Professional Documents

Culture Documents

Adaptive Damping

Uploaded by

sebaducatorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adaptive Damping

Uploaded by

sebaducatorCopyright:

Available Formats

ADAPTIVE DAMPING

Adaptive Damping Overview

The continuously variable damping system – known

as Adaptive Damping – is available on F-TYPE S and

F-TYPE V8 S models. Adaptive Damping is an electron-

ically controlled suspension system that continuously

adjusts the damping characteristics of the suspension

shock absorbers in response to the existing driving

conditions.

The system is controlled by an Integrated Suspension

Control Module (ISCM). The ISCM receives signals

from three accelerometers, four suspension height

sensors, and other vehicle systems to determine:

• Vehicle state

• Body and wheel motions

• Driver inputs

These signals are used by the ISCM to continuously

control the damping characteristics of each shock

absorber to the appropriate level to provide the opti-

mum body control and vehicle ride.

NP14-FT: 2014 MY F-TYPE Technical Introduction Chassis Systems | 04/15/2013 5.5

ADAPTIVE DAMPING

Adaptive Damping Components

RH REAR SHOCK ABSORBER AND SPRING INTEGRATED SUSPENSION CONTROL MODULE

RH REAR

HEIGHT SENSOR

REAR ACCELEROMETER

LH REAR SHOCK ABSORBER AND SPRING

LH REAR

HEIGHT SENSOR

RH FRONT RH FRONT LH FRONT

ACCELEROMETER HEIGHT SENSOR ACCELEROMETER

LH FRONT

HEIGHT SENSOR

RH FRONT SHOCK ABSORBER AND SPRING LH FONT SHOCK ABSORBER AND SPRING

NP14FT059

5.6 Chassis Systems | 04/15/2013 NP14-FT: 2014 MY F-TYPE Technical Introduction

ADAPTIVE DAMPING

Component Description

Shock Absorbers

The adaptive shock absorbers are nitrogen gas and oil filled monotube units. The shock absorbers are continuously

variable, which allows the damping force to be electrically adjusted while the vehicle is being driven. The shock

absorbers provide the optimum compromise between vehicle control and ride comfort.

FRONT

SHOCK ABSORBER

AND SPRING

REAR

SHOCK ABSORBER

AND SPRING

NP14FT060

NP14-FT: 2014 MY F-TYPE Technical Introduction Chassis Systems | 04/15/2013 5.7

ADAPTIVE DAMPING

In each shock absorber, the damping adjustment is In the firm setting, oil flows through the main (firm)

achieved by a variable orifice operated by a solenoid. The valve only, although when the bypass is opened

orifice is used to open up alternative paths to allow oil by variable amounts, the oil flows through both

flow within the shock absorber. When de-energized, the valves – allowing the shock absorber to operate in

bypass is closed and all the oil flows through the main a softer setting. When fully energized, the solenoid

(firm) piston. When energized, the solenoid moves an moves the armature (and therefore the slider) to the

armature and control blade, which work against a spring. maximum extension and opens the orifice completely.

The control blade incorporates an orifice that slides inside The shock absorber operates continuously between

a sintered housing to open up the bypass as required. these two boundary conditions.

When the shock absorber is compressed, the oil flows

The solenoid in each shock absorber is operated by

from the lower portion of the shock absorber through

a 526 Hz Pulse Width Modulation (PWM) signal from

a hollow piston rod, which is a separate soft (comfort)

the ISCM. The ISCM controls the PWM duty ratio to

valve. The oil then flows through the slider housing and

provide 1.5A to operate the shock absorber in the soft

orifice into the upper portion of the shock absorber,

setting. When de-energized (0.0A) the shock absorber

bypassing the main (firm) valve. In rebound, the oil flows

is in the firm setting. The current varies continuously

in the opposite direction.

as required to increase and decrease the damping

individually in each of the shock absorbers.

Shock Absorber Operating States

FIRM SETTING SOFT SETTING

PISTON AND ROD

ASSEMBLY

BYPASS VALVE: BYPASS VALVE:

CLOSED OPEN

MAIN VALVE MAIN VALVE

OUTER TUBE

MAIN OIL FLOW BYPASS OIL FLOW

NP14FT061

5.8 Chassis Systems | 04/15/2013 NP14-FT: 2014 MY F-TYPE Technical Introduction

ADAPTIVE DAMPING

Accelerometers Integrated Suspension Control Module

Three accelerometers are used in the Adaptive Damp- The Integrated Suspension Control Module (ISCM) is

ing system: two at the front of the vehicle and one at installed at the rear of the vehicle.

the rear.

The ISCM receives its power supply via a relay and

fuse in the CJB. The relay remains energized for a

period of time after the ignition is off. This allows the

ISCM to record and store any DTC relating to Adaptive

Damping system faults.

System Fault Message

If a fault is detected by the ISCM, a message is sent via

the HS CAN to the instrument cluster and the message

ADAPTIVE DAMPING FAULT is displayed. The ISCM also

logs an appropriate DTC. The ISCM can be interrogated

using a Jaguar approved diagnostic system.

When a fault is detected, the ISCM implements a

strategy based on the type of fault. If there is an elec-

NP14FT062 trical power fault, or if the ISCM cannot control the

shock absorbers, they default to the firm condition.

The accelerometers measure acceleration in the vertical If a sensor fails that only affects one or more control

plane and output a corresponding analog signal to the modes, then an intermediate damper setting is used

ISCM. The algorithms in the ISCM calculate the heave, as the lower threshold and the remaining working

pitch, and roll motions of the vehicle, which are used by modes can demand higher damping as required. In the

the controller to control road-induced body motion. event of a high speed CAN bus fault, the shock absorb-

Each accelerometer is connected to the ISCM via ers are fixed at an intermediate setting (no control) or

three wires, which supply ground, 5V supply, and sig- default to the firm condition, depending on the severity

nal return. of the fault.

Suspension Height Sensors

Four suspension height sensors are used in the Adap-

tive Damping system: two for the front suspension

and two for the rear suspension.

NP14FT064

NP14FT063

Each suspension height sensor is connected to the

ISCM via three wires, which supply ground, 5V supply,

and signal return.

NP14-FT: 2014 MY F-TYPE Technical Introduction Chassis Systems | 04/15/2013 5.9

ADAPTIVE DAMPING

Principles of Operation

The ISCM uses a combination of information from other system modules and data from the accelerometers and

suspension height sensors to measure the vehicle and suspension states and driver inputs. Using this information,

the ISCM applies algorithms to control the shock absorbers for the current driving conditions.

ISCM control functions are as follows:

ISCM Functions Input Strategy

Calculates road induced body motions 100 times per

Body Control CAN Data / Accelerometers second and sets each shock absorber to the appropriate

level to maintain a flat and level body

Predicts vehicle roll rate due to driver steering inputs

Roll Rate Control CAN Data 100 times per second and increases damping to reduce

roll rate.

Predicts vehicle pitch rate due to driver throttle and

Pitch Rate Control CAN Data braking inputs 100 times per second and increases

damping to reduce pitch rate.

Monitors the position of the wheel 500 times per second

Bump Rebound Control Height Sensors and increases the damping rate as the shock absorber

approaches the end of its travel

Monitors the position of the wheel 500 times per second

and detects when the wheel begins to vibrate at its

Wheel Hop Control Height Sensors / CAN Data

natural frequency and increases the damping to reduce

vertical wheel motion.

Under normal road conditions when the vehicle is stationary with the engine running, the shock absorbers are set

to the firm condition to reduce power consumption.

5.10 Chassis Systems | 04/15/2013 NP14-FT: 2014 MY F-TYPE Technical Introduction

ADAPTIVE DAMPING

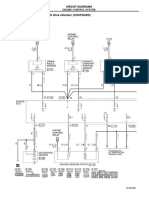

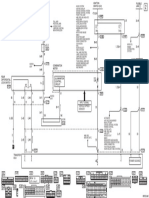

Adaptive Damping Control Diagram

2 3 4 5 6

19

18

1 7

17

8

16

15 14

12

9

10

13 11

9

A D

NP14FT065

A Hardwired 6 Engine control Module (ECM) 13 LH Rear Height Sensor

D HS CAN 7 RH Front Spring and Shock Absorber Assembly 14 RH Rear Height Sensor

1 Integrated Suspension Control Module (ISCM) 8 LH Front Spring and Shock Absorber Assembly 15 LH Front Height Sensor

2 Instrument Cluster (IC) 9 RH Rear Spring and Shock Absorber Assembly 16 RH Front Height Sensor

3 Transmission Control Switch (TCS) 10 LH Rear Spring and Shock Absorber Assembly 17 Rear Accelerometer

4 Anti-Lock Brake System Control Module (ABS) 11 Ground wire 18 LH Front Accelerometer

5 Transmission Control Module (TCM) 12 Power supply 19 RH Front Accelerometer

NP14-FT: 2014 MY F-TYPE Technical Introduction Chassis Systems | 04/15/2013 5.11

You might also like

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Whitepaper Reciprocating MachineryDocument19 pagesWhitepaper Reciprocating MachinerySofiane HalimiNo ratings yet

- Whitepaper Reciprocating Machinery PDFDocument19 pagesWhitepaper Reciprocating Machinery PDFSofiane HalimiNo ratings yet

- Adaptive Damper SystemDocument37 pagesAdaptive Damper Systemwilder0l0pezNo ratings yet

- Smart Entry System Push Button Start 15" Alloy WheelsDocument2 pagesSmart Entry System Push Button Start 15" Alloy WheelsJosh RaddleNo ratings yet

- SUBARU AbsDocument12 pagesSUBARU Absamrelshawarby100% (1)

- BMW E60 Dynamic DriveDocument33 pagesBMW E60 Dynamic Driveemiliqn velikovNo ratings yet

- A Review of Antilock Braking and Traction Control SystemsDocument8 pagesA Review of Antilock Braking and Traction Control SystemsRamParvathaneniNo ratings yet

- Manual OyM - Compresor 900hDocument2 pagesManual OyM - Compresor 900hCARLOSNo ratings yet

- Alexander Dennis Enviro 400Document6 pagesAlexander Dennis Enviro 400Agustin BerriosNo ratings yet

- Engince Control CircuitsDocument12 pagesEngince Control Circuitsferas alkassmNo ratings yet

- Brake ControlDocument105 pagesBrake ControlLuis PerezNo ratings yet

- Barnetts ch38 SuspensionforksDocument74 pagesBarnetts ch38 SuspensionforksJonathan BishopNo ratings yet

- Tire Pressure Monitoring SystemsDocument19 pagesTire Pressure Monitoring SystemsRavi GoyalNo ratings yet

- Hybrid Vehicle ControlDocument600 pagesHybrid Vehicle ControlMirceaNo ratings yet

- Wabco IngDocument45 pagesWabco IngNicu TerciuNo ratings yet

- LH Drive Vehicles-03-01Document1 pageLH Drive Vehicles-03-01oretuertoyanapaNo ratings yet

- Nissan Almera n15 Series Service ManualDocument1,712 pagesNissan Almera n15 Series Service ManualFieru CorsuNo ratings yet

- Mitsubishi Triton: ABS and ASTC Overview: 2006 - 2009 ML Triton 2009 - 2014 MN TritonDocument10 pagesMitsubishi Triton: ABS and ASTC Overview: 2006 - 2009 ML Triton 2009 - 2014 MN Tritonjorge Angel Lope100% (1)

- Wspwheelsliding ProtectionsystemDocument40 pagesWspwheelsliding ProtectionsystemAdithya BandiNo ratings yet

- Pico ScopeDocument161 pagesPico ScopeDavianGiurca100% (1)

- WelcomeDocument80 pagesWelcomeAhemad100% (1)

- US Chamm8997Document46 pagesUS Chamm8997SuckmytickNo ratings yet

- DRZX Angle Sensor 1.6-3.4 Volt AdjustementDocument9 pagesDRZX Angle Sensor 1.6-3.4 Volt AdjustementMBAREKNo ratings yet

- Activity 4 CompleteDocument12 pagesActivity 4 CompleteMelissa CamargoNo ratings yet

- ls9 Crate Engine Control System 19354338Document40 pagesls9 Crate Engine Control System 19354338Sebastian OlayaNo ratings yet

- XK8 CATS SuspensionDocument6 pagesXK8 CATS Suspensionjuha_teuvonnen100% (1)

- Kyron ChassisDocument1,172 pagesKyron Chassistallerr.360No ratings yet

- FRR 1O7-21O Tipper: Now With Sat Nav Fitted As StandardDocument4 pagesFRR 1O7-21O Tipper: Now With Sat Nav Fitted As StandardHugo RodriguezNo ratings yet

- Honda Combined ABS: Press InformationDocument7 pagesHonda Combined ABS: Press Informationapi-3815109No ratings yet

- Almera: GI MA EM EM LC EC FE CL - 5Mt CL - 6Mt MT - 5Mt MT - 6Mt AT AX SU BR ST RS BT HA ATC SC EL IDXDocument1 pageAlmera: GI MA EM EM LC EC FE CL - 5Mt CL - 6Mt MT - 5Mt MT - 6Mt AT AX SU BR ST RS BT HA ATC SC EL IDXAlex RonNo ratings yet

- HINO US Chap07Document48 pagesHINO US Chap07Andres Gomez0% (1)

- Section A: Transmission Familiarization: Allison Off-Highway TransmissionsDocument8 pagesSection A: Transmission Familiarization: Allison Off-Highway Transmissionsamin chaabenNo ratings yet

- Pub20025871 A Eng GBDocument11 pagesPub20025871 A Eng GBJulio FernandoNo ratings yet

- Anti Lock Brake System ABSDocument90 pagesAnti Lock Brake System ABSXuân VinhNo ratings yet

- Relay BOXDocument1 pageRelay BOXLuiz Ricardo StocoNo ratings yet

- US Chap07Document34 pagesUS Chap07Xuân VinhNo ratings yet

- Chapter3 Automotive Embedded ApplicationsDocument156 pagesChapter3 Automotive Embedded ApplicationsKomal KalkutkarNo ratings yet

- MAVA FAN Digital Catalog Ver.8 MidDocument22 pagesMAVA FAN Digital Catalog Ver.8 Mid3623 DarwishNo ratings yet

- DSC Part 2Document15 pagesDSC Part 2Nguyễn Hoàng LongNo ratings yet

- Daelim S3 125cc Service Manual ENG PDFDocument253 pagesDaelim S3 125cc Service Manual ENG PDFJULIO100% (1)

- Automotive Horn System CompleteDocument6 pagesAutomotive Horn System CompleteTaha Kassala100% (1)

- Teves ABS ModuleDocument44 pagesTeves ABS ModuleAlex KuzmenkoNo ratings yet

- UN5000 Excitation SystemDocument36 pagesUN5000 Excitation SystemDinesh Prasad Senapati100% (1)

- Engine Control System 1. General: Engine K3-Ve Engine EG-28Document13 pagesEngine Control System 1. General: Engine K3-Ve Engine EG-28foreman pemudaNo ratings yet

- Fssabs We 0125msDocument59 pagesFssabs We 0125mshigui2013No ratings yet

- Acceleration and Vibration SensorDocument28 pagesAcceleration and Vibration Sensoramirul lexNo ratings yet

- Adaptive Braking Systems (ABS) : National Semiconductor System Brief 106 October 1990Document6 pagesAdaptive Braking Systems (ABS) : National Semiconductor System Brief 106 October 1990Hari S PillaiNo ratings yet

- Diagnostico Freios Abs MK Ii PDFDocument17 pagesDiagnostico Freios Abs MK Ii PDFtadeuNo ratings yet

- lt4 Erod Engine Installation Guide 19356048 19417727Document83 pageslt4 Erod Engine Installation Guide 19356048 19417727Carl YelvingtonNo ratings yet

- 0013 TR-10 Series ManuelDocument66 pages0013 TR-10 Series ManuelPartagon Pow0% (1)

- Brake ControlDocument86 pagesBrake ControlNicolás BozzoNo ratings yet

- Steering ObrtitolDocument52 pagesSteering ObrtitolJose FigueroaNo ratings yet

- 3406Document4 pages3406Ivan Morel100% (2)

- Thrust Position, Differential Expansion, and Rod Position Monitor SpecificationsDocument1 pageThrust Position, Differential Expansion, and Rod Position Monitor SpecificationsTu PhamNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Bstab 5 & 6 Improvement Project MLNG TigaDocument5 pagesBstab 5 & 6 Improvement Project MLNG Tigaanon_714194540No ratings yet

- Digital TachometerDocument5 pagesDigital TachometerAnwaar SafdarNo ratings yet

- CH 10 Task 10eDocument2 pagesCH 10 Task 10eJay RodneyNo ratings yet

- Cat Forklift t40d t50d Service ManualDocument27 pagesCat Forklift t40d t50d Service Manualalexhughes210188sxi98% (49)

- Company Oil Type Product # Brand Name Company Type Nu-Calgon Replacement Viscosity Sus/IsoDocument4 pagesCompany Oil Type Product # Brand Name Company Type Nu-Calgon Replacement Viscosity Sus/IsoHcs TeknikNo ratings yet

- Vicprop - Prop Calculator For Displacement and Semi-Displacement HullsDocument3 pagesVicprop - Prop Calculator For Displacement and Semi-Displacement HullsMuhammad Rafi SiratNo ratings yet

- Failure ManagementDocument2 pagesFailure ManagementAlexis PadillaNo ratings yet

- BrochureDocument40 pagesBrochureYousef AlipourNo ratings yet

- Accelerate - Google SearchDocument1 pageAccelerate - Google SearchpuffNo ratings yet

- Airport Engineering, Design, & Construction - AirportsDocument4 pagesAirport Engineering, Design, & Construction - AirportsdwrreNo ratings yet

- Quasar NV: Technical Specification 9-601 S-FDocument4 pagesQuasar NV: Technical Specification 9-601 S-FJean Carlos RomanNo ratings yet

- Ford Bronco Workshop Manual (V8-351 5.8L VIN G 2-Bbl (1982) )Document3,163 pagesFord Bronco Workshop Manual (V8-351 5.8L VIN G 2-Bbl (1982) )Marcos RomeroNo ratings yet

- 245 J - Ultraflex 2018Document1 page245 J - Ultraflex 2018yafet indra tjoenediNo ratings yet

- A-1 PIPE Terms Coaching Part 1Document351 pagesA-1 PIPE Terms Coaching Part 1Ralph Adrian MielNo ratings yet

- CDV-00-015 Marlow Navigation Crew Training Policies and Training ActivitiesDocument7 pagesCDV-00-015 Marlow Navigation Crew Training Policies and Training ActivitiesVasilii TatarnikovNo ratings yet

- 18bcp111 - ProjectDocument96 pages18bcp111 - Project21BA040- Renuga ANo ratings yet

- Track Side Indicator Boards and Sign AgesDocument41 pagesTrack Side Indicator Boards and Sign AgesGishnu100% (1)

- Haulotte Diesel Articulating Boom Lift HA20 RTJ PRO - Boom Lift EquipmentDocument8 pagesHaulotte Diesel Articulating Boom Lift HA20 RTJ PRO - Boom Lift EquipmentNada. PNG LtdNo ratings yet

- Lifting PlatformsDocument12 pagesLifting PlatformsHector MoragaNo ratings yet

- Soillmec®: Drilling and Foundation EquipmentDocument6 pagesSoillmec®: Drilling and Foundation EquipmentFarras ZulfahmiNo ratings yet

- SWOT Analysis On Construction IndustriesDocument21 pagesSWOT Analysis On Construction IndustriesPawan2186% (35)

- Manitou MT 1637 SL Serie 2Document2 pagesManitou MT 1637 SL Serie 2Gábor MartzNo ratings yet

- Wuling Confero SDocument2 pagesWuling Confero SMP AditNo ratings yet

- Live Graving Dry DockDocument36 pagesLive Graving Dry DockAshiq AbdullahNo ratings yet

- Overview of Hybrid Excitation Synchronous Machines TechnologyDocument10 pagesOverview of Hybrid Excitation Synchronous Machines TechnologyMurat Erhan BalciNo ratings yet

- Main Parameters of XCMG Wheel Loader LW300KDocument2 pagesMain Parameters of XCMG Wheel Loader LW300KRAMON CALDERONNo ratings yet

- 3 - Idt Af - BKMDocument106 pages3 - Idt Af - BKMVishnuNo ratings yet

- Wilton Plane CrashDocument3 pagesWilton Plane CrashEricNo ratings yet

- A70e1fa5925da00958ada7900 PDFDocument2 pagesA70e1fa5925da00958ada7900 PDFAravindhan Gunasekaran PaediatricianNo ratings yet

- 2014 Rockshox SPC Rev ADocument110 pages2014 Rockshox SPC Rev AfmbasilioNo ratings yet