Professional Documents

Culture Documents

Process Design For Production of Acetone and Phenol From Cumene

Uploaded by

MUDKANNA OMKAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Design For Production of Acetone and Phenol From Cumene

Uploaded by

MUDKANNA OMKARCopyright:

Available Formats

Process Design for Production of Acetone and Phenol from

Cumene

Chemical processes; Material and Energy balance; Process design; Vessel

sizing; Process flow diagram design; Process and Instrumentation diagram

design; Process utility diagram design; Process optimization

Guides Abstract

Dr. Satchidananda Satpute This research article presents a comprehensive study on the design and

manufacturing process of acetone and phenol from cumene. The production of these

Authors compounds involves several critical steps, such as oxidation, separation, and

purification, which are thoroughly discussed in this study. The manufacturing phase

Omkar Mudkanna

of this process focuses on scaling up the designed process to an industrial level. Key

Mihir Gole

factors, including reactor design, process control, and safety measures, are

meticulously considered to ensure efficient and reliable production. Equipment

Group Leaders’

selection and optimization, along with operational parameter adjustments, play a

Omkar Mudkanna crucial role in achieving high yield, purity, and product quality. This research further

emphasizes the development of a conceptual design for process control, along with

Software’s used the optimization of reactor sizing and equipment specifications using Aspen HYSYS

AutoCAD 2D simulation software. Moreover, conceptual designs for process flow diagrams (PFD),

Aspen HYSYS

piping and instrumentation diagrams (PID), and equipment layouts utilizing

Microsoft Excel

AutoCAD software are provided. The integrated approach presented in this study

aims to offer valuable insights for the design and manufacturing of acetone and

Publication Status phenol from cumene, contributing to the advancement of industrial processes in the

N/A ( Industrial design problem )

chemical sector.

Authors’ Contributions

Omkar Mudkanna's contributions to the research include the development of

process flow diagrams (PFD), piping and instrumentation diagrams (PID), and

equipment layouts using AutoCAD software, as well as the creation of material and

energy balance sheets and equipment design in Excel. Mihir Gole's contributions

involve conducting process optimization and safety analysis using Aspen HYSYS

software, aiming to enhance the efficiency and safety of the acetone and phenol

manufacturing process.

You might also like

- Kundan Kumar Mechanical Engineer ManufacturingDocument4 pagesKundan Kumar Mechanical Engineer ManufacturingMelinda WaltersNo ratings yet

- Htmanufac System DesingDocument13 pagesHtmanufac System Desingakash7190No ratings yet

- 1 s2.0 S2214785322022945 MainDocument7 pages1 s2.0 S2214785322022945 MainJosé LuisNo ratings yet

- Current Trend in Computer Aided Process Planning: October 2001Document13 pagesCurrent Trend in Computer Aided Process Planning: October 2001starboyNo ratings yet

- CAD 2011 DemolyDocument20 pagesCAD 2011 DemolyAli NasseriNo ratings yet

- Casting Cost Estimation in An Integrated Product ADocument20 pagesCasting Cost Estimation in An Integrated Product AshasaNo ratings yet

- Optimized Methodology To Build An Integrated SolutDocument9 pagesOptimized Methodology To Build An Integrated Soluthoangduy7696No ratings yet

- Optimized Methodology To Build An Integrated SolutDocument9 pagesOptimized Methodology To Build An Integrated SolutSanat KumarNo ratings yet

- Change ManagementDocument9 pagesChange ManagementHassaanNo ratings yet

- CastingProcess Plan CBRDocument10 pagesCastingProcess Plan CBRImags GamiNo ratings yet

- Process Design Engineering Manual Part 1-1Document67 pagesProcess Design Engineering Manual Part 1-1Shrikant Yadav100% (1)

- Process Design EngineeringDocument196 pagesProcess Design EngineeringAriyanto Purnomo IlBewokll100% (2)

- Abdurrahman M Syed: Professional SummaryDocument3 pagesAbdurrahman M Syed: Professional SummaryRamesh AmuluruNo ratings yet

- Sulphur Acid Plant Modelling (PFD Detailed) PDFDocument5 pagesSulphur Acid Plant Modelling (PFD Detailed) PDFCristian GómezNo ratings yet

- Design of Spoon Mold Using Flow Analysis and Higher End Design SoftwareDocument6 pagesDesign of Spoon Mold Using Flow Analysis and Higher End Design SoftwareashishNo ratings yet

- 3 RDDocument21 pages3 RDGODWYN MNo ratings yet

- JBSMSE 2016 Celik Rennie AkinciDocument16 pagesJBSMSE 2016 Celik Rennie AkinciAnonymous PufNjgNo ratings yet

- Medical Device Engineer ResumeDocument3 pagesMedical Device Engineer ResumeAbdul samiNo ratings yet

- 1 OnlineDocument13 pages1 OnlineNguyen Tran Bao Tram B2011771No ratings yet

- Puzzle Bar 6061: ObjectivesDocument1 pagePuzzle Bar 6061: ObjectivesManuel LopezNo ratings yet

- Design and Optimization of Aircraft Assembling Based On Comprehensive Simulation of Manufacturing Processes - A. Rozhdestvensky, O. SamsonovDocument10 pagesDesign and Optimization of Aircraft Assembling Based On Comprehensive Simulation of Manufacturing Processes - A. Rozhdestvensky, O. SamsonovSamuel JiménezNo ratings yet

- Chapter 1 - Part1Document20 pagesChapter 1 - Part1SyafiyatulMunawarahNo ratings yet

- Optimization of Facility Layout For Improvement in ProductivityDocument7 pagesOptimization of Facility Layout For Improvement in ProductivityTania MajumderNo ratings yet

- 1 s2.0 S2214785321015327 MainDocument8 pages1 s2.0 S2214785321015327 MainJorge MoralesNo ratings yet

- To Understand The Application of Computers in Various Aspects of Manufacturing Viz., Design, Proper Planning, Manufacturing Cost, Layout & Material Handling SystemDocument33 pagesTo Understand The Application of Computers in Various Aspects of Manufacturing Viz., Design, Proper Planning, Manufacturing Cost, Layout & Material Handling Systemmkumar_234155No ratings yet

- Rohini 51209880610Document46 pagesRohini 51209880610pariNo ratings yet

- Ijs DR 1604042Document6 pagesIjs DR 1604042Habtamu GesesuNo ratings yet

- Control Cabinet Manufacturing 4.0 StudyDocument19 pagesControl Cabinet Manufacturing 4.0 StudyHitesh PanigrahiNo ratings yet

- A Guide To Chemical Process Design and OptimizationDocument36 pagesA Guide To Chemical Process Design and OptimizationAbarasi HartNo ratings yet

- MSEC2018-6613: An Approach To Complete Product Definition Using Step in Cloud ManufacturingDocument9 pagesMSEC2018-6613: An Approach To Complete Product Definition Using Step in Cloud ManufacturingMukunthNo ratings yet

- Application of CAD/CAE Tools in The Design and Analysis of Plastic Injection MouldDocument10 pagesApplication of CAD/CAE Tools in The Design and Analysis of Plastic Injection MouldARVIN ARSENALNo ratings yet

- Vishnu Priya RamakrishnanDocument2 pagesVishnu Priya RamakrishnanarunashireenNo ratings yet

- Midas NFX BrochureDocument36 pagesMidas NFX BrochureApoorv SharmaNo ratings yet

- Installation of Pharmaceutical Process Piping - A Case StudyDocument5 pagesInstallation of Pharmaceutical Process Piping - A Case StudyVarun ZotaNo ratings yet

- Anil CV 20170101Document4 pagesAnil CV 20170101ANILNo ratings yet

- Design, Fabrication and Development of Portable Oxygen GeneratorDocument4 pagesDesign, Fabrication and Development of Portable Oxygen GeneratorBotch BelmiNo ratings yet

- 150 37 682 2 10 20220301 PDFDocument11 pages150 37 682 2 10 20220301 PDFSoliman MohamedNo ratings yet

- Process Design Development and Comparison of Different ProcessesDocument27 pagesProcess Design Development and Comparison of Different ProcessesAbdisa GemechuNo ratings yet

- Concurrent Engineering PDFDocument9 pagesConcurrent Engineering PDFLeo Dev WinsNo ratings yet

- Applied Sciences: Layout Design and Die Casting Using CAE Simulation For Household AppliancesDocument11 pagesApplied Sciences: Layout Design and Die Casting Using CAE Simulation For Household AppliancesOsman ErsanNo ratings yet

- Keywords:-Bill of Materials (Boms), Production LayoutDocument33 pagesKeywords:-Bill of Materials (Boms), Production LayoutAnonymous izrFWiQNo ratings yet

- ME 473 Unit 6ADocument19 pagesME 473 Unit 6AAma Serwaa YeboahNo ratings yet

- An Optimisation Framework For Designs For Additive Manufacturing Combining Design Manufacturing and PostprocessingRapid Prototyping JournalDocument16 pagesAn Optimisation Framework For Designs For Additive Manufacturing Combining Design Manufacturing and PostprocessingRapid Prototyping JournalBalakrishna T SNo ratings yet

- Current Trend in Computer Aided Process Planning: Authers: Nafis Ahmad, Dr. A.F.M. Anwarul Haque, Dr. A. A. HasinDocument12 pagesCurrent Trend in Computer Aided Process Planning: Authers: Nafis Ahmad, Dr. A.F.M. Anwarul Haque, Dr. A. A. HasinRajeshNo ratings yet

- Ergonomics Oversight in Engineering DesignDocument11 pagesErgonomics Oversight in Engineering Designabhimanyu adhikaryNo ratings yet

- Unmsm/Fqiq/Epiq/Daadp/Inglés Técnico/Ef14/2020-I Chapter 1. Diagrams For Understanding Chemical ProcessesDocument4 pagesUnmsm/Fqiq/Epiq/Daadp/Inglés Técnico/Ef14/2020-I Chapter 1. Diagrams For Understanding Chemical ProcessesKevin Javier QuispeNo ratings yet

- JOIE - Volume 12 - Issue 2 - Pages 21-32Document12 pagesJOIE - Volume 12 - Issue 2 - Pages 21-32sam mammoNo ratings yet

- Taus IfDocument3 pagesTaus IftausifkagziNo ratings yet

- Design and Fabrication Technology of A PAU and PARDocument7 pagesDesign and Fabrication Technology of A PAU and PAR1988praveen.mpNo ratings yet

- Manufacturing Feature-Based Cost Estimation of Cast Parts: AbstractDocument6 pagesManufacturing Feature-Based Cost Estimation of Cast Parts: AbstractproffrahulNo ratings yet

- Using Value Stream Mapping ToDocument12 pagesUsing Value Stream Mapping ToAlexanderHFFNo ratings yet

- Chemical Plant Design and Process EconomicsDocument14 pagesChemical Plant Design and Process Economicsespinosa_mra978No ratings yet

- Computer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - inDocument12 pagesComputer Aided Manufacturability Analysis of Die-Cast Parts: Pvmrao@mech - Iitd.ac - in Tkkundra@mech - Iitd.ac - indamonlanglois100% (1)

- Concurrent Engineering Development and Practices For Aircraft Design at AirbusDocument9 pagesConcurrent Engineering Development and Practices For Aircraft Design at Airbusanon_658728459No ratings yet

- Cost Benefit Analysis of Rapid Manufacturing in Automotive IndustriesDocument9 pagesCost Benefit Analysis of Rapid Manufacturing in Automotive IndustriesAditya TiwariNo ratings yet

- Unit 1Document26 pagesUnit 1bhargav kotadiyaNo ratings yet

- On Case Studies For Concurrent Engineering Concept in Shipbuilding IndustryDocument16 pagesOn Case Studies For Concurrent Engineering Concept in Shipbuilding IndustryAman BaghelNo ratings yet

- Shinno 2006Document11 pagesShinno 2006cutiepieNo ratings yet

- Productivity Gains in A Line Flow Precast Concrete Process After A Basic Stability EffortDocument9 pagesProductivity Gains in A Line Flow Precast Concrete Process After A Basic Stability Effortumaandressaqualquer2.0No ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Netapp Cloud Volumes Ontap and Veeam Backup & Replication Buyer'S Guide and Reviews July 2020Document32 pagesNetapp Cloud Volumes Ontap and Veeam Backup & Replication Buyer'S Guide and Reviews July 2020osoriohjNo ratings yet

- SensIt 161 ExampleDocument17 pagesSensIt 161 ExampleMessy CoolNo ratings yet

- Turmeric ProposalDocument7 pagesTurmeric ProposalVIVIAN BINUEZANo ratings yet

- Improving Project Documentation and Quality with 3D Reality Capture (35 charactersDocument4 pagesImproving Project Documentation and Quality with 3D Reality Capture (35 charactersVis Dom100% (1)

- 488 - ASM2 - Huyen TrangDocument28 pages488 - ASM2 - Huyen TrangHuyền Trang ÔngNo ratings yet

- Autocad 3D Max Revit Brochure SoftproDocument18 pagesAutocad 3D Max Revit Brochure SoftproMruga RautNo ratings yet

- Final Thesis Smart Home Food Delivery AppDocument76 pagesFinal Thesis Smart Home Food Delivery Appnik droidNo ratings yet

- Ciphertrace - DS Armada Inspector 20201203Document2 pagesCiphertrace - DS Armada Inspector 20201203GaurEeshNo ratings yet

- Srs Document For Tour Guide SystemDocument4 pagesSrs Document For Tour Guide Systemsibhat mequanintNo ratings yet

- Resume - Scott Lipinoga - 2023Document2 pagesResume - Scott Lipinoga - 2023scott lipinogaNo ratings yet

- ONLINE FOOD ORDERDocument12 pagesONLINE FOOD ORDERBasit FayazNo ratings yet

- The Beginners Guide To Bug Bounty Programs PDFDocument23 pagesThe Beginners Guide To Bug Bounty Programs PDFjhondavid100% (1)

- Module 4 - MKTG 206Document17 pagesModule 4 - MKTG 206HarshitaNo ratings yet

- Practice Test and AnswerDocument97 pagesPractice Test and AnswerKien NguyenNo ratings yet

- Meesho (B)Document3 pagesMeesho (B)rishabh mundhadaNo ratings yet

- User Acceptance Testing ChecklistDocument2 pagesUser Acceptance Testing ChecklistJaved Ahmad QureshiNo ratings yet

- Barangay E-Complaint Management SystemDocument66 pagesBarangay E-Complaint Management SystemRodalita MandoNo ratings yet

- Lecture 02 - The Need For Security-2Document48 pagesLecture 02 - The Need For Security-2Umair AmjadNo ratings yet

- A Structural Equation Model For Analyzing The Impact of ERP On SCMDocument14 pagesA Structural Equation Model For Analyzing The Impact of ERP On SCMBruno RezendeNo ratings yet

- #1 Engineering Project Management (1) - SUMMARY OF Initiating and PlanningDocument14 pages#1 Engineering Project Management (1) - SUMMARY OF Initiating and PlanningtaanvisworldNo ratings yet

- KyliemccabeDocument1 pageKyliemccabeapi-272563028No ratings yet

- Study Guide For Oracle Certified MasterDocument132 pagesStudy Guide For Oracle Certified MasterpablovivasveNo ratings yet

- USDA PlanDocument48 pagesUSDA Planuser9216No ratings yet

- Accenture Powering SMB Resiliency in A COVID 19 World POVDocument16 pagesAccenture Powering SMB Resiliency in A COVID 19 World POVkushalvarshneyNo ratings yet

- Emerging Trends in Digital Marketing: November 2019Document9 pagesEmerging Trends in Digital Marketing: November 2019kushagra sonekarNo ratings yet

- Dell Company - Strategy AnalysisDocument4 pagesDell Company - Strategy AnalysisLelouch LamperougeNo ratings yet

- The Ultimate C - C - TS4CO - 2020 - SAP Certified Application Associate - SAP S/4HANA For Management Accounting (SAP S/4HANA 2020)Document2 pagesThe Ultimate C - C - TS4CO - 2020 - SAP Certified Application Associate - SAP S/4HANA For Management Accounting (SAP S/4HANA 2020)KirstingNo ratings yet

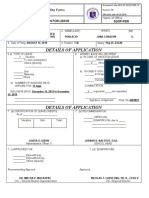

- Details of Application: Quality FormDocument2 pagesDetails of Application: Quality FormjunapoblacioNo ratings yet

- Week 1 - 11Document35 pagesWeek 1 - 11asdasdNo ratings yet

- Stylumia AssignmentDocument3 pagesStylumia AssignmentAnimE WeeBNo ratings yet