Professional Documents

Culture Documents

Proximate Analysis of Saw Dust From Tipper Garage Saw Mill Lugbe Abuja Nigeria To Be Uploaded Into The Abundant Regional

Uploaded by

Shafira RiskinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proximate Analysis of Saw Dust From Tipper Garage Saw Mill Lugbe Abuja Nigeria To Be Uploaded Into The Abundant Regional

Uploaded by

Shafira RiskinaCopyright:

Available Formats

Kwaji MJ, et al.

J Ecosys Ecograph 2020, 10:3

Journal of Ecosystem and Ecography

Research Article Open Access

Proximate Analysis of Saw Dust from Tipper Garage Saw Mill Lugbe,

Abuja Nigeria to be Uploaded into the Abundant Regional Substrate

Database for Biogas Production

Magdaline Joseph Kwaji1*,Niyi Ogunjobi1, Oyedeji TT2, Ayoade Desmond Babalola3, Lawyer EF4, Richard Olebe TC1 and Hajara lakka

Durkwa5

1

Department of Microbiology,University of Ibadan,Nabda, Biodec, Abuja

2

Department of National Biotechnology Development Agency,Abuja

3

Department of Biochemistry, University of Ibadan,Biodec, Abuja

4

Department of Biotechnology and National Centre for Genetic Resources, Nabda, Biodec, Abuja

5

National Centre for Genetic Resources and Biotechnology, Moor Plantation, Apata, Ibadan

Abstract

In view of the ever increasing costs and the negative environmental impacts of petroleum-based fuels and enormous amount of

sawdust generated yearly in Nigeria. This study was undertaken to assess the suitability of sawdust as source of energy by determining

their chemical properties via proximate analysis carried out at the International Institute of Tropical Agriculture, Ibadan, Oyo state, Nigeria.

The results shows the moisture to be (%MC) 9.08 of the sawdust samples, respectively, the ash contents (%Ash) was 2.8 and the organic

matter was 88.10 and the fixed carbon contents ranged between 51.10%, Nitrogen (N) was 0.2.The chemical properties showed that

the sawdust of wood would be suitable as source of energy for thermal plant, electricity and automobile engines compared with those

of Nigerian coal species. The required [C:N] ratio for optimum biogas production in organic matter ranges from 20:1 and 30:1. The [C:N]

ratio obtained in this work is 50:0.1 which implies that the substrate or wood have a very high concentration of carbon and is deficient in

Nitrogen. Therefore, if this wood substrate must be used for biomethenation, nitrogen should be augmented by using supplements rich in

nitrogen such as tannery effluent, corn, soya bean milk, ground nut cake, gram flour, ammonium sulfate and urea during pretreatment of

substrates, and also, the concentration of carbon must be regulated to meet up with the biomethane potential (BMP) requirement for this

substrate. The aim of this work is geared towards determining the chemical constituents of this substrate and to ascertain it’s usability in

biomethenation, to be added to the substrate biomethane potential (BMP) database of these substrates for referral purposes in scientific

findings and research. This is because optimum methanization (biogas production) is only possible with the right range of pH, Carbon,

Nitrogen, Carbon Nitrogen ratio, ash content, sulfur and others of these factors and macro nutrients.

Keywords: Chemical properties; Nigerian coal; Biomethenation; (0.9%) which were the major components analyzed in this work. Dry

Biomethane potential wood is primarily composed of cellulose, lignin, hemicelluloses, and

minor amounts (5%–10%) of extraneous substances (Horisawa et al.,).

Introduction India is found as 4th largest petroleum consuming country followed by

As a result of increasing global concern regarding environmental USA, China and Japan, with high impact on grown economy of 6%–

impacts especially climate change from the use of fossil and, the need 8% per year which can create further strong dependency on various

for an independent energy supply to sustain economic growth and type of petroleum products (petrol, kerosene or natural gases) with

development, there is currently a great deal of interest in renewable more environmental causing health problems, risks and challenges like

energy in general. McKendry [1] reported that biomass is one of the global warming and climate change. Biogas and biomass based energy

most common and easily accessible renewable energy resources and (bioethanol and biohydrogen) production can be provided good option

gives opportunity as a feed stock for bioenergy. Odunlami et al. [2] for replacing fossil fuel energy via developing and enhancing cost-

reported the implication of the use of fossil fuels. As rightly noted by effectiveness bioprocess for bioenergy opportunity in rural communities

Stout and Best [3], a transition to a sustainable energy system is urgently worldwide. Third-generation biofuels from wood sawdust species can

needed for developing countries. Sawdust is a waste from the wood and be suitably synthesized with environmental, economical and social

timber industry. As it possesses a firing capacity, it is normally used benefits for the worldwide population with reflection of high energy

as a fuel source in thermal processes (biomass) [4]. It is also used as efficiency for road map of individual to industry level consumption.

insulating material, and in this work, as substrate for developing the Different types of wood waste

referral database for biogas production. Biogas is primarily a mixture

of carbon dioxide, methane, hydrogen sulfide and other trace elements Plate 1: Waste of lingo cellulosic biomass (Figure 1)

produced after anaerobic digestion by microorganism (Renu Bala et al.,).

This is achieved by the breakdown of complex polymeric substances *Corresponding author: Kwaji MJ, Department of National Biotechnology

such as carbohydrate, protein, fatty acid to simple compounds like Development Agency, Biodec Odi, Abuja, Bayelsa, Nigeria, E-mail:

carbon dioxide (CO2), methane (CH4), hydrogen sulfide and other magdalinejoseph8@gmail.com

trace elements. Miguel et al., [5] described the chemical composition Received: August 21, 2020; Accepted date: September 05, 2020; Published

in tree (Alnus acuminata, A. jorullensis, Quercus candicans) branches date: September 12, 2020

use as wood in Mexico. These chemical composition in tree were Citation: kwaji MJ, Ogunjobi N, Oyedeji TT, Babalola AD, Lawyer EF,

determined and the tanin content was evaluated by two methods of Olebe RTC,Lakka L (2020) Proximate Analysis of Saw Dust from Tipper

extraction: aqueous extraction and ethanolic extraction, in general, Garage Saw Mill Lugbe, Abuja Nigeria to be Uploaded into the Abundant

the result obtained varied as follows: (4.25-5.19), (0.08%-10.23%), Regional Substrate Database for Biogas Production. J Ecosys Ecograph

total extractives (6.9%-49.5%), solubility to soda (25.36-70.9), Runkel 10: 275

lignin (17.64%-47.33%), holocellulose (32.74%-86.51%). The main Copyright: © 2020 Kwaji MJ. This is an open-access article distributed under the

chemical components (in terms of macro-nutrients) of sawdust are terms of the Creative Commons Attribution License, which permits unrestricted

carbon (60.8%), hydrogen (5.2%), and oxygen (33.8%), and nitrogen use, distribution, and reproduction in any medium, provided the original author and

source are credited.

J Ecosys Ecograph, an open access journal Volume 10 • Issue 3 • 1000275

ISSN: 2157-7625

Citation: kwaji MJ, Ogunjobi N, Oyedeji TT, Babalola AD, Lawyer EF, Olebe RTC,Lakka L (2020) Proximate Analysis of Saw Dust from Tipper Garage

Saw Mill Lugbe, Abuja Nigeria to be Uploaded into the Abundant Regional Substrate Database for Biogas Production. J Ecosys Ecograph

10: 275

Page 2 of 4

The first biomass in plate 1 represent SAWDUST Determination of dry ash

The second biomass represents WOODCHIP Dry ash was determined using a high temperature muffle furnace

The third biomass represents PEATS capable of maintaining temperatures between 500°C and 600℃

(Averagely 550).Water and other volatile materials was vaporized and

The fourth biomass represents the BARKCHIP

organic substances were burned in the presence of the oxygen in air

The fifth biomass represents the RAPESTRAW to CO2, H20 and N2 which gives the ash content when measured in

The sixth biomass represents the WHEATSRAW grams. Most minerals were converted to oxides, sulfate, phosphates,

chlorides and silicate. Although most minerals have fairly low volatility

at these high temperature, some are volatile and may be partially lost,

e.g., iron, lead and mercury. The sample was weighed before and after

ashing to determine the concentration of ash present.

The ash content can be expressed as:

%Ash=(Mass of Arsh/Mass of dried sample) ×100 [7].

Determination of organic matter

Principle: The sample was ignited slowly in a muffle furnace to a

final temperature of 550°C. The loss in weight represents the moisture

and organic matter content of the sample, while the residue represents

the ash.

Procedure: 10 - 0.1 g of well mixed air dry (less than 2 mm) manure

or compost sample of a known moisture content was weighed in a dry

porcelain or nickel crucible. This was slowly heated in a furnace, raising

the temperature setting in steps (100°C, 200°C and 550°C). The final

temperature setting of 550°C was maintained for 8 hours.

The crucible containing a grayish white ash was removed. It was

allowed to cool in a dessicator and weighed.

Figure 1: Different types of wood waste.

Calculations: The percentage ash and organic matter was calculated

by the differences in weight of the crucibles before and after combustion

Materials and Methods as follows:

% Ash=[(w3-w1)/(w2-w1)] ×100

Source of sample

And

Saw dust samples were collected from the Saw mill located at Tipper

garage, federal Housing, airport road, Ahmadu Bello way, Lugbe, Abuja. % Organic matter=100- % Ash [8]

Sterile polyethylene bags were used to collect the sample (50 kg) and

were transported to the International Institute of Tropical Agriculture, Determination of volatile matter content

Ibadan, Ibadan, Oyo state, Nigeria.

The samples were pre weighed in two test tubes pieces of 2 g each

Chemical analysis with an AB54-S mettle Toledo balance. The volatile matter is the

condition of the material at which when heated in the absence of air

All elemental analysis was carried out at International Institute of under prescribed conditions, liberate gasses and vapours. The volatile

Tropical Agriculture, Ibadan Oyo state. matter was determined based on the procedure recommended in

150562/1974 (Debdoubi et al.,). The pre weighed sample was made to

Flow chart showing steps taken to determine total volatile content

undergo dry oxidation muffle furnace at 550+ 25’C for 10 minutes. This

by moisture lost

was removed and allowed to cool in a dessicator. The final weight of the

Crucibles with the lid was preheated for an hour. After preheating, sample was taken with the aid of Mettler Toledo analytical balance. The

the crucible was placed in a dessicator crucible to cool for 20-30 minutes. volatile matter was calculated using the formulae;

Crucible was removed from the dessicator after cooling and weighed.

%VM= Zi-Zf/ Zi × 100

Samples were weighed and fed into the crucible then the crucibles with

samples were also weighed [6]. Where

Samples and crucible was placed into oven and the temperature was Zi=Initial weight of the wood sample (before dry oxidation).

set to 105°C-115°C

Zf=Final weight of the dry wood after dry oxidation.

The oven was turned on and the timer was set

Dry Samples was dried until constant weight was achieved Determination of Fixed carbon content

After cooling, crucible was taken from dessicator and weighed The fixed carbon content of sawdust samples was determined by

to get new weight of dried sample, and then the percentage moisture using the following relationships (Debdoubi et al) as shown in the

content was calculated. formulae below.

J Ecosys Ecograph, an open access journal Volume 10 • Issue 3 • 1000275

ISSN: 2157-7625

Citation: kwaji MJ, Ogunjobi N, Oyedeji TT, Babalola AD, Lawyer EF, Olebe RTC,Lakka L (2020) Proximate Analysis of Saw Dust from Tipper Garage

Saw Mill Lugbe, Abuja Nigeria to be Uploaded into the Abundant Regional Substrate Database for Biogas Production. J Ecosys Ecograph

10: 275

Page 3 of 4

%FC=100% -%Ash -% VM about 150.

Where %Ash=Determined ash content Crucibles was removed and placed in dessicator for 30 minutes.

Samples were weighed to the nearest mg (Table 1).

%VM=determined volatile matter [9,10].

Calculation of total carbon

Determination of moisture content

Carbon by loss of ignition (%)=Weight of oven dried samples (g)-

1. Test portion containing approximately 2 g dry material was dried

weight of samples after (g) ignition / weight of dry samples. [11].

to approximately 5 hrs.

For feeds with high molasses content, temperature<70°C and

pressure<50 mmHg will be used. Results and Discussion

2. Covered AL dish>50 mm diameter and 40 mm deep was used

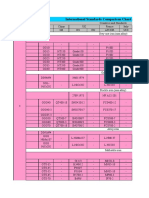

Table 1: Shows the concentration of macro elements of the sawdust samples.

3. Report loss on drying (LOD) was recorded as estimate of

Lab My N MC Ash OM (C)LOI C/N

moisture content. ID ID (%) (%) (%) (%) (%) (%)

Calculations: %(w/w) LOD=%(w/w) moisture = 100 × wt loss on 20200009 Saw dust 0.2 9.08 2.8 88.1 51 0.2:51.1

drying, g% Dry matter=100–0 Key: N: Nitrogen; MC: Moisture content; OM: Organic matter; C(loi): Carbon

(by loss of ignition); C/N: Carbon/Nitrogen ratio or C:N

Determination of total nitrogen

Some general conditions apply to the methanization of substrates

Digestion procedure: Selenium/Sulfuric acid mixture; To1 liter of in anaerobic digestion for the production of biogas [12], while other

sulfuric acid, 3.5 g of selenium powder will be added. This was heated process conditions must be kept at very strict operational ranges. Crow

on hot plate until it was clear. The selenium was dissolved into the Miller [13] where the carbon nitrogen ratio was expressed as a function

sulfuric acid at about 280. The hotplate was turned off after the selenium of the percentage concentration of carbon divided by the percentage

dissolves and was left until it cools down. concentration of Nitrogen. Electro chemical excitation can be used for

efficient nitrogen fixation also as in Liu et al., 2019 [14,15].

N/P Stock solution: 4.714 g(NH4 )2 SO4 and 0.439 g of KH2PO4

was added to a 100 ml volumetric flask. The chemical was oven dried at Conclusion

105 before weighing. This was diluted to mark.

The relationship between the process conditions is always an

Procedure: 0.200 g (of dry) was weighed out, samples was grinded important consideration for stable methanization. Therefore, the need

into a 50 ml digestion tube. 2.5 ml of H2SO4 mixture w added to the for proximate analysis cannot be overemphasized. This work gives the

sample tube and to 5 blanks, to be used as standards. These were placed concentration of macro elements essential in methanization that are

on an aluminum block on a hot plate and were heated to approximately found present in saw dust substrate domiciled in Tipper garage, Lugbe,

200 until sample fumes. Abuja. The results shows the moisture to be (%MC) 9.08 of the sawdust

Tubes was removed from hot plate and allowed to cool for 10 samples, respectively, the ash contents (%Ash) was 2.8 and the organic

minutes. 1 ml of 30% H202 was added to the sample and standards. matter was 88.10 and the fixed carbon contents ranged between 51.10%,

When the reaction subsides, 2 ml of H202 was added. Nitrogen (N) was 0.2, Carbon Nitrogen concentration [C/N] was 51.1:

0.2 which is in line with the findings of. From the findings in this work,

Tubes were replaced on hot plate and 15 ml glass vial was placed carbon nitrogen ratio is 51:0.2 which gives a very wide interval range.

on top of each tube and heated to 330. The tubes were left on hot plate This entails that if this substrate is to be used for bio methnation, the

until a clear solution is formed (2 hrs). The yellow tints of the sample concentration of nitrogen should be supplemented with nitrogen rich

disappear as the digestion is completed. substrate as groundnut cake, urea, gram flour, ammonium sulfate

Samples were allowed to cool. 0, 0.200, 0.400, 0.600 and 0.800 and soya bean milk. Therefore, the relationship between the process

ml of the N/P stock solution was added to the 5 standard solutions. conditions and chemical elements is always an important factor for

Samples and standards were diluted to the 50 ml mark. Samples were stable methanization.

transferred into the auto analyzer cup. Nitrogen content was read on

the auto analyzer machine.

References

1. McKendry P (2002) Energy production from biomass (part 1): Overview of

Note: These can also be used to calculate protein content using this biomass. Resource Technol 83:37-46.

formula 2. Odunlami OA, Elehinafe FB, Oladimeji TE, Fajobi MA, Akeredolu FA, et al.

(2018) Implications of lack of maintenance of vehicles on Ambient Air Quality,

Protein= %N × 6.25 [11]. 9: 647-654.

Determination of total carbon (LOI) (Loss of ignition) 3. Stout BA, Best G (2001) Effective energy use and climate change needs of rural

areas in developing countries. Agricultural Eng Internat: CIGR E-J Scientific

Principle: Organic matter was oxidized by heating at 500 and was Res Devel 111:19.

estimated as weight in loss.

4. Zerbe JI (2004) Non Wood products/ Energy from wood. Energy from wood

Procedure: Porce clean crucibles were heated for one hour at Chemicals from wood Cork Oak, Resins, Latex and Palm oil Rubber Trees

Seasonal Greenery. USDA Forest Products Laboratory, Madison, WI, USA.

375.Crucibles was allowed to cool to about 150. This was placed in a

dessicator and cooled for 30 minutes and weighed.5 g of the sample was 5. Angel M, Gutirrez C, Euginia F (2018) In chemical components of the branches

of six hardwood species. Wood Research 63: 795-808.

weighed into the crucible. Sample was placed slowly and temperature

was increased to 500+ 5 .The temperature was maintained (500-5) for 6. Ruiz IS, Colin R, Ward (2008) Basic Factors Controlling Coal Quality and

5 hrs. Furnance was turned off and temperature was allowed to drop to Technological Behaviour of Coal. Elsevier, Process Chemistry of Coal

Utilization.

J Ecosys Ecograph, an open access journal Volume 10 • Issue 3 • 1000275

ISSN: 2157-7625

Citation: kwaji MJ, Ogunjobi N, Oyedeji TT, Babalola AD, Lawyer EF, Olebe RTC,Lakka L (2020) Proximate Analysis of Saw Dust from Tipper Garage

Saw Mill Lugbe, Abuja Nigeria to be Uploaded into the Abundant Regional Substrate Database for Biogas Production. J Ecosys Ecograph

10: 275

Page 4 of 4

7. Bboluwaji EF, Babatunde OO, Abosede OO, Onose MA, Bamidele S, et al. 12. Mir MA, Hussain A ,Verma C (2016) Design considerations and operational

(2019) Proximate analysis of the properties of some southwestern Nigeria performance of anaerobic digester. A review, Cogent Eng. 3: 1181696.

Sawdust of different wood species. Internat J Civil Eng Technol 10: 51-59.

13. Miller C (2000) Carbon Nitrogen ratio: Understanding components chemical

8. Escosteguy PAV, Galliassi K, Caretta CA (2007) Soil organic matter elements in organic matter. Acres U.S.A magazine.

determination by loss on ignition in samples from the state of Rio Grande do

Sul, Brazil. R. Bras. Ci. Solo 31:247-255. 14. Liu S, Wang M (2019) Facilitating nitrogen accessibility to boron rich covalent

organic frame works via electrochemical excitation for efficient nitrogen fixation.

9. Nystron J, Dahlquist E (2004) Methods for determination of moisture content in Nature Communications 10: 1-9.

wood chips for power plants. Fuel 83:773-779.

15. Olorunnisola J, Canon R, Kiveka E (2007) Production of fuel briquettes from

10. Angela M, Fakinle BS, Odunlami O, Elehinafe FB (2019) Proximate analysis esparto partially paralyzed. Energy conversion and management. Internat

of some southwest Nigeria Sawdust of different wood species. Internat J Civil commission. Agricult Eng.

Eng Technol .10:51-59.

11. Bremner JM, Mulvaner CS (1982) Nitrogen- Total. In A.L. Page R.H. Miller, D.R.

Keeney (Eds.). Methods of soil analysis. Part 2, Agronomy 9: 595-624.

J Ecosys Ecograph, an open access journal Volume 10 • Issue 3 • 1000275

ISSN: 2157-7625

You might also like

- Effect of Mixing Ratio of Slurry On Biogas ProductDocument12 pagesEffect of Mixing Ratio of Slurry On Biogas ProductMuhammad Talha JavedNo ratings yet

- Production, Activation, and Applications of Biochar in Recent TimesDocument33 pagesProduction, Activation, and Applications of Biochar in Recent TimesArsal KhanNo ratings yet

- Tecnología Verde para La Producción Sostenible de Biohidrógeno (Waste To Energy) Una RevisiónDocument13 pagesTecnología Verde para La Producción Sostenible de Biohidrógeno (Waste To Energy) Una RevisiónKathiza Annais MadueñoNo ratings yet

- A Comprehensive Review of Renewable Energy Production From Biomass-Derived Bio-OilDocument16 pagesA Comprehensive Review of Renewable Energy Production From Biomass-Derived Bio-OilElbanhawy4EverNo ratings yet

- 1 s2.0 S0956053X19307482 MainDocument10 pages1 s2.0 S0956053X19307482 Mainbruno barrosNo ratings yet

- Biogas EnergyDocument6 pagesBiogas EnergyHayan JanakatNo ratings yet

- Waste Management: Chao-Yi Hung, Wen-Tien Tsai, Jie-Wei Chen, Yu-Quan Lin, Yuan-Ming ChangDocument8 pagesWaste Management: Chao-Yi Hung, Wen-Tien Tsai, Jie-Wei Chen, Yu-Quan Lin, Yuan-Ming ChangGhimis Simona BiancaNo ratings yet

- Bioresource Technology: SciencedirectDocument9 pagesBioresource Technology: Sciencedirectsushmita karNo ratings yet

- Uba and Basil Publication 2Document9 pagesUba and Basil Publication 2Bright UbaNo ratings yet

- Abid2017 Feasibility of Carbon Dioxide Sequestration by Spongiochloris SP Microalgae During Petroleum Wastewater TreatmetDocument29 pagesAbid2017 Feasibility of Carbon Dioxide Sequestration by Spongiochloris SP Microalgae During Petroleum Wastewater TreatmetSacra PsyntergiaNo ratings yet

- s13399 020 01104 2Document15 pagess13399 020 01104 2lunarNo ratings yet

- Microalgae Biofuel Review: Present & Future OutlookDocument10 pagesMicroalgae Biofuel Review: Present & Future OutlookAyesha MukhtarNo ratings yet

- Bucker Et Al 2018 - Residuos de Pescado BiometanoDocument8 pagesBucker Et Al 2018 - Residuos de Pescado BiometanoJulio ReyesNo ratings yet

- Evaluation of Water Hyacinth EichhorniaDocument6 pagesEvaluation of Water Hyacinth Eichhorniaqiaomali02No ratings yet

- From Waste To Energy Comparative Assessment of Heat Values of Biomass Briquettes and Fuel Wood For Bio-Fuel Utilization and Strategic Waste Management in EthiopiaDocument8 pagesFrom Waste To Energy Comparative Assessment of Heat Values of Biomass Briquettes and Fuel Wood For Bio-Fuel Utilization and Strategic Waste Management in EthiopiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Materials Today: Proceedings: Prashant Sharma, Bhupendra Gupta, Mukesh Pandey, Keshav Singh Bisen, Prashant BaredarDocument9 pagesMaterials Today: Proceedings: Prashant Sharma, Bhupendra Gupta, Mukesh Pandey, Keshav Singh Bisen, Prashant BaredarRoberto Macias NNo ratings yet

- AlgasDocument25 pagesAlgasDayanneNo ratings yet

- Biomass: The Ultimate Source of Bio Energy: Sushmita Mohapatra, Kasturi GadgilDocument4 pagesBiomass: The Ultimate Source of Bio Energy: Sushmita Mohapatra, Kasturi GadgilRaghu RamNo ratings yet

- An Analysis of The Use of Biochar Technology in BeninDocument11 pagesAn Analysis of The Use of Biochar Technology in BeninIJAR JOURNALNo ratings yet

- Pirolisis Por MicroondasDocument7 pagesPirolisis Por MicroondasJulianaGomezNo ratings yet

- Methane Generation From Cow Dung With The Aid of ADocument9 pagesMethane Generation From Cow Dung With The Aid of AZeusKirster VitangcolNo ratings yet

- Group 6 Research Proposal .Docx 1Document11 pagesGroup 6 Research Proposal .Docx 1Luccia Isabelle K. GaborNo ratings yet

- Biomass Valorization For Converting Fuels and ChemicalsDocument51 pagesBiomass Valorization For Converting Fuels and ChemicalsJuanFleitesNo ratings yet

- Bio 2Document14 pagesBio 2ajitsssNo ratings yet

- Research PaperDocument6 pagesResearch PaperAsnaAfsalNo ratings yet

- Woody Biomass As A Potential Feedstock FDocument15 pagesWoody Biomass As A Potential Feedstock FXymon ZubietaNo ratings yet

- Design, Construction and Testing of A Biogas Reactor For Production of Biogas Using Cassava Peel and Cow Dung As BiomassDocument11 pagesDesign, Construction and Testing of A Biogas Reactor For Production of Biogas Using Cassava Peel and Cow Dung As BiomassAZOJETENo ratings yet

- 1 s2.0 S0360319922042549 MainDocument18 pages1 s2.0 S0360319922042549 MainpurbadreeNo ratings yet

- Life cycle assessment of microalgal biodiesel using hybrid cultivationDocument13 pagesLife cycle assessment of microalgal biodiesel using hybrid cultivationnaturally youNo ratings yet

- Renewable Energy: SciencedirectDocument11 pagesRenewable Energy: SciencedirectCici refieyanaNo ratings yet

- GJESM Volume 7 Issue 3 Pages 331-346Document16 pagesGJESM Volume 7 Issue 3 Pages 331-346GJESMNo ratings yet

- Agro Waste To Refuse-Derived Fuel Converting Machine PaperDocument4 pagesAgro Waste To Refuse-Derived Fuel Converting Machine PaperCronsentNo ratings yet

- Revisión Bibliometrica Azolla PDFDocument21 pagesRevisión Bibliometrica Azolla PDFJuan Carlos Abad ChinchayNo ratings yet

- Biochar Production Technical, Environmental and Economics From Palm Biomass PDFDocument8 pagesBiochar Production Technical, Environmental and Economics From Palm Biomass PDFMelumzi NontanganaNo ratings yet

- Biomass. Incineration, Pyrolysis, Combustion and GasificationDocument13 pagesBiomass. Incineration, Pyrolysis, Combustion and GasificationSaifAdamz's100% (1)

- Energies 15 09586 v3Document16 pagesEnergies 15 09586 v3theoNo ratings yet

- ISIC2015 - Extended AbstractDocument2 pagesISIC2015 - Extended Abstractmozaikart jogjaNo ratings yet

- Divya Tandon and Nivedita SharmaDocument13 pagesDivya Tandon and Nivedita SharmaDianaElenaNo ratings yet

- Kinetic model study of biogas production from banana wasteDocument13 pagesKinetic model study of biogas production from banana wasteSaliha SattiNo ratings yet

- 2136-Vol 3Document28 pages2136-Vol 3BSRNo ratings yet

- Chapter One Victor Abe ProjectDocument7 pagesChapter One Victor Abe ProjectErhueh Kester AghoghoNo ratings yet

- Bioresource Technology: Yongwoon Lee, Pu-Reun-Byul Eum, Changkook Ryu, Young-Kwon Park, Jin-Ho Jung, Seunghun HyunDocument6 pagesBioresource Technology: Yongwoon Lee, Pu-Reun-Byul Eum, Changkook Ryu, Young-Kwon Park, Jin-Ho Jung, Seunghun HyunAshfaq AhmedNo ratings yet

- Review of Anaerobic Digestion Process For Biogas Production: March 2022Document17 pagesReview of Anaerobic Digestion Process For Biogas Production: March 2022lutfi ramadaniNo ratings yet

- Bioethanol Production Through Syngas Fermentation in A Tar Free Bioreactor Using Clostridium ButyricumDocument8 pagesBioethanol Production Through Syngas Fermentation in A Tar Free Bioreactor Using Clostridium Butyricumoki trisnaNo ratings yet

- Chapter OneDocument46 pagesChapter OneibukunadedayoNo ratings yet

- Full-Text PotentialofbiocharuseinbuildingmaterialsDocument12 pagesFull-Text Potentialofbiocharuseinbuildingmaterialsfali64560No ratings yet

- Nitrogen Content Reduction On Scenedesmus Obliquus Biomass Used ToDocument7 pagesNitrogen Content Reduction On Scenedesmus Obliquus Biomass Used Torafael wadniparNo ratings yet

- Flow Rate2Document10 pagesFlow Rate2keiji jindoNo ratings yet

- Good - Co-Pelletization of Sewage Sludge and Agricultural WastesDocument7 pagesGood - Co-Pelletization of Sewage Sludge and Agricultural WastesgftalerorNo ratings yet

- The Use of Microalgae For Coupling Wastewater Treatment With CO BiofixationDocument12 pagesThe Use of Microalgae For Coupling Wastewater Treatment With CO BiofixationbazediNo ratings yet

- Utilization of Microalgal Bacterial Energy Nexus Improves - 2023 - EcotoxicologyDocument16 pagesUtilization of Microalgal Bacterial Energy Nexus Improves - 2023 - EcotoxicologyCristhian RodriguezNo ratings yet

- Ajib 13 (Q1)Document10 pagesAjib 13 (Q1)NuriyahNo ratings yet

- The Potentials of Sugar Cane Bites Asasource of Biogas MethaneDocument7 pagesThe Potentials of Sugar Cane Bites Asasource of Biogas MethaneOsuizugbe Esom kennethNo ratings yet

- Co-Pyrolysis of Sugarcane Bagasse and Polystyrene With Ex-Situ Catalytic Bed of Metal Oxides or HZSM-5 With Focus On Liquid YieldDocument9 pagesCo-Pyrolysis of Sugarcane Bagasse and Polystyrene With Ex-Situ Catalytic Bed of Metal Oxides or HZSM-5 With Focus On Liquid Yieldbambang_teknikkimiaNo ratings yet

- BIOGAS-Technology For IndiaDocument43 pagesBIOGAS-Technology For IndiaH.J.Prabhu100% (3)

- 1 s2.0 S0165237023003650 MainDocument22 pages1 s2.0 S0165237023003650 Mainkffi1009No ratings yet

- A Review On Production of Biogas From SL PDFDocument5 pagesA Review On Production of Biogas From SL PDFJosephine ChirwaNo ratings yet

- 10 1016@j Matpr 2020 04 045Document7 pages10 1016@j Matpr 2020 04 045arifrifanNo ratings yet

- energies-14-04916-v2Document54 pagesenergies-14-04916-v2Shafira RiskinaNo ratings yet

- 2020-E Ect of Temperature On Oil Quality Obtained Through Pyrolysis of Sugarcane BagasseDocument9 pages2020-E Ect of Temperature On Oil Quality Obtained Through Pyrolysis of Sugarcane BagasseShafira RiskinaNo ratings yet

- Silvestre 2016Document5 pagesSilvestre 2016VictorRaulLujanGonzalesNo ratings yet

- PTM01Document6 pagesPTM01Shafira RiskinaNo ratings yet

- ChemosphereDocument16 pagesChemosphereShafira RiskinaNo ratings yet

- Review On Phase Change Material As Thermal Energy Storage Medium: Materials, ApplicationDocument6 pagesReview On Phase Change Material As Thermal Energy Storage Medium: Materials, ApplicationShafira RiskinaNo ratings yet

- Silvestre 2016Document5 pagesSilvestre 2016VictorRaulLujanGonzalesNo ratings yet

- Thermodynamic Properties of The Nacl + H O System. 4. Heat Capacities of H O and Nacl (Aq) in Cold-Stable and Supercooled StatesDocument22 pagesThermodynamic Properties of The Nacl + H O System. 4. Heat Capacities of H O and Nacl (Aq) in Cold-Stable and Supercooled StatesShafira RiskinaNo ratings yet

- Thermal energy storage using salt hydratesDocument13 pagesThermal energy storage using salt hydratesShafira RiskinaNo ratings yet

- Energy Conversion and Management: Evangelos Bellos, Christos Tzivanidis, Dimitrios TsimpoukisDocument15 pagesEnergy Conversion and Management: Evangelos Bellos, Christos Tzivanidis, Dimitrios TsimpoukisShafira RiskinaNo ratings yet

- Ctab 0,7 Sds 0,1Document3 pagesCtab 0,7 Sds 0,1Shafira RiskinaNo ratings yet

- Defence Journal Reviews Phase Change Materials for Defence ApplicationsDocument7 pagesDefence Journal Reviews Phase Change Materials for Defence ApplicationsShafira RiskinaNo ratings yet

- Ar3421 - BCBM - U 2Document45 pagesAr3421 - BCBM - U 2LokeshNo ratings yet

- Innovating Nickel and Cobalt Battery MaterialsDocument15 pagesInnovating Nickel and Cobalt Battery MaterialsNURIZZANIE FEBRINA ARISMANNo ratings yet

- Rod End SeriesDocument14 pagesRod End SeriesNopNo ratings yet

- Acid Properties and Fluid Flow CharacteristicsDocument20 pagesAcid Properties and Fluid Flow CharacteristicsPablo SotoNo ratings yet

- Navsea s9086-Rq-stm-010 NSTM Ch. 510 Rev. 7 Heating, Ventilating, Etc.Document166 pagesNavsea s9086-Rq-stm-010 NSTM Ch. 510 Rev. 7 Heating, Ventilating, Etc.Matthew SmithNo ratings yet

- STPM Trial 2009 Che Q&A KelantanDocument37 pagesSTPM Trial 2009 Che Q&A KelantanSimPorNo ratings yet

- Department of Mechanical EngineeringDocument3 pagesDepartment of Mechanical EngineeringJames Patrick TorresNo ratings yet

- GasLiquid Reactions - First Order - Hatta NumberDocument4 pagesGasLiquid Reactions - First Order - Hatta NumberShivahari GopalakrishnanNo ratings yet

- Al Salem 2017Document22 pagesAl Salem 2017Xing KaiNo ratings yet

- Iron International StandardsDocument2 pagesIron International StandardsAmir MusaibNo ratings yet

- Experiment 3Document22 pagesExperiment 3Sophiah RachelleNo ratings yet

- Experiment 6 Lab ReportDocument21 pagesExperiment 6 Lab ReportmarkkkkkNo ratings yet

- Lattice Energy: The Born-Haber CycleDocument4 pagesLattice Energy: The Born-Haber CycleAllalannNo ratings yet

- Octahedral and Tetrahedral Voids in FCCDocument11 pagesOctahedral and Tetrahedral Voids in FCCHasna RiazNo ratings yet

- Welding ProcessesDocument77 pagesWelding ProcessesRahul75% (4)

- Solubility modelling of hydrocarbons and light ends in amine solutionsDocument6 pagesSolubility modelling of hydrocarbons and light ends in amine solutionsANo ratings yet

- Battery Thermal ManagementDocument20 pagesBattery Thermal ManagementvadanNo ratings yet

- Mc1091 Recrushed SlagDocument4 pagesMc1091 Recrushed Slagtoxicity23No ratings yet

- Acs Energyfuels 7b03733Document12 pagesAcs Energyfuels 7b03733Dinesh JoshiNo ratings yet

- Formulas For Converting Latitude and Longitude To UTM - GIS Blog GIS BlogDocument3 pagesFormulas For Converting Latitude and Longitude To UTM - GIS Blog GIS BlogSalam DjdjNo ratings yet

- Resistance+List+Tank+Linings,+Protective (1) JotunDocument28 pagesResistance+List+Tank+Linings,+Protective (1) JotunIbrahim KhalilNo ratings yet

- Tantalum: Arihant Jain 6 PeriodDocument7 pagesTantalum: Arihant Jain 6 PeriodbudyNo ratings yet

- Melbourne Soil Shrink-Swell Index Database EstablishedDocument16 pagesMelbourne Soil Shrink-Swell Index Database EstablishedTharun DelpachitraNo ratings yet

- Condenser and feedwater performance testingDocument23 pagesCondenser and feedwater performance testingShambhu MehtaNo ratings yet

- Sulfide Stress CrackingDocument5 pagesSulfide Stress Crackingsyahril siddiq arelNo ratings yet

- European Steel and Alloy Grades: About Us EN 10025-2Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10025-2farshid KarpasandNo ratings yet

- Descriptive Physical Oceanography An IntroductionDocument3 pagesDescriptive Physical Oceanography An IntroductionAnonymous xdDh30QONo ratings yet

- Astm D 3341Document4 pagesAstm D 3341Manuel GuzmanNo ratings yet

- Cbiescss 07Document6 pagesCbiescss 07Ayush BeheraNo ratings yet

- Molykote 3400A MSDSDocument11 pagesMolykote 3400A MSDSDkC gunsNo ratings yet