Professional Documents

Culture Documents

Procedure For Restoring To Service An Engine That Has Been in Extended Storage

Procedure For Restoring To Service An Engine That Has Been in Extended Storage

Uploaded by

Miguel Cardenas0 ratings0% found this document useful (0 votes)

5 views2 pagesOriginal Title

Procedure for Restoring to Service an Engine that Has Been in Extended Storage

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesProcedure For Restoring To Service An Engine That Has Been in Extended Storage

Procedure For Restoring To Service An Engine That Has Been in Extended Storage

Uploaded by

Miguel CardenasCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

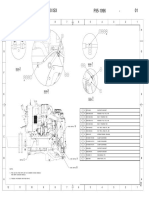

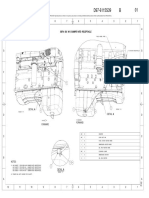

EPAO7/10/GHG14 DD Platform General Information / Preventive Maintenance Workshop Manual

Procedure for Restoring to Service an Engine that Has Been in Extended Storage

If an engine has been in extended storage, prepare it for service as follows:

1. Remove the covers and tape from all the openings of the engine, fuel tank and electrical equipment. Do not

overlook the exhaust outlet.

2. Remove the plugs from the inlet and outlet fuel lines and reconnect the lines to their proper positions.

3. Wash the exterior of the engine with fuel oil to remove the rust preventive. Do not wash electrical

components.

4, Remove the rust preventive from the flywheel. Flush any soluble oil rust inhibitor (if used) in the cooling

system.

5. Remove the paper strips from between the pulleys and drive belts.

6. Fill the crankcase to the proper level with the required grade of lubricating oil. Use a pressure lubricator to

insure all bearings and rocker shafts are lubricated

7. Fill the fuel tank with the required fuel

8 Close all drain cocks and fll the engine cooling system with clean, soft water and required inhibitors. If the

engine is to be exposed to freezing temperatures, install genuine Detroit Power Cool antifreeze or an

equivalent ethylene glyco/-base or propylene glycol-base antifreeze solution which provides required freeze,

boil over, and inhibitor protection. Coolant Selections and Maintenance

9. Install and connect the battery, Make sure the average specific gravity of the battery is 1.260 or higher.

Charge the battery, if necessary,

10. Service the air cleaner, if required.

11. “Transmission: Follow the manufacturer's recommendations covering the return of the transmission to

service,

12. Power Take-Off: If equipped, follow the manufacturer's recommendations covering the return of the power

take-off to service.

13. Turbocharger: Remove the covers from the turbocharger air inlet and turbine outlet connections.

Reconnect piping as required. Pre-lube the turbocharger center bearing housing. Lubrication System Checks

1

14, Fill the cooling system. Cooling System Fill Procedure

© Wamin:

To avoid injury from inhaling engine exhaust, always operate the engine in a well-

ventilated area. Engine exhaust is toxic.

15. After all preparations are completed, start the engine.

s@ Note: The small amount of rust preventive which remains in the fuel system will

cause smoky exhaust for a few minutes,

st Note: Before subjecting the engine to a load or high speed, allow it to reach

normal operating temperature.

16. Check for trouble codes.

a. Ifthere are no codes, perform a parked regeneration

b. Ifthere are codes, repair what is necessary then perform a parked regeneration.

note

Fecha de punsesn2023.0604

Comentar ovjruncomentario

22.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Parts Catalog of XML6112J14 Euro 4 (Peru)Document176 pagesParts Catalog of XML6112J14 Euro 4 (Peru)Miguel CardenasNo ratings yet

- Monitoring The Lubricating OilDocument2 pagesMonitoring The Lubricating OilMiguel CardenasNo ratings yet

- Preventive Maintenance IntervalsDocument6 pagesPreventive Maintenance IntervalsMiguel CardenasNo ratings yet

- Engine Model and Serial Number Designation DD13-DD15Document7 pagesEngine Model and Serial Number Designation DD13-DD15Miguel CardenasNo ratings yet

- Temporary Storage (30 Days or Less)Document1 pageTemporary Storage (30 Days or Less)Miguel CardenasNo ratings yet

- EPA07-EPA10-GHG14-GHG17 Preventive Maintenance Tables - 93K218 (CJ-4)Document2 pagesEPA07-EPA10-GHG14-GHG17 Preventive Maintenance Tables - 93K218 (CJ-4)Miguel CardenasNo ratings yet

- Fluids and Lubrication RequirementsDocument2 pagesFluids and Lubrication RequirementsMiguel CardenasNo ratings yet

- Multiplex Steering Wheel R414-1257 01: View ADocument1 pageMultiplex Steering Wheel R414-1257 01: View AMiguel CardenasNo ratings yet

- Desarrollo de Producto - Amortiguadores Linea AmericanaDocument13 pagesDesarrollo de Producto - Amortiguadores Linea AmericanaMiguel CardenasNo ratings yet

- Engine Oil Capacities DD13-DD15-DD16Document1 pageEngine Oil Capacities DD13-DD15-DD16Miguel CardenasNo ratings yet

- Routing - HVAC 2007 T660 ISX F95-1096 - 01: DWG SizeDocument3 pagesRouting - HVAC 2007 T660 ISX F95-1096 - 01: DWG SizeMiguel CardenasNo ratings yet

- D97 6115S39Document4 pagesD97 6115S39Miguel CardenasNo ratings yet

- Daimler Trucks North AmericaDocument2 pagesDaimler Trucks North AmericaMiguel CardenasNo ratings yet

- Data de Embragues Mercedes BenzDocument2 pagesData de Embragues Mercedes BenzMiguel CardenasNo ratings yet

- Part Number Definition: R97-1455-A B CC: TolerancesDocument4 pagesPart Number Definition: R97-1455-A B CC: TolerancesMiguel CardenasNo ratings yet

- ProStar ES Sales Deck For MRCDocument22 pagesProStar ES Sales Deck For MRCMiguel CardenasNo ratings yet

- Camiseta de O500Document5 pagesCamiseta de O500Miguel CardenasNo ratings yet