Professional Documents

Culture Documents

Product Ref Sheet U 75-110 PACE KD WUX 2960 1910 00 EN

Uploaded by

duroux.thibaultCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Ref Sheet U 75-110 PACE KD WUX 2960 1910 00 EN

Uploaded by

duroux.thibaultCopyright:

Available Formats

Product Reference

U 75-110 PACE KD WUX

Portable Compressor

Standard Scope of Supply

The Atlas Copco U 75, U 110 and U 110 PACE are silenced, single-stage, oil-injected screw compressors, powered by liquid-

cooled, three-cylinder Kubota diesel engine.

The unit consist of one high efficient compressor element, diesel engine, cooling, air/oil separation and control systems - all

enclosed within silenced XA strong steel canopy.

Special attention has been given to the overall product quality, user friendliness, ease of serviceability, and economical operation to

ensure best in class cost of ownership.

The Unique feature of this new range is the PACE functionality coupled with the intuitive XC2003 controller.

This pioneering technology enables multiple pressure and flow settings, ensuring you match air flow and pressure to your

application needs.

Available Models

U 75 Single Stage – 75 cfm – Kubota Diesel Engine

U 110 Single Stage – 100 cfm – Kubota Diesel Engine

U 110 PACE Single Stage – 45-100 cfm – Kubota Diesel Engine

Features Benefits

• 10% compact and 3-layer stackable • Save transport and storage cost

• You control the pressure and flow

• PACE

• Optimal protection against corrosion

• 3 layers Zincor, Primer and Powder coating

• Change of consumable in 1 hour

• Single side service

• Able to work in noise sensitive area

• Low noise emissions

• Increase uptime, save service cost

• 1500 hours service interval

• Air and power combined in one machine

Product Reference - 2960 1910 00 Page 1 of 5

U 75-110 PACE KD WUX - Product Reference

Technical data basic unit*

Model U 75 U 110 U 110 PACE

Normal effective working pressure bar 7 7 5-10.5

Absolute inlet pressure bar 1 1 1

Relative air humidity % 0 0 0

Air inlet temperature °C 20 20 20

Minimum effective receiver pressure bar 2 2 2

Maximum effective receiver pressure (Unloaded) bar 8.8 8.8 8.8

Actual free air delivery m³/min 2.1 2.8 1.3 -2.8

Fuel consumption

at 100% FAD (full load) kg/h 3.83 4.68 4.68

at 75% FAD kg/h 3.05 3.84 3.84

at 50% FAD kg/h 2.48 2.79 2.79

at 25% FAD kg/h 1.53 1.83 1.83

Specific fuel consumption at 100% FAD g/m³ 33.86 31.59 31.59

Max. sound pressure level (Lw @ 2000/14/EC) dB(A) 97 98 98

Max. sound pressure level (Lp @ ISO 2151) dB(A) 70 70 70

Compressed air temperature at outlet without aftercooler °C 85 85 85

Max. ambient temperature at sea level with aftercooler °C 50 50 50

Min. starting temperature with cold weather equipment °C -20 -20 -20

Min. starting temperature without cold weather equipment °C -10 -10 -10

Number of compression stages 1 1 1

Engine Kubota Kubota Kubota

Type D722 D902 D902

Coolant Parcool Parcool Parcool

Number of cylinders 3 3 3

Bore mm 67 72 72

Stroke mm 68 73.6 73.6

Swept volume l 0.719 0.898 0.898

Engine power at normal shaft speed @ SAE J 1995 kW 14.9 18.5 18.5

Full Load rpm 3400 3600 3600

Unload rpm 1800 2000 2000

Capacity of oil sump l 3 3 3

Capacity of cooling system l 5 5 5

Capacity of compressor oil system l 5 5 5

Net capacity of air receiver l 7.5 7.5 7.5

Air volume at inlet grating (approx.) m3/s 0.75 0.75 0.75

Capacity of standard fuel tanks l 20 20 20

Optional extended fuel tank l 10 10 10

Dimensions (L x W x H) mm 1580 x 740 x 850 1580 x 740 x 850 1580 x 740 x 850

Weight – Wet * kg 500 500 500

*Refer to data plate for exact value

Product Reference - 2960 1910 00 Page 2 of 5

U 75-110 PACE KD WUX - Product Reference

Dimensions

Principle Data

Compressor Element

The quality of a compressor can be measured through the reliability, efficiency and durability of the compressor element used. Through decades of

expertise in the design of compressor elements, the result is the production of most efficient and reliable compressors on the market.

Air/Oil Separator

Air and oil separation is achieved through a centrifugal oil separator combined with a filter element.

Designed for a higher maximum working pressure, the separator is equipped with a high pressure sealed and certified safety relief valve, automatic

blow-down valve.

Cooling System

The engine is provided with a coolant cooler and the compressor is provided with an oil cooler. The cooling air is generated by a fan, driven by the

engine.

Compressor Regulating System

The compressor is provided with a continuous pneumatic regulating system and a blow-off valve which is integrated in the unloader assembly.

Introduction of intuitive PACE functionality allows the compressor to operate at any pressure setting between 5 and 10.5 bar.

The compressor can have 2 pressure presets and we can use the controller to toggle between the pressure presets

Economic power consumption is assured by the fully automatic, step-less speed regulator that adapts engine speed to air demand.

Discharge Outlets

Compressed air is available from 2 x G3/4 outlet valves.

Engine

Kubota Diesel Engine

The compressor is driven by a liquid-cooled, three-cylinder Kubota D722 - D902 diesel engine. The engine’s power is transmitted to the compressor

element through a heavy-duty coupling.

Product Reference - 2960 1910 00 Page 3 of 5

U 75-110 PACE KD WUX - Product Reference

Electrical System

The U 75, U 110 and U 110 PACE are equipped with a 12-volt negative ground electrical system.

Instrumentation – U 75 and U 110 - Control Panel

The instrument control panel is located on the side of the compressor canopy.

The control panel has the following: Engine ignition key port, Pressure gauge, Battery malfunction indicator,

Compressor outlet temperature high indicator, Fuel gauge, Meter for running hours and Oil temperature indicator.

Starting is achieved with a three-position switch for ease of operation.

Instrumentation – U 110 PACE - XC2003

The XC2003 control panel is located on the side of the compressor canopy.

The intuitive Atlas Copco XC2003 controller is easy to operate with all functions conveniently at your fingertips. The controller also

manages the engine ECU operating system, and a number of safety warnings and shut downs on various parameters (listed below).

XC2003 Controller Functionality:

• Displayed while running • Operational Buttons

- Hours - Start and stop of the unit

- Fuel level - View measurements, settings and alarms

- DEF level - Multi position cursor to navigate menus

- RPM

- Outlet pressure

• Compressor measurements displayed • Engine measurements displayed

- Running hours - Current fuel rate

- Fuel level - Engine coolant temperature

- Clock - Engine oil pressure

- Battery voltage - DPF Soot level

- Running hours - Engine RPM

- Regulating pressure

- Emergency stop count

- Average fuel consumption

- Minor and major service counters in hours and

days

• Warnings and Shutdowns • Alarms

- High temperature engine coolant - View current & historical alarms present

- High temperature compressor oil - History of last 20 alarms and events with time

- Engine oil pressure and date stamps

- Low fuel level - DM1 & DM2: View current engine codes

- High DPF soot level (SPN/FMI)

• Settings

- Manual regeneration of DPF

- Reset service timers

- Diagnostics for engine ECU

- Language settings

- Unit of measure changes

Product Reference - 2960 1910 00 Page 4 of 5

U 75-110 PACE KD WUX - Product Reference

Safety Devices

The compressor is standard equipped with safety devices for the compressor and the engine. The unit will be completely turned off should:

- Engine oil temperature rise too high

- Engine oil pressure drop too low

- Outlet temperature of the compressed air goes outside a specified range.

- Low fuel level

The main switch is a protection against unintended starting of the compressor.

Bodywork

The compressor is delivered as standard with a zinc or coated steel canopy with double-layer powder coat paint finish providing excellent corrosion

protection. The canopy is sound attenuated to meet the most current legal noise requirements. Wide doors provide complete service access to all

components.

Manufacturing & Environmental Standards

The U 75, U 100 and U 110 PACE are manufactured following stringent ISO 9001 regulations, and by a fully implemented Environmental

Management System fulfilling ISO 14001 requirements. Attention has been given to ensure minimum negative impact to the environment.

Supplied Documentation

The unit is delivered with the following documents and certificates:

- Spare parts list for compressor.

- Instruction manual for both compressor and Engine.

- Machine test certificate

- Vessel certificate.

Warranty Coverage

• Please refer to product presentation for warranty info.

• Extended Warranty Programs are available; please contact your local sales representative for more info.

* Note: Due to continuous improvements in the products, the technical specifications are subject to change without prior notice.

Product Reference - 2960 1910 00 Page 5 of 5

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Atlas Copco XAS 400, XATS 350, XAHS 350 and XAHS 400 PACE compressorsDocument5 pagesAtlas Copco XAS 400, XATS 350, XAHS 350 and XAHS 400 PACE compressorswayan mardanaNo ratings yet

- Atlas Copco U 110 KD WUX Product Reference SheetDocument4 pagesAtlas Copco U 110 KD WUX Product Reference SheetYanNo ratings yet

- PRS XAS 48-7 G 6 kVA KD S5 EN Antwerp 2960 7180 00Document5 pagesPRS XAS 48-7 G 6 kVA KD S5 EN Antwerp 2960 7180 00duroux.thibaultNo ratings yet

- Hurricane B7-41/1000: Product ReferenceDocument8 pagesHurricane B7-41/1000: Product ReferenceY.EbadiNo ratings yet

- XAVS450 LEAFLET2@New CrusherDocument5 pagesXAVS450 LEAFLET2@New Crusherสิทธิพล โพธิ์ประยูร100% (1)

- Atlas Copco: Small Portable Air CompressorsDocument2 pagesAtlas Copco: Small Portable Air CompressorsAsad AijazNo ratings yet

- Product Reference Sheet XR (H, V, X, Y) S 1150-1500, Y1200-1260, XAVS 1800 CD T3 WUX 2960 2340 02 EN PDFDocument6 pagesProduct Reference Sheet XR (H, V, X, Y) S 1150-1500, Y1200-1260, XAVS 1800 CD T3 WUX 2960 2340 02 EN PDFmoisesNo ratings yet

- The 8 Series Utility Range: What Do You Integrate?Document4 pagesThe 8 Series Utility Range: What Do You Integrate?Asad AijazNo ratings yet

- Trident Edv-X - AUTO DRAIN VALVESDocument2 pagesTrident Edv-X - AUTO DRAIN VALVESBOOBALANNo ratings yet

- Product Reference CPS 275 - 400Document4 pagesProduct Reference CPS 275 - 400Anderson Lopez100% (1)

- Technical data sheet 75DV,10DV 2Document1 pageTechnical data sheet 75DV,10DV 2kwstdbjp5fNo ratings yet

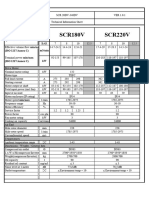

- Technical data sheet 180V,220V ver2Document1 pageTechnical data sheet 180V,220V ver2kwstdbjp5fNo ratings yet

- Data Sheet - CompressorDocument2 pagesData Sheet - CompressorPruthviraj JuniNo ratings yet

- Midea LC - Product Presentation & Technical Details - 16092021Document85 pagesMidea LC - Product Presentation & Technical Details - 16092021YUVI RAJNo ratings yet

- 2x1, 3x1, 4x1 and 5x1: Multisplit Inverter H6 Outdoor Unit MUEX-H6 SeriesDocument7 pages2x1, 3x1, 4x1 and 5x1: Multisplit Inverter H6 Outdoor Unit MUEX-H6 SeriesAbdelbagiNo ratings yet

- Data Sheets: For Hfc/Hfo/Hcfc Refrigerants Standard and Ecoinside SeriesDocument3 pagesData Sheets: For Hfc/Hfo/Hcfc Refrigerants Standard and Ecoinside SeriesPatricia Lizeth Cossio ZuritaNo ratings yet

- Screw Compressors: Model: VD55-10DGDocument20 pagesScrew Compressors: Model: VD55-10DGVoştinar IoanNo ratings yet

- AB Series BrochureDocument2 pagesAB Series BrochureUttam KumarNo ratings yet

- Aicool XB - SeriesDocument9 pagesAicool XB - Seriessarjono100% (1)

- SN75 Series - 100 HP 60 HZ Horsepower Rated: Model SN7507 SN7509 SN7510 SN7512 Compressor PerformanceDocument2 pagesSN75 Series - 100 HP 60 HZ Horsepower Rated: Model SN7507 SN7509 SN7510 SN7512 Compressor PerformanceRicardo Guerrero SosaNo ratings yet

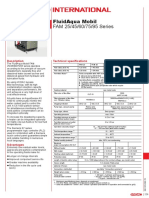

- EN7654 3 06 18 - FAM Economy PDFDocument8 pagesEN7654 3 06 18 - FAM Economy PDFPritesh KoratNo ratings yet

- Pisgsfeoilxpxdcaoaa 02 enDocument8 pagesPisgsfeoilxpxdcaoaa 02 enJumaidi AbdyNo ratings yet

- Technical Data Sheet EG75-10 BarDocument1 pageTechnical Data Sheet EG75-10 Barabdur rohmanNo ratings yet

- Ecotec Pro Combi Boiler 1786926Document2 pagesEcotec Pro Combi Boiler 1786926Mohsin KhanNo ratings yet

- CMV Mini (50HzDocument12 pagesCMV Mini (50HzMouyed Al QasemNo ratings yet

- Atb2 100 Piston CompressorDocument2 pagesAtb2 100 Piston CompressorClariss CrisolNo ratings yet

- CCI & CHI Series Inverter Minisplits GuideDocument5 pagesCCI & CHI Series Inverter Minisplits GuidebatcommanderNo ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- En7613 5 03 19 - Fam25 - 95 PDFDocument8 pagesEn7613 5 03 19 - Fam25 - 95 PDFhamsterNo ratings yet

- Compresor de Aire Atlas Copco XAS96Document9 pagesCompresor de Aire Atlas Copco XAS96Coni Fuenzalida VarelaNo ratings yet

- Mattei Rotary Vane Air Compressor AC 90 HDocument10 pagesMattei Rotary Vane Air Compressor AC 90 HÁrgyó András-BotondNo ratings yet

- EJ200 Turbofan Engine: The Innovative PowerDocument2 pagesEJ200 Turbofan Engine: The Innovative PowerufcNo ratings yet

- Product Ref Sheet XAS 27, XAS 65 APP 2954 6130 01 ENDocument5 pagesProduct Ref Sheet XAS 27, XAS 65 APP 2954 6130 01 ENduroux.thibaultNo ratings yet

- Technical Data:-: Diesel Generator Set C SeriesDocument2 pagesTechnical Data:-: Diesel Generator Set C Seriesmozes tamarapalliNo ratings yet

- MovinCool Climate Pro K60 CatalogDocument4 pagesMovinCool Climate Pro K60 CatalogMiguel VieiraNo ratings yet

- VacPumpReq TSB007Document6 pagesVacPumpReq TSB007zosuryantoNo ratings yet

- CP Range Guide LRC EnglishDocument8 pagesCP Range Guide LRC EnglishEverAngelNo ratings yet

- Air-Cooled Series R (TM) Product ReportDocument2 pagesAir-Cooled Series R (TM) Product ReportBernard Bonnin CervantesNo ratings yet

- Vacuum Regeneration Dryer AdvantagesDocument4 pagesVacuum Regeneration Dryer AdvantagesAcika PeleNo ratings yet

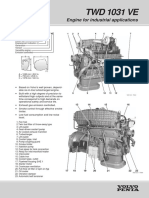

- Twd1031ve Twd1031veDocument2 pagesTwd1031ve Twd1031veHamtaro Animation75% (8)

- Compresor XP750WCU - TIER 2BDocument8 pagesCompresor XP750WCU - TIER 2BSergio RiveroNo ratings yet

- Parker&Hiross Antares Tandem KurutucuDocument8 pagesParker&Hiross Antares Tandem Kurutucumaxigas120No ratings yet

- One - Pager - SOGEVAC SV 320 BDocument2 pagesOne - Pager - SOGEVAC SV 320 BEOLOS COMPRESSORS LTDNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- Vacuum GVD 40-80 Datasheet 2014 0729 NocropDocument2 pagesVacuum GVD 40-80 Datasheet 2014 0729 NocropJohn KingNo ratings yet

- Especificaciones Mist Cannon CompletasDocument9 pagesEspecificaciones Mist Cannon CompletasIvan VascoNo ratings yet

- Aj1120 9mtu Ma enDocument2 pagesAj1120 9mtu Ma enCristian A.No ratings yet

- Room Air Conditioner: SVC MANUAL (Exploded View)Document8 pagesRoom Air Conditioner: SVC MANUAL (Exploded View)dougsanNo ratings yet

- Compair Serie CDocument16 pagesCompair Serie CJulio VolcanNo ratings yet

- ADT Catalogue.Document2 pagesADT Catalogue.pranesh kadamNo ratings yet

- Catalogo Comfortstar Piso TechoDocument3 pagesCatalogo Comfortstar Piso TechoSolucionesenfrio saNo ratings yet

- RTAF - Air-Cooled Series R (TM) Product ReportDocument2 pagesRTAF - Air-Cooled Series R (TM) Product ReportRafaelDutraNo ratings yet

- BITZER Software Analysis of Open Screw CompressorsDocument6 pagesBITZER Software Analysis of Open Screw CompressorsRajkumar GulatiNo ratings yet

- Data Sheets: UL Semi-Hermetic Reciprocating Compressors UL Standard Series / For HFC-HCFC-HFO BlendsDocument3 pagesData Sheets: UL Semi-Hermetic Reciprocating Compressors UL Standard Series / For HFC-HCFC-HFO BlendsAruna MadhuchinthakaNo ratings yet

- ), 1$/ DRAWINGS FOR Centrifugal SeparatorDocument2,113 pages), 1$/ DRAWINGS FOR Centrifugal SeparatorCvetelin TodorovNo ratings yet

- The Ready To Go Range: The 8 Series. What Do You Tow?Document8 pagesThe Ready To Go Range: The 8 Series. What Do You Tow?Mohamad NasserNo ratings yet

- BITZER OS Compressor SimulationDocument6 pagesBITZER OS Compressor SimulationRajkumar GulatiNo ratings yet

- Manual Bomba EspumaDocument108 pagesManual Bomba EspumaFrancisco ManriquezNo ratings yet

- Ventilacion PROVAL Iny y Ext - SubmittalDocument10 pagesVentilacion PROVAL Iny y Ext - SubmittaloscarNo ratings yet

- Report For RCC Practical FinalDocument23 pagesReport For RCC Practical FinalBollywood RetroNo ratings yet

- European Tracked Micro-Rover For Planetary SurfaceDocument9 pagesEuropean Tracked Micro-Rover For Planetary SurfaceSuryank JoshiNo ratings yet

- Surfactant Classes GuideDocument27 pagesSurfactant Classes GuideromaNo ratings yet

- Slide Acceleration PracticalDocument14 pagesSlide Acceleration PracticalLucas MorganNo ratings yet

- Working With Stainless SteelDocument145 pagesWorking With Stainless SteelDanem HalasNo ratings yet

- Heat ExchangerDocument23 pagesHeat ExchangerchawarepNo ratings yet

- Pentens E-620F Data SheetDocument2 pagesPentens E-620F Data Sheetamelinda jocelinNo ratings yet

- METALUBE OCG5000 Statement of ConformityDocument3 pagesMETALUBE OCG5000 Statement of ConformityMohammedNo ratings yet

- BK9780851865027 00079Document98 pagesBK9780851865027 00079melikecerenNo ratings yet

- MercerizationDocument141 pagesMercerizationkreeshnuNo ratings yet

- Combination of Coprecipitation and Sonochemical Methods in Synthesizing Spinel Hausmannite NanomaterialDocument9 pagesCombination of Coprecipitation and Sonochemical Methods in Synthesizing Spinel Hausmannite NanomaterialM Faris AlfariziNo ratings yet

- 1 s2.0 S0022024813002820 Main PDFDocument6 pages1 s2.0 S0022024813002820 Main PDFSamah SamahNo ratings yet

- Heat Exchanger Design Problems in HysisDocument7 pagesHeat Exchanger Design Problems in HysisMuhammad Shariq Khan100% (3)

- ThermodynamicsDocument2 pagesThermodynamicsbalusharma1212No ratings yet

- Freeze DryingDocument20 pagesFreeze DryingWanda Suryadinata100% (1)

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument10 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingIOCL SHUTDOWNNo ratings yet

- Soil Sample AnalysisDocument10 pagesSoil Sample AnalysisOm MauryaNo ratings yet

- Benzofused HeterocyclesDocument6 pagesBenzofused HeterocyclesMohini Bajaj50% (2)

- Photosynthesis and Respiration ExplainedDocument1 pagePhotosynthesis and Respiration ExplainedjazsloanNo ratings yet

- Ce6021-Repair and Rehabilitation StructuresDocument46 pagesCe6021-Repair and Rehabilitation StructuresChandan Kumar100% (1)

- AMCP 706-185 Pyrotechnics Theory (Clean Scan) PDFDocument268 pagesAMCP 706-185 Pyrotechnics Theory (Clean Scan) PDFSam LarterNo ratings yet

- Packaged Rooftop Cooling, Heat Pumps and Gas Heating UnitsDocument80 pagesPackaged Rooftop Cooling, Heat Pumps and Gas Heating UnitsMohammad IsmailNo ratings yet

- Inkjet Printing of TextilesDocument71 pagesInkjet Printing of Textilesnagpal_aakashNo ratings yet

- PBT 17 Smart MaterialsDocument12 pagesPBT 17 Smart MaterialsRama WijayaNo ratings yet

- Atmospheric Distillation SOPDocument4 pagesAtmospheric Distillation SOPinvooo prabamadhanNo ratings yet

- Inert GasesDocument42 pagesInert GasesRAVI KUMAR INSANNo ratings yet

- AP Government GATE Online Classes: Day-10 (04.06.2020) Dr. R. Srikanth Professor ANITS-VisakhapatnamDocument74 pagesAP Government GATE Online Classes: Day-10 (04.06.2020) Dr. R. Srikanth Professor ANITS-VisakhapatnamRajmangal NishadNo ratings yet

- JIF103 PHYSICS 1: Solving Galilean Transformations of PositionDocument11 pagesJIF103 PHYSICS 1: Solving Galilean Transformations of PositionAhmad Haikal Ahmad Mochtar0% (1)

- Summary of ASTM D4628Document6 pagesSummary of ASTM D4628Dewi WulandhariNo ratings yet

- Laser Plasma Accelerators For Charged Particles PDFDocument105 pagesLaser Plasma Accelerators For Charged Particles PDFAjit UpadhyayNo ratings yet