Professional Documents

Culture Documents

Ein Real Ale Bitte Brewer and Distiller International November 2019

Uploaded by

martina.capozzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ein Real Ale Bitte Brewer and Distiller International November 2019

Uploaded by

martina.capozzaCopyright:

Available Formats

BREWING

iStock.com/Nikada

Ein real ale, bitte

Brewing German beer in the UK

By Stuart Howe Mental Health Act in 2017. As well as its

descent into insanity the 13 years saw a

Historically the brewers of Great Britain and Germany gradual shift of identity from a ‘real ale’

to craft beer producer.

have existed largely independently of each other. The Now, as well as free-trade sales,

language barrier and some disagreements early in the the brewery has eight brewery taps

and bottle shops located in well-to-do

20th century led to separate paths being followed.

market towns in the Chiltern hills just

Today, thanks to an increased number of breweries – outside London. This route to market

and most Germans speaking better English than the accounts for 20% of sales. Who said

the days of the vertically-integrated

average Brit – there is an increasing number of German- brewing business were gone?

trained brewers taking up the reins in the UK. Production this year is expected to top

10khL with strong growth on all fronts.

B ritish brewers would study at

Nottingham, Heriot Watt or with

the IBD and pursue a career in the UK

them, their breweries and get their per-

spective on the strange things we do in

Great Britain.

Matthias Seidl, Brewing Director at

Mad Squirrel is originally from Germany

and has an MSc in Brewery Engineering

and English-speaking countries in the from the Technical University of Munich

southern hemisphere. German brewers Matthias Seidl at the Mad Weihenstephan. Matthias joined the

would study at Munich or Berlin and go Squirrel Brewery brewery in 2016. Originally he didn’t

on to work in Germany, occasionally The Mad Squirrel Brewery didn’t start want to be a brewer – he wanted to set

in Europe but very rarely in the UK. In off mad, it was originally Red. The Red the world of music alight with his jazz

this article we will meet two who have Squirrel Brewery started up in 2004 with guitar. After failing to rotate the celebrity

recently made the jump, find out about the squirrel officially sectioned under the armchairs at two auditions for music

32 ● BREWER AND DISTILLER INTERNATIONAL I november 2019 ib d .o r g .uk

BREWING

The Mad Squirrel: lurking menacingly in the undergrowth Matthias Seidl in the brewhouse

school in Munich he decided not to risk the Chiltern Hills and hence is very high

seeing if third time really was lucky and in bicarbonates, so alkalinity is adjusted

considered an alternative career. by acid addition.

As someone keen on food and drink All malt is supplied by Crisp and is

who dabbled in homebrew, the brewing mashed isothermally for ales and with a

engineer course at Weihenstephan was three-step (62°C - 72°C - 78°C) tem-

of interest, the only downside being the perature programmed mash for lagers.

physics and engineering theme of the All yeast is supplied dried with W34/70

course. Or as Matthias puts it “Everything used for lagers and the East Coast

I didn’t like at school”. The first year of IPA strain used for ales. The yeast is

the Weihenstephan course was almost cropped and repitched up to five gener-

exclusively mechanical and chemical ations for lagers and ten for ales.

engineering. Rather like chemical and Typically for modern craft breweries,

The Mad Squirrel cellar

process engineering at Heriott-Watt and liquids and SKUs are numerous – ranging

Module 3 of the IBD Diploma in Brewing, from Pilsner to milk stout in cask, can,

Beer Name Bitterness ABV (%)

this sorted the wheat from the chaff and bottle and keg. Mad Squirrel’s biggest-

Units (BU)

saw half of Matthias’ classmates decide selling brand is $umo an American pale

their future would involve drinking rather ale at 4.7% ABV and 34 IBU. Close on its Zealous Pilsner 34 4.4

than making beer. heels is its new (and I think superb) Native

$umo American Pale Ale 34 4.7

The engineering emphasis on the Helles which is 5% ABV and 18 IBU.

Weihenstephan course means that as The table sets out a full list of regular Hopfest Pale Ale 27 3.8

many graduates tend to end up working brands. And because there are only 10

for equipment suppliers as progress regular beers, there are of course always London Porter 27 5

into brewing operations. Of those who several seasonal offerings available! Dela Crème Mild Stout 25 4.5

graduated with Matthias, more are now All lagers have a 42-day cold

designing breweries and packaging maturation, with tanks spunded* Roadkill New England IPA 36 6.5

lines than are designing beers. During to preserve as much of the natural Illuminate Red Ale 26 4.5

his studies Matthias also worked at carbonation and protection against

Brauerei Aldersbach in Bavaria. staling in the form of SO2. Big Sea East Coast IPA 33 5.5

Matthias’ decision to pursue a brew- All beers are supplied unfiltered and

Mr. Squirrel Premium Bitter 32 4

ing career in England was made for him some of the cask beers are fined. Beer is

by his wife who is from Leeds. They canned on an ABE linear four-head can- Native Munich Helles 18 5

met at university in Munich but she was ning line and kegging and cask racking

Mad Squirrel brands

seemingly homesick for a decent cuppa undertaken manually and direct from tank.

and the opinions of Geoffrey Boycott, The plan for the business is to con- Utopian Brewing and Jeremy

so they moved back to England. tinue with the current strategy pushing Swainson

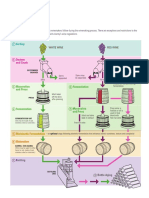

The current Mad Squirrel brewery for growth. Utopian is a new brewery. And I mean

was installed in 2017 and was made *Spunding is a process often used new. At only six months old, some

by American Beer Equipment. It is by lager brewers to naturally carbonate breweries have stock older than their

a semi-automated 30hL brewhouse a beer. A device called a spunding valve equipment! Utopian is different to a lot of

comprising an MCV, lauter tun, kettle is used to adjust and release pressure start-ups in that it has a brand-new 35hL

and whirlpool. Water comes from a on a pressure-capable fermenter such semi-automated brewhouse, 7khL annual

borehole deep in the chalk deposits of as a Unitank. fermentation and maturation capacity –

i b d .org.uk november 2019 I BREWER AND DISTILLER INTERNATIONAL ● 33

BREWING

Mad Squirrel’s biggest-selling brand is

$umo – an American pale ale at 4.7%

ABV and 34 IBU

and flooring so posh it costs more than German brewing apprenticeships can find employment as an opera-

most brewhouses under 50hL. It has also are three years in length, are based tor-level brewer or maltster.

set out to brew only lagers. at one or more breweries and involve After completing his apprentice-

Another element which sets Utopian full-time employment at the brewer(y)ies ship, Jeremy completed the Master

apart from your average new brewery with three months of classroom brewing of Brewing and Malting course at

is the head brewer being a Doemens study per year. In Jeremy’s case at Fritz Doemens Academy in Munich. He then

Academy-qualified brewmaster. Henßler college in Dortmund. left Germany for the delights of Enfield

As his name suggests Jeremy Over the course of the German and AB InBev’s Camden Town Brewery

Swainson is not a 5th generation brewing apprenticeship, the student where he was Brewing Manager and

Bavarian but is originally from Canada. experiences each area of brewing oper- worked on the team that commissioned

He developed a love for German beer ations – from brewhouse to packaging and implemented the new Krones

while on a one-year exchange pro- as well as maltings and laboratory Steineker brewery.

gramme in Germany, so after school exposure – with practical and written He chose England for a career

he enrolled on the German brewing exams covering each element of train- because although he would have been

and malting apprenticeship working at ing. At the end of the apprenticeship assured a sound career

Bolten Brauerie in Korschenbroich. he/she is given the title ‘Brewer’ and path in Germany,

The Utopian kettle The Utopian set-up

34 ● BREWER AND DISTILLER INTERNATIONAL I november 2019 ib d .o r g .uk

BREWING

the pace of growth in number of brewer- Although the brewery has access Fuggles can be used to make com-

ies is far slower and it would be decades to water from a borehole it has opted parable beers to those found in the

before he could be in control of a brewery to use municipal supply. The borehole beer halls of Bavaria, while retaining a

or its beer. water is too hard for brewing and would unique English character. Especially for

The UK offered an opportunity to require RO treatment to be suitable. a lightly-hopped style like Helles, where

have greater influence sooner – and The energy consumed and wastewater hops take a back seat to the clean malt

you don’t get any more influence than produced would not fit well within the profile and bitterness is restrained. For

starting up a brand-new brewery and sustainable model – and the municipal the Lager he uses Whitbread Golding

designing each beer from scratch. water is as soft as kitten fur. Variety and East Kent Goldings and for

The Utopian Brewery is on a farm Jeremy uses two mashing regimes. the Pilsner, generous amounts of the

specialising in Ruby Red Devon cows For his British Lager which is based on modern variety Jester.

near the hamlet of Bow which is about six the German Helles style, he uses a two- Fermentation is undertaken at 8-9°C

miles outside Exeter. In recognition of the step temperature programmed mash and as at Mad Squirrel 1bar top pressure

beautiful location of the brewery Utopian with stands at 63°C and 72°C. For is maintained at the end to retain natural

has set out to brew according to sustain- his Pilsner which is more in the Czech carbonation. At the end of fermentation,

able but commercially sensible principles. style he uses an exotic programme/ beers are transferred to dish-bottomed

A key part of that sustainability is decoction mash, or perhaps procoction cylindrical conditioning tanks and after

limiting the food miles of its beers. This (someone should trademark that term a VDK rest at 5°C, chilled to -5°C for the

means that Jeremy was set the chal- now, before it really takes off). 21-day lagering. 20% of production

lenge of making excellent lager without The mash starts in the same way is sold unfiltered and for the remainder

access to continental malt and noble as the Helles with a temperature- filtration is via two lenticular filters. Beers

European hops. One slight compromise programmed mash heated in the are currently kegged in-house on a

is the Frohberg-type lager yeast from MCV from 63°C to 72°C, but for the final Malek Twin II 1- RF kegger.

NCYC which is pitched vessel-to-ves- temperature raise a third of the mash is So far, it’s so good for Utopian. The

sel for up to eight generations. That pumped to the kettle and boiled for 10 brewery is so busy Jeremy has already

said, I’m not sure it’s possible to give minutes before being returned to the MCV. recruited another German-trained

micro-organisms nationalities (unless Using English hops to produce brewer to work alongside him. The

you can clearly identify their lederhosen beer which evolved around the use Great British drinking public seemed

under the microscope). of classic European varieties like to have wholeheartedly embraced the

Malt is supplied by Bairds and Mittelfruh and Saaz would probably be concept of a British lager.

Jeremy uses dextrin malt, which is top of the list of concerns most brew-

produced to be under-modified, along ers would have about Utopian’s lager The German-trained brewer’s view

with the company’s standard lager malt. meets sustainability approach. Both Jeremy and Matthias have been

This is designed to mimic the less-well Jeremy argues that when used brewing in the UK for nearly four years.

modified malt typical in Germany. correctly, hops like Goldings and Their experience in the UK is very much

At the end of fermentation Utopia’s beers

are transferred to dish bottomed cylindrical

conditioning tanks and after a VDK rest at 5°C,

chilled to -5°C for the 21-day lagering.

i b d .org.uk november 2019 I BREWER AND DISTILLER INTERNATIONAL ● 35

BREWING

The question in their minds seems to

be one of: “Why do I need to add this? Is

Jeremy posing for the obligatory “Can you pretend

there really a benefit?” This is seldom the

to be stirring it?” brewery action photo

case with British brewers. This conserv-

ative approach to process changes and

additions seems to be another significant

difference. In Germany, because every-

one is trained in the same way, most

brewers tend to accept there is a correct

way to do things.

In the UK most brewers accept there

is a correct way, it’s just that everyone

tends to disagree about what that way

actually is. And in the craft brewing move-

ment, the correct way is often researched

from blog posts or books on beers styles

written by US home brewers.

Neither brewer saw the less con-

servative attitude of British brewers as a

negative. And in fact, the ability to inno-

vate was one of the main factors behind

Jeremy’s decision to move to the UK.

The control of oxygen

The final observation from Matthias

was about the British brewer’s relaxed

attitude to oxygen throughout the pro-

cess, particularly in the brewhouse. He

the new/modern/craft end of our richly tutes an average brewery. Matthias said jokes that the English translation of the

diverse brewing industry – but having in Germany there are very few brewing German word for oxidisation is flavour.

experience on both sides of the channel operations working on 10hL manual In Germany, processes are engineered

gives them an insight into the differ- breweries in a business unit – whereas in and managed to ensure oxygen is

ences that exist. The following areas are the UK they are prevalent. excluded from all stages apart from

those they felt were most significant. It would be fair to say that if he wort oxygenation.

had come to the UK in 2002 he may Matthias has modified his bre-

Brewer development have found no difference. In Germany whouse so that he can purge oxygen

The German brewer education system an average brewery tends to produce out of the system to minimise hot side

places a heavier emphasis on the applica- 100-200khL per year and have a fully pickup and measures and manag-

tion of brewing knowledge and science. automated brewhouse, cellar and es-down oxygen at all other stages. He

Even the more academically-weighted high-spec packaging lines. Jeremy was concerned especially when making

Weihenstephan course features a nine- commented that even small pub or village cask beer that his zero-tolerance

month internship at a brewery. breweries with 20hL brewhouses have approach may remove some of the

Both brewers more than raised their well-designed equipment from suppliers oxygen-derived flavour valued by drink-

eyebrows when they learned of the level like Kasper Schultz and a brewer who has ers in the pub. Mad Squirrel sales data

of practical knowledge held by graduates passed an apprenticeship at the helm. tend to suggest otherwise.

of Heriott-Watt entering the job market. In the average brewery all staff oper-

In Germany, technical decision-makers in ating on the brewing side would have at

breweries tend to measure experience in least passed the brewing apprenticeship

decades rather than years. with several of the team having brewing

Perhaps the German system is more degrees. Perhaps when the transatlan-

akin to graduates already employed in tic tsunami of craft finally breaks over

the brewing industry studying for the Germany this disparity will be removed

IBD Diploma. What is extremely rare in

Germany is the ‘Head Brewer’ who was The use of additives

a barista or IT professional last week. Having been trained in the land of the

Career progression in Germany is also Reinheitsgebot it is small wonder that

slower with the ‘fast-track’ to the top both brewers have found the Brits a

being about 20 years! great deal more liberal with process

aids. The use of de-glutenising enzymes

What a brewery is seemed to be a particular cause of

It may be that because both Jeremy and consternation. Even with the shackles

Matthias are at the smaller end of the UK of the Reinheitsgebot removed Matthias

brewing industry they note that there is and Jeremy seem to view all process Utopian British Lager (please note

a significant difference in what consti- aids with caution. consumption does not turn you blue)

36 ● BREWER AND DISTILLER INTERNATIONAL I november 2019 ib d .o r g .uk

You might also like

- The Geography of BeerDocument211 pagesThe Geography of BeerTaís Suhre100% (1)

- Saturday White Bread Recipe From Flour Water Salt Yeast by Ken ForkishDocument13 pagesSaturday White Bread Recipe From Flour Water Salt Yeast by Ken ForkishThe Recipe Club65% (57)

- Wild Brews - Beer Beyond The Influence of - Jeff SparrowDocument207 pagesWild Brews - Beer Beyond The Influence of - Jeff SparrowAlessandro De Oliveira GonçalvesNo ratings yet

- Literature ReviewDocument27 pagesLiterature Reviewstanwilsequeira0% (1)

- Oligopolies in Beer Industry: Dinh Khanh ThyDocument26 pagesOligopolies in Beer Industry: Dinh Khanh ThyKhánh Thy ĐinhNo ratings yet

- World's Best Ciders SamplerDocument20 pagesWorld's Best Ciders SamplerSterling PublishingNo ratings yet

- Beer 101 - The Basics of BeerDocument19 pagesBeer 101 - The Basics of BeerJúlio Gabriel Queiroz dos SantosNo ratings yet

- Sec B - Group 3 - Freemark Abbey WineryDocument3 pagesSec B - Group 3 - Freemark Abbey WineryAscharya DebasishNo ratings yet

- DangerDaves Dragon Blood WineDocument4 pagesDangerDaves Dragon Blood WineStephen90No ratings yet

- Harrison 2009Document11 pagesHarrison 2009JUAN DAVID DAZA BURGOSNo ratings yet

- Globalization of Brewing Industry and Brewing ProcessDocument20 pagesGlobalization of Brewing Industry and Brewing Processabhinav8803No ratings yet

- Micro Breweries-ResearchDocument125 pagesMicro Breweries-ResearchSaurabh BaneNo ratings yet

- Brewery History: Brewing in Belgium and Belgian BeersDocument11 pagesBrewery History: Brewing in Belgium and Belgian BeersJ Elver SilvaNo ratings yet

- Hogs Back Brewery Case Study - 12478Document11 pagesHogs Back Brewery Case Study - 12478GrailleNo ratings yet

- Classic Beer Style Series #17 - Bavarian Helles - History, Brewing Techniques, Recipes - by Horst Dornbusch (2000)Document177 pagesClassic Beer Style Series #17 - Bavarian Helles - History, Brewing Techniques, Recipes - by Horst Dornbusch (2000)Lourenço AssumpçãoNo ratings yet

- BitburgerDocument5 pagesBitburgerRoman CooperNo ratings yet

- HandBook of BrewingDocument64 pagesHandBook of BrewingLuanPedroNo ratings yet

- Cooking and Pairing Written Exam Key: / FalseDocument6 pagesCooking and Pairing Written Exam Key: / FalseAmreesh MisraNo ratings yet

- Presentation 2 Beer in GermanyDocument28 pagesPresentation 2 Beer in GermanySanket MedhekarNo ratings yet

- Home Brew Beer GuideDocument27 pagesHome Brew Beer Guidesunburst100% (3)

- Belgian Beer Experiences tcm24-7788 PDFDocument64 pagesBelgian Beer Experiences tcm24-7788 PDFAlejandro HercenbergNo ratings yet

- Brewing Beer: The Simple Guide to Homebrewing BeerFrom EverandBrewing Beer: The Simple Guide to Homebrewing BeerRating: 2.5 out of 5 stars2.5/5 (2)

- Brands of BeersDocument26 pagesBrands of BeersRavi KshirsagerNo ratings yet

- A Snapshot Mapping of The Danish Beer MaDocument9 pagesA Snapshot Mapping of The Danish Beer MaMd Zaber Tauhid AbirNo ratings yet

- ICS CaseDocument18 pagesICS CaseVargees LouisNo ratings yet

- The Microdistillers Handbook 09.2020Document196 pagesThe Microdistillers Handbook 09.2020Zsuzsa PeterdiNo ratings yet

- Micro Brewing Guide EnglishDocument27 pagesMicro Brewing Guide EnglishZamir HadesNo ratings yet

- Beer InformationDocument23 pagesBeer InformationMinerva JuárezNo ratings yet

- Kasus MS 1Document3 pagesKasus MS 1Assyifa Puteri ShansariNo ratings yet

- Old British BeersDocument31 pagesOld British BeerspixtaccioNo ratings yet

- Classic Beer Style Series #16 - Pale Ale (Second Edition) - History, Brewing, Techniques, Recipes - by Terry Foster (1999)Document455 pagesClassic Beer Style Series #16 - Pale Ale (Second Edition) - History, Brewing, Techniques, Recipes - by Terry Foster (1999)alvarozero100% (1)

- Make Your Own Beer: A Guide to All Things Beer & How to Brew it YourselfFrom EverandMake Your Own Beer: A Guide to All Things Beer & How to Brew it YourselfNo ratings yet

- Installing ServerpilotDocument31 pagesInstalling ServerpilotAkshayNo ratings yet

- Beer BarDocument8 pagesBeer BarMylg UwuNo ratings yet

- Beer ShopDocument30 pagesBeer ShopHarshad AhireNo ratings yet

- Beer Market ReportDocument3 pagesBeer Market ReportWill HodgettsNo ratings yet

- Subject-Topic-: Food & Beverage Service Beer 3 YearDocument77 pagesSubject-Topic-: Food & Beverage Service Beer 3 YearAbhinav Saxena�No ratings yet

- Brewed ForcexDocument3 pagesBrewed ForcexseniorudcNo ratings yet

- The Home Brew Handbook: 75 recipes for the aspiring backyard brewerFrom EverandThe Home Brew Handbook: 75 recipes for the aspiring backyard brewerNo ratings yet

- Strategic Group AssignmentDocument9 pagesStrategic Group AssignmentDung NguyenNo ratings yet

- Equivalencias Levaduras Liquidas-Secas PDFDocument2 pagesEquivalencias Levaduras Liquidas-Secas PDFMaxi OhanNo ratings yet

- Consumer Behaviour On Kingfisher BeerDocument47 pagesConsumer Behaviour On Kingfisher Beersamy7541No ratings yet

- Group 1 Budweiser Company AnalysisDocument14 pagesGroup 1 Budweiser Company AnalysisNhư ThảoNo ratings yet

- Lonely Planet Lonely Planet's Global Beer TourFrom EverandLonely Planet Lonely Planet's Global Beer TourRating: 3.5 out of 5 stars3.5/5 (1)

- Top Ten Craft BeersDocument10 pagesTop Ten Craft BeersWendy RamosNo ratings yet

- Wikipedia Belgian Beer PDFDocument52 pagesWikipedia Belgian Beer PDFbartekguzikNo ratings yet

- BEERDocument8 pagesBEERBhavesh UmraniaNo ratings yet

- KingfisherDocument31 pagesKingfisherShailly Garg100% (1)

- Belgian Beers: Where History Meets Globalization Damiaan Persyn, Johan F.M. Swinnen and Stijn VanormelingenDocument40 pagesBelgian Beers: Where History Meets Globalization Damiaan Persyn, Johan F.M. Swinnen and Stijn Vanormelingenshelly dineltonNo ratings yet

- MabdDocument11 pagesMabdKishore RaghupathiNo ratings yet

- American Wheat: Style of The Month: January 1997Document3 pagesAmerican Wheat: Style of The Month: January 1997pejotageNo ratings yet

- The Encyclopedia of Beer: The Beer Lover's Bible - A Complete Reference To Beer Styles, Brewing Methods, Ingredients, Festivals, Traditions, And More)From EverandThe Encyclopedia of Beer: The Beer Lover's Bible - A Complete Reference To Beer Styles, Brewing Methods, Ingredients, Festivals, Traditions, And More)Rating: 4 out of 5 stars4/5 (1)

- New Belgium Brewing CompanyDocument26 pagesNew Belgium Brewing CompanyTanzie PanNo ratings yet

- Research Paper On Beer Production PDFDocument4 pagesResearch Paper On Beer Production PDFkgtyigvkg100% (1)

- 12.beer Quality ControlDocument242 pages12.beer Quality ControlAlija IbrisevicNo ratings yet

- 12.beer Quality ControlDocument242 pages12.beer Quality ControlAlija IbrisevicNo ratings yet

- Mtu Parttime 2022 WebDocument236 pagesMtu Parttime 2022 Webmartina.capozzaNo ratings yet

- Main-Programme 24.04.09Document100 pagesMain-Programme 24.04.09martina.capozzaNo ratings yet

- ChemDocument9 pagesChemIpshita BanerjeeNo ratings yet

- Harry's Country Club Beer MenuDocument4 pagesHarry's Country Club Beer Menusupport_local_flavorNo ratings yet

- Pengaruh Penggunaan Jenis Gula Merah Dan Lama Fermentasi Terhadap Karakteristik Water KefirDocument16 pagesPengaruh Penggunaan Jenis Gula Merah Dan Lama Fermentasi Terhadap Karakteristik Water KefirFarahnaz MustikaNo ratings yet

- Chemistry ProjectDocument17 pagesChemistry Projectkryptonite EditzNo ratings yet

- Rhone 2323Document2 pagesRhone 2323Anonymous ePcnZoBENo ratings yet

- Cherry Wine RecipesDocument5 pagesCherry Wine Recipesvero66No ratings yet

- Weyermann Product Information GB 05 2017 PDFDocument42 pagesWeyermann Product Information GB 05 2017 PDFnevenenNo ratings yet

- Wine GuideDocument4 pagesWine GuidepankajkhakareNo ratings yet

- All Grain3Document100 pagesAll Grain3JohnRykerNo ratings yet

- Wines and Basic OenologyDocument14 pagesWines and Basic OenologyRalph Kevin BaroloNo ratings yet

- He-Cookery 9 q3 Las3 FinalDocument11 pagesHe-Cookery 9 q3 Las3 FinalSalgie Masculino100% (1)

- Wikipedia Belgian Beer PDFDocument52 pagesWikipedia Belgian Beer PDFbartekguzikNo ratings yet

- Arrack: Jump To Navigation Jump To SearchDocument8 pagesArrack: Jump To Navigation Jump To SearchDamith Nishantha KarunarathnaNo ratings yet

- BEER-Craft Brew - 50 Homebrew Recipes From The World's Best Craft BreweriesDocument260 pagesBEER-Craft Brew - 50 Homebrew Recipes From The World's Best Craft BreweriesWilliam CI100% (1)

- NaturalWineDec May17Document4 pagesNaturalWineDec May17Marco LamiNo ratings yet

- Carti PaineDocument2 pagesCarti Painenicalex17No ratings yet

- SSAT Practice Test 1Document17 pagesSSAT Practice Test 1Talha SiddiquiNo ratings yet

- SOUR BEER - Arnold O'BrienDocument46 pagesSOUR BEER - Arnold O'BriensosNo ratings yet

- Beer ManufacturingDocument23 pagesBeer ManufacturingDivya AggarwalNo ratings yet

- Open Sandwich: 2. 2. History SejarahDocument6 pagesOpen Sandwich: 2. 2. History SejarahBocah NdesoNo ratings yet

- Wine Fermentation Kit For Wine-Making BusinessDocument7 pagesWine Fermentation Kit For Wine-Making BusinessGyl DimpasNo ratings yet

- Baking Artisan Bread - Update Errata, Baguette Dough PDFDocument5 pagesBaking Artisan Bread - Update Errata, Baguette Dough PDFDidi ArsandiNo ratings yet

- WineDocument3 pagesWineVarinder Singh0% (1)

- Active Dry Wine YeastDocument5 pagesActive Dry Wine YeastoldpenguinNo ratings yet

- ALCOHOLDocument8 pagesALCOHOLRaul GNZNo ratings yet

- Brand NameDocument4 pagesBrand NameAnjnaKandariNo ratings yet

- Garden City BrewFest 23Document4 pagesGarden City BrewFest 23NBC MontanaNo ratings yet