Professional Documents

Culture Documents

FT CYC en Rev1

FT CYC en Rev1

Uploaded by

Michel NdiayeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FT CYC en Rev1

FT CYC en Rev1

Uploaded by

Michel NdiayeCopyright:

Available Formats

TECHNICAL DATA SHEET

EV-H EV-M GD-Z

GR-Z SJ-Z TS-GA

CHARACTERISTICS

Accessories for cable and chain

Zinc plated

Forged steel elements

For securing large loads

Applications: securing, cable fixing and protection, etc.

BASE MATERIAL

Ref. FT CYC-en Rev: 1 16/03/22 1 de 12

TECHNICAL DATA SHEET

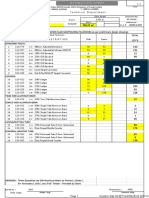

1. SELECTION CHART

SURFACE

ITEM CODE TYPE PHOTO MATERIAL

TREATMENT

1 EV-H 582 Carbon steel

2 EV-M 580 Carbon steel

3 GD-Z DIN 6899A Carbon steel

4 GR-Z 82101 Carbon steel

5 SJ-Z DIN 741 Carbon steel

6 TS-GA DIN 1480 Carbon steel

Ref. FT CYC-en Rev: 1 16/03/22 2 de 12

TECHNICAL DATA SHEET

2. INSTALLACION DATA

2.1 EV-H Female elevation ring

Surface Treatment Base Material

Zinc plated ≥ 5 µm s/ISO 4042 Cable Chain Rope

Installation Data

D1 D2 L1 H1

CODE Ø CABLE M Characteristics

[mm] [mm] [mm] [mm]

EVH06 20 M6 20 20 36 36

EBH08 20 M8 20 20 36 36

EVH10 25 M10 25 25 45 45 - Elevation ring type 582

EVH12 30 M12 30 30 54 53 - Zinc plated

EVH14 35 M14 35 35 63 62 - Forged steel

EVH16 35 M16 35 35 63 62

- Female thread

- Easy installation

EVH18 40 M18 40 40 72 71

- Consult resistance section for load capacity information

EVH20 40 M20 40 40 72 71

- Not valid for use as personal protective equipment (PPE)

EVH22 45 M22 50 50 90 90

- Perform lifts according to the sketches extracted from

EVH24 50 M24 50 50 90 90 de standard

EVH30 60 M30 65 65 108 128

EVH36 70 M36 75 70 126 147

PLAN

Ref. FT CYC-en Rev: 1 16/03/22 3 de 12

TECHNICAL DATA SHEET

2.2 EV-M Male elevation ring

Surface Treatment Base Material

Zinc plated ≥ 5 µm s/ISO 4042 Cable Chain Rope

Installation Data

CODE Ø CABLE M L1 D1 D2 H1 H2 Characteristics

EVM06 20 M6 36 20 20 36 13

EVM08 20 M8 36 20 20 36 13

EVM10 25 M10 45 25 25 45 17

EVM12 30 M12 54 30 30 53 20,5 - Elevation ring type 580

EVM14 35 M14 63 35 35 62 27 - Zinc plated

EVM16 35 M16 63 35 35 62 27 - Forged steel

EVM18 40 M18 72 40 40 71 30

- Male thread

- Easy installation

EVM20 40 M20 72 40 40 71 30

- Not valid for use as personal protective equipment (PPE)

EVM22 45 M22 90 50 50 90 36

- Consult resistance section for load capacity information

EVM24 50 M24 90 50 50 90 36

- Perform lifts according to the sketches extracted from

EVM30 60 M30 108 65 60 109 45 de standard

EVM36 70 M36 126 75 70 128 54

EVM42 80 M42 144 85 80 147 63

EVM48 90 M48 166 100 90 168 68

PLAN

Ref. FT CYC-en Rev: 1 16/03/22 4 de 12

TECHNICAL DATA SHEET

2.3 GD-Z Thimble

Surface Treatment Base Material

Zinc plated ≥ 5 µm s/ISO 4042 Cable Chain Rope

Installation Data

CODE Ø CABLE A B L1 L2 Characteristics

GDZ03 3,5 12 26,5 4 0,75

GDZ04 4 13 28,5 5 0,75

GDZ05 5 14 30 6 1

GDZ06 6 15 33 7 1 - Thimble according to DIN-6899A

GDZ08 8 18 39 9 1,25 - Zinc plated

GDZ10 10 22 47,5 11 1,5

- Easy installation

- Element to ensure the protection of the cable against

GDZ13 13 28 61 14 0,8

any friction

GDZ15 15 32 68,5 16 2

- Excellent finish

GDZ18 18 40 86,5 20 2,5

GDZ20 20 44 95 22 2,5

GDZ24 24 48 103 26 4

PLANO

Ref. FT CYC-en Rev: 1 16/03/22 5 de 12

TECHNICAL DATA SHEET

2.4 GR-Z Straight shackle

Surface Treatment Base Material

Zinc plated ≥ 5 µm s/ISO 4042 Cable Chain Rope

Installation Data

CODE Ø CABLE M A B D L1 L2 H1 Characteristics

GRZ05 10 M5 10 20 5 5 11 21

GRZ06 2 M6 12 25 6 6 14 28

GRZ08 16 M8 16 32 8 8 18 36

GRZ10 19 M10 19 39 10 10 20 43

GRZ11 22 M11 22 44 11 11 24 50 - Straight shackle type 82101

GRZ12 25 M12 25 49 12 12 28 57 - Zinc plated

GRZ14 28 M14 28 56 14 14 30 64 - Forged steel

GRZ16 32 M16 32 64 16 16 33 72 - Easy installation

GRZ18 36 M18 36 70 18 18 33,5 74 - Securing element for use with rings and others

GRZ20 38 M19 38 78 20 20 70 89

- For a correct use, the pin always has to be attached to

the ring while the cable must pull the shackle bow

GRZ22 44 M22 44 88 22 22 50 91

- Excellent finish

GRZ24 50 M25 50 97 24 24 47,5 99

- Not valid for use as personal protective equipment

GRZ28 56 M28 56 113 28 28 68 129

(PPE)

GRZ32 64 M32 64 128 32 32 73 143 - Consult resistance section for load capacity

GRZ36 70 M35 70 144 36 36 80 155 information

GRZ38 76 M48 76 152 38 38 85 171

GRZ42 76 M42 76 168 42 42 90 185

GRZ45 80 M45 80 180 45 45 98 202

GRZ50 90 M50 90 202 50 50 108 225

PLANO

Ref. FT CYC-en Rev: 1 16/03/22 6 de 12

TECHNICAL DATA SHEET

2.5 SJ-Z Wire rope clip

Surface Treatment Base Material

Zinc plated ≥ 5 µm s/ISO 4042 Cable Chain Rope

Installation Data

CODE ØCABLE M A B D H1 H2 L1 L2 Sw Characteristics

SJZ0403 3 M4 9 12 4 20 10 21 10 6,78 ÷ 7

SJZ0505 5 M5 11 13 6 24 10 23 11 - Wire rope clip according to DIN 741

7,78 ÷ 8

SJZ0506 6 – 6,5 M5 13 15 8 28 11 26 12 - Zinc plated

SJZ0608 8 M6 16 19 9 34 15 30 14 9,78 ÷ 10 - Forged steel

SJZ0810 10 M8 19 22 11 42 17 34 18 - Easy installation

12,73 ÷ 13 - Fixing element for cables in conjunction with

SJZ0811 11 M8 20 22 12 44 18 36 19

SJZ1013 13 M10 24 30 14 55 21 42 23 thimble and others

16,73 ÷ 17 - For a correct use, the distance between

SJZ1014 14 M10 25 30 15 57 22 44 23

attachments must be between 1.5 and 3 times

SJZ1216 16 M12 29 33 17 63 26 50 26

18,67 ÷ 19 the width L2..

SJZ1220 20 M12 32 38 20 75 30 54 29

- Excellent finish

SJZ1422 22 M14 37 44 23 85 34 61 33

21,67 ÷ 22 - Not valid for use as personal protective

SJZ1426 26 M14 41 45 27 95 37 5 35 equipment (PPE)

SJZ1630 30 M16 48 50 32 110 43 74 37 - Consult resistance section for load capacity

SJZ1634 34 M16 52 55 36 120 50 80 42 23,67 ÷ 24 information

SJZ1640 40 M16 58 60 42 140 55 88 45

PLAN

Ref. FT CYC-en Rev: 1 16/03/22 7 de 12

TECHNICAL DATA SHEET

2.6 TS-GA Turnbuckle hook/ring

Surface Treatment Base Material

Zinc plated ≥ 5 µm s/ISO 4042 Cable Chain Rope

Installation Data

CODE ØCABLE M A B C D1 D2 E H1 H2 L1 L2

TSGA06 1/4“ M6 12 109,5 ÷ 111,5 50 9 8 55 74 76 155 235

TSGA08 5/16” M8 15 109,5 ÷ 111,5 52 10 10,5 57 80 89 160 240

TSGA10 3/8” M10 18 124,4 ÷ 126,2 60 14 13 68 97 103 200 270

TSGA12 1/2" M12 21 124,4 ÷ 126,2 67 16 16 70 106 121 205 270

TSGA14 9/16” M14 24 139,3 ÷ 141,3 83 18 18 75 126 144 245 330

TSGA16 5/8” M16 27 169,3 ÷ 171,3 97 22 20 188 160 172 285 390

TSGA20 3/4" M20 34 199,3 ÷ 201,3 116 24 21 105 190 185 315 425

TSGA22 7/8” M22 36 219,3 ÷ 221,3 120 28 24 118 200 216 330 450

TSGA24 1” M24 39 254,3 ÷ 256,3 125 28 26 135 210 225 405 570

TSGA30 1 1/4" M30 45 254,3 ÷ 256,3 150 31 34 135 240 250 450 595

TSGA36 1 1/2" M36 55 294,2, ÷ 296,7 160 38 46 160 276 284 516 676

Characteristics

- Turnbuckle hook/ring according to DIN 1480

- Zinc plated

- Forged steel

- Easy installation

- Versatility in the installation thanks to his combination of hook and ring

- Excellent finish

- Not valid for use as personal protective equipment (PPE)

PLAN

Ref. FT CYC-en Rev: 1 16/03/22 8 de 12

TECHNICAL DATA SHEET

3. LOADS

3.1 EV-H Female elevation ring

Load capacity Load capacity Load capacity

Axial load capacity

per ring (WLL) per ring (WLL) per ring (WLL)

per ring (WLL)

0° < β ≤ 45° β > 45° - 60° 0° ≤ β ≤ 45°

Code Cable Metrics

EVH06 20 M6 75 55 38

EBH08 20 M8 140 100 70

EVH10 25 M10 230 170 115

EVH12 30 M12 340 240 170

EVH14 35 M14 490 350 245

EVH16 35 M16 700 500 350

EVH18 40 M18 850 600 425

EVH20 40 M20 1200 860 600

EVH22 45 M22 1400 1000 700

EVH24 50 M24 1800 1290 900

EVH30 60 M30 3200 2300 1600

EVH36 70 M36 4600 3300 2300

3.2 EV-M Male elevation ring

Load capacity Load capacity Load capacity

Axial load capacity

per ring (WLL) per ring (WLL) per ring (WLL)

per ring (WLL)

0° < β ≤ 45° β > 45° - 60° 0° ≤ β ≤ 45°

Code Cable Metrics

EVM06 20 M6 75 55 38

EVM08 20 M8 140 100 70

EVM10 25 M10 230 170 115

EVM12 30 M12 340 240 170

EVM14 35 M14 490 350 245

EVM16 35 M16 700 500 350

EVM18 40 M18 850 600 425

EVM20 40 M20 1200 860 600

EVM22 45 M22 1400 1000 700

EVM24 50 M24 1800 1290 900

EVM30 60 M30 3200 2300 1600

EVM36 70 M36 4600 3300 2300

EVM42 80 M42 6300 4500 3150

EVM48 90 M48 8600 6100 4300

Ref. FT CYC-en Rev: 1 16/03/22 9 de 12

TECHNICAL DATA SHEET

3.3 GR-Z Straight shackle

Axial load capacity per thimble (WLL)

Code Cable Metrics

GRZ05 10 M5 70

GRZ06 12 M6 100

GRZ08 16 M8 250

GRZ10 19 M10 400

GRZ11 22 M11 470

GRZ12 25 M12 630

GRZ14 28 M14 750

GRZ16 32 M16 1000

GRZ18 36 M18 1300

GRZ20 38 M19 1600

GRZ22 44 M22 2000

GRZ24 50 M25 2500

GRZ28 56 M28 3150

GRZ32 64 M32 4000

GRZ36 70 M35 5000

GRZ38 76 M48 6300

GRZ42 76 M42 8000

GRZ45 80 M45 10000

GRZ50 90 M50 12500

3.4 TS-GA Turnbuckle hook/ring

Axial load capacity per shackle (WLL)

Code Cable Metrics

TSGA06 1/4“ M6 75

TSGA08 5/16” M8 165

TSGA10 3/8” M10 235

TSGA12 1/2" M12 320

TSGA14 9/16” M14 420

TSGA16 5/8” M16 530

TSGA20 3/4" M20 730

TSGA22 7/8” M22 1120

TSGA24 1” M24 1550

TSGA30 1 1/4" M30 2240

TSGA36 1 1/2" M36 3530

Ref. FT CYC-en Rev: 1 16/03/22 10 de 12

TECHNICAL DATA SHEET

4. INSTALLATION PROCESS AND RECOMMENDATIONS

4.1 EV-H / EV-M Female/male elevation ring

- Before use it, the ring must be checked for its correct seating and apparent damage.

- Do not continue with the use of deformed rings or reuse them, if possible these should be

replaced.

- In case of installing the elevation ring in a through hole, one nut must be fully threaded and

tightened from the other side.

- The allowable load values shown in the second column apply to a maximum angle of 45 °, and

the maximum values shown in the third column apply to a maximum angle of 45° in all

directions regarding the plane of the ring. The rings must not be loaded laterally (see attached

images). In those cases where a specific position has been specified to thread the ring, use

appropriate washers to avoid not allowable loads.

4.2 GR-Z Straight shackle

1.Installation:

- Shackles should be inspected before its use to ensure that:

a) The body and the pin of the shackle are of the same size, type and manufacture.

b) All marks are legible.

c) The body and pin threads are not damaged.

d) The body and the pin are not twisted.

e) The body and the pin are not unduly worn.

f) El cuerpo y el pasador estén exentos de entallas, muescas, grietas y corrosión.

g) The body and the pin are free of notches, nicks, cracks and corrosion.

- Make sure, if applicable, that the pin is correctly screwed into the shackle head, that is,

tighten by hand and then with a punch or another appropriate tool, until the flattened part of

the pin seats on the head of the shackle. Make sure that the pin is long enough so that it can

Figure 1 be fully inserted in the threaded head, or the flattened part of the pin reaches the other head.

- In all cases, when the pin is correctly attached to the shackle body, the width between the

two legs, W, should not be significantly reduced.

- An incorrect pin positioning may be due to a bent pin, a lower pitch threading, or a

misalignment between the holes. In these cases, the shackle is never used.

- Never substitute the shackle pin except for one of the same size, class and specification,

because it may not be appropriate for the required loads.

2.Use

- The correct type of shackle for each application is selected from the provided information.

- Shackles should not be used in a way that creates lateral loads. This means that the body of

the shackle should be loaded along the axis of its center line (see Figure 1).

- When using multi-leg sling shackles, the effect of the angle between the legs of the sling

should be considered. The more the angle opens, the more the load increases in each leg of

the sling and therefore on the shackles.

- When a shackle is used to attach two slings to the hook of a lifting device, the two slings

should be attached to the body of a bow shackle, and the hook should be placed on the pin of

Figure 2 the shackle. The angles between the slings must not exceed 120°.

- To avoid loading the shackle with an eccentric load, spacers can be placed on one or both

ends of the shackle pin (see Figure 2).

Ref. FT CYC-en Rev: 1 16/03/22 11 de 12

TECHNICAL DATA SHEET

- The width between the shackle jaws should not be reduced by welding washers or spacers to

the inside faces of the heads, or by closing the jaws, because this will have a detrimental

effect on the properties of the shackle.

- When a shackle is used to secure the upper part of a set of cable groups, the load on that

shackle is increased by the block and tackle effect.

- Avoid applications in which due to movement (for example, the load or the cable ones) the

shackle pin can rotate and eventually unscrew (see Figures 3 and 4).

- In applications where the pin must be left in place for extended periods of time, or when

maximum security is required, a type X pin should be used.

- Avoid applications where the load is unstable (see Figure 4).

- Shackles should not be modified, heat treated, galvanized or coated without the approval of

the manufacturer.

Figure 3

- Do not use shackles outside the temperature range -20 ° C to 200 ° C without consulting the

manufacturer.

- Shackles should not be immersed in acidic solutions or exposed to acid fumes or another

chemicals without the approval of the manufacturer. Attention must be paid to the fact that

certain manufacturing processes involve acid solutions, vapors, etc. and in these cases advice

should be ask to the manufacturer.

- The choice of shackles assumes the absence of exceptionally dangerous conditions.

Exceptionally hazardous conditions include offshore activities, lifting people, and lifting

potentially dangerous loads such as molten metals, corrosive materials or fissile materials. In

these cases a competent person should assess the level of risk and the safe lifting load should

be reduced in accordance with the maximum working load.

Figure 4

Ref. FT CYC-en Rev: 1 16/03/22 12 de 12

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- The Design of Continuous Polycondensation ReactorsDocument189 pagesThe Design of Continuous Polycondensation ReactorsArmiee Infinite100% (1)

- 22B QS001B en P PDFDocument18 pages22B QS001B en P PDFtechlabNo ratings yet

- Bushings PDFDocument32 pagesBushings PDFRacha AmelNo ratings yet

- Technical Specification: Group Standards Department ©Document3 pagesTechnical Specification: Group Standards Department ©Mohamed MusaNo ratings yet

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayNo ratings yet

- Chhatisgarh SIDDocument3 pagesChhatisgarh SIDbijayaceNo ratings yet

- Industrial Batteries - Network Power Sonnenschein A600 Premium Quality For Uninterrupted CommunicationDocument16 pagesIndustrial Batteries - Network Power Sonnenschein A600 Premium Quality For Uninterrupted CommunicationglukkerNo ratings yet

- Datasheet YM2D24-C50PN1MRJA4 2121276 enDocument5 pagesDatasheet YM2D24-C50PN1MRJA4 2121276 enavinashrai1No ratings yet

- N Sschou JDocument3 pagesN Sschou JdraganbabicNo ratings yet

- MV Full CatalogueDocument11 pagesMV Full Catalogueayabulela421No ratings yet

- Fork Sensor LeuzeDocument2 pagesFork Sensor LeuzeArtemis StateNo ratings yet

- 1N4148WS (SMD) PDFDocument5 pages1N4148WS (SMD) PDFRobmixNo ratings yet

- ວາວຄອນໂທມDocument2 pagesວາວຄອນໂທມPhomma KhinphommavongNo ratings yet

- Lapp Pro143886enDocument8 pagesLapp Pro143886enFILE SERVERNo ratings yet

- Photovoltaic PV1-F DC Solar Cable: ApplicationDocument17 pagesPhotovoltaic PV1-F DC Solar Cable: Applicationkser82No ratings yet

- 400v Parts List dp10 2 Ang 090609Document8 pages400v Parts List dp10 2 Ang 090609gerahunterz96No ratings yet

- Apm50-B1Document7 pagesApm50-B1Rafael NunesNo ratings yet

- CM Fc9000-Eng-Int-F-CatalogueDocument20 pagesCM Fc9000-Eng-Int-F-CatalogueEdgardo Ariel RodriguezNo ratings yet

- Clamp PDFDocument36 pagesClamp PDFRamadan RashadNo ratings yet

- Powerflex 40 Adjustable Frequency Ac Drive: General PrecautionsDocument18 pagesPowerflex 40 Adjustable Frequency Ac Drive: General PrecautionsOrlando BoNo ratings yet

- Cable GlandDocument1 pageCable GlandDevy MangimbaNo ratings yet

- Ebara Pumps Europe S.p.a.'s Data&CertificatesDocument7 pagesEbara Pumps Europe S.p.a.'s Data&CertificatesErdi AkkusNo ratings yet

- Welding Stal 20 PDFDocument20 pagesWelding Stal 20 PDFFaraj KhalikovNo ratings yet

- Bushings For PT MY2014Document36 pagesBushings For PT MY2014Shung Tak ChanNo ratings yet

- Industrial Low Voltage Cables: Construction: ResistanceDocument2 pagesIndustrial Low Voltage Cables: Construction: ResistanceFer F. Rodriguez CNo ratings yet

- N 2 XHDocument1 pageN 2 XHElda DokaNo ratings yet

- Easy Servo Motors: Stepper Motors With Encoders, 0.9 NM To 20 0 NMDocument13 pagesEasy Servo Motors: Stepper Motors With Encoders, 0.9 NM To 20 0 NMKarthick MNo ratings yet

- Stick Electrode For Mild Steel: ClassificationDocument1 pageStick Electrode For Mild Steel: Classificationmohamed AdelNo ratings yet

- Flexidrum Nshtou 1Document3 pagesFlexidrum Nshtou 1Anonymous ItzBhUGoiNo ratings yet

- FPJ 320 Series: Explosion Proof Cum Weatherproof Junction BoxesDocument2 pagesFPJ 320 Series: Explosion Proof Cum Weatherproof Junction BoxestejassidhpuraNo ratings yet

- Low Voltage Range of CablesDocument78 pagesLow Voltage Range of CablesstaffxavierNo ratings yet

- CM Bc9000-Eng-Int-B-CatalogueDocument20 pagesCM Bc9000-Eng-Int-B-CatalogueMoussa BANo ratings yet

- Test Certificate: D&H Secheron Electrodes Pvt. LTDDocument1 pageTest Certificate: D&H Secheron Electrodes Pvt. LTDAmit DamaNo ratings yet

- Krisbow Welding KatalogDocument16 pagesKrisbow Welding Katalogpro.bacotgamingNo ratings yet

- Irrigation Slab SCAFFOLDING BOQ (CRCC)Document1 pageIrrigation Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelNo ratings yet

- Sonnenschein A600 en BateriasDocument15 pagesSonnenschein A600 en Bateriasgilberto floresNo ratings yet

- UK-0009 EN 14399-3 8 HR NutDocument4 pagesUK-0009 EN 14399-3 8 HR NutPınar YeloğluNo ratings yet

- NYCWY PVC 0.6/1kV Power CableDocument3 pagesNYCWY PVC 0.6/1kV Power CableUserNo ratings yet

- RD 2015-05-001-V01 Evaluation Board For M909 ModulesDocument24 pagesRD 2015-05-001-V01 Evaluation Board For M909 ModulesasokanenNo ratings yet

- Product CertificateDocument1 pageProduct CertificateMURSHID MUHAMMEDNo ratings yet

- Fixations-Ms21047 MS21055Document1 pageFixations-Ms21047 MS21055FredNo ratings yet

- Valbol Worcester Actuador ElectricoDocument5 pagesValbol Worcester Actuador ElectricoasdrumelNo ratings yet

- EJ Handbook.A5Document261 pagesEJ Handbook.A5ElMacheteDelHuesoNo ratings yet

- 03 Bushing-Cedaspa Type FDocument7 pages03 Bushing-Cedaspa Type FKatherine SmithNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- Datasheet en 20170526Document10 pagesDatasheet en 20170526LODELBARRIO RDNo ratings yet

- K034 - Daikoflux 940Document1 pageK034 - Daikoflux 940cwiksjNo ratings yet

- RFE-FRHF (I) : Armoured and Individually Screened Instrumentation and Communication Cable 250VDocument2 pagesRFE-FRHF (I) : Armoured and Individually Screened Instrumentation and Communication Cable 250Vacastanopadilla4100No ratings yet

- Connector - SACC-M12MST-3PECON-PG11-M - 1404643: Product FeaturesDocument6 pagesConnector - SACC-M12MST-3PECON-PG11-M - 1404643: Product FeaturesAndres LopezNo ratings yet

- Technor TL2 Led enDocument4 pagesTechnor TL2 Led enArmin HajdarovićNo ratings yet

- OPzV2 1000Document2 pagesOPzV2 1000HabibNo ratings yet

- Test Certificate: D&H Secheron Electrodes Pvt. LTDDocument1 pageTest Certificate: D&H Secheron Electrodes Pvt. LTDAmit DamaNo ratings yet

- Technical Data - HVR APC - U Series ResistorsDocument2 pagesTechnical Data - HVR APC - U Series ResistorsNuma LumaNo ratings yet

- LC.D09-18 Batam HU 003710 M1Document5 pagesLC.D09-18 Batam HU 003710 M1Hudzaifah Abdurrazaq ANo ratings yet

- Varistors Data SheetDocument11 pagesVaristors Data SheetEdilsonMatiasdeCastroNo ratings yet

- Wire Spec 44 PDFDocument5 pagesWire Spec 44 PDFAdnan khanNo ratings yet

- A600 T E-2017Document13 pagesA600 T E-2017RezaYulisnaPNNo ratings yet

- MARATHON - M12V105FT BatteriesDocument12 pagesMARATHON - M12V105FT BatteriesAntonio Fernandez GonzalezNo ratings yet

- Az 16 12zvrk m16 2023 05 26 02 34Document6 pagesAz 16 12zvrk m16 2023 05 26 02 34Ian RustNo ratings yet

- AL - CU - ND523-11 - Manguitos MET (En)Document3 pagesAL - CU - ND523-11 - Manguitos MET (En)Deepak KumarNo ratings yet

- Conarc 49C: Basic ElectrodeDocument2 pagesConarc 49C: Basic ElectrodeMark Williams100% (1)

- Unit G - Punchlist BasementDocument8 pagesUnit G - Punchlist BasementjhecyNo ratings yet

- Coordinate CompoundDocument13 pagesCoordinate CompoundAman KapoorNo ratings yet

- Ohmic Heating of FoodsDocument18 pagesOhmic Heating of FoodsHarish SrinivasanNo ratings yet

- Eshmuno S ResinDocument4 pagesEshmuno S ResinTuyền KimNo ratings yet

- Tutorials 1-12: Tutorial Sheet 1Document11 pagesTutorials 1-12: Tutorial Sheet 1NarasimharaoNo ratings yet

- Grup XII.B Autoclave MA-678GEDocument2 pagesGrup XII.B Autoclave MA-678GEFàçtïoñ Arya RõçkNo ratings yet

- Christy Catalytics-Product OverviewDocument2 pagesChristy Catalytics-Product OverviewWili Nur RahmanNo ratings yet

- John Maulbetsch CoolingDocument32 pagesJohn Maulbetsch Coolingsmartleo_waloNo ratings yet

- 6.730 Physics For Solid State Applications: Lecture 32: Introduction To Boltzmann TransportDocument12 pages6.730 Physics For Solid State Applications: Lecture 32: Introduction To Boltzmann TransportHùng NguyễnNo ratings yet

- Module-3: Cutting Tool Materials, Geometry and Surface FinishDocument18 pagesModule-3: Cutting Tool Materials, Geometry and Surface FinishYashas KattemaneNo ratings yet

- DasdDocument2 pagesDasdAnonymous lApm6PsfNo ratings yet

- Opening Systems For Flap and Drop Down DoorsDocument24 pagesOpening Systems For Flap and Drop Down DoorsPedro Alexander Alfonso AceroNo ratings yet

- Cigweld Weldskill 170 HF PDFDocument48 pagesCigweld Weldskill 170 HF PDFRizaNo ratings yet

- Li 2018Document19 pagesLi 2018Eduardo SaavedraNo ratings yet

- 2 Electrochemistry (Redox)Document61 pages2 Electrochemistry (Redox)Gerald Paul SumagpaoNo ratings yet

- Excelitas VTP4085H DatasheetDocument1 pageExcelitas VTP4085H DatasheetAlexNo ratings yet

- R1116010-00000-CI-SPC-0006-0A-Civil WorksDocument37 pagesR1116010-00000-CI-SPC-0006-0A-Civil WorksLNo ratings yet

- Dissimilar Welding ChartDocument4 pagesDissimilar Welding ChartMehmet Soysal0% (1)

- AASHTO T-153 Blaine (Ingles)Document6 pagesAASHTO T-153 Blaine (Ingles)Adrii FHNo ratings yet

- Surface Engineering For CorrosionDocument24 pagesSurface Engineering For CorrosionSreedhar Patnaik.MNo ratings yet

- Thermochimica Acta: Tarik Sadik, Caroline Pillon, Christian Carrot, Jose-Antonio Reglero RuizDocument8 pagesThermochimica Acta: Tarik Sadik, Caroline Pillon, Christian Carrot, Jose-Antonio Reglero RuizphillynovitaNo ratings yet

- Coa MG StearatDocument3 pagesCoa MG StearatJelietha Poenya JyeethaNo ratings yet

- Biopolymers From Waste Valorization Nutracos 2015Document5 pagesBiopolymers From Waste Valorization Nutracos 2015EL Hassania EL HERRADINo ratings yet

- Pipe Log Book: Integrated Field Plan Execution Services in Satellite Field in Rj-On-90/1 Block ProjectDocument2 pagesPipe Log Book: Integrated Field Plan Execution Services in Satellite Field in Rj-On-90/1 Block ProjectPRAKASH PANDEYNo ratings yet

- GridDocument8 pagesGridأنس الجعديNo ratings yet

- 1 - NOTES Reactions and Stoichiometry PreAP ReviewDocument5 pages1 - NOTES Reactions and Stoichiometry PreAP ReviewspamNo ratings yet

- Ship Collector: Ge Healthcare D 5180882-100, R 12 B S S S: I P LDocument20 pagesShip Collector: Ge Healthcare D 5180882-100, R 12 B S S S: I P LMario RamosNo ratings yet

- Jak 0cDocument4 pagesJak 0cOliver MendozaNo ratings yet