Tech2 PathsHaji RashidNo ratings yet

- 2.0l Ecoboost I4 Escape Spec SheetDocument2 pages2.0l Ecoboost I4 Escape Spec SheetHaji RashidNo ratings yet

- Can Bus Explained 2021Document22 pagesCan Bus Explained 2021Haji RashidNo ratings yet

- 4 Drivers Airbag ModuleDocument2 pages4 Drivers Airbag ModuleHaji RashidNo ratings yet

- Cars With SRS Table of Contents 1:2, 2:2 Abbreviation How To Use The Wiring Diagram 1:2, 2:2 Electrical Distribution FusesDocument265 pagesCars With SRS Table of Contents 1:2, 2:2 Abbreviation How To Use The Wiring Diagram 1:2, 2:2 Electrical Distribution FusesHaji RashidNo ratings yet

- Shift Point Road TestDocument3 pagesShift Point Road TestHaji RashidNo ratings yet

- Wzs bcr142Document8 pagesWzs bcr142Haji RashidNo ratings yet

- 3 Inspection Locations After A CollisionDocument9 pages3 Inspection Locations After A CollisionHaji RashidNo ratings yet

- Transmission TSBDocument3 pagesTransmission TSBHaji Rashid100% (1)

- 2 Spark PlugDocument5 pages2 Spark PlugHaji RashidNo ratings yet

- TouaregDocument18 pagesTouaregHaji RashidNo ratings yet

- 4 Cylinder Diesel Engine 2.0L Common Rail - VW Amarok 10-16 - PDF DownloadDocument419 pages4 Cylinder Diesel Engine 2.0L Common Rail - VW Amarok 10-16 - PDF DownloadHaji RashidNo ratings yet

- 17238-Touareg 01 07 08Document5 pages17238-Touareg 01 07 08Haji Rashid0% (1)

- Tou 50-01Document11 pagesTou 50-01Haji RashidNo ratings yet

- BMW NBTevo CarPlayDocument1 pageBMW NBTevo CarPlayHaji RashidNo ratings yet

- Radio RCD 300: Wiring DiagramDocument6 pagesRadio RCD 300: Wiring DiagramHaji RashidNo ratings yet

- Untitled Spreadsheet - Module ListDocument2 pagesUntitled Spreadsheet - Module ListHaji RashidNo ratings yet

- VW 5n CL AllWheelDriveDocument1 pageVW 5n CL AllWheelDriveHaji RashidNo ratings yet

- Compass: Wiring DiagramDocument2 pagesCompass: Wiring DiagramHaji RashidNo ratings yet

- 05 E65-66 Model UpdateDocument46 pages05 E65-66 Model UpdateHaji RashidNo ratings yet

- 04wj Post Cat O2Document1 page04wj Post Cat O2Haji RashidNo ratings yet

- All ToyotaDocument192 pagesAll ToyotaHaji RashidNo ratings yet

- ZF 5HP30 Transmission Repair ManualDocument104 pagesZF 5HP30 Transmission Repair ManualHaji RashidNo ratings yet

- Data Link ConnectorDocument35 pagesData Link ConnectorHaji RashidNo ratings yet

- SSP 074 1,2 CBZB 77kW TSI Petrol Engine With TurbochargerDocument44 pagesSSP 074 1,2 CBZB 77kW TSI Petrol Engine With TurbochargerHaji RashidNo ratings yet

- Toyota L 2l 2l T Engine Workshop Service Repair ManualDocument228 pagesToyota L 2l 2l T Engine Workshop Service Repair ManualHaji Rashid100% (1)