0% found this document useful (0 votes)

1K views5 pagesSop of RMG

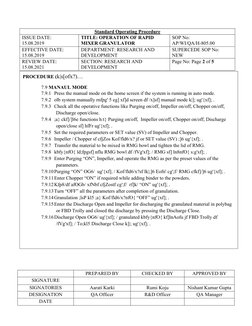

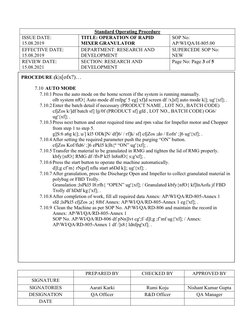

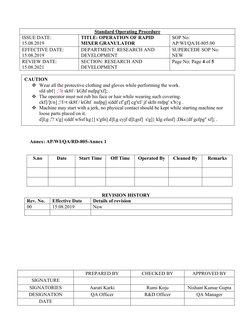

This document provides the standard operating procedure for operating a rapid mixer granulator machine. It details the steps an operator must take which include preparing the work area, ensuring proper machine clearance, setting parameters, transferring materials, and monitoring the machine during operation. The operator is responsible for following this procedure properly and cleaning the machine afterwards. Safety precautions are also provided such as wearing protective equipment.

Uploaded by

HamidCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views5 pagesSop of RMG

This document provides the standard operating procedure for operating a rapid mixer granulator machine. It details the steps an operator must take which include preparing the work area, ensuring proper machine clearance, setting parameters, transferring materials, and monitoring the machine during operation. The operator is responsible for following this procedure properly and cleaning the machine afterwards. Safety precautions are also provided such as wearing protective equipment.

Uploaded by

HamidCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd