Professional Documents

Culture Documents

FGM 160

Uploaded by

k OOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FGM 160

Uploaded by

k OCopyright:

Available Formats

Document number: 62.120.

001

Document title: FGM 160 Installation and Hook-Up

Instructions

Scope: ISO 9001:2008 §7.2.3

Additional Information (when applicable)

F 2016.03.01 Draining plug note added AH MW - MB MW

E 2014.07.14 Updated installation guidelines AP MS KP MB KP

D 2013.11.29 Proofread and updated AP MR CT MB MW

Removed from User Manual, updated:

C 2013.02.14 MKJ KH - MW MW

changes in content.

B 2009.05.29 Updated information MS DIÅ RT N/A AAJ

Issued for Fluenta release; moved to User

A 2007.11.26 MS DIÅ TM N/A AAJ

Manual

Rev. Review

Issue date Reason for issue Author Review Review Approved

index by QA

Replacement for:

Total pages:

Fluenta source doc. 40

(for translations):

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

TABLE OF CONTENTS

1. Purpose ............................................................................................................................................. 4

2. Abbreviations / Definitions .............................................................................................................. 4

2.1 Abbreviations .............................................................................................................................. 4

2.2 Definitions ................................................................................................................................... 4

3. General .............................................................................................................................................. 5

4. Unpacking ......................................................................................................................................... 5

4.1 Inspection of Goods .................................................................................................................... 5

4.2 Ex-Classification Marking ........................................................................................................... 5

4.3 Equipment Information................................................................................................................ 6

4.4 Manufacturer Information ............................................................................................................ 6

5. Transducer/Probe Installation ......................................................................................................... 6

5.1 Installation of Transducer Holders .............................................................................................. 6

5.1.1 Space Requirements ....................................................................................................... 6

5.1.1.1 Space requirements for the Transducer Full Size, TFS ................................. 7

5.1.1.2 Space requirements for the Temperature and Pressure Transmitters ........... 7

5.2 Mounting the Transducer Holders .............................................................................................. 9

5.2.1 Orientation ....................................................................................................................... 9

5.2.1.1 Horizontal Flare Pipe ...................................................................................... 9

5.2.1.2 Vertical Flare Pipe ........................................................................................ 10

5.2.2 Cold Tapping ................................................................................................................. 11

5.2.3 Using the Sighting Tool ................................................................................................. 15

5.2.4 Hot Tapping Transducers Full Size, TFS ...................................................................... 16

5.3 Mounting the Ultrasonic Transducers ....................................................................................... 17

5.3.1 Determining the Correct Position for the Transducers .................................................. 17

5.3.2 Edge Flush Transducer Mounting ................................................................................. 18

5.3.2.1 Setting the correct insertion depth ................................................................ 18

5.3.2.2 45° installations ............................................................................................ 19

5.3.2.3 48°/42° installations ...................................................................................... 20

5.3.3 Insertion of the Transducer Full Size (TFS) .................................................................. 21

6. Field Computer Installation ........................................................................................................... 21

6.1 The Field Computer Mounting Frame ....................................................................................... 22

6.2 Electrical Wiring ........................................................................................................................ 22

6.2.1 Cable Preparations ........................................................................................................ 23

6.2.2 Power Cable .................................................................................................................. 24

6.2.3 Ultrasonic Transducer Cables ....................................................................................... 24

6.2.4 Connecting the Pressure and Temperature Transmitters ............................................. 27

6.2.5 Control Room and Data Cables ..................................................................................... 29

6.2.5.1 DCS Port, Modbus ........................................................................................ 29

6.2.5.2 Foundation Fieldbus Output ......................................................................... 29

6.2.5.3 Service Port .................................................................................................. 30

6.2.5.4 Current Loop Outputs (4-20mA) ................................................................... 30

6.2.5.5 HART Output ................................................................................................ 35

6.2.5.6 Pulse/Frequency/Level Output ..................................................................... 36

6.3 Upgrading from the FGM 130 ................................................................................................... 38

7. References ...................................................................................................................................... 39

8. Appendix I - Space requirements for the TFS ............................................................................. 40

TABLE OF FIGURES

Figure 1: Fluenta’s minimum straight up- and downstream distances to disturbances. ......................... 7

62.120.001 Page 2 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 2: Distance requirements for the pressure and temperature transmitters. .................................. 8

Figure 3: The preferred and non-preferred orientation for horizontal pipe installation. ........................... 9

Figure 4: Vertical flare boom with the transducer holders and transducers installed. ........................... 10

Figure 5: Cold tapping – placement of spot marks. ............................................................................... 11

Figure 6: Cold tapping – centerlines. ..................................................................................................... 11

Figure 7: Cold tapping – contour marker. .............................................................................................. 11

Figure 8: Marking a line around the pipe using a marking band. .......................................................... 12

Figure 9: Machined hole. ....................................................................................................................... 13

Figure 10: Machined holder. .................................................................................................................. 13

Figure 11: As you raise the transducer holder, you must also move it backwards to keep the centering

correct. ................................................................................................................................................... 13

Figure 12: Welding jig and transducer holder........................................................................................ 14

Figure 13: Transducer holder welded to the pipe. ................................................................................. 14

Figure 14: The sighting tool for the 42°/48° transducer holders ............................................................ 15

Figure 15: The sighting tool for 45° transducer holders. ....................................................................... 15

Figure 16: The stop washer for the sighting tool for the 42°/48° transducer holders. ........................... 15

Figure 17: A 45° sighting tool mounted in a transducer holder. ............................................................ 15

Figure 18: A 42°/48° sighting tool with stop washer mounted in a transducer holder. .......................... 15

Figure 19: Look through the holes on the sighting tool. Rotate the sighting tool on the left to get a

correct alignment. .................................................................................................................................. 16

Figure 20: A good alignment. ................................................................................................................ 16

Figure 21: A bad alignment. .................................................................................................................. 16

Figure 22: The gas-proof measuring tool. ............................................................................................. 17

Figure 23: A schematic of the gas-proof measuring tool. ...................................................................... 18

Figure 24: Insertion depth. ..................................................................................................................... 18

Figure 25: Retracted tranducers distance. ............................................................................................ 19

Figure 26: Edge-flush position for a 45° transducer holder. .................................................................. 19

Figure 27: Edge-flush position for a 42° transducer holder. .................................................................. 20

Figure 28: Edge-flush position for a 48° transducer holder. .................................................................. 20

Figure 29: Mounting the Transducer Full Size. ..................................................................................... 21

Figure 30: The FGM 160 Field Computer mounting frame versions. .................................................... 22

Figure 31: Ex-e enclosure terminals overview. ..................................................................................... 23

Figure 32: Power to the FGM 160. ........................................................................................................ 24

Figure 33: Connecting the Ultrasonic Transducers to the FGM 160. .................................................... 25

Figure 34: Connection details for ultrasonic transducers. ..................................................................... 26

Figure 35: Pressure and temperature transmitter hook-up. .................................................................. 27

Figure 36: FGM 160 – 4-20 mA pressure and temperature transmitter connections. ........................... 28

Figure 37: Pressure and Temperature HART transmitter connection. .................................................. 28

Figure 38: Data and Signal Cables. ...................................................................................................... 29

Figure 39: Foundation Fieldbus Connection ......................................................................................... 30

Figure 40: Active output current loop(s), wiring ..................................................................................... 31

Figure 41: Passive output current loop(s), wiring .................................................................................. 32

Figure 42: Current loop outputs, details ................................................................................................ 33

Figure 43: Current loop outputs, Load/Voltage limitations .................................................................... 34

Figure 44: Current loop active output, High side load and Low side load ............................................. 34

Figure 45: Current loop passive output, High side load and Low side load .......................................... 34

Figure 46: Multiple current loop outputs, Active output configuration ................................................... 35

Figure 47: Multiple current loop outputs, Passive output configuration ................................................ 35

Figure 48: FGM 160 Pulse/frequency output connections .................................................................... 37

Figure 49: FGM 160 Pulse/frequency output connections. Without external power ............................. 37

Figure 50: FGM 130 –> FGM 160 upgrade ........................................................................................... 38

Figure 51: Space requirements for the TFS .......................................................................................... 40

LIST OF TABLES

Table 1: The space requirements for Transducer Full Size, TFS. .......................................................... 7

Table 2: Min./max. loop resistance at typical loop voltages. ................................................................. 33

62.120.001 Page 3 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

1. PURPOSE

The purpose of this procedure is to provide a traceable point-by-point installation guideline

for the Fluenta Flare Gas meter, Field Computer (FGM 160) system. This document provides

details on the different options that are available on the FGM 160 system, the installation

of the base system, and the optional configurations. The optional configurations include the

two types of transducer, possible upgrade from previous Fluenta Flare Gas Meters, and the

different interfaces available from the Flow Computer to the Plant Control System.

The procedure also provides a means to establish an “Installation and Hook-Up Record”

to document the installation.

2. ABBREVIATIONS / DEFINITIONS

2.1 Abbreviations

FGM Flare Gas Meter

TFS Transducer Full Size

2.2 Definitions

Metering Spool Section A section of pipe that has the transducer, pressure, and

temperature holders already mounted.

Cold Tapping Mounting the transducer, pressure, and temperature holders

on a section of the flare pipe which has been shut off from the

flare system.

Hot Tapping Mounting the transducer, pressure, and temperature holders

on a section of the flare pipe which is an active part of the flare

system.

Center flush The center of the tip of the transducer is flush with the inner

wall of the pipe.

Edge-Flush The part of the transducer tip that is inserted furthest into the

transducer holder/ball valve, and is flush with the inner wall

of the pipe.

Insertion depth The distance from the tip of the transducer to the raised part

of the transducer flange.

62.120.001 Page 4 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

3. GENERAL

The FGM 160 system supplied from Fluenta is designed to work with no substantial pre-

installation preparations. Due to the complexity and the required accuracy of the

measurements, it is mandatory to obtain a very high degree of precision and care during all

phases of the installation.

This procedure includes the required steps from unpacking to commissioning. After

unpacking and inspection of the received goods has been carried out, the system should be

ready for installation. The description of the installation of the system is divided into

subsections as follows:

• Transducer/ Probe installation.

• FGM 160 Field Computer installation.

NOTE:

Installation of transducers is forbidden and causes loss of warranty,

unless it is performed by certified personnel. Certified personnel

includes Fluenta service engineers, service engineers of Fluenta agents

who have received proper training and operators who have attended and

completed Fluenta’s 2-day Operators Training Course. Installation

of computers should be performed for preparation, but it is forbidden to

energize them without a properly trained person (same condition as for

transducers) to supervise it. Additionally, any interference within

transducers and computers (opening, configuring, etc.) is forbidden and

will cause loss of warranty.

4. UNPACKING

4.1 Inspection of Goods

Installation of the equipment supplied by Fluenta must never occur without the inspection

of the supplied goods carried out first. This should be performed according to the instructions

and tasks described in:

FGM 160 – Preservation, Packing, Unpacking and Storage Procedure[1].

It is important to verify the goods according to the packing list and inspect for damages

caused by transportation, and to save packing material for storing and reshipping of the

equipment, if required.

Fluenta ensures that equipment is packed and shipped properly. Mechanical

damage caused during transportation on Ex-works terms or on customer’s site

will not be considered as warranty.

4.2 Ex-Classification Marking

Make sure that the FGM 160 is certified for the area and hazardous zone it is intended to be

installed in. The Ex-Classification marking of the equipment is described in:

FGM 160 – Hazardous Area Installation Guidelines [2].

62.120.001 Page 5 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

4.3 Equipment Information

The FGM 160 requires +24 VDC power supply (nominal). If 24 VDC is not available,

an optional 110-230 VAC/24 VDC converter can be supplied by Fluenta.

For more detailed equipment information and equipment ratings, please refer to: FGM 160 –

Hazardous Area Installation Guidelines[1].

4.4 Manufacturer Information

The FGM 160 Flare Gas Meter is manufactured by Fluenta AS:

Operations Office: Telephone:

ul. Lęborska 3B General: +47 21 02 19 27

80-386 Gdańsk Sales: +47 21 02 19 38

Poland

Head Office: E-mail:

Haraldsgate 90 Sales: sales@fluenta.com

PO Box 420 Support: support@fluenta.com

N-5501 Haugesund

Norway

5. TRANSDUCER/PROBE INSTALLATION

5.1 Installation of Transducer Holders

There are three alternatives for mounting the transducer holders. The first uses a metering

spool piece that has the transducer, pressure, and temperature holders already installed.

The second is referred to as “Cold Tapping”, where the holders are installed on a section

of pipe that is shut off from the flare system. The third option is referred to as “Hot Tapping”,

where the holders are mounted onto a flare pipe that is active. The metering spool piece is

assembled in a mechanical workshop, and “Cold Tapping” and “Hot Tapping” are done by

welders under the supervision of Fluenta personnel.

It is recommended that all of the above three methods are performed under Fluenta

supervision, including spool piece inspection and welding supervision.

5.1.1 Space Requirements

The space requirements around the pipe vary depending on transducer models and pipe

diameters. This will be covered in the following sections. The transducers must be mounted,

regardless of the pipe diameter or transducer model, on a straight section of pipe. The length

of this straight section must be at least 15 times the diameter of the pipe. The nearest

upstream disturbance must be at least 10 times the diameter of the pipe away from the

center of the metering section, and the nearest downstream disturbance must be at least 5

times the diameter of the pipe long. These distances are illustrated in Figure 1. For

installations that cannot meet these requirements, Fluenta should be contacted as this may

have an effect on the measurement uncertainty. As this product is a fiscal measurement

system, this effect should be evaluated.

62.120.001 Page 6 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 1: Fluenta’s minimum straight up- and downstream distances to disturbances.

5.1.1.1 Space Requirements for the Transducer Full Size, TFS

There are two different space requirements for the TFS installation. This is due to the fact

that for pipes with a diameter of 10” and less, the mounting angle for the upstream holder (U)

is 48°, and for the downstream holder (D) the angle is 42°. Pipes with diameters from 12” to

72” have a mounting angle of 45° for both holders. Table 1 below shows the distances

required and in Appendix I there is a schematic of the installation for both sets of diameters.

Note that the Perpendicular Distance is the distance that the mounted transducer assembly

protrudes from the side of the pipe, and the Length is the length of the assembly without

regard to the pipe.

Table 1: The space requirements for Transducer Full Size, TFS.

Pipe Size

6” – 10” 12” – 72”

Perpendicular Distance

Operational upstream perpendicular distance 525 mm 500 mm

Operational downstream perpendicular distance 475 mm 500 mm

Retracted upstream perpendicular distance 770 mm 730 mm

Retracted downstream perpendicular distance 690 mm 730 mm

Length

Operational 700 mm 700 mm

Retracted 1,030 mm 1,030 mm

5.1.1.2 Space Requirements for the Temperature and Pressure Transmitters

The pressure and temperature transmitters must be mounted no closer than 2D (where D =

diameter of the pipe) downstream of path between the transducers (this does not apply to

certain pre fabricated spool pieces) and no longer away than 1,000 mm (where 2D is more

than 1,000 mm the transmitters must be mounted 1,000 mm away). The temperature

transmitter’s intrusive design requires that it be mounted as the furthermost transmitter.

62.120.001 Page 7 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

These transmitters should be mounted on top of pipe if the pipe is horizontality oriented or at

a 90° angle to the transducers if the pipe is vertically oriented. These positions are chosen in

accordance with best engineering practice. Due to the possibility that there is liquid in the

pipe, and mounting on the top of the pipe reduces the chance that they will be damaged by

an accumulation of liquid. Figure 2 illustrates the minimum distance and orientation of the

pressure and temperature transmitters.

Figure 2: Distance requirements for the pressure and temperature transmitters.

62.120.001 Page 8 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

5.2 Mounting the Transducer Holders

There are three ways to mount the transducer holders. The first is by mounting a Spool piece

which is a pre-fabricated pipe with all of the holders (transducer, pressure, and temperature)

already mounted. This pre-fabricated spool piece is inserted into the existing flare pipe

system. The second option is to perform Cold Tapping which means that the transducer

holders are mounted directly onto a flare pipe which has been temporarily removed or cut off

from the flare system. The last option is Hot Tapping which means that the transducer

holders are mounted directly onto a pipe that is being used by the flare system. Due to the

dangerous nature of this option, it is performed by a third party specialist, under supervision

of Fluenta personnel.

5.2.1 Orientation

5.2.1.1 Horizontal Flare Pipe

The optimal orientation of the transducers on the flare pipe depends on whether the flare

pipe is horizontal, vertical, or inclined at a certain angle. If the transducer holders are to be

installed on a horizontal section of the flare line, the transducers should be horizontally

oriented as shown left in Figure 3. The reason for this is that there may be fluid accumulation

in the flare pipe, and if the transducers are oriented in any other way than horizontally, fluids

might accumulate in the lower transducer holder. Then, the fluid must be drained to ensure

the functionality of the meter.

Figure 3: The preferred and non-preferred orientation for horizontal pipe installation.

62.120.001 Page 9 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

5.2.1.2 Vertical Flare Pipe

The transducer holders may also be mounted on a vertical section of flare pipe. The

orientation of the transducer holders in this case does not matter, as the possibility of fluid

filling the upstream transducer holder is the same regardless of the orientation. In this case

the transducer holders may be mounted in a position that suits space and access

requirements. If this is the chosen orientation, then the upstream transducer holder must be

periodically checked for liquid accumulation and emptied, if necessary. Figure 4 shows the

transducer holder orientations for a vertical pipe. A continuous drain system may be installed

by leading the fluids back into the pipeline at a lower point of the flare stack.

Figure 4: Vertical flare boom with the transducer holders and transducers installed.

The orientation of the transducers is irrelevant for installation on a vertical pipe run.

62.120.001 Page 10 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

5.2.2 Cold Tapping

Installation of transducer holders must always be supervised by trained Fluenta personnel.

Before installing the transducer holders on the pipe, the correct placement of the spot marks

must be ensured. There are numerous ways this can be done.

The first consideration is the location of where the spot marks are supposed to be placed.

Figure 5 shows that the horizontal distance between spot A and spot B is the same as the

outer diameter of the pipe (applies only to 45° installations).

D

Spot B

45° Flow Direction

Spot A

Figure 5: Cold tapping – placement of spot marks.

The first thing to do is to find the centerlines on the pipe. Note that the centerlines are exactly

opposite each other on the pipe, ref. Figure 6. Always ensure that the centerlines are placed

accurately by measuring the distance between them, both on the upper and lower

circumference. The measured lengths should be the same.

½pD

Figure 7: Cold tapping – contour

Figure 6: Cold tapping –

marker.

centerlines.

If the pipe is horizontal, use the Curv-O-Mark contour marker to find the centerlines on each

side of the pipe, ref. Figure 7. Remember to turn the contour marker and set a second spot,

to avoid problems in regards to misalignment of the grade scale.

If the pipe is vertical or inclined at a certain angle, other means of finding the centerlines

must be applied. Confer with the pipe fitter or welder, as they usually have the tools and

experience needed to help you.

One proven method is to use a marking band. After the centerlines have been marked and

their position has been verified, use the labeling band to mark a line around the pipe, placed

at the first spot (spot A), ref. Figure 8. Then, on the other side of the pipe, measure the

distance to the second spot (spot B). It is also a good idea to mark another line around the

pipe at spot B, as this will help when placing transducer holder B.

62.120.001 Page 11 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Spot A

Figure 8: Marking a line around the pipe using a marking band.

Mark the hole for the sensors on the pipe wall following the inside rim of the transducer

holder when they are mounted in the welding-jig. Repeat the procedure for the other

transducer holder. The holes can now be cut according to the marked line on the pipe-wall.

After the holes are cut, ensure that the inner edges are grinded to be smooth, and beveled in

the correct way, ref. Figure 9. Before the welding starts, the groove angle must be grinded on

the holders. Normally the holders must be taken off the welding-jigs for grinding/adjustment

to get the right opening and joint, ref. Figure 10.

62.120.001 Page 12 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 9: Machined hole. Figure 10: Machined holder.

Adjust the gap between the pipe and the transducer holder until it is correct. This is done to

get a satisfactory welding connection. Usually, the spacing will be between 2mm and 4mm,

depending on the welder’s preference, but always at the correct angle (45º/48º/42). Note that

as you raise the transducer holder from the pipe, it must be moved backwards with the same

amount (applies only to 45º installations), see Figure 11.

Figure 11: As you raise the transducer holder, you must also move it backwards to keep the

centering correct.

When the transducer holders are grinded and the holes have been made, the welding-jig

should be located in the right position and the transducer holder connected. The transducer

holder can now be tacked to the pipe. Usually, the welder will use three or four tacks. Ensure

that there is enough space to insert the transducer. Fluenta recommends using the sighting

tool to verify this. The tool should be able to be inserted without any friction or obstructions.

The next step is to mount the second transducer holder. Repeat the procedure, but to verify

the exact location/position, you must use the special measuring/view tool.

It is assumed that the buyer’s welding procedure is approved before the work starts and that

the welding is performed by certified welders.

When correct alignment of both transducer holders is ensured (see section 0), the welder

can weld and fill out both transducer holders. Be aware that as the welding is in progress, the

transducer holders can be pulled off their angles by the welding process. Therefore, it is

62.120.001 Page 13 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

necessary to pay close attention during the welding, regularly checking the angles with the

digital electronic level.

Figure 12: Welding jig and transducer Figure 13: Transducer holder welded to the pipe.

holder.

This activity needs to be carried out by a skilled welder as precision and accuracy is

necessary to get the transducer holders welded into their right positions. The transducer

holders are welded onto the pipe according to the buyer’s welding procedure. Next step will

be NDT and final approval of the welding. The welding-jigs can be dismounted when the

transducer holders are properly connected to the pipe as shown in Figure 13.

62.120.001 Page 14 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

5.2.3 Using the Sighting Tool

There are two types of sighting tool, one for each angle set. The first type, shown in Figure

15, is for transducer holders mounted at a 45° angle. There are two tools in a set, one fits

tightly in each transducer holder. Each of the tools has a hole in the center.

Figure 15: The sighting tool for 45°

transducer holders.

Figure 16: The stop

Figure 14: The washer for the

sighting tool for the

sighting tool

42°/48° transducer

for the 42°/48°

holders.

transducer

holders

The second type of sighting tool is made for transducer holders that are mounted on pipes

with a diameter of 10” and less and with 42°/48° transducer holders, ref. Figure 14. This set

of tools uses the path of light for verification like the first. As the transducer holder’s mounting

angles are not equal, these tools require some adjustments before they can be used. The set

comes with a pair of stop washers, shown in Figure 16. The tool must penetrate the

transducer holder to the same depth as the transducer.

Figure 17: A 45° sighting tool

mounted in a transducer holder.

Figure 18: A 42°/48° sighting tool with stop

washer mounted in a transducer holder.

When using the sighting tool for pipes that have a diameter greater than 10”, insert the

sighting tool into the transducer holder so that the flange of the sighting tool is flush with the

flange of the transducer holder. This is shown in Figure 17.

62.120.001 Page 15 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

When using the sighting tool for pipes that are 10” and less, use the measurement from the

special tool as described in section 5.3.1 to find the correct depth for the transducer. This

depth should be the same for the sighting tool. Measure from the narrow end of the sighting

tool and tighten the stop washer at that position. Insert the sighting tool so that the stop

washer is flush with the flange on the transducer holder, this is shown in Figure 18. There is

a groove in the head of this type of sighting tool shown in Figure 19. Align one sighting tool

with the pipe, and rotate the other until the light is visible. Adjust the sensor holder so that the

circle of light is seen as described below.

Visual check

Figure 19: Look through the holes on the sighting tool. Rotate the sighting tool on the left to

get a correct alignment.

When the transducer holders are properly aligned and the sighting tools are inserted, it is

possible to see a perfect circle of light when looking through the hole in one of the sighting

tools, shown in Figure 20. If there is not enough ambient light, it may be necessary to shine a

light source through the hole in the opposite sighting tool.

Figure 20: A good alignment. Figure 21: A bad alignment.

5.2.4 Hot Tapping Transducers Full Size, TFS

If hot tapping is needed, use the same procedure as described in “Cold Tapping” but do not

drill the pilot holes. When the welding of the transducer holders has been performed and the

ball valves are mounted, connect the hot-tapping equipment to the 2" ball valve. Open the

62.120.001 Page 16 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

ball valve and drill the hole. The hole should be as close to 49.3 mm as possible, but care

should be taken to avoid damage to the ball valve. If possible, use a 49 mm drill and avoid

sharp edges.

5.3 Mounting the Ultrasonic Transducers

5.3.1 Determining the Correct Position for the Transducers

Fluenta will use a special gas proof measuring tool to find the correct position for the

transducers, as shown in Figure 22. The method is shown in the figure below. This is carried

out on site during installation of the transducers due to the fact that the entire length is

measured, including ball valves and gaskets. The transducer is thereafter positioned

correctly.

Figure 22: The gas-proof measuring tool.

62.120.001 Page 17 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 23: A schematic of the gas-proof measuring tool.

5.3.2 Edge Flush Transducer Mounting

5.3.2.1 Setting the correct insertion depth

The insertion depth measurement should be performed as usual. When setting the insertion

depth, remember that the retraction of the transducer means that the insertion depth should

be reduced (see Figure 24).

Figure 24: Insertion depth.

The insertion depth (green arrow) must be reduced (red arrow) according to the angle of the

transducer holder

As a result of the reduced insertion depth, the distance between the transducer tips will

increase (see Figure 25). The transducer tip distance is a parameter that directly affects the

flow velocity calculations, therefore the transducer distance must be updated in the

configuration of the flow computer.

For the FGM 160, the transducer distance can be found in the O&S Console software under

Config – Config Main Page – Mechanical Parameters – Measured (length in m).

62.120.001 Page 18 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 25: Retracted tranducers distance.

When the transducers are retracted, the transducer distance will increase from the original

distance (red arrow in Figure 25) to the new transducer distance (green arrow). This must be

updated in the flow computer.

5.3.2.2 45° installations

Figure 26: Edge-flush position for a 45° transducer holder.

For an installation where the transducer-holder angles are 45°, the retraction needed for

each transducer is 18mm (see Figure 26). The transducer distance must then be increased

by 36mm (2x18mm) in the flow computer configuration.

62.120.001 Page 19 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

5.3.2.3 48°/42° installations

For an installation where the transducer-holder angles are 48° (Downstream) and 42°

(Upstream), the retraction needed for each transducer is 16.2mm for the 48° transducer (see

Figure 27), and 20mm for the 42° transducer (see Figure 28). The transducer distance must

then be increased by 36.2mm (16.2mm+20mm) in the flow computer configuration.

Figure 27: Edge-flush position for a 42° Figure 28: Edge-flush position for a 48°

transducer holder. transducer holder.

62.120.001 Page 20 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

5.3.3 Insertion of the Transducer Full Size (TFS)

When the transducer holders and ball valves are installed, the ultrasonic transducers may be

inserted. This shall ONLY be done by personnel certified by Fluenta. If this is a first time

installation, the transducer holder should be checked for liquid and drained prior to

installation. Care must be taken to avoid any impact or friction to the ultrasonic sensor head.

Also, it must be ensured that the sensor casing is connected to protective earth.

NOTE:

During transducer installation, the power supply to FGM 160 must be turned

OFF!

Verify that the installed ball valves are gas tight (no gas leaks). This should be done by the

on-site personnel - using a gas monitoring device. Measure and adjust the installation depth

of each transducer, which is set by fastening the A-lock lock-ring. Mount the

transducer/packbox. Open the ball valve, and push the transducer all the way in, until

meeting the A-lock locker ring. Fasten the A-lock nut to the transducer packbox.

1 2 Open the ball valve

Mount the transducer

3 4 Screw in the

Insert the transducer locking nut

Figure 29: Mounting the Transducer Full Size.

NOTE:

Make sure that the Draining Plug is in its place in the Packing Box.

It can be removed only in order to remove impurities while no media is flowing

through the pipe. After cleaning the Packing Box, the Draining Plug should be

immediately screwed back.

6. FIELD COMPUTER INSTALLATION

In order to reduce signal loss and maintain signal quality, the length of the signal cables

should be kept as short as possible. Thus the FGM 160 (Ex-d/e Enclosure) must be mounted

close to the spool piece/ transducers. The FGM 160 has lugs that enable easy mounting on

either a separate frame or on top of the spool piece by brackets.

62.120.001 Page 21 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.1 The Field Computer Mounting Frame

The field computer can be mounted on existing infrastructure, or a custom mounting frame.

The custom mounting frame comes in four versions. The first is shown in Figure 30 a), and

includes legs for a free standing mount, as well as two frames for mounting a separate AC to

DC converter in an Ex-d housing. The frame shown in b) is the same, except it does not

include a mounting frame for an AC to DC converter. The mounting frame in d) shows a

frame that mounts onto the existing infrastructure. The frame in c) shows the same frame as

d) with a frame for an AC to DC converter.

a) b)

c) d)

Figure 30: The FGM 160 Field Computer mounting frame versions.

6.2 Electrical Wiring

Before the installation starts, power and signal cables between the FGM 160 and the local

equipment room should be pulled and ready for termination. Normally, the routing and

preparation of the cables are not part of Fluenta’s scope of work.

External wiring is to be carried out according to:

FGM 160 – Field Wiring Diagram, Fluenta Doc.no.: 77.120.509 [3].

Power source should not be connected until verification of supply voltage has been

performed. Main fuses should not be inserted at any stage of the installation phase

All cables should be connected to the terminals in the Ex-e enclosure of the FGM 160.

The blue terminals are IS (Intrinsically Safe) and are connected to the field computer through

internal IS barriers. The gray terminals are not connected to an IS barrier, and are meant for

signals between the field computer and safe area equipment and systems.

62.120.001 Page 22 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 31: Ex-e enclosure terminals overview.

Note:

Foundation Fieldbus terminal overview available in doc. no. 77.120.217.

6.2.1 Cable Preparations

The steps described below should be carried out at both ends of the cables. However, the

installation of glands is not applicable for the Local Equipment Room.

• Verify the labeling/tag name on the cable.

• Verify whether the cable is “megged” or not.

• Cut the cable to a length that allows slack.

• Pull the cable through its respective gland, and make sure that the cable gland is

of the required type and size.

• Terminate and secure the cable and cable gland according to instructions for the

specific cable gland.

• Strip and terminate the conductors and screen according to good workmanship.

• If the cable is not “megged”, it should be carried out at this point.

• The conductors and screens should also be checked for continuity.

62.120.001 Page 23 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.2.2 Power Cable

The FGM 160 requires a 24 VDC power supply (ref. section 4.3 Equipment Information).

Keep the twisting of the conductor pair and route the conductors to the power input terminals

(ref. Figure 31). If applicable, terminate the screen to the PE Earthbar.

Figure 32: Power to the FGM 160.

NOTE:

It is forbidden to energize the computer without a properly trained

personnel to supervise it. Certified personnel include Fluenta service

engineers, service engineers of our agents who have received proper

training and operators who have attended and completed Fluenta’s

2-day Operators Training Course. Energizing the computer without

Fluenta certified personnel will cause loss of warranty.

6.2.3 Ultrasonic Transducer Cables

The ultrasonic transducer cables are already prepared at the Fluenta production facilities.

These cables should be handled with care.

Verify the labeling/tag name on the cable. Pull the cable through its respective gland; make

sure that the cable gland is of the required type and size. Secure the cable and cable gland.

It is recommended that the cable between the FGM and the transducers is kept as short as

possible, 10 meter cable is supplied as a standard. For other lengths than standard, Fluenta

must be notified.

62.120.001 Page 24 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 33: Connecting the Ultrasonic Transducers to the FGM 160.

62.120.001 Page 25 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

The ultrasonic transducers shall be connected as follows. This is carried out at the Fluenta

production facilities.

Upstream:

Ch1Up–IS

Ch1Up+IS

Ch1Up_G

Downstream:

Ch1Dn-IS

Ch1Dn+Is

Ch1Dn_G

Keep the twisting of the conductor pairs when connecting to terminals.

All conductors of the prefabricated transducer cables are labeled according to the signal

names of the Ex-e terminals (ref. Figure 34)

Figure 34: Connection details for ultrasonic transducers.

62.120.001 Page 26 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.2.4 Connecting the Pressure and Temperature

Transmitters

Pressure and temperature transmitters should be connected directly to the connection

terminals in the Ex-e enclosure, no barriers are required, as these are built-in in the IS

Barrier module within the FGM 160. For detailed information regarding the built-in barriers

and the optional grounding wire shown in Figure 35, please refer to: FGM 160 – Hazardous

Area Installation Guidelines [2].

The FGM 160 can interface either to 4-20 mA current loop transmitters or HART transmitters.

Depending on the transmitter interface to the FGM 160, a connection described in figures

below should be used. Up to four HART transmitters can be connected to the HART input

terminals, e.g. if condition based maintenance scheme is utilized with double or dual

transmitters.

The pressure and temperature inputs at the FGM 160 are always configured as active

current loop inputs (i.e. the pressure and temperature transmitters are always powered from

the FGM 160 field computer).

Figure 35: Pressure and temperature transmitter hook-up.

62.120.001 Page 27 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 36: FGM 160 – 4-20 mA pressure and temperature transmitter connections.

Figure 37: Pressure and Temperature HART transmitter connection.

62.120.001 Page 28 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.2.5 Control Room and Data Cables

The FGM 160 Flow Computer can be connected to the control room in several different

ways. These allow the DCS or SCADA software in the control room to communicate with the

FGM 160 Flow Computer. The connection options are as follows:

• DCS port, Modbus protocol (RS-485)

• Three (3) 4-20 mA, with additional three (3) as option.

• HART interface (optional).

• One (1) Pulse, Frequency or Level output (optional).

Figure 38: Data and Signal Cables.

The Service port is for the Operator & Service Console. This connection must be available

in the safe area in order to enable Fluenta support personnel to check the meter’s

performance, configure the meter and upload new firmware. Figure 38 shows the different

connections. Normally, Operator Console and DCS wiring is not a part of Fluenta’s scope

of work.

6.2.5.1 DCS Port, Modbus

The FGM 160 can be interfaced to a DCS Modbus system by an RS 485 signal interface.

Normally a 2-wire interface is used, but 4-wire interface can also be used.

For detailed information regarding the DCS port wiring, please refer to:

FGM 160 – DCS Modbus Interface Specifications [4].

DCS Modbus Interface is disabled in FGM 160 Foundation Fieldbus configuration

6.2.5.2 Foundation Fieldbus Output

In FGM 160, FF configuration 4-20mA Outputs are not available. They are replaced by

Foundation Fieldbus Outputs. Wires for FF should be connected to FF_1 and FF_2 outputs

marked on the Figure below.

62.120.001 Page 29 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 39: Foundation Fieldbus Connection

6.2.5.3 Service Port

The wiring of the service port is similar to the DCS port wiring.

For more detailed information, please refer to: FGM 160 – Operator Console Description [5].

6.2.5.4 Current Loop Outputs (4-20mA)

The FGM 160 has three operational 4-20mA current loop outputs as default, with additional

three as an option.

Each of the current loop outputs can be configured either as active or passive output.

In active output configuration, the current loop is powered from the FGM 160 field computer.

In passive output configuration, an external power source is required.

In default configuration, all current loop outputs are configured as active outputs.

The current loop outputs can be configured as follows:

Analog output.

o The output is assigned to a specific parameter/process variable and

configured with a desired range.

Alarm status output.

o The output can be configured as a specific alarm output (e.g. temperature

alarm) or as a general global alarm output.

o Alarm level can be set to 4mA or 20mA.

Level indicator output.

o The output can be configured to shift from 4mA to 20mA (or opposite) at a

certain level of the assigned variable.

Current Loop Outputs are replaced by Foundation Fieldbus Outputs in FGM 160 Foundation

Fieldbus configuration.

62.120.001 Page 30 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.2.5.4.1 Active Output Configuration (Default Configuration)

In active output configuration, the current loops are powered from FGM 160 computer (30V

loop voltage).

In active output configuration:

- “CLx out” terminal is connected to CL-GND.

- Current loop is connected between CL+Supply and “CLx in” terminals.

(as default all “CLx out” terminals are connected to CL-GND by jumpers at the terminal blocks)

Figure 40: Active output current loop(s), wiring

62.120.001 Page 31 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.2.5.4.2 Passive Output Configuration

In passive output configuration, the current loops are powered from an external loop power

source (5V – 50V, see section 6.2.5.4.4, Load / Loop Voltage Limitations, for more details).

In passive output configuration:

- Current loop is connected between “CLx in” and “CLx out” terminals.

- The jumpers between “CLx out” terminals and CL-GND (installed by default) must be removed.

Figure 41: Passive output current loop(s), wiring

62.120.001 Page 32 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.2.5.4.3 Current Loop Outputs Details

The current loop outputs of the FGM 160 are galvanic

isolated from the rest of the FGM 160 field computer.

However, they are not individually isolated with respect

to each other (they all share the same ground reference

point).

The outputs are protected against reverse polarity.

See Figure 42 for detailed schematic of the current loop

outputs.

6.2.5.4.4 Load / Loop Voltage

Limitations

A typical load resistor value is 250Ω.

This value gives a voltage on the DCS input within the

range of 1 – 5V.

Active Output Configuration

In active output configuration, the loop voltage is 30V.

Minimum loop resistance: 100Ω.

Maximum loop resistance: 1350Ω.

Passive Output Configuration

Minimum loop voltage: 5V.

Maximum loop voltage: 50V.

Minimum loop resistance:

- Loop voltage < 30V: Rloop min. = 100Ω.

- Loop voltage > 30V:

Rloop min. = (Loop voltage - 28V) x 50 [Ω].

Maximum loop resistance:

Rloop max. = (Loop voltage - 3V) x 50 [Ω].

Table 2: Min./max. loop resistance at typical loop

voltages.

Loop voltage Rloop min. Rloop max.

12 V 100 Ω 450 Ω

24 V 100 Ω 1050 Ω

30 V 100 Ω 1350 Ω

36 V 400 Ω 1650 Ω

48 V 1000 Ω 2250 Ω

Figure 42: Current loop

outputs, details

62.120.001 Page 33 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 43: Current loop outputs, Load/Voltage limitations

6.2.5.4.5 Restrictions of the Current Loop Outputs

High side load/Low side load

The load resistor should normally be connected on high side (see Figure 44 and Figure 45).

Low side load can be used alternatively, but only when a single current loop outputs is

used/connected. If more than one current loop output is used and load resistor is connected

on low side, the readings on each output will show erroneous values. The reason for this is

that the current from each output will disperse over all connected outputs. (see Figure 46 and

Figure 47)

Figure 44: Current loop active output, High side load and Low side load

Figure 45: Current loop passive output, High side load and Low side load

62.120.001 Page 34 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

Figure 46: Multiple current loop outputs, Active output configuration

Figure 47: Multiple current loop outputs, Passive output configuration

6.2.5.5 HART Output

One of the current loop outputs (CL6) can be configured and used as a HART

communication channel.

62.120.001 Page 35 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

For detailed information regarding wiring of the HART output channel, please refer to: FGM

160 – HART Output Interface Specification [6].

6.2.5.6 Pulse/Frequency/Level Output

As an option, the FGM 160 can be configured with one passive pulse/frequency/level output.

This output can be configured in three different ways:

Pulse output configuration.

o The pulse signal can be used e.g. to interface an external totalizer/counter.

Frequency output configuration.

o The frequency signal can be used as an alternative to analog current loop

output.

Level output configuration.

o This signal can e.g. be used for alarm or status output.

62.120.001 Page 36 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.2.5.6.1 Voltage / Current Limitations

Maximum voltage: 30V

Maximum current: 40 mA (output is protected by a 62mA internal fuse)

Figure 48: FGM 160 Pulse/frequency output connections

Figure 49: FGM 160 Pulse/frequency output connections. Without external power

62.120.001 Page 37 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

6.3 Upgrading from the FGM 130

It is strongly recommended to upgrade all FGM 130 installations to FGM 160. The upgrade is

relatively simple and easy to perform. Existing mounts can be used, although the transducers

must be replaced, as the FGM 160 uses upgraded Ultrasonic Transducers, and the signal is

not backward compatible with the Ultrasonic Transducers used with the FGM 130. The

existing temperature and pressure sensors can be used, and the fiber optic cables can be re-

used for DCS signal transmission with the addition of an RS485 optical converter. The figure

below shows the similarities and differences between the FGM 130 and FGM 160 setups.

Figure 50: FGM 130 –> FGM 160 upgrade

62.120.001 Page 38 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

The table below shows the components of the FGM 130 that can be re-used when upgrading

to the FGM 160.

FGM 130 FGM 160

Flow Computer No Replaced by FGM 160 Computer

Field Electronics Enclosure No Integrated in FGM 160 Computer

Ultrasonic Sensors No New FGM 160 sensors

Pressure Transmitter Yes Interface directly to FGM 160 Computer

Temperature Transmitter Yes Interface directly to FGM 160 Computer

Power Cable Yes Power or Communication

Fiber Optic Signal Cable Yes Communication (RS422/RS485)

Sensor Holders Yes

Compatible, with an additional HART

DCS/SCADA Interface Yes

interface

7. REFERENCES

[1] FGM 160 – Preservation, Packing, Unpacking and Storage Procedure

[2] FGM 160 – Hazardous Area Installation Guidelines

[3] FGM 160 – Field Wiring Diagram, Fluenta Doc.no.: 77.120.509

[4] FGM 160 – DCS Modbus Interface Specifications

[5] FGM 160 – Operator Console Description

[6] FGM 160 – HART Output Interface Specification

62.120.001 Page 39 of 40

Downloaded from www.Manualslib.com manuals search engine

FGM 160 Installation and Hook-Up Instructions

8. APPENDIX I - SPACE REQUIREMENTS FOR THE

TFS

Figure 51: Space requirements for the TFS

62.120.001 Page 40 of 40

Downloaded from www.Manualslib.com manuals search engine

You might also like

- SoakingInTheSpirit FREE-FeatureDocument69 pagesSoakingInTheSpirit FREE-Featurek O0% (1)

- Health-Food-DevotionsKenneth-E.-Hagin-Kingdomsermons.com_Document304 pagesHealth-Food-DevotionsKenneth-E.-Hagin-Kingdomsermons.com_k O100% (1)

- Manual Kaeser PDFDocument270 pagesManual Kaeser PDFPABLO0% (1)

- VSD ManualDocument317 pagesVSD Manualfernando Hurtado100% (1)

- LSI gs550 PDFDocument85 pagesLSI gs550 PDFIvan ivan budiNo ratings yet

- Tokimec ES160 - Simrad RGC11manual RevADocument192 pagesTokimec ES160 - Simrad RGC11manual RevAornardys PenicheNo ratings yet

- Copeland Compressor PDFDocument24 pagesCopeland Compressor PDFveerapen clydeNo ratings yet

- A035j931 I3 201710Document74 pagesA035j931 I3 201710Quang Pham100% (2)

- Heat Pump (50Hz) Cooling Only (50Hz) : RXS, RKS, RZQ SeriesDocument462 pagesHeat Pump (50Hz) Cooling Only (50Hz) : RXS, RKS, RZQ SeriesstevenloNo ratings yet

- Split System Air Conditioners: Inverter SeriesDocument428 pagesSplit System Air Conditioners: Inverter SeriesstevenloNo ratings yet

- Lamiaceae Species: Biology, Ecology and Practical UsesDocument142 pagesLamiaceae Species: Biology, Ecology and Practical UsesneverwritNo ratings yet

- KST ServoGun Basic 31 enDocument214 pagesKST ServoGun Basic 31 enRáfaga CoimbraNo ratings yet

- Chapter 3 Issues On Human DevelopmentDocument25 pagesChapter 3 Issues On Human DevelopmentJheny Palamara75% (4)

- General Electric SX Z1-2 (Ingles 01-1999) PDFDocument74 pagesGeneral Electric SX Z1-2 (Ingles 01-1999) PDFJuan Carlos Rubio FrescoNo ratings yet

- Applications: Functions andDocument350 pagesApplications: Functions andJason UchennnaNo ratings yet

- Dpharp Vigilantplant Eja310aDocument76 pagesDpharp Vigilantplant Eja310aOscarNo ratings yet

- User's Manual: Model EJA438W and EJA438N Diaphragm Sealed Gauge Pressure TransmittersDocument79 pagesUser's Manual: Model EJA438W and EJA438N Diaphragm Sealed Gauge Pressure Transmittersfikri rahmanNo ratings yet

- Model EJA115 Low Flow Transmitter (Style: S3)Document90 pagesModel EJA115 Low Flow Transmitter (Style: S3)Guru KathirNo ratings yet

- Im01c22c01-01e 017Document79 pagesIm01c22c01-01e 017Manuel GonzalezNo ratings yet

- KST ServoGun FC 21 enDocument125 pagesKST ServoGun FC 21 enSergei Kublanov100% (1)

- User's Manual: EJX110A, EJX120A, EJX130A, EJX310A, EJX430A and EJX440A Differential Pressure and Pressure TransmittersDocument76 pagesUser's Manual: EJX110A, EJX120A, EJX130A, EJX310A, EJX430A and EJX440A Differential Pressure and Pressure TransmittersotavioNo ratings yet

- Manuals Bettis G GH GHC Series Bettis en en 7770542Document76 pagesManuals Bettis G GH GHC Series Bettis en en 7770542jaime HernandezNo ratings yet

- Yokogawa PDT ManualDocument83 pagesYokogawa PDT Manualvikkoo7No ratings yet

- User's Manual: EJX510A, EJX530A, EJX610A and EJX630A Absolute Pressure and Gauge Pressure TransmittersDocument51 pagesUser's Manual: EJX510A, EJX530A, EJX610A and EJX630A Absolute Pressure and Gauge Pressure TransmittersInstrumentation GCS GanaNo ratings yet

- Cambi e Nap YokogawaDocument73 pagesCambi e Nap YokogawaKhánh LêNo ratings yet

- BKF 6 6000Document276 pagesBKF 6 6000fathazamNo ratings yet

- Transmisor Yokogawa IM01C25F01-01EN 013Document62 pagesTransmisor Yokogawa IM01C25F01-01EN 013juanNo ratings yet

- IG-A05 Pressure Transmitter - EJX530ADocument52 pagesIG-A05 Pressure Transmitter - EJX530AAdhitya ReNo ratings yet

- Seagate Iron Wolf Pro Standard 512E Model SATA Product ManualDocument36 pagesSeagate Iron Wolf Pro Standard 512E Model SATA Product ManualPatrick StivénNo ratings yet

- RDT 200 Owners Manual - MPAC 500Document88 pagesRDT 200 Owners Manual - MPAC 500MP DieselNo ratings yet

- Senao AP User GuideDocument38 pagesSenao AP User GuideSergej FarmakovskiNo ratings yet

- Installation and Operating Instruction: Gas Burner WG10 /1-D ZM-LNDocument112 pagesInstallation and Operating Instruction: Gas Burner WG10 /1-D ZM-LNdarrel gimoteaNo ratings yet

- CPU 265 ManualDocument96 pagesCPU 265 Manualngoctuyen,ktNo ratings yet

- X18 SATA Product Manual: 512E Models Standard 512E Models Self-EncryptingDocument57 pagesX18 SATA Product Manual: 512E Models Standard 512E Models Self-EncryptingnarciszuNo ratings yet

- AKE200 - UserManual - C53000 G6540 C265 2Document56 pagesAKE200 - UserManual - C53000 G6540 C265 2franduxNo ratings yet

- Section 1: Introduction: Reference ManualDocument1 pageSection 1: Introduction: Reference ManualTanuTiganuNo ratings yet

- Endo Sac Acp ServicemanDocument126 pagesEndo Sac Acp ServicemanNatalia VilchesNo ratings yet

- Standard - LV - Motors - Manual - ML - 01 - 2009 Rev DDocument160 pagesStandard - LV - Motors - Manual - ML - 01 - 2009 Rev DraluntitledNo ratings yet

- Standard - LV - Motors - Manual - EN - 01 - 2009 Rev D PDFDocument26 pagesStandard - LV - Motors - Manual - EN - 01 - 2009 Rev D PDFasifdcetNo ratings yet

- Assembly Instructions - ECblue - B (090) - IP20Document44 pagesAssembly Instructions - ECblue - B (090) - IP20Ricardo AyarzagoitiaNo ratings yet

- User's Manual: Model EJA510A and EJA530A Absolute Pressure and Gauge Pressure Transmitters (Style: S2)Document70 pagesUser's Manual: Model EJA510A and EJA530A Absolute Pressure and Gauge Pressure Transmitters (Style: S2)Himanshu ShuklaNo ratings yet

- Automotive Power: High Current PN Half Bridge Novalithic™Document31 pagesAutomotive Power: High Current PN Half Bridge Novalithic™Marin VlahovićNo ratings yet

- Momentus Thin: Product ManualDocument38 pagesMomentus Thin: Product ManualjabbanNo ratings yet

- GC-250 ManualDocument139 pagesGC-250 ManualMajid Raja ChauhanNo ratings yet

- Im01c25c01-01en 012Document68 pagesIm01c25c01-01en 012muhammad.wajahat194No ratings yet

- Digitaler Servoverstärker AX2500: Assembly, Installation, SetupDocument81 pagesDigitaler Servoverstärker AX2500: Assembly, Installation, Setupalejandro garciaNo ratings yet

- Yokogawa Lit Eja118wDocument84 pagesYokogawa Lit Eja118wDaniela ArrietaNo ratings yet

- DCRP-Products Active ListDocument48 pagesDCRP-Products Active ListskanthsnNo ratings yet

- CP051Document84 pagesCP051ngoctuyen,ktNo ratings yet

- Engineering Data - NU-V1 - Y1 R22Document210 pagesEngineering Data - NU-V1 - Y1 R22Thai CaoNo ratings yet

- Gas Burner WG30... 1-C ZM-LN CA2019-02Document124 pagesGas Burner WG30... 1-C ZM-LN CA2019-02SAID GUERROUTNo ratings yet

- W803E Battery Powered Electromagnetic ConverterV47Document49 pagesW803E Battery Powered Electromagnetic ConverterV47Davi RebouçasNo ratings yet

- Honeywell VersaFlow Manuel Pour 100 - 200 - 1000 PDFDocument124 pagesHoneywell VersaFlow Manuel Pour 100 - 200 - 1000 PDF112233No ratings yet

- Standard 0 Guide KKS RevDinworkDocument45 pagesStandard 0 Guide KKS RevDinworkAnonymous sLRlLluNo ratings yet

- (Balance) Digi DC-782-Manual PDFDocument43 pages(Balance) Digi DC-782-Manual PDFanon_336750144No ratings yet

- User's Manual: Model EJA310A, EJA430A and EJA440A Absolute Pressure and Gauge Pressure TransmittersDocument83 pagesUser's Manual: Model EJA310A, EJA430A and EJA440A Absolute Pressure and Gauge Pressure TransmittersMarion TelliezNo ratings yet

- Circuit Description Board4 0 DocV1 3Document38 pagesCircuit Description Board4 0 DocV1 3CONG TRAN NGOCNo ratings yet

- CP 263S & CP 236X CPU ModuleDocument42 pagesCP 263S & CP 236X CPU Moduleforce ramdomNo ratings yet

- SIGMA 910 & 920 Flow Meters Instrument ManualDocument48 pagesSIGMA 910 & 920 Flow Meters Instrument ManualdtalaveraNo ratings yet

- Busch Instruction Manual Cobra NC 0100 0300 B WCV en 0870573306Document40 pagesBusch Instruction Manual Cobra NC 0100 0300 B WCV en 0870573306Fatih YAŞARNo ratings yet

- Sma Installation smc7000hv Vers70 enDocument88 pagesSma Installation smc7000hv Vers70 enJuanTrenadosTorresNo ratings yet

- X.. Series Vertical and Upright Gear UnitsDocument452 pagesX.. Series Vertical and Upright Gear UnitsRavi kumarNo ratings yet

- TB-0004 RevE - ThunderBolt - Slide in Racks Service ManualDocument51 pagesTB-0004 RevE - ThunderBolt - Slide in Racks Service ManualKhánh NgânNo ratings yet

- GE Panametrics PanaView ManualDocument120 pagesGE Panametrics PanaView Manualk ONo ratings yet

- Bidirectional Sphere Type Prover: Smith Meter ProversDocument2 pagesBidirectional Sphere Type Prover: Smith Meter Proversk ONo ratings yet

- 1997 19 Performance Testing of Ultrasonic Flow Meters Grimley Southwest Research InstituteDocument22 pages1997 19 Performance Testing of Ultrasonic Flow Meters Grimley Southwest Research Institutek ONo ratings yet

- How To Be Filled and Walk in The Holy Spirit by Bill Bright (PDFDrive)Document17 pagesHow To Be Filled and Walk in The Holy Spirit by Bill Bright (PDFDrive)k ONo ratings yet

- Sense It! Connect It! Bus It! Solve It!: Safety ManualDocument44 pagesSense It! Connect It! Bus It! Solve It!: Safety Manualk ONo ratings yet

- RFinley Extenze ReviewDocument23 pagesRFinley Extenze Reviewk ONo ratings yet

- 41 SAfrican LJ269Document6 pages41 SAfrican LJ269Ruchira JoshiNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument4 pagesCambridge International Advanced Subsidiary and Advanced LevelWarda Ul HasanNo ratings yet

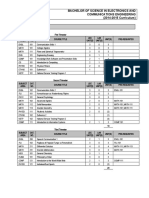

- Program Structure: Bachelor of Science in Electronics and Communications Engineering (2014-2015 Curriculum)Document5 pagesProgram Structure: Bachelor of Science in Electronics and Communications Engineering (2014-2015 Curriculum)Zainab KadhemNo ratings yet

- Bio Physics: Prepared by Gayathry SatheesanDocument19 pagesBio Physics: Prepared by Gayathry SatheesanrehandeshmukhNo ratings yet

- VENTILATIONDocument7 pagesVENTILATIONkhairulaqib.baha01No ratings yet

- Diploma in Mechanical Engineering Colleges in NoidaDocument3 pagesDiploma in Mechanical Engineering Colleges in NoidaGalgotias UniversityNo ratings yet

- Department of Education: Republic of The PhilippinesDocument36 pagesDepartment of Education: Republic of The PhilippinesKristine Rose CADUTDUTNo ratings yet

- What We Mean by CreativityDocument18 pagesWhat We Mean by CreativityChris PetrieNo ratings yet

- Vocabulary AssignmentDocument5 pagesVocabulary Assignmentsimran simranNo ratings yet

- NotesverifDocument4 pagesNotesverifSabitri SanyalNo ratings yet

- Particle Size DistributionDocument23 pagesParticle Size Distributionanon_332134197No ratings yet

- Xglo & Lightsystem Indoor/Outdoor Loosetube, Dca - Emea: Ordering InformationDocument2 pagesXglo & Lightsystem Indoor/Outdoor Loosetube, Dca - Emea: Ordering InformationDemetri M. ScytheNo ratings yet

- 21CLD Learning Activity Cover SheetDocument9 pages21CLD Learning Activity Cover SheetMariana VoloshynNo ratings yet

- GAE - Affine and Euclidean GeometryDocument4 pagesGAE - Affine and Euclidean GeometryMîån ÅbdûllãhNo ratings yet

- Alt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalDocument19 pagesAlt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalSan JongNo ratings yet

- Practice Essay For Passage TwoDocument2 pagesPractice Essay For Passage TwoVictoria KairooNo ratings yet

- Instructions:: Exam Papers Must Not Be Removed From The Exam Room Examiners: R.Russo T.KreouzisDocument9 pagesInstructions:: Exam Papers Must Not Be Removed From The Exam Room Examiners: R.Russo T.KreouziszcaptNo ratings yet

- Customer Service-Telephone SkillsDocument18 pagesCustomer Service-Telephone SkillsRashida SimmsNo ratings yet

- Guidelines For Online DLEPCDocument21 pagesGuidelines For Online DLEPCdrkantinifNo ratings yet

- Pengaruh Kelas Lereng Dan Tutupan Lahan Terhadap Solum Tanah, Kedalaman Efektif Akar Dan PH TanahDocument10 pagesPengaruh Kelas Lereng Dan Tutupan Lahan Terhadap Solum Tanah, Kedalaman Efektif Akar Dan PH TanahAPRI YANSYAHNo ratings yet

- MSDS - SpaDocument6 pagesMSDS - SpaChing ching FongNo ratings yet

- 4 29 2016Document25 pages4 29 2016Aiman LatifNo ratings yet

- Activity 9 Measuring Mass Calculating DensityDocument5 pagesActivity 9 Measuring Mass Calculating Densityapi-285524270No ratings yet

- Rachel Woodward - Military GeographyDocument7 pagesRachel Woodward - Military GeographyPeter BalogNo ratings yet

- SAQOL 39 Proxy Version Sr55z7Document5 pagesSAQOL 39 Proxy Version Sr55z7Fernanda VegaNo ratings yet

- Role of Geotechnical Properties of Soil On Civil Engineering StructuresDocument8 pagesRole of Geotechnical Properties of Soil On Civil Engineering StructuresSaša MarinNo ratings yet

- Influence of Drying and Hydrothermal Treatment of Corn On The Denaturationof Salt-Soluble Proteins and Color ParametersDocument10 pagesInfluence of Drying and Hydrothermal Treatment of Corn On The Denaturationof Salt-Soluble Proteins and Color ParametersShania GintingNo ratings yet