Professional Documents

Culture Documents

DACE Labour Norms Piping Tables V2

Uploaded by

Amir Abaza0 ratings0% found this document useful (0 votes)

5 views33 pagesOriginal Title

DACE_Labour_Norms_Piping_Tables_V2

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views33 pagesDACE Labour Norms Piping Tables V2

Uploaded by

Amir AbazaCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 33

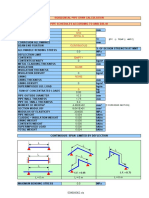

Size ASA/DIN 1/8" / 6

Outside diameter in mm 10.3

Wallthickness in mm 1.2 1.7 2.4

Schedule 10S 40 STD 80 XS

3.1 Installation of pipe in plant (ISBL) 0.21 0.21 0.22

3.2 Install pipe on sleepers/ in rack (OSBL) 0.18 0.18 0.18

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.10

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 0.15

4.3 Fitting with 3 ends (T and Y pieces) 0.20

5.1 Butt weld 0.33 0.33 0.33

5.2 Fillet weld 0.20 0.20 0.20

5.3 Mittre weld 0.43 0.43 0.43

5.4 Branch weld 0.53 0.53 0.53

5.5 Reinforcing ring 0.59 0.59 0.59

5.6 Olet weld 0.63 0.64 0.65

5.7 Cutting pipe in case of changes 0.05 0.05 0.05

6.1 Flange connection 150# , PN 10-16 0.43

6.2 Flange connection 300# , PN 25-40 0.49

6.3 Flange connection 600#- 900# , PN 64-160 0.54

6.4 Flange connection 1500#-2500# , PN 250-320 0.61

6.5 Spectacle blind, blind flange, spade 0.09

6.6 Bending of pipe 0.15

6.7 Cutting thread 0.08

6.8 Threaded connection 0.07

7.1 Installation of valve 150# , PN 10-16 0.08

7.2 Installation of valve 300# , PN 25-40 0.08

7.3 Installation of valve 600#- 900# , PN 64-160 0.09

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.11

7.5 Installation of valve incl. drive 0.03

7.6 Installation of wafer-type valve 0.02

8.1 Pressure testing : hydrostatic/pneumatic 0.03

Size ASA/DIN 1/4" / 8

Outside diameter in mm 13.7

Wallthickness in mm 1.7 2.2 3.0

Schedule 10S 40 STD 80 XS

3.1 Installation of pipe in plant (ISBL) 0.22 0.22 0.23

3.2 Install pipe on sleepers/ in rack (OSBL) 0.18 0.19 0.19

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.12

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 0.17

4.3 Fitting with 3 ends (T and Y pieces) 0.22

5.1 Butt weld 0.36 0.36 0.37

5.2 Fillet weld 0.22 0.22 0.22

5.3 Mittre weld 0.47 0.47 0.48

5.4 Branch weld 0.58 0.58 0.59

5.5 Reinforcing ring 0.65 0.65 0.66

5.6 Olet weld 0.69 0.71 0.73

5.7 Cutting pipe in case of changes 0.05 0.06 0.06

6.1 Flange connection 150# , PN 10-16 0.44

6.2 Flange connection 300# , PN 25-40 0.50

6.3 Flange connection 600#- 900# , PN 64-160 0.55

6.4 Flange connection 1500#-2500# , PN 250-320 0.62

6.5 Spectacle blind, blind flange, spade 0.09

6.6 Bending of pipe 0.15

6.7 Cutting thread 0.08

6.8 Threaded connection 0.07

7.1 Installation of valve 150# , PN 10-16 0.10

7.2 Installation of valve 300# , PN 25-40 0.11

7.3 Installation of valve 600#- 900# , PN 64-160 0.13

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.14

7.5 Installation of valve incl. drive 0.04

7.6 Installation of wafer-type valve 0.02

8.1 Pressure testing : hydrostatic/pneumatic 0.03

Size ASA/DIN 3/8" / 10

Outside diameter in mm 17.1

Wallthickness in mm 1.7 2.0 2.3 2.6 2.9 3.2 4.0 4.5

Schedule 5S STD XS

3.1 Installation of pipe in plant (ISBL) 0.22 0.22 0.23 0.23 0.23 0.23 0.24 0.24

3.2 Install pipe on sleepers/ in rack (OSBL) 0.19 0.19 0.19 0.20 0.20 0.20 0.20 0.21

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.13

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 0.18

4.3 Fitting with 3 ends (T and Y pieces) 0.24

5.1 Butt weld 0.39 0.40 0.40 0.40 0.40 0.40 0.41 0.41

5.2 Fillet weld 0.24 0.24 0.24 0.24 0.24 0.24 0.24 0.25

5.3 Mittre weld 0.51 0.51 0.52 0.52 0.52 0.52 0.53 0.53

5.4 Branch weld 0.63 0.63 0.63 0.64 0.64 0.64 0.65 0.65

5.5 Reinforcing ring 0.70 0.70 0.71 0.71 0.71 0.71 0.72 0.73

5.6 Olet weld 0.75 0.76 0.77 0.78 0.79 0.80 0.82 0.83

5.7 Cutting pipe in case of changes 0.06 0.06 0.06 0.06 0.06 0.06 0.06 0.06

6.1 Flange connection 150# , PN 10-16 0.45

6.2 Flange connection 300# , PN 25-40 0.50

6.3 Flange connection 600#- 900# , PN 64-160 0.56

6.4 Flange connection 1500#-2500# , PN 250-320 0.62

6.5 Spectacle blind, blind flange, spade 0.09

6.6 Bending of pipe 0.16

6.7 Cutting thread 0.09

6.8 Threaded connection 0.07

7.1 Installation of valve 150# , PN 10-16 0.13

7.2 Installation of valve 300# , PN 25-40 0.14

7.3 Installation of valve 600#- 900# , PN 64-160 0.16

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.18

7.5 Installation of valve incl. drive 0.05

7.6 Installation of wafer-type valve 0.03

8.1 Pressure testing : hydrostatic/pneumatic 0.03

Size ASA/DIN 1/2" / 15

Outside diameter in mm 21.3

Wallthickness in mm 1.7 2.0 2.1 2.3 2.6 2.8 2.9 3.2 3.7 3.9 4 4.3 4.8 5.6 6 6.3 7.1 7.5

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.23 0.23 0.23 0.23 0.24 0.24 0.24 0.24 0.25 0.25 0.25 0.25 0.26 0.26 0.27 0.27 0.27 0.27

3.2 Install pipe on sleepers/ in rack (OSBL) 0.19 0.20 0.20 0.20 0.20 0.20 0.20 0.21 0.21 0.21 0.21 0.22 0.22 0.22 0.23 0.23 0.23 0.23

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.16

4.2 Fitting with 2 ends (elbows, reducers, mitre bends 0.23

4.3 Fitting with 3 ends (T and Y pieces) 0.29

5.1 Butt weld 0.43 0.43 0.43 0.44 0.44 0.44 0.44 0.44 0.45 0.45 0.45 0.45 0.46 0.46 0.47 0.47 0.47 0.48

5.2 Fillet weld 0.26 0.26 0.26 0.26 0.26 0.26 0.26 0.27 0.27 0.27 0.27 0.27 0.27 0.28 0.28 0.28 0.28 0.29

5.3 Mittre weld 0.56 0.56 0.56 0.57 0.57 0.57 0.57 0.57 0.58 0.58 0.58 0.59 0.59 0.60 0.60 0.61 0.62 0.62

5.4 Branch weld 0.69 0.69 0.69 0.70 0.70 0.70 0.70 0.71 0.71 0.72 0.72 0.72 0.73 0.74 0.74 0.75 0.76 0.76

5.5 Reinforcing ring 0.77 0.77 0.77 0.77 0.78 0.78 0.78 0.79 0.79 0.80 0.80 0.80 0.81 0.82 0.83 0.83 0.84 0.85

5.6 Olet weld 0.82 0.83 0.83 0.84 0.86 0.86 0.87 0.88 0.90 0.91 0.91 0.92 0.94 0.97 0.98 0.98 1.00 1.00

5.7 Cutting pipe in case of changes 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07

6.1 Flange connection 150# , PN 10-16 0.46

6.2 Flange connection 300# , PN 25-40 0.52

6.3 Flange connection 600#- 900# , PN 64-160 0.58

6.4 Flange connection 1500#-2500# , PN 250-320 0.65

6.5 Spectacle blind, blind flange, spade 0.09

6.6 Bending of pipe 0.17

6.7 Cutting thread 0.10

6.8 Threaded connection 0.08

7.1 Installation of valve 150# , PN 10-16 0.19

7.2 Installation of valve 300# , PN 25-40 0.21

7.3 Installation of valve 600#- 900# , PN 64-160 0.24

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.26

7.5 Installation of valve incl. drive 0.08

7.6 Installation of wafer-type valve 0.04

8.1 Pressure testing : hydrostatic/pneumatic 0.04

Size ASA/DIN 3/4" / 20 20

Outside diameter in mm 26.7 26.9

Wallthickness in mm 1.7 2.1 2.9 3.9 4.3 5.6 6 7.1 7.8 10.6 2 2.3 2.6 2.9 3.6 4.5 6.3

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.23 0.24 0.25 0.26 0.27 0.28 0.29 0.29 0.30 0.31 0.24 0.24 0.25 0.25 0.26 0.27 0.29

3.2 Install pipe on sleepers/ in rack (OSBL) 0.20 0.20 0.21 0.22 0.23 0.24 0.24 0.25 0.25 0.27 0.20 0.21 0.21 0.21 0.22 0.23 0.25

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.19 0.19

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 0.27 0.27

4.3 Fitting with 3 ends (T and Y pieces) 0.35 0.35

5.1 Butt weld 0.48 0.48 0.49 0.50 0.51 0.52 0.53 0.54 0.55 0.58 0.48 0.49 0.49 0.49 0.50 0.51 0.53

5.2 Fillet weld 0.29 0.29 0.29 0.30 0.30 0.31 0.32 0.32 0.33 0.35 0.29 0.29 0.29 0.30 0.30 0.31 0.32

5.3 Mittre weld 0.62 0.63 0.64 0.65 0.66 0.68 0.68 0.70 0.71 0.75 0.63 0.63 0.64 0.64 0.65 0.66 0.69

5.4 Branch weld 0.77 0.77 0.79 0.80 0.81 0.83 0.84 0.86 0.88 0.92 0.77 0.78 0.78 0.79 0.80 0.82 0.85

5.5 Reinforcing ring 0.85 0.86 0.87 0.89 0.90 0.93 0.94 0.96 0.97 1.03 0.86 0.87 0.87 0.88 0.89 0.91 0.95

5.6 Olet weld 0.91 0.93 0.97 1.03 1.05 1.11 1.13 1.17 1.19 1.21 0.92 0.94 0.96 0.97 1.01 1.06 1.14

5.7 Cutting pipe in case of changes 0.07 0.07 0.07 0.08 0.08 0.08 0.08 0.08 0.08 0.09 0.07 0.07 0.07 0.07 0.08 0.08 0.08

6.1 Flange connection 150# , PN 10-16 0.48 0.48

6.2 Flange connection 300# , PN 25-40 0.54 0.54

6.3 Flange connection 600#- 900# , PN 64-160 0.60 0.60

6.4 Flange connection 1500#-2500# , PN 250-320 0.67 0.67

6.5 Spectacle blind, blind flange, spade 0.10 0.10

6.6 Bending of pipe 0.19 0.19

6.7 Cutting thread 0.11 0.11

6.8 Threaded connection 0.09 0.09

7.1 Installation of valve 150# , PN 10-16 0.25 0.25

7.2 Installation of valve 300# , PN 25-40 0.28 0.28

7.3 Installation of valve 600#- 900# , PN 64-160 0.31 0.31

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.35 0.35

7.5 Installation of valve incl. drive 0.10 0.10

7.6 Installation of wafer-type valve 0.05 0.05

8.1 Pressure testing : hydrostatic/pneumatic 0.04 0.04

Size ASA/DIN 1" / 25 25

Outside diameter in mm 33.4 33.7

Wallthickness in mm 1.7 2.8 3.4 3.9 4.3 4.5 6 6.4 7.1 9.1 10.6 13.8 2 2.3 2.6 3.2 4 5 5.6 6.3 7.1

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.24 0.26 0.27 0.28 0.29 0.29 0.31 0.32 0.32 0.34 0.36 0.37 0.25 0.25 0.26 0.27 0.28 0.30 0.31 0.31 0.32

3.2 Install pipe on sleepers/ in rack (OSBL) 0.20 0.22 0.23 0.24 0.24 0.25 0.26 0.27 0.27 0.29 0.30 0.32 0.21 0.21 0.22 0.23 0.24 0.25 0.26 0.27 0.28

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.22 0.22

4.2 Fitting with 2 ends (elbows, reducers, mitre bends 0.31 0.31

4.3 Fitting with 3 ends (T and Y pieces) 0.40 0.40

5.1 Butt weld 0.54 0.55 0.56 0.57 0.57 0.58 0.60 0.61 0.62 0.65 0.68 0.73 0.55 0.55 0.55 0.56 0.57 0.59 0.60 0.61 0.62

5.2 Fillet weld 0.32 0.33 0.34 0.34 0.34 0.35 0.36 0.37 0.37 0.39 0.41 0.44 0.33 0.33 0.33 0.34 0.34 0.35 0.36 0.37 0.37

5.3 Mittre weld 0.70 0.72 0.73 0.74 0.75 0.75 0.78 0.79 0.81 0.85 0.88 0.94 0.71 0.71 0.72 0.73 0.74 0.76 0.78 0.79 0.81

5.4 Branch weld 0.86 0.88 0.90 0.91 0.92 0.92 0.96 0.97 0.99 1.05 1.09 1.16 0.87 0.88 0.88 0.90 0.92 0.94 0.96 0.98 1.00

5.5 Reinforcing ring 0.96 0.98 1.00 1.01 1.02 1.03 1.07 1.08 1.10 1.16 1.21 1.29 0.97 0.98 0.98 1.00 1.02 1.05 1.06 1.09 1.11

5.6 Olet weld 1.01 1.09 1.13 1.17 1.20 1.21 1.32 1.34 1.39 1.48 1.52 1.51 0.88 0.87 0.87 0.87 0.85 0.82 0.80 0.77 0.72

5.7 Cutting pipe in case of changes 0.08 0.08 0.08 0.09 0.09 0.09 0.09 0.09 0.09 0.10 0.10 0.11 0.08 0.08 0.08 0.08 0.09 0.09 0.09 0.09 0.09

6.1 Flange connection 150# , PN 10-16 0.50 0.50

6.2 Flange connection 300# , PN 25-40 0.56 0.56

6.3 Flange connection 600#- 900# , PN 64-160 0.62 0.62

6.4 Flange connection 1500#-2500# , PN 250-320 0.70 0.70

6.5 Spectacle blind, blind flange, spade 0.10 0.10

6.6 Bending of pipe 0.21 0.21

6.7 Cutting thread 0.12 0.12

6.8 Threaded connection 0.10 0.10

7.1 Installation of valve 150# , PN 10-16 0.31 0.31

7.2 Installation of valve 300# , PN 25-40 0.35 0.35

7.3 Installation of valve 600#- 900# , PN 64-160 0.39 0.39

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.44 0.44

7.5 Installation of valve incl. drive 0.13 0.13

7.6 Installation of wafer-type valve 0.06 0.06

8.1 Pressure testing : hydrostatic/pneumatic 0.04 0.04

Size ASA/DIN 1 1/4" / 32 32

Outside diameter in mm 42.2 42.4

Wallthickness in mm 1.7 2.8 3.6 3.9 4 4.3 4.5 4.9 6 6.4 7.1 9.7 10.6 13.8 2 2.3 2.6 2.9 3.6 4.5 5.6 6.3

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.25 0.28 0.29 0.30 0.30 0.31 0.31 0.32 0.34 0.35 0.36 0.40 0.41 0.44 0.26 0.27 0.27 0.28 0.30 0.31 0.33 0.35

3.2 Install pipe on sleepers/ in rack (OSBL) 0.21 0.24 0.25 0.26 0.26 0.26 0.27 0.27 0.29 0.30 0.31 0.34 0.35 0.37 0.22 0.23 0.23 0.24 0.25 0.27 0.28 0.30

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.26 0.26

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, 0.37 0.37

4.3 Fitting with 3 ends (T and Y pieces) 0.48 0.48

5.1 Butt weld 0.62 0.64 0.65 0.66 0.66 0.66 0.67 0.68 0.70 0.71 0.73 0.79 0.81 0.89 0.63 0.63 0.63 0.64 0.65 0.67 0.69 0.71

5.2 Fillet weld 0.37 0.38 0.39 0.39 0.40 0.40 0.40 0.41 0.42 0.43 0.44 0.47 0.49 0.53 0.38 0.38 0.38 0.38 0.39 0.40 0.42 0.43

5.3 Mittre weld 0.81 0.83 0.85 0.85 0.86 0.86 0.87 0.88 0.91 0.92 0.94 1.03 1.06 1.16 0.81 0.82 0.82 0.83 0.85 0.87 0.90 0.92

5.4 Branch weld 0.99 1.02 1.04 1.05 1.05 1.06 1.07 1.08 1.12 1.14 1.16 1.27 1.30 1.42 1.00 1.01 1.01 1.02 1.04 1.07 1.11 1.14

5.5 Reinforcing ring 1.10 1.13 1.16 1.17 1.17 1.18 1.19 1.20 1.25 1.26 1.29 1.41 1.45 1.58 1.11 1.12 1.13 1.14 1.16 1.19 1.24 1.26

5.6 Olet weld 1.16 1.26 1.33 1.36 1.37 1.40 1.42 1.46 1.57 1.60 1.67 1.88 1.94 2.05 1.19 1.21 1.24 1.27 1.34 1.42 1.53 1.60

5.7 Cutting pipe in case of changes 0.09 0.10 0.10 0.10 0.10 0.10 0.10 0.10 0.11 0.11 0.11 0.12 0.12 0.13 0.09 0.09 0.10 0.10 0.10 0.10 0.10 0.11

6.1 Flange connection 150# , PN 10-16 0.53 0.53

6.2 Flange connection 300# , PN 25-40 0.59 0.59

6.3 Flange connection 600#- 900# , PN 64-160 0.66 0.66

6.4 Flange connection 1500#-2500# , PN 250-320 0.74 0.74

6.5 Spectacle blind, blind flange, spade 0.11 0.11

6.6 Bending of pipe 0.25 0.25

6.7 Cutting thread 0.14 0.14

6.8 Threaded connection 0.12 0.12

7.1 Installation of valve 150# , PN 10-16 0.40 0.40

7.2 Installation of valve 300# , PN 25-40 0.45 0.45

7.3 Installation of valve 600#- 900# , PN 64-160 0.50 0.50

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.56 0.56

7.5 Installation of valve incl. drive 0.16 0.16

7.6 Installation of wafer-type valve 0.08 0.08

8.1 Pressure testing : hydrostatic/pneumatic 0.05 0.05

Size ASA/DIN 1 1/2" / 40

Outside diameter in mm 48.3

Wallthickness in mm 1.7 2 2.3 2.6 2.8 3.2 3.7 3.9 4.3 4.5 5 5.1 6 6.3 7.1 8.8 10.2 10.6 13.8

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.26 0.27 0.27 0.28 0.29 0.30 0.31 0.32 0.32 0.33 0.34 0.34 0.36 0.37 0.38 0.42 0.44 0.44 0.49

3.2 Install pipe on sleepers/ in rack (OSBL) 0.22 0.23 0.23 0.24 0.24 0.25 0.26 0.27 0.28 0.28 0.29 0.29 0.31 0.31 0.33 0.35 0.37 0.38 0.41

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.30

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 0.43

4.3 Fitting with 3 ends (T and Y pieces) 0.56

5.1 Butt weld 0.67 0.68 0.68 0.69 0.69 0.70 0.71 0.72 0.73 0.73 0.74 0.75 0.77 0.78 0.80 0.85 0.89 0.91 1.00

5.2 Fillet weld 0.40 0.41 0.41 0.41 0.42 0.42 0.43 0.43 0.44 0.44 0.45 0.45 0.46 0.47 0.48 0.51 0.54 0.54 0.60

5.3 Mittre weld 0.88 0.88 0.89 0.90 0.90 0.91 0.93 0.93 0.94 0.95 0.97 0.97 1.00 1.01 1.04 1.11 1.16 1.18 1.31

5.4 Branch weld 1.08 1.09 1.09 1.10 1.11 1.12 1.14 1.15 1.16 1.17 1.19 1.19 1.23 1.24 1.28 1.36 1.43 1.45 1.61

5.5 Reinforcing ring 1.20 1.21 1.22 1.23 1.23 1.25 1.27 1.28 1.29 1.30 1.32 1.33 1.37 1.38 1.42 1.51 1.59 1.61 1.79

5.6 Olet weld 1.26 1.29 1.32 1.35 1.37 1.41 1.47 1.49 1.54 1.56 1.62 1.63 1.74 1.77 1.86 2.05 2.18 2.22 2.43

5.7 Cutting pipe in case of changes 0.10 0.10 0.10 0.10 0.10 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.12 0.12 0.12 0.13 0.13 0.14 0.15

6.1 Flange connection 150# , PN 10-16 0.56

6.2 Flange connection 300# , PN 25-40 0.63

6.3 Flange connection 600#- 900# , PN 64-160 0.70

6.4 Flange connection 1500#-2500# , PN 250-320 0.79

6.5 Spectacle blind, blind flange, spade 0.11

6.6 Bending of pipe 0.29

6.7 Cutting thread 0.16

6.8 Threaded connection 0.14

7.1 Installation of valve 150# , PN 10-16 0.50

7.2 Installation of valve 300# , PN 25-40 0.56

7.3 Installation of valve 600#- 900# , PN 64-160 0.63

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.70

7.5 Installation of valve incl. drive 0.20

7.6 Installation of wafer-type valve 0.10

8.1 Pressure testing : hydrostatic/pneumatic 0.05

Size ASA/DIN 2" / 50

Outside diameter in mm 60.3

Wallthickness in mm 1.7 2 2.6 2.8 2.9 3.2 3.9 4.3 4.5 5.5 5.6 6 6.3 7.1 8.7 10.6 11.1 13.8

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.27 0.28 0.30 0.31 0.31 0.32 0.34 0.35 0.36 0.39 0.39 0.40 0.41 0.43 0.47 0.51 0.52 0.57

3.2 Install pipe on sleepers/ in rack (OSBL) 0.23 0.24 0.26 0.26 0.26 0.27 0.29 0.30 0.31 0.33 0.33 0.34 0.35 0.37 0.40 0.44 0.44 0.49

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.36

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, 0.52

4.3 Fitting with 3 ends (T and Y pieces) 0.67

5.1 Butt weld 0.78 0.79 0.80 0.81 0.81 0.82 0.84 0.85 0.85 0.89 0.89 0.91 0.92 0.95 1.01 1.09 1.11 1.23

5.2 Fillet weld 0.47 0.47 0.48 0.48 0.49 0.49 0.50 0.51 0.51 0.53 0.53 0.54 0.55 0.57 0.61 0.65 0.67 0.74

5.3 Mittre weld 1.02 1.02 1.04 1.05 1.05 1.06 1.09 1.10 1.11 1.15 1.16 1.18 1.19 1.23 1.31 1.42 1.44 1.60

5.4 Branch weld 1.25 1.26 1.28 1.29 1.29 1.31 1.34 1.36 1.37 1.42 1.43 1.45 1.47 1.51 1.61 1.74 1.78 1.97

5.5 Reinforcing ring 1.39 1.40 1.43 1.44 1.44 1.45 1.49 1.51 1.52 1.58 1.59 1.61 1.63 1.68 1.80 1.94 1.98 2.19

5.6 Olet weld 1.45 1.49 1.57 1.59 1.61 1.65 1.75 1.81 1.84 2.00 2.01 2.08 2.12 2.25 2.50 2.78 2.85 3.18

5.7 Cutting pipe in case of changes 0.12 0.12 0.12 0.12 0.12 0.12 0.13 0.13 0.13 0.13 0.13 0.14 0.14 0.14 0.15 0.16 0.17 0.18

6.1 Flange connection 150# , PN 10-16 0.61

6.2 Flange connection 300# , PN 25-40 0.68

6.3 Flange connection 600#- 900# , PN 64-160 0.76

6.4 Flange connection 1500#-2500# , PN 250-320 0.85

6.5 Spectacle blind, blind flange, spade 0.12

6.6 Bending of pipe 0.36

6.7 Cutting thread 0.20

6.8 Threaded connection 0.17

7.1 Installation of valve 150# , PN 10-16 0.63

7.2 Installation of valve 300# , PN 25-40 0.70

7.3 Installation of valve 600#- 900# , PN 64-160 0.78

7.4 Installation of valve 1500#- 2500# , PN 250-320 0.88

7.5 Installation of valve incl. drive 0.25

7.6 Installation of wafer-type valve 0.13

8.1 Pressure testing : hydrostatic/pneumatic 0.06

Size ASA/DIN 2 1/2" / 65 65

Outside diameter in mm 73.0 76.1

Wallthickness in mm 2.1 3.1 5.2 7 9.5 14 2 2.3 2.9 3.2 3.5 3.6 4.0 5.0 5.6 6.3 7.1 8.0

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.30 0.34 0.42 0.48 0.55 0.67 0.30 0.31 0.34 0.35 0.36 0.37 0.38 0.42 0.44 0.47 0.49 0.52

3.2 Install pipe on sleepers/ in rack (OSBL) 0.26 0.29 0.36 0.41 0.47 0.57 0.26 0.27 0.29 0.30 0.31 0.31 0.32 0.36 0.38 0.40 0.42 0.44

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.45 0.45

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, 0.64 0.64

4.3 Fitting with 3 ends (T and Y pieces) 0.83 0.83

5.1 Butt weld 0.91 0.94 1.01 1.10 1.22 1.48 0.93 0.94 0.96 0.97 0.98 0.98 1.00 1.04 1.07 1.10 1.14 1.18

5.2 Fillet weld 0.54 0.56 0.61 0.66 0.73 0.89 0.56 0.56 0.58 0.58 0.59 0.59 0.60 0.62 0.64 0.66 0.68 0.71

5.3 Mittre weld 1.18 1.22 1.32 1.42 1.59 1.92 1.21 1.22 1.25 1.26 1.27 1.28 1.30 1.35 1.38 1.43 1.48 1.54

5.4 Branch weld 1.45 1.50 1.62 1.75 1.96 2.36 1.49 1.50 1.53 1.55 1.57 1.57 1.60 1.66 1.70 1.76 1.82 1.89

5.5 Reinforcing ring 1.61 1.66 1.80 1.95 2.18 2.63 1.66 1.67 1.71 1.72 1.74 1.75 1.78 1.85 1.90 1.95 2.02 2.11

5.6 Olet weld 1.72 1.88 2.27 2.64 3.15 4.01 1.72 1.77 1.87 1.92 1.98 2.00 2.08 2.27 2.40 2.55 2.72 2.91

5.7 Cutting pipe in case of changes 0.14 0.14 0.15 0.16 0.18 0.22 0.14 0.14 0.14 0.15 0.15 0.15 0.15 0.16 0.16 0.17 0.17 0.18

6.1 Flange connection 150# , PN 10-16 0.68 0.68

6.2 Flange connection 300# , PN 25-40 0.77 0.77

6.3 Flange connection 600#- 900# , PN 64-160 0.85 0.85

6.4 Flange connection 1500#-2500# , PN 250-320 0.95 0.95

6.5 Spectacle blind, blind flange, spade 0.14 0.14

6.6 Bending of pipe 0.14

6.7 Cutting thread 0.27 0.27

6.8 Threaded connection 0.23 0.23

7.1 Installation of valve 150# , PN 10-16 0.81 0.81

7.2 Installation of valve 300# , PN 25-40 0.92 0.92

7.3 Installation of valve 600#- 900# , PN 64-160 1.02 1.02

7.4 Installation of valve 1500#- 2500# , PN 250-320 1.14 1.14

7.5 Installation of valve incl. drive 0.33 0.33

7.6 Installation of wafer-type valve 0.16 0.16

8.1 Pressure testing : hydrostatic/pneumatic 0.07 0.07

Size ASA/DIN 3" / 80

Outside diameter in mm 88.9

Wallthickness in mm 2.1 2.3 2.5 2.6 3.1 3.2 3.6 4.5 5.5 5.6 6.3 7.1 7.6 8.8 11.1 15.2

Schedule 5S 10S 40 STD 80 XS 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.32 0.33 0.34 0.35 0.37 0.37 0.39 0.43 0.48 0.48 0.51 0.54 0.56 0.61 0.69 0.82

3.2 Install pipe on sleepers/ in rack (OSBL) 0.27 0.28 0.29 0.29 0.31 0.32 0.33 0.37 0.40 0.41 0.43 0.46 0.48 0.52 0.58 0.69

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.54

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 0.77

4.3 Fitting with 3 ends (T and Y pieces) 1.00

5.1 Butt weld 1.05 1.06 1.07 1.07 1.09 1.09 1.11 1.15 1.20 1.21 1.25 1.29 1.32 1.40 1.56 1.87

5.2 Fillet weld 0.63 0.64 0.64 0.64 0.65 0.66 0.67 0.69 0.72 0.72 0.75 0.78 0.79 0.84 0.94 1.12

5.3 Mittre weld 1.37 1.38 1.38 1.39 1.41 1.42 1.44 1.49 1.56 1.57 1.62 1.68 1.72 1.82 2.03 2.43

5.4 Branch weld 1.68 1.69 1.70 1.71 1.74 1.75 1.77 1.84 1.92 1.93 1.99 2.07 2.12 2.24 2.50 3.00

5.5 Reinforcing ring 1.87 1.88 1.90 1.90 1.94 1.94 1.97 2.05 2.14 2.15 2.22 2.30 2.35 2.49 2.78 3.33

5.6 Olet weld 1.99 2.03 2.07 2.09 2.19 2.21 2.30 2.51 2.75 2.78 2.96 3.17 3.30 3.62 4.25 5.32

5.7 Cutting pipe in case of changes 0.16 0.16 0.16 0.16 0.16 0.16 0.17 0.17 0.18 0.18 0.19 0.19 0.20 0.21 0.23 0.28

6.1 Flange connection 150# , PN 10-16 0.76

6.2 Flange connection 300# , PN 25-40 0.86

6.3 Flange connection 600#- 900# , PN 64-160 0.95

6.4 Flange connection 1500#-2500# , PN 250-320 1.07

6.5 Spectacle blind, blind flange, spade 0.15

6.6 Bending of pipe

6.7 Cutting thread 0.34

6.8 Threaded connection 0.29

7.1 Installation of valve 150# , PN 10-16 1.00

7.2 Installation of valve 300# , PN 25-40 1.13

7.3 Installation of valve 600#- 900# , PN 64-160 1.25

7.4 Installation of valve 1500#- 2500# , PN 250-320 1.40

7.5 Installation of valve incl. drive 0.40

7.6 Installation of wafer-type valve 0.20

8.1 Pressure testing : hydrostatic/pneumatic 0.08

Size ASA/DIN 4" / 100

Outside diameter in mm 114.3

Wallthickness in mm 2.1 2.6 2.9 3.1 3.6 4.0 5.0 5.6 6.0 6.3 7.1 8.0 8.6 10.0 11.1 12.5 13.5 17.1

Schedule 5S 10S 40 STD 80 XS 120 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.35 0.38 0.40 0.41 0.44 0.47 0.52 0.56 0.58 0.59 0.64 0.68 0.71 0.78 0.83 0.89 0.93 1.08

3.2 Install pipe on sleepers/ in rack (OSBL) 0.30 0.33 0.34 0.35 0.38 0.40 0.44 0.47 0.49 0.50 0.54 0.58 0.60 0.66 0.70 0.76 0.79 0.92

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.65

4.2 Fitting with 2 ends (elbows, reducers, mitre bends 0.93

4.3 Fitting with 3 ends (T and Y pieces) 1.21

5.1 Butt weld 1.28 1.31 1.32 1.33 1.36 1.38 1.44 1.49 1.52 1.54 1.60 1.67 1.73 1.85 1.96 2.10 2.21 2.60

5.2 Fillet weld 0.77 0.78 0.79 0.80 0.81 0.83 0.87 0.89 0.91 0.92 0.96 1.00 1.04 1.11 1.18 1.26 1.32 1.56

5.3 Mittre weld 1.67 1.70 1.72 1.73 1.76 1.79 1.88 1.93 1.97 2.00 2.08 2.18 2.24 2.41 2.55 2.73 2.87 3.39

5.4 Branch weld 2.05 2.09 2.11 2.13 2.17 2.21 2.31 2.38 2.42 2.46 2.56 2.68 2.76 2.97 3.14 3.36 3.53 4.17

5.5 Reinforcing ring 2.28 2.32 2.35 2.37 2.42 2.46 2.57 2.64 2.70 2.74 2.85 2.98 3.07 3.30 3.49 3.74 3.93 4.63

5.6 Olet weld 2.42 2.55 2.63 2.69 2.83 2.95 3.26 3.46 3.60 3.70 3.98 4.31 4.53 5.07 5.49 6.04 6.43 7.83

5.7 Cutting pipe in case of changes 0.19 0.20 0.20 0.20 0.20 0.21 0.22 0.22 0.23 0.23 0.24 0.25 0.26 0.28 0.29 0.32 0.33 0.39

6.1 Flange connection 150# , PN 10-16 0.88

6.2 Flange connection 300# , PN 25-40 0.99

6.3 Flange connection 600#- 900# , PN 64-160 1.10

6.4 Flange connection 1500#-2500# , PN 250-320 1.23

6.5 Spectacle blind, blind flange, spade 0.18

6.6 Bending of pipe

6.7 Cutting thread 0.47

6.8 Threaded connection 0.40

7.1 Installation of valve 150# , PN 10-16 1.25

7.2 Installation of valve 300# , PN 25-40 1.41

7.3 Installation of valve 600#- 900# , PN 64-160 1.56

7.4 Installation of valve 1500#- 2500# , PN 250-320 1.75

7.5 Installation of valve incl. drive 0.50

7.6 Installation of wafer-type valve 0.25

8.1 Pressure testing : hydrostatic/pneumatic 0.10

Size ASA/DIN 5" / 125 125

Outside diameter in mm 139.7 141.3

Wallthickness in mm 2.6 2.9 3.2 3.6 4.0 4.5 5.0 5.6 6.3 7.1 8.0 8.8 10.0 11.0 12.5 14.2 2.8 3.4 6.6 9.5 12.7 15.9 19.0

Schedule 5S 10S 40 STD 80 XS 120 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.42 0.44 0.46 0.49 0.52 0.56 0.59 0.63 0.68 0.73 0.78 0.83 0.90 0.96 1.04 1.14 0.44 0.48 0.70 0.88 1.07 1.24 1.39

3.2 Install pipe on sleepers/ in rack (OSBL) 0.36 0.38 0.39 0.42 0.44 0.47 0.50 0.54 0.57 0.62 0.67 0.71 0.77 0.82 0.89 0.97 0.37 0.41 0.60 0.75 0.91 1.05 1.18

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.80 0.80

4.2 Fitting with 2 ends (elbows, reducers, mitre bends 1.14 1.14

4.3 Fitting with 3 ends (T and Y pieces) 1.48 1.48

5.1 Butt weld 1.54 1.56 1.58 1.61 1.64 1.67 1.71 1.77 1.83 1.91 2.00 2.09 2.23 2.35 2.54 2.77 1.57 1.61 1.88 2.19 2.59 3.04 3.51

5.2 Fillet weld 0.93 0.94 0.95 0.96 0.98 1.00 1.03 1.06 1.10 1.14 1.20 1.25 1.34 1.41 1.52 1.66 0.94 0.97 1.13 1.31 1.56 1.83 2.11

5.3 Mittre weld 2.01 2.03 2.05 2.09 2.13 2.18 2.23 2.30 2.38 2.48 2.60 2.71 2.89 3.05 3.30 3.60 2.04 2.09 2.44 2.85 3.37 3.95 4.56

5.4 Branch weld 2.47 2.50 2.53 2.57 2.62 2.68 2.74 2.82 2.93 3.05 3.20 3.34 3.56 3.75 4.06 4.43 2.51 2.57 3.00 3.50 4.15 4.87 5.62

5.5 Reinforcing ring 2.75 2.78 2.81 2.86 2.91 2.98 3.05 3.14 3.26 3.39 3.56 3.72 3.96 4.18 4.52 4.93 2.79 2.86 3.34 3.90 4.61 5.41 6.25

5.6 Olet weld 3.01 3.11 3.21 3.36 3.50 3.70 3.89 4.14 4.44 4.80 5.21 5.59 6.18 6.69 7.46 8.35 3.11 3.32 4.62 6.00 7.65 9.36 11.02

5.7 Cutting pipe in case of changes 0.23 0.23 0.24 0.24 0.25 0.25 0.26 0.27 0.27 0.29 0.30 0.31 0.33 0.35 0.38 0.42 0.24 0.24 0.28 0.33 0.39 0.46 0.53

6.1 Flange connection 150# , PN 10-16 1.03 1.03

6.2 Flange connection 300# , PN 25-40 1.16 1.16

6.3 Flange connection 600#- 900# , PN 64-160 1.29 1.29

6.4 Flange connection 1500#-2500# , PN 250-320 1.44 1.44

6.5 Spectacle blind, blind flange, spade 0.21 0.21

6.6 Bending of pipe

6.7 Cutting thread 0.66 0.66

6.8 Threaded connection 0.56 0.56

7.1 Installation of valve 150# , PN 10-16 1.56 1.56

7.2 Installation of valve 300# , PN 25-40 1.76 1.76

7.3 Installation of valve 600#- 900# , PN 64-160 1.95 1.95

7.4 Installation of valve 1500#- 2500# , PN 250-320 2.19 2.19

7.5 Installation of valve incl. drive 0.63 0.63

7.6 Installation of wafer-type valve 0.31 0.31

8.1 Pressure testing : hydrostatic/pneumatic 0.11 0.11

Size ASA/DIN 6" / 150

Outside diameter in mm 168.3

Wallthickness in mm 2.0 2.8 2.9 3.4 3.6 4.0 4.5 5.0 5.6 6.3 7.1 8.0 8.8 10.0 11.0 12.5 14.3 16.0 18.3 21.9

Schedule 5S 10S 40 STD 80 XS 120 160 XXS

3.1 Installation of pipe in plant (ISBL) 0.41 0.48 0.49 0.53 0.55 0.58 0.62 0.66 0.71 0.77 0.83 0.90 0.95 1.04 1.11 1.21 1.33 1.44 1.58 1.79

3.2 Install pipe on sleepers/ in rack (OSBL) 0.35 0.41 0.41 0.45 0.47 0.49 0.53 0.56 0.61 0.65 0.70 0.76 0.81 0.89 0.94 1.03 1.13 1.22 1.34 1.52

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 0.95

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 1.35

4.3 Fitting with 3 ends (T and Y pieces) 1.76

5.1 Butt weld 1.77 1.82 1.83 1.87 1.89 1.92 1.97 2.02 2.08 2.16 2.25 2.37 2.47 2.64 2.79 3.03 3.33 3.63 4.06 4.77

5.2 Fillet weld 1.06 1.09 1.10 1.12 1.13 1.15 1.18 1.21 1.25 1.30 1.35 1.42 1.48 1.59 1.68 1.82 2.00 2.18 2.44 2.86

5.3 Mittre weld 2.30 2.37 2.38 2.43 2.45 2.50 2.56 2.62 2.70 2.81 2.93 3.08 3.22 3.44 3.63 3.94 4.33 4.72 5.28 6.21

5.4 Branch weld 2.83 2.92 2.93 2.99 3.02 3.08 3.15 3.23 3.33 3.45 3.61 3.79 3.96 4.23 4.47 4.85 5.33 5.81 6.50 7.64

5.5 Reinforcing ring 3.15 3.25 3.26 3.33 3.36 3.42 3.50 3.59 3.70 3.84 4.01 4.21 4.40 4.71 4.97 5.39 5.93 6.47 7.23 8.50

5.6 Olet weld 3.31 3.61 3.65 3.86 3.95 4.13 4.36 4.61 4.91 5.28 5.72 6.23 6.70 7.44 8.07 9.05 10.26 11.43 13.03 15.54

5.7 Cutting pipe in case of changes 0.27 0.27 0.28 0.28 0.28 0.29 0.30 0.30 0.31 0.32 0.34 0.36 0.37 0.40 0.42 0.46 0.50 0.55 0.61 0.72

6.1 Flange connection 150# , PN 10-16 1.19

6.2 Flange connection 300# , PN 25-40 1.34

6.3 Flange connection 600#- 900# , PN 64-160 1.49

6.4 Flange connection 1500#-2500# , PN 250-320 1.67

6.5 Spectacle blind, blind flange, spade 0.24

6.6 Bending of pipe

6.7 Cutting thread 0.88

6.8 Threaded connection 0.75

7.1 Installation of valve 150# , PN 10-16 1.88

7.2 Installation of valve 300# , PN 25-40 2.11

7.3 Installation of valve 600#- 900# , PN 64-160 2.34

7.4 Installation of valve 1500#- 2500# , PN 250-320 2.62

7.5 Installation of valve incl. drive 0.75

7.6 Installation of wafer-type valve 0.38

8.1 Pressure testing : hydrostatic/pneumatic 0.13

Size ASA/DIN 8" / 200

Outside diameter in mm 219.1

Wallthickness in mm 2.8 3.2 3.6 3.8 4.5 5.6 5.9 6.3 6.4 7.0 8.0 8.2 8.8 10.3 12.7 14.2 15.1 16.0 18.3 20.6 22.2 23.0 28.0

Schedule 5S 10S 20 30 40 STD 60 80 XS 100 120 140 XXS 160

3.1 Installation of pipe in plant (ISBL) 0.55 0.60 0.64 0.66 0.74 0.85 0.88 0.92 0.93 0.99 1.09 1.11 1.17 1.31 1.52 1.65 1.73 1.81 1.99 2.18 2.30 2.36 2.72

3.2 Install pipe on sleepers/ in rack (OSBL) 0.47 0.51 0.55 0.57 0.63 0.73 0.75 0.79 0.79 0.85 0.93 0.94 0.99 1.11 1.30 1.41 1.47 1.54 1.70 1.85 1.95 2.00 2.31

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 1.24

4.2 Fitting with 2 ends (elbows, reducers, mitre bends 1.77

4.3 Fitting with 3 ends (T and Y pieces) 2.30

5.1 Butt weld 2.30 2.34 2.39 2.41 2.49 2.64 2.68 2.74 2.76 2.85 3.02 3.05 3.16 3.45 3.95 4.29 4.50 4.72 5.30 5.92 6.37 6.59 8.09

5.2 Fillet weld 1.38 1.41 1.43 1.45 1.50 1.58 1.61 1.65 1.66 1.71 1.81 1.83 1.90 2.07 2.37 2.57 2.70 2.83 3.18 3.55 3.82 3.96 4.85

5.3 Mittre weld 2.99 3.05 3.10 3.13 3.24 3.43 3.49 3.57 3.59 3.71 3.93 3.97 4.11 4.48 5.13 5.57 5.85 6.13 6.89 7.69 8.28 8.57 10.51

5.4 Branch weld 3.68 3.75 3.82 3.85 3.99 4.22 4.29 4.39 4.41 4.56 4.83 4.89 5.06 5.51 6.32 6.86 7.20 7.55 8.48 9.47 10.18 10.55 12.94

5.5 Reinforcing ring 4.10 4.17 4.25 4.29 4.44 4.70 4.78 4.88 4.91 5.08 5.37 5.44 5.63 6.14 7.03 7.63 8.01 8.40 9.44 10.54 11.33 11.74 14.40

5.6 Olet weld 4.56 4.78 5.01 5.12 5.55 6.27 6.48 6.76 6.83 7.27 8.04 8.19 8.67 9.93 12.06 13.47 14.33 15.21 17.50 19.85 21.51 22.34

5.7 Cutting pipe in case of changes 0.35 0.35 0.36 0.36 0.37 0.40 0.40 0.41 0.41 0.43 0.45 0.46 0.47 0.52 0.59 0.64 0.68 0.71 0.80 0.89 0.96 0.99 1.21

6.1 Flange connection 150# , PN 10-16 1.54

6.2 Flange connection 300# , PN 25-40 1.73

6.3 Flange connection 600#- 900# , PN 64-160 1.92

6.4 Flange connection 1500#-2500# , PN 250-320 2.16

6.5 Spectacle blind, blind flange, spade 0.31

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 2.50

7.2 Installation of valve 300# , PN 25-40 2.81

7.3 Installation of valve 600#- 900# , PN 64-160 3.13

7.4 Installation of valve 1500#- 2500# , PN 250-320 3.50

7.5 Installation of valve incl. drive 1.00

7.6 Installation of wafer-type valve 0.50

8.1 Pressure testing : hydrostatic/pneumatic 0.17

Size ASA/DIN 10" / 250

Outside diameter in mm 273.0

Wallthickness in mm 2.9 3.2 3.4 3.6 4.0 4.2 5.0 5.6 6.3 6.4 7.1 7.8 8.0 8.8 9.3 10.0 11.0 12.0 12.7 14.2 15.1 16.0 17.5 18.0 18.3 20.0 21.4 22.2 25.4 28.6

Schedule 5S 10S 20 30 40 STD 80S 60 XS 80 100 120 140 X 160

3.1 Installation of pipe in plant (ISBL) 0.65 0.69 0.71 0.74 0.79 0.82 0.92 1.00 1.09 1.10 1.19 1.27 1.29 1.39 1.45 1.53 1.64 1.75 1.83 1.99 2.09 2.19 2.34 2.39 2.42 2.59 2.73 2.81 3.11 3.40

3.2 Install pipe on sleepers/ in rack (OSBL) 0.55 0.58 0.61 0.63 0.68 0.70 0.79 0.85 0.92 0.93 1.01 1.08 1.10 1.18 1.23 1.30 1.40 1.49 1.56 1.70 1.78 1.86 1.99 2.03 2.06 2.20 2.32 2.39 2.64 2.89

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 1.53

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 2.18

4.3 Fitting with 3 ends (T and Y pieces) 2.84

5.1 Butt weld 2.82 2.86 2.89 2.91 2.97 3.00 3.13 3.23 3.36 3.38 3.52 3.67 3.71 3.89 4.01 4.18 4.43 4.70 4.89 5.32 5.59 5.87 6.35 6.52 6.62 7.20 7.70 7.99 9.20 10.48

5.2 Fillet weld 1.69 1.72 1.73 1.75 1.78 1.80 1.88 1.94 2.02 2.03 2.11 2.20 2.23 2.33 2.40 2.51 2.66 2.82 2.93 3.19 3.35 3.52 3.81 3.91 3.97 4.32 4.62 4.79 5.52 6.29

5.3 Mittre weld 3.67 3.72 3.75 3.79 3.86 3.90 4.07 4.20 4.37 4.40 4.58 4.77 4.83 5.06 5.21 5.43 5.76 6.10 6.35 6.92 7.27 7.63 8.26 8.47 8.60 9.36 10.01 10.39 11.96 13.62

5.4 Branch weld 4.52 4.58 4.62 4.66 4.75 4.80 5.01 5.17 5.38 5.41 5.63 5.87 5.94 6.23 6.41 6.68 7.09 7.51 7.82 8.51 8.95 9.39 10.16 10.43 10.59 11.52 12.32 12.78 14.72 16.76

5.5 Reinforcing ring 5.02 5.09 5.14 5.19 5.29 5.34 5.57 5.76 5.99 6.02 6.27 6.53 6.61 6.93 7.13 7.44 7.89 8.36 8.70 9.47 9.95 10.45 11.31 11.60 11.78 12.82 13.70 14.22 16.38 18.65

5.6 Olet weld 5.64 5.84 5.98 6.12 6.42 6.57 7.21 7.72 8.34 8.43 9.08 9.75 9.95 10.77 11.29 12.04 13.15 14.30 15.12

5.7 Cutting pipe in case of changes 0.42 0.43 0.43 0.44 0.45 0.45 0.47 0.49 0.50 0.51 0.53 0.55 0.56 0.58 0.60 0.63 0.66 0.70 0.73 0.80 0.84 0.88 0.95 0.98 0.99 1.08 1.16 1.20 1.38 1.57

6.1 Flange connection 150# , PN 10-16 1.92

6.2 Flange connection 300# , PN 25-40 2.16

6.3 Flange connection 600#- 900# , PN 64-160 2.39

6.4 Flange connection 1500#-2500# , PN 250-320 2.68

6.5 Spectacle blind, blind flange, spade 0.38

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 4.25

7.2 Installation of valve 300# , PN 25-40 4.78

7.3 Installation of valve 600#- 900# , PN 64-160 5.31

7.4 Installation of valve 1500#- 2500# , PN 250-320 5.95

7.5 Installation of valve incl. drive 1.70

7.6 Installation of wafer-type valve 0.85

8.1 Pressure testing : hydrostatic/pneumatic 0.20

Size ASA/DIN 12" / 300

Outside diameter in mm 323.9

Wallthickness in mm 3.2 3.6 4.0 4.6 5.0 5.6 6.4 7.1 8.0 8.4 8.8 9.5 10.3 11.0 12.7 14.3 16 17.5 20 21.4 22.2 25.4 28.6 33.3

Schedule 5S 10S 20 30 40S STD 40 80S XS 60

3.1 Installation of pipe in plant (ISBL) 0.77 0.83 0.89 0.99 1.05 1.14 1.25 1.35 1.48 1.54 1.59 1.69 1.80 1.89 2.12 2.32 2.54 2.72 3.02 3.19 3.28 3.64 3.99 4.49

3.2 Install pipe on sleepers/ in rack (OSBL) 0.65 0.71 0.76 0.84 0.89 0.97 1.07 1.15 1.26 1.31 1.35 1.44 1.53 1.61 1.80 1.97 2.16 2.31 2.57 2.71 2.79 3.10 3.40 3.82

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 1.82

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, 2.60

4.3 Fitting with 3 ends (T and Y pieces) 3.38

5.1 Butt weld 3.35 3.41 3.48 3.59 3.67 3.79 3.97 4.14 4.37 4.47 4.58 4.78 5.01 5.23 5.78 6.33 6.96 7.54 8.57 9.17 9.52 11.00 12.56 14.99

5.2 Fillet weld 2.01 2.05 2.09 2.16 2.20 2.28 2.38 2.48 2.62 2.68 2.75 2.87 3.01 3.14 3.47 3.80 4.17 4.52 5.14 5.50 5.71 6.60 7.54 8.99

5.3 Mittre weld 4.35 4.44 4.53 4.67 4.77 4.93 5.16 5.38 5.67 5.81 5.95 6.21 6.52 6.79 7.51 8.23 9.04 9.80 11.14 11.92 12.38 14.30 16.33 19.49

5.4 Branch weld 5.36 5.46 5.57 5.75 5.87 6.07 6.35 6.62 6.98 7.15 7.33 7.64 8.02 8.36 9.24 10.13 11.13 12.06 13.71 14.67 15.24 17.60 20.09 23.98

5.5 Reinforcing ring 5.96 6.08 6.20 6.39 6.53 6.75 7.07 7.37 7.77 7.96 8.15 8.50 8.92 9.30 10.28 11.27 12.38 13.42 15.25 16.32 16.95 19.58 22.35 26.68

5.6 Olet weld 6.84 7.18 7.53 8.09 8.48 9.08 9.93 10.71 11.76 12.25 12.74 13.63 14.67 15.62 18.01

5.7 Cutting pipe in case of changes 0.50 0.51 0.52 0.54 0.55 0.57 0.60 0.62 0.66 0.67 0.69 0.72 0.75 0.78 0.87 0.95 1.04 1.13 1.29 1.38 1.43 1.65 1.88 2.25

6.1 Flange connection 150# , PN 10-16 2.31

6.2 Flange connection 300# , PN 25-40 2.60

6.3 Flange connection 600#- 900# , PN 64-160 2.89

6.4 Flange connection 1500#-2500# , PN 250-320 3.24

6.5 Spectacle blind, blind flange, spade 0.46

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 5.10

7.2 Installation of valve 300# , PN 25-40 5.74

7.3 Installation of valve 600#- 900# , PN 64-160 6.38

7.4 Installation of valve 1500#- 2500# , PN 250-320 7.14

7.5 Installation of valve incl. drive 2.04

7.6 Installation of wafer-type valve 1.02

8.1 Pressure testing : hydrostatic/pneumatic 0.24

Size ASA/DIN 14" / 350

Outside diameter in mm 355.6

Wallthickness in mm 3.2 3.6 4.0 4.8 5.0 5.6 6.4 7.1 7.9 8.8 9.5 11.1 12.7 14.2 15.1 17.5 19.0 22.2 23.8 25.0 27.8 31.8 35.7

Schedule 10 20 30 STD 40 XS 60 80 100 120 140 160

3.1 Installation of pipe in plant (ISBL) 0.82 0.89 0.96 1.09 1.12 1.22 1.35 1.46 1.58 1.72 1.82 2.06 2.29 2.50 2.63 2.95 3.15 3.57 3.77 3.92 4.26 4.74 5.18

3.2 Install pipe on sleepers/ in rack (OSBL) 0.70 0.76 0.81 0.93 0.95 1.04 1.15 1.24 1.34 1.46 1.55 1.75 1.95 2.13 2.23 2.51 2.68 3.03 3.21 3.33 3.62 4.02 4.40

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 2.11

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adap 3.02

4.3 Fitting with 3 ends (T and Y pieces) 3.92

5.1 Butt weld 3.65 3.72 3.80 3.96 4.01 4.14 4.34 4.52 4.74 5.01 5.23 5.76 6.33 6.90 7.26 8.28 8.95 10.48 11.28 11.91 13.41 15.68 18.02

5.2 Fillet weld 2.19 2.24 2.28 2.38 2.40 2.49 2.60 2.71 2.85 3.01 3.14 3.45 3.80 4.14 4.36 4.97 5.37 6.29 6.77 7.14 8.05 9.41 10.81

5.3 Mittre weld 4.75 4.84 4.94 5.15 5.21 5.39 5.64 5.88 6.17 6.51 6.79 7.48 8.23 8.97 9.44 10.76 11.64 13.62 14.67 15.48 17.43 20.39 23.42

5.4 Branch weld 5.85 5.96 6.08 6.34 6.41 6.63 6.94 7.23 7.59 8.01 8.36 9.21 10.13 11.04 11.62 13.25 14.32 16.77 18.06 19.05 21.46 25.09 28.83

5.5 Reinforcing ring 6.50 6.63 6.76 7.05 7.13 7.37 7.72 8.05 8.44 8.92 9.30 10.24 11.26 12.29 12.93 14.74 15.94 18.65 20.09 21.19 23.87 27.91 32.07

5.6 Olet weld 7.47 7.84 8.23 9.05 9.27 9.93 10.87 11.73 12.76 13.97 14.95 17.30 19.81

5.7 Cutting pipe in case of changes 0.55 0.56 0.57 0.59 0.60 0.62 0.65 0.68 0.71 0.75 0.78 0.86 0.95 1.04 1.09 1.24 1.34 1.57 1.69 1.79 2.01 2.35 2.70

6.1 Flange connection 150# , PN 10-16 2.73

6.2 Flange connection 300# , PN 25-40 3.08

6.3 Flange connection 600#- 900# , PN 64-160 3.42

6.4 Flange connection 1500#-2500# , PN 250-320 3.83

6.5 Spectacle blind, blind flange, spade 0.55

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 5.95

7.2 Installation of valve 300# , PN 25-40 6.69

7.3 Installation of valve 600#- 900# , PN 64-160 7.44

7.4 Installation of valve 1500#- 2500# , PN 250-320 8.33

7.5 Installation of valve incl. drive 2.38

7.6 Installation of wafer-type valve 1.19

8.1 Pressure testing : hydrostatic/pneumatic 0.27

Size ASA/DIN 16" / 400

Outside diameter in mm 406.4

Wallthickness in mm 3.6 4.0 4.2 4.8 5.6 6.4 7.1 7.9 8.8 9.5 11.0 12.7 14.2 16.0 16.7 17.5 20.0 21.4 22.2 25.0 26.2 31.0 36.5 40.5

Schedule 5S 10S 10 20 30 STD 40 XS 60 80 100 120 140 160

3.1 Installation of pipe in plant (ISBL) 0.98 1.05 1.09 1.20 1.35 1.50 1.62 1.76 1.92 2.04 2.29 2.57 2.81 3.09 3.20 3.32 3.70 3.91 4.03 4.43 4.60 5.26 5.99 6.49

3.2 Install pipe on sleepers/ in rack (OSBL) 0.83 0.90 0.93 1.02 1.15 1.27 1.38 1.50 1.63 1.73 1.95 2.18 2.39 2.63 2.72 2.83 3.15 3.32 3.42 3.77 3.91 4.47 5.09 5.52

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 2.40

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, 3.43

4.3 Fitting with 3 ends (T and Y pieces) 4.46

5.1 Butt weld 4.22 4.31 4.35 4.50 4.70 4.93 5.14 5.39 5.70 5.95 6.52 7.21 7.88 8.72 9.06 9.46 10.78 11.56 12.01 13.67 14.40 17.52 21.37 24.33

5.2 Fillet weld 2.53 2.59 2.61 2.70 2.82 2.96 3.08 3.24 3.42 3.57 3.91 4.33 4.73 5.23 5.44 5.68 6.47 6.93 7.21 8.20 8.64 10.51 12.82 14.60

5.3 Mittre weld 5.49 5.60 5.66 5.85 6.11 6.40 6.68 7.01 7.40 7.73 8.47 9.38 10.24 11.34 11.78 12.30 14.01 15.02 15.61 17.77 18.73 22.77 27.78 31.63

5.4 Branch weld 6.76 6.89 6.97 7.19 7.52 7.88 8.22 8.63 9.11 9.51 10.42 11.54 12.60 13.95 14.50 15.14 17.25 18.49 19.22 21.86 23.05 28.03 34.19 38.93

5.5 Reinforcing ring 7.52 7.67 7.75 8.00 8.37 8.77 9.14 9.60 10.14 10.58 11.60 12.84 14.02 15.52 16.13 16.85 19.19 20.57 21.38 24.32 25.64 31.18 38.03 43.31

5.6 Olet weld 8.90 9.34 9.57 10.28 11.29 12.37 13.36 14.54 15.94 17.07 19.62 22.69

5.7 Cutting pipe in case of changes 0.63 0.65 0.65 0.67 0.71 0.74 0.77 0.81 0.85 0.89 0.98 1.08 1.18 1.31 1.36 1.42 1.62 1.73 1.80 2.05 2.16 2.63 3.21 3.65

6.1 Flange connection 150# , PN 10-16 3.17

6.2 Flange connection 300# , PN 25-40 3.57

6.3 Flange connection 600#- 900# , PN 64-160 3.97

6.4 Flange connection 1500#-2500# , PN 250-320 4.44

6.5 Spectacle blind, blind flange, spade 0.63

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 6.80

7.2 Installation of valve 300# , PN 25-40 7.65

7.3 Installation of valve 600#- 900# , PN 64-160 8.50

7.4 Installation of valve 1500#- 2500# , PN 250-320 9.52

7.5 Installation of valve incl. drive 2.72

7.6 Installation of wafer-type valve 1.36

8.1 Pressure testing : hydrostatic/pneumatic 0.31

Size ASA/DIN 18" / 450

Outside diameter in mm 457.0

Wallthickness in mm 3.6 4.0 4.2 4.8 5.6 6.4 7.1 7.9 8.8 9.5 11.1 12.7 14.3 16.0 17.5 19.0 22.2 23.8 25.0 29.4 34.9 39.7 45.2

Schedule 5S 10S 10 20 STD 30 XS 40 60 80 100 120 140 160

3.1 Installation of pipe in plant (ISBL) 1.06 1.15 1.19 1.32 1.48 1.64 1.78 1.94 2.11 2.25 2.55 2.84 3.13 3.43 3.69 3.94 4.48 4.74 4.93 5.63 6.46 7.16 7.93

3.2 Install pipe on sleepers/ in rack (OSBL) 0.91 0.98 1.01 1.12 1.26 1.40 1.51 1.65 1.80 1.91 2.16 2.41 2.66 2.91 3.13 3.35 3.81 4.03 4.19 4.78 5.49 6.08 6.74

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 2.70

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, ada 3.85

4.3 Fitting with 3 ends (T and Y pieces) 5.01

5.1 Butt weld 4.72 4.82 4.87 5.03 5.26 5.51 5.75 6.04 6.38 6.66 7.35 8.10 8.90 9.80 10.65 11.53 13.53 14.60 15.42 18.60 22.90 26.92 31.80

5.2 Fillet weld 2.83 2.89 2.92 3.02 3.16 3.31 3.45 3.62 3.83 4.00 4.41 4.86 5.34 5.88 6.39 6.92 8.12 8.76 9.25 11.16 13.74 16.15 19.08

5.3 Mittre weld 6.14 6.26 6.33 6.54 6.84 7.17 7.47 7.85 8.29 8.66 9.56 10.53 11.57 12.74 13.84 14.99 17.59 18.98 20.04 24.17 29.77 35.00 41.34

5.4 Branch weld 7.55 7.71 7.79 8.04 8.42 8.82 9.20 9.66 10.21 10.66 11.76 12.95 14.23 15.68 17.03 18.44 21.65 23.35 24.67 29.75 36.64 43.08 50.88

5.5 Reinforcing ring 8.40 8.57 8.66 8.95 9.36 9.81 10.23 10.75 11.36 11.86 13.08 14.41 15.84 17.45 18.95 20.52 24.09 25.98 27.44 33.10 40.76 47.92 56.60

5.6 Olet weld 9.95 10.45 10.70 11.51 12.65 13.86 14.98 16.32 17.90 19.18 22.27 25.56

5.7 Cutting pipe in case of changes 0.71 0.72 0.73 0.75 0.79 0.83 0.86 0.91 0.96 1.00 1.10 1.21 1.33 1.47 1.60 1.73 2.03 2.19 2.31 2.79 3.44 4.04 4.77

6.1 Flange connection 150# , PN 10-16 3.63

6.2 Flange connection 300# , PN 25-40 4.08

6.3 Flange connection 600#- 900# , PN 64-160 4.53

6.4 Flange connection 1500#-2500# , PN 250-320 5.08

6.5 Spectacle blind, blind flange, spade 0.73

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 7.65

7.2 Installation of valve 300# , PN 25-40 8.61

7.3 Installation of valve 600#- 900# , PN 64-160 9.56

7.4 Installation of valve 1500#- 2500# , PN 250-320 10.71

7.5 Installation of valve incl. drive 3.06

7.6 Installation of wafer-type valve 1.53

8.1 Pressure testing : hydrostatic/pneumatic 0.34

Size ASA/DIN 20" / 500

Outside diameter in mm 508

Wallthickness in mm 2.9 4.0 4.5 4.8 5.0 5.5 6.3 6.4 7.1 8.0 8.8 9.5 10.0 11.0 12.7 14.2 15.1 16.0 17.5 20.0 20.6 22.2 25.0 26.2 32.5 38.1 44.4 50.0

Schedule 5S 10 20 STD 30 XS 40 60 80 100 120 140 160

3.1 Installation of pipe in plant (ISBL) 0.98 1.25 1.36 1.43 1.48 1.59 1.77 1.79 1.94 2.14 2.31 2.45 2.56 2.77 3.11 3.41 3.59 3.76 4.05 4.52 4.63 4.93 5.43 5.65 6.74 7.66 8.66 9.51

3.2 Install pipe on sleepers/ in rack (OSBL) 0.84 1.06 1.16 1.22 1.25 1.35 1.50 1.52 1.65 1.82 1.96 2.09 2.18 2.35 2.64 2.90 3.05 3.20 3.44 3.84 3.94 4.19 4.62 4.80 5.73 6.51 7.36 8.08

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 2.99

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adap 4.27

4.3 Fitting with 3 ends (T and Y pieces) 5.55

5.1 Butt weld 5.05 5.33 5.47 5.56 5.63 5.79 6.07 6.10 6.37 6.73 7.07 7.38 7.62 8.10 8.99 9.82 10.35 10.89 11.83 13.51 13.92 15.07 17.18 18.13 23.44 28.60 34.84 40.72

5.2 Fillet weld 3.03 3.20 3.28 3.34 3.38 3.47 3.64 3.66 3.82 4.04 4.24 4.43 4.57 4.86 5.39 5.89 6.21 6.54 7.10 8.10 8.35 9.04 10.31 10.88 14.06 17.16 20.90 24.43

5.3 Mittre weld 6.56 6.93 7.11 7.23 7.31 7.52 7.89 7.93 8.28 8.75 9.19 9.60 9.90 10.53 11.68 12.77 13.45 14.16 15.39 17.56 18.10 19.59 22.34 23.57 30.47 37.18 45.29 52.93

5.4 Branch weld 8.08 8.52 8.75 8.90 9.00 9.26 9.71 9.76 10.19 10.77 11.31 11.82 12.19 12.96 14.38 15.71 16.56 17.43 18.94 21.61 22.28 24.11 27.49 29.01 37.50 45.76 55.74 65.15

5.5 Reinforcing ring 8.98 9.48 9.74 9.90 10.01 10.30 10.80 10.86 11.33 11.98 12.59 13.14 13.56 14.42 15.99 17.48 18.42 19.39 21.07 24.04 24.78 26.83 30.59 32.27 41.72 50.90 62.01 72.48

5.6 Olet weld 10.09 11.56 12.29 12.75 13.06 13.86 15.20 15.37 16.62 18.31 19.88 21.31 22.37 24.54 28.45

5.7 Cutting pipe in case of changes 0.76 0.80 0.82 0.83 0.84 0.87 0.91 0.92 0.96 1.01 1.06 1.11 1.14 1.22 1.35 1.47 1.55 1.63 1.78 2.03 2.09 2.26 2.58 2.72 3.52 4.29 5.23 6.11

6.1 Flange connection 150# , PN 10-16 4.10

6.2 Flange connection 300# , PN 25-40 4.61

6.3 Flange connection 600#- 900# , PN 64-160 5.12

6.4 Flange connection 1500#-2500# , PN 250-320 5.74

6.5 Spectacle blind, blind flange, spade 0.82

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 8.50

7.2 Installation of valve 300# , PN 25-40 9.56

7.3 Installation of valve 600#- 900# , PN 64-160 10.63

7.4 Installation of valve 1500#- 2500# , PN 250-320 11.90

7.5 Installation of valve incl. drive 3.40

7.6 Installation of wafer-type valve 1.70

8.1 Pressure testing : hydrostatic/pneumatic 0.38

Size ASA/DIN 22" / 550

Outside diameter in mm 559

Wallthickness in mm 4.5 4.8 5.0 5.5 6.4 7.1 8.0 8.8 9.5 11.0 12.7 14.2 15.9 17.5 20.0 22.2 25.0 28.6 34.9 41.3 47.6 54.0

Schedule 5S 10S 10 20 STD 30 XS 40 60 80 100 120 140 160

3.1 Installation of pipe in plant (ISBL) 1.47 1.54 1.59 1.71 1.93 2.10 2.31 2.50 2.66 3.00 3.38 3.71 4.07 4.41 4.93 5.37 5.93 6.63 7.81 8.95 10.04 11.10

3.2 Install pipe on sleepers/ in rack (OSBL) 1.25 1.31 1.35 1.46 1.64 1.79 1.97 2.12 2.26 2.55 2.87 3.15 3.46 3.75 4.19 4.57 5.04 5.63 6.63 7.61 8.53 9.43

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 3.28

4.2 Fitting with 2 ends (elbows, reducers, mitre bends 4.68

4.3 Fitting with 3 ends (T and Y pieces) 6.09

5.1 Butt weld 6.00 6.10 6.17 6.35 6.69 6.98 7.38 7.76 8.11 8.90 9.87 10.80 11.91 13.02 14.87 16.61 18.95 22.17 28.30 35.11 42.32 50.08

5.2 Fillet weld 3.60 3.66 3.70 3.81 4.02 4.19 4.43 4.66 4.86 5.34 5.93 6.48 7.15 7.82 8.92 9.97 11.37 13.30 16.98 21.07 25.39 30.05

5.3 Mittre weld 7.80 7.93 8.02 8.25 8.70 9.08 9.60 10.09 10.54 11.57 12.84 14.04 15.49 16.93 19.34 21.59 24.64 28.82 36.79 45.65 55.01 65.10

5.4 Branch weld 9.60 9.76 9.87 10.15 10.71 11.18 11.81 12.42 12.97 14.24 15.80 17.28 19.06 20.84 23.80 26.57 30.32 35.47 45.28 56.18 67.71 80.12

5.5 Reinforcing ring 10.68 10.85 10.98 11.30 11.91 12.43 13.14 13.81 14.43 15.84 17.58 19.22 21.21 23.18 26.48 29.56 33.73 39.46 50.38 62.50 75.32 89.14

5.6 Olet weld 13.48 13.98 14.33 15.21 16.88 18.26 20.12 21.86 23.44 27.02 31.34

5.7 Cutting pipe in case of changes 0.90 0.92 0.93 0.95 1.00 1.05 1.11 1.16 1.22 1.34 1.48 1.62 1.79 1.95 2.23 2.49 2.84 3.33 4.25 5.27 6.35 7.51

6.1 Flange connection 150# , PN 10-16 4.58

6.2 Flange connection 300# , PN 25-40 5.16

6.3 Flange connection 600#- 900# , PN 64-160 5.73

6.4 Flange connection 1500#-2500# , PN 250-320 6.42

6.5 Spectacle blind, blind flange, spade 0.92

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 9.35

7.2 Installation of valve 300# , PN 25-40 10.52

7.3 Installation of valve 600#- 900# , PN 64-160 11.69

7.4 Installation of valve 1500#- 2500# , PN 250-320 13.09

7.5 Installation of valve incl. drive 3.74

7.6 Installation of wafer-type valve 3.74

8.1 Pressure testing : hydrostatic/pneumatic 0.41

Size ASA/DIN 24" / 600

Outside diameter in mm 610.0

Wallthickness in mm 4.5 5.0 5.5 5.6 6.3 6.4 7.1 8.0 8.8 9.5 10.0 12.7 14.3 16.0 17.5 20.0 22.2 24.6 25.0 31.0 38.9 46.0 52.4 59.5

Schedule 10 20 STD XS 30 40 60 80 100 120 140 160

3.1 Installation of pipe in plant (ISBL) 1.57 1.71 1.84 1.87 2.05 2.08 2.26 2.49 2.69 2.87 2.99 3.64 4.02 4.42 4.76 5.33 5.81 6.33 6.42 7.68 9.26 10.62 11.79 13.05

3.2 Install pipe on sleepers/ in rack (OSBL) 1.34 1.45 1.56 1.59 1.74 1.77 1.92 2.12 2.29 2.44 2.54 3.10 3.42 3.76 4.05 4.53 4.94 5.38 5.46 6.53 7.87 9.02 10.02 11.09

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 3.57

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adap 5.10

4.3 Fitting with 3 ends (T and Y pieces) 6.63

5.1 Butt weld 6.52 6.71 6.90 6.94 7.24 7.28 7.60 8.04 8.45 8.83 9.11 10.76 11.85 13.07 14.21 16.24 18.15 20.34 20.72 26.74 35.63 44.40 52.87 62.81

5.2 Fillet weld 3.91 4.03 4.14 4.17 4.34 4.37 4.56 4.82 5.07 5.30 5.47 6.46 7.11 7.84 8.53 9.75 10.89 12.20 12.43 16.05 21.38 26.64 31.72 37.69

5.3 Mittre weld 8.48 8.72 8.98 9.03 9.41 9.47 9.88 10.45 10.99 11.48 11.84 13.99 15.40 16.99 18.48 21.11 23.59 26.44 26.93 34.77 46.31 57.72 68.73 81.65

5.4 Branch weld 10.44 10.73 11.05 11.11 11.58 11.65 12.16 12.86 13.52 14.13 14.58 17.22 18.95 20.91 22.74 25.99 29.03 32.54 33.15 42.79 57.00 71.04 84.59 100.49

5.5 Reinforcing ring 11.61 11.94 12.29 12.36 12.89 12.97 13.53 14.31 15.04 15.72 16.22 19.16 21.08 23.27 25.30 28.91 32.30 36.20 36.88 47.60 63.41 79.03 94.11 111.80

5.6 Olet weld 14.67 15.59 16.56 16.75 18.18 18.39 19.89 21.93 23.84 25.57 26.85 34.24

5.7 Cutting pipe in case of changes 0.98 1.01 1.04 1.04 1.09 1.09 1.14 1.21 1.27 1.32 1.37 1.62 1.78 1.96 2.13 2.44 2.72 3.05 3.11 4.01 5.34 6.66 7.93 9.42

6.1 Flange connection 150# , PN 10-16 5.08

6.2 Flange connection 300# , PN 25-40 5.72

6.3 Flange connection 600#- 900# , PN 64-160 6.35

6.4 Flange connection 1500#-2500# , PN 250-320 7.11

6.5 Spectacle blind, blind flange, spade 1.02

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 10.20

7.2 Installation of valve 300# , PN 25-40 11.48

7.3 Installation of valve 600#- 900# , PN 64-160 12.75

7.4 Installation of valve 1500#- 2500# , PN 250-320 14.28

7.5 Installation of valve incl. drive 4.08

7.6 Installation of wafer-type valve 4.08

8.1 Pressure testing : hydrostatic/pneumatic 0.45

Size ASA/DIN 26" / 650

Outside diameter in mm 660.0

Wallthickness in mm 5.0 5.6 6.3 7.1 7.9 8.8 9.5 11.0 12.7 14.2 17.5 22.2

Schedule 10 STD 20 XS

3.1 Installation of pipe in plant (ISBL) 1.82 1.99 2.19 2.41 2.63 2.88 3.06 3.46 3.90 4.29 5.11 6.24

3.2 Install pipe on sleepers/ in rack (OSBL) 1.55 1.69 1.86 2.05 2.24 2.45 2.60 2.94 3.32 3.64 4.34 5.30

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 3.86

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 5.52

4.3 Fitting with 3 ends (T and Y pieces) 7.17

5.1 Butt weld 7.24 7.50 7.82 8.21 8.63 9.13 9.54 10.48 11.64 12.73 15.38 19.65

5.2 Fillet weld 4.34 4.50 4.69 4.92 5.18 5.48 5.72 6.29 6.98 7.64 9.23 11.79

5.3 Mittre weld 9.41 9.74 10.16 10.67 11.21 11.87 12.40 13.62 15.13 16.55 20.00 25.55

5.4 Branch weld 11.58 11.99 12.50 13.13 13.80 14.60 15.26 16.77 18.62 20.37 24.61 31.44

5.5 Reinforcing ring 12.89 13.34 13.91 14.61 15.35 16.25 16.98 18.65 20.71 22.67 27.38 34.98

5.6 Olet weld 16.84 18.09 19.64 21.50 23.46 25.78 27.66 31.91 37.07

5.7 Cutting pipe in case of changes 1.09 1.12 1.17 1.23 1.29 1.37 1.43 1.57 1.75 1.91 2.31 2.95

6.1 Flange connection 150# , PN 10-16 5.59

6.2 Flange connection 300# , PN 25-40 6.29

6.3 Flange connection 600#- 900# , PN 64-160 6.99

6.4 Flange connection 1500#-2500# , PN 250-320 7.83

6.5 Spectacle blind, blind flange, spade 1.12

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 11.05

7.2 Installation of valve 300# , PN 25-40 12.43

7.3 Installation of valve 600#- 900# , PN 64-160 13.81

7.4 Installation of valve 1500#- 2500# , PN 250-320 15.47

7.5 Installation of valve incl. drive 4.42

7.6 Installation of wafer-type valve 4.42

8.1 Pressure testing : hydrostatic/pneumatic 0.48

Size ASA/DIN 28" / 700

Outside diameter in mm 711.0

Wallthickness in mm 4.0 5.0 5.6 6.0 6.3 7.1 7.9 8.8 9.5 10.0 11.0 12.7 14.2 15.9 17.5 20.0

Schedule 10 STD 20 XS 30

3.1 Installation of pipe in plant (ISBL) 1.62 1.93 2.12 2.24 2.33 2.57 2.80 3.06 3.27 3.41 3.69 4.16 4.58 5.03 5.46 6.11

3.2 Install pipe on sleepers/ in rack (OSBL) 1.38 1.64 1.80 1.90 1.98 2.18 2.38 2.60 2.78 2.90 3.14 3.54 3.89 4.28 4.64 5.19

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 4.15

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 5.93

4.3 Fitting with 3 ends (T and Y pieces) 7.71

5.1 Butt weld 7.36 7.78 8.06 8.25 8.40 8.83 9.28 9.82 10.26 10.59 11.28 12.53 13.71 15.14 16.57 18.95

5.2 Fillet weld 4.42 4.67 4.83 4.95 5.04 5.30 5.57 5.89 6.16 6.35 6.77 7.52 8.23 9.09 9.94 11.37

5.3 Mittre weld 9.57 10.12 10.47 10.73 10.92 11.47 12.06 12.76 13.34 13.77 14.66 16.28 17.82 19.68 21.54 24.64

5.4 Branch weld 11.78 12.45 12.89 13.20 13.44 14.12 14.84 15.71 16.42 16.94 18.04 20.04 21.94 24.23 26.51 30.32

5.5 Reinforcing ring 13.11 13.85 14.34 14.69 14.96 15.71 16.51 17.47 18.26 18.85 20.07 22.29 24.40 26.95 29.50 33.73

5.6 Olet weld 16.00 18.11 19.46 20.40 21.13 23.14 25.25 27.76 29.79 31.29 34.39 39.97

5.7 Cutting pipe in case of changes 1.10 1.17 1.21 1.24 1.26 1.32 1.39 1.47 1.54 1.59 1.69 1.88 2.06 2.27 2.49 2.84

6.1 Flange connection 150# , PN 10-16 6.11

6.2 Flange connection 300# , PN 25-40 6.88

6.3 Flange connection 600#- 900# , PN 64-160 7.64

6.4 Flange connection 1500#-2500# , PN 250-320 8.56

6.5 Spectacle blind, blind flange, spade 1.22

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 11.90

7.2 Installation of valve 300# , PN 25-40 13.39

7.3 Installation of valve 600#- 900# , PN 64-160 14.87

7.4 Installation of valve 1500#- 2500# , PN 250-320 16.66

7.5 Installation of valve incl. drive 4.76

7.6 Installation of wafer-type valve 4.76

8.1 Pressure testing : hydrostatic/pneumatic 0.52

Size ASA/DIN 30 " / 750

Outside diameter in mm 762.0

Wallthickness in mm 5.6 6.3 6.4 7.1 7.9 8.8 9.5 11.0 12.7 14.2 15.9 17.5 20.0

Schedule 5S 10 STD 20 XS 30

3.1 Installation of pipe in plant (ISBL) 2.24 2.47 2.50 2.72 2.97 3.25 3.47 3.92 4.42 4.86 5.35 5.80 6.50

3.2 Install pipe on sleepers/ in rack (OSBL) 1.90 2.10 2.12 2.31 2.53 2.76 2.95 3.33 3.76 4.13 4.55 4.93 5.53

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 4.45

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 6.35

4.3 Fitting with 3 ends (T and Y pieces) 8.26

5.1 Butt weld 8.62 8.99 9.04 9.44 9.93 10.51 10.98 12.07 13.41 14.69 16.23 17.76 20.32

5.2 Fillet weld 5.17 5.39 5.43 5.67 5.96 6.30 6.59 7.24 8.05 8.81 9.74 10.66 12.19

5.3 Mittre weld 11.20 11.69 11.76 12.28 12.91 13.66 14.28 15.69 17.44 19.09 21.09 23.09 26.42

5.4 Branch weld 13.79 14.38 14.47 15.11 15.88 16.81 17.57 19.32 21.46 23.50 25.96 28.42 32.51

5.5 Reinforcing ring 15.34 16.00 16.10 16.81 17.67 18.70 19.55 21.49 23.88 26.14 28.88 31.61 36.17

5.6 Olet weld 20.83 22.62 22.88 24.77 27.05 29.73 31.92 36.86 42.86

5.7 Cutting pipe in case of changes 1.29 1.35 1.36 1.42 1.49 1.58 1.65 1.81 2.01 2.20 2.43 2.66 3.05

6.1 Flange connection 150# , PN 10-16 6.65

6.2 Flange connection 300# , PN 25-40 7.48

6.3 Flange connection 600#- 900# , PN 64-160 8.31

6.4 Flange connection 1500#-2500# , PN 250-320 9.31

6.5 Spectacle blind, blind flange, spade 1.33

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 12.75

7.2 Installation of valve 300# , PN 25-40 14.34

7.3 Installation of valve 600#- 900# , PN 64-160 15.94

7.4 Installation of valve 1500#- 2500# , PN 250-320 17.85

7.5 Installation of valve incl. drive 5.10

7.6 Installation of wafer-type valve 5.10

8.1 Pressure testing : hydrostatic/pneumatic 0.55

Size ASA/DIN 32" / 800

Outside diameter in mm 813.0

Wallthickness in mm 4.0 5.0 5.6 6.0 6.3 7.1 7.9 8.8 9.5 10.0 11.0 12.7 14.2 15.9 17.5 20.0 22.2

Schedule 10 STD 20 XS 30 40

3.1 Installation of pipe in plant (ISBL) 1.80 2.15 2.36 2.50 2.60 2.87 3.14 3.44 3.66 3.83 4.15 4.68 5.15 5.67 6.15 6.89 7.53

3.2 Install pipe on sleepers/ in rack (OSBL) 1.53 1.83 2.01 2.13 2.21 2.44 2.67 2.92 3.11 3.25 3.52 3.98 4.38 4.82 5.23 5.86 6.40

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 4.74

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 6.77

4.3 Fitting with 3 ends (T and Y pieces) 8.80

5.1 Butt weld 8.39 8.86 9.18 9.40 9.58 10.06 10.58 11.20 11.71 12.08 12.87 14.30 15.66 17.31 18.95 21.69 24.26

5.2 Fillet weld 5.03 5.32 5.51 5.64 5.75 6.04 6.35 6.72 7.02 7.25 7.72 8.58 9.40 10.39 11.37 13.01 14.56

5.3 Mittre weld 10.90 11.52 11.93 12.22 12.45 13.08 13.75 14.56 15.22 15.71 16.73 18.59 20.36 22.50 24.64 28.19 31.54

5.4 Branch weld 13.42 14.18 14.69 15.04 15.32 16.10 16.92 17.92 18.73 19.33 20.59 22.89 25.06 27.69 30.32 34.70 38.82

5.5 Reinforcing ring 14.93 15.78 16.34 16.74 17.04 17.91 18.83 19.93 20.84 21.51 22.91 25.46 27.88 30.81 33.73 38.60 43.19

5.6 Olet weld

5.7 Cutting pipe in case of changes 1.26 1.33 1.38 1.41 1.44 1.51 1.59 1.68 1.76 1.81 1.93 2.15 2.35 2.60 2.84 3.25 3.64

6.1 Flange connection 150# , PN 10-16 7.19

6.2 Flange connection 300# , PN 25-40 8.09

6.3 Flange connection 600#- 900# , PN 64-160 8.99

6.4 Flange connection 1500#-2500# , PN 250-320 10.07

6.5 Spectacle blind, blind flange, spade 1.44

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 13.60

7.2 Installation of valve 300# , PN 25-40 15.30

7.3 Installation of valve 600#- 900# , PN 64-160 17.00

7.4 Installation of valve 1500#- 2500# , PN 250-320 19.04

7.5 Installation of valve incl. drive 5.44

7.6 Installation of wafer-type valve 5.44

8.1 Pressure testing : hydrostatic/pneumatic 0.59

Size ASA/DIN 34" / 850

Outside diameter in mm 864.0

Wallthickness in mm 6.3 7.1 7.9 8.8 9.5 11.0 12.7 14.2 15.9 17.5 20.0

Schedule 10 STD 20 XS 30 40

3.1 Installation of pipe in plant (ISBL) 2.74 3.02 3.31 3.62 3.86 4.37 4.94 5.43 5.98 6.49 7.28

3.2 Install pipe on sleepers/ in rack (OSBL) 2.33 2.57 2.81 3.08 3.28 3.72 4.20 4.62 5.08 5.52 6.18

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 5.03

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 7.18

4.3 Fitting with 3 ends (T and Y pieces) 9.34

5.1 Butt weld 10.16 10.68 11.23 11.89 12.43 13.67 15.19 16.64 18.39 20.14 23.06

5.2 Fillet weld 6.10 6.41 6.74 7.13 7.46 8.20 9.12 9.98 11.04 12.08 13.83

5.3 Mittre weld 13.21 13.88 14.60 15.45 16.16 17.77 19.75 21.63 23.91 26.18 29.97

5.4 Branch weld 16.26 17.08 17.96 19.02 19.89 21.87 24.31 26.63 29.43 32.22 36.89

5.5 Reinforcing ring 18.09 19.01 19.99 21.16 22.12 24.33 27.04 29.62 32.74 35.85 41.04

5.6 Olet weld

5.7 Cutting pipe in case of changes 1.52 1.60 1.68 1.78 1.86 2.05 2.28 2.50 2.76 3.02 3.46

6.1 Flange connection 150# , PN 10-16 7.75

6.2 Flange connection 300# , PN 25-40 8.72

6.3 Flange connection 600#- 900# , PN 64-160 9.68

6.4 Flange connection 1500#-2500# , PN 250-320 10.85

6.5 Spectacle blind, blind flange, spade 1.55

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 14.45

7.2 Installation of valve 300# , PN 25-40 16.26

7.3 Installation of valve 600#- 900# , PN 64-160 18.06

7.4 Installation of valve 1500#- 2500# , PN 250-320 20.23

7.5 Installation of valve incl. drive 5.78

7.6 Installation of wafer-type valve 5.78

8.1 Pressure testing : hydrostatic/pneumatic 0.62

Size ASA/DIN 36" / 900

Outside diameter in mm 914.0

Wallthickness in mm 4.0 5.0 5.6 6.3 7.1 7.9 8.0 8.8 9.5 10.0 11.0 12.7 14.2 15.9 17.5 19.1 20.0 22.2

Schedule 10 STD 20 XS 30 40

3.1 Installation of pipe in plant (ISBL) 1.98 2.37 2.60 2.87 3.17 3.47 3.51 3.80 4.05 4.23 4.59 5.19 5.71 6.29 6.82 7.36 7.65 8.37

3.2 Install pipe on sleepers/ in rack (OSBL) 1.68 2.02 2.21 2.44 2.70 2.95 2.98 3.23 3.45 3.60 3.90 4.41 4.85 5.34 5.80 6.25 6.50 7.11

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 5.32

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, a 7.60

4.3 Fitting with 3 ends (T and Y pieces) 9.88

5.1 Butt weld 9.40 9.94 10.29 10.74 11.28 11.87 11.94 12.56 13.14 13.56 14.45 16.06 17.60 19.45 21.31 23.26 24.40 27.31

5.2 Fillet weld 5.64 5.96 6.18 6.44 6.77 7.12 7.16 7.54 7.88 8.14 8.67 9.64 10.56 11.67 12.78 13.96 14.64 16.38

5.3 Mittre weld 12.22 12.92 13.38 13.96 14.67 15.43 15.52 16.33 17.08 17.63 18.78 20.88 22.88 25.29 27.70 30.24 31.72 35.50

5.4 Branch weld 15.04 15.90 16.47 17.18 18.05 18.99 19.11 20.10 21.02 21.70 23.12 25.70 28.16 31.13 34.09 37.21 39.04 43.69

5.5 Reinforcing ring 16.73 17.69 18.32 19.11 20.08 21.12 21.26 22.36 23.38 24.14 25.72 28.59 31.33 34.63 37.93 41.40 43.43 48.60

5.6 Olet weld

5.7 Cutting pipe in case of changes 1.41 1.49 1.54 1.61 1.69 1.78 1.79 1.89 1.97 2.03 2.17 2.41 2.64 2.92 3.20 3.49 3.66 4.10

6.1 Flange connection 150# , PN 10-16 8.31

6.2 Flange connection 300# , PN 25-40 9.35

6.3 Flange connection 600#- 900# , PN 64-160 10.39

6.4 Flange connection 1500#-2500# , PN 250-320 11.64

6.5 Spectacle blind, blind flange, spade 1.66

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 15.30

7.2 Installation of valve 300# , PN 25-40 17.21

7.3 Installation of valve 600#- 900# , PN 64-160 19.13

7.4 Installation of valve 1500#- 2500# , PN 250-320 21.42

7.5 Installation of valve incl. drive 6.12

7.6 Installation of wafer-type valve 6.12

8.1 Pressure testing : hydrostatic/pneumatic 0.66

Size ASA/DIN 40" / 1000

Outside diameter in mm 1016.0

Wallthickness in mm 5.0 5.6 6.3 7.1 8.0 8.8 9.5 10.0 11.0 12.5 12.7 14.2 16.0 17.5 20.0 22.2

Schedule

3.1 Installation of pipe in plant (ISBL) 2.59 2.85 3.14 3.47 3.84 4.16 4.44 4.64 5.03 5.62 5.69 6.27 6.94 7.50 8.41 9.20

3.2 Install pipe on sleepers/ in rack (OSBL) 2.20 2.42 2.67 2.95 3.26 3.54 3.78 3.94 4.28 4.77 4.84 5.33 5.90 6.37 7.15 7.82

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 5.90

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 8.43

4.3 Fitting with 3 ends (T and Y pieces) 10.96

5.1 Butt weld 11.02 11.42 11.91 12.52 13.25 13.94 14.58 15.05 16.04 17.62 17.84 19.55 21.75 23.69 27.13 30.38

5.2 Fillet weld 6.61 6.85 7.15 7.51 7.95 8.37 8.75 9.03 9.63 10.57 10.71 11.73 13.05 14.21 16.28 18.23

5.3 Mittre weld 14.33 14.84 15.48 16.27 17.23 18.13 18.96 19.57 20.85 22.91 23.20 25.42 28.27 30.79 35.27 39.49

5.4 Branch weld 17.63 18.27 19.06 20.03 21.20 22.31 23.33 24.09 25.67 28.20 28.55 31.28 34.79 37.90 43.42 48.61

5.5 Reinforcing ring 19.61 20.32 21.20 22.28 23.59 24.82 25.96 26.80 28.55 31.37 31.76 34.80 38.71 42.16 48.30 54.07

5.6 Olet weld

5.7 Cutting pipe in case of changes 1.65 1.71 1.79 1.88 1.99 2.09 2.19 2.26 2.41 2.64 2.68 2.93 3.26 3.55 4.07 4.56

6.1 Flange connection 150# , PN 10-16 9.47

6.2 Flange connection 300# , PN 25-40 10.66

6.3 Flange connection 600#- 900# , PN 64-160 11.84

6.4 Flange connection 1500#-2500# , PN 250-320 13.26

6.5 Spectacle blind, blind flange, spade 1.89

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 17.00

7.2 Installation of valve 300# , PN 25-40 19.13

7.3 Installation of valve 600#- 900# , PN 64-160 21.25

7.4 Installation of valve 1500#- 2500# , PN 250-320 23.80

7.5 Installation of valve incl. drive 6.80

7.6 Installation of wafer-type valve 6.80

8.1 Pressure testing : hydrostatic/pneumatic 0.73

Size ASA/DIN 42" / 1050

Outside diameter in mm 1067.0

Wallthickness in mm 6.3 7.1 8.0 8.8 9.5 11.0 12.7 14.2 17.5

Schedule

3.1 Installation of pipe in plant (ISBL) 3.27 3.62 4.00 4.34 4.64 5.25 5.94 6.54 7.83

3.2 Install pipe on sleepers/ in rack (OSBL) 2.78 3.08 3.40 3.69 3.94 4.47 5.05 5.56 6.66

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 6.20

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 8.85

4.3 Fitting with 3 ends (T and Y pieces) 11.51

5.1 Butt weld 12.50 13.14 13.91 14.63 15.30 16.84 18.73 20.53 24.88

5.2 Fillet weld 7.50 7.88 8.34 8.78 9.18 10.10 11.24 12.32 14.93

5.3 Mittre weld 16.25 17.08 18.08 19.02 19.90 21.89 24.35 26.69 32.34

5.4 Branch weld 20.00 21.02 22.25 23.41 24.49 26.94 29.97 32.85 39.80

5.5 Reinforcing ring 22.25 23.38 24.75 26.05 27.24 29.97 33.34 36.54 44.28

5.6 Olet weld

5.7 Cutting pipe in case of changes 1.88 1.97 2.09 2.20 2.30 2.53 2.81 3.08 3.73

6.1 Flange connection 150# , PN 10-16 10.06

6.2 Flange connection 300# , PN 25-40 11.32

6.3 Flange connection 600#- 900# , PN 64-160 12.58

6.4 Flange connection 1500#-2500# , PN 250-320 14.09

6.5 Spectacle blind, blind flange, spade 2.01

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 17.85

7.2 Installation of valve 300# , PN 25-40 20.08

7.3 Installation of valve 600#- 900# , PN 64-160 22.31

7.4 Installation of valve 1500#- 2500# , PN 250-320 24.99

7.5 Installation of valve incl. drive 7.14

7.6 Installation of wafer-type valve 7.14

8.1 Pressure testing : hydrostatic/pneumatic 0.76

Size ASA/DIN 44" / 1100

Outside diameter in mm 1118.0

Wallthickness in mm 7.1 9.5 12.7

Schedule

3.1 Installation of pipe in plant (ISBL) 3.77 4.83 6.19

3.2 Install pipe on sleepers/ in rack (OSBL) 3.20 4.10 5.26

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 6.49

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 9.27

4.3 Fitting with 3 ends (T and Y pieces) 12.05

5.1 Butt weld 13.75 16.03 19.62

5.2 Fillet weld 8.25 9.62 11.77

5.3 Mittre weld 17.88 20.83 25.51

5.4 Branch weld 22.01 25.64 31.39

5.5 Reinforcing ring 24.48 28.53 34.93

5.6 Olet weld

5.7 Cutting pipe in case of changes 2.06 2.40 2.94

6.1 Flange connection 150# , PN 10-16 10.66

6.2 Flange connection 300# , PN 25-40 12.00

6.3 Flange connection 600#- 900# , PN 64-160 13.33

6.4 Flange connection 1500#-2500# , PN 250-320 14.93

6.5 Spectacle blind, blind flange, spade 2.13

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 18.70

7.2 Installation of valve 300# , PN 25-40 21.04

7.3 Installation of valve 600#- 900# , PN 64-160 23.38

7.4 Installation of valve 1500#- 2500# , PN 250-320 26.18

7.5 Installation of valve incl. drive 7.48

7.6 Installation of wafer-type valve 7.48

8.1 Pressure testing : hydrostatic/pneumatic 0.80

Size ASA/DIN 48" / 1200 1200

Outside diameter in mm 1219.0 1220.0

Wallthickness in mm 7.1 9.5 10.3 12.7 15.9 5.0 8.0 10.0 20.0

Schedule

3.1 Installation of pipe in plant (ISBL) 4.06 5.21 5.58 6.68 8.12 3.02 4.50 5.44 9.91

3.2 Install pipe on sleepers/ in rack (OSBL) 3.45 4.42 4.74 5.68 6.90 2.57 3.82 4.63 8.43

4.1 Fitting with 1 end (flanges, lap joints, caps etc) 7.07 7.07

4.2 Fitting with 2 ends (elbows, reducers, mitre bends, adapt 10.10 10.10

4.3 Fitting with 3 ends (T and Y pieces) 13.13 13.13

5.1 Butt weld 14.98 17.46 18.38 21.38 25.93 13.19 15.87 18.04 32.61

5.2 Fillet weld 8.99 10.47 11.03 12.83 15.56 7.91 9.52 10.82 19.56

5.3 Mittre weld 19.47 22.70 23.89 27.80 33.71 17.14 20.63 23.45 42.39

5.4 Branch weld 23.96 27.93 29.40 34.21 41.49 21.10 25.39 28.87 52.17

5.5 Reinforcing ring 26.66 31.07 32.71 38.06 46.16 23.47 28.25 32.11 58.04

5.6 Olet weld

5.7 Cutting pipe in case of changes 2.25 2.62 2.76 3.21 3.89 1.98 2.38 2.71 4.89

6.1 Flange connection 150# , PN 10-16 11.89 11.89

6.2 Flange connection 300# , PN 25-40 13.38 13.38

6.3 Flange connection 600#- 900# , PN 64-160 14.86 14.86

6.4 Flange connection 1500#-2500# , PN 250-320 16.65 16.65

6.5 Spectacle blind, blind flange, spade 2.38 2.38

6.6 Bending of pipe

6.7 Cutting thread

6.8 Threaded connection

7.1 Installation of valve 150# , PN 10-16 20.40 20.40

7.2 Installation of valve 300# , PN 25-40 22.95 22.95

7.3 Installation of valve 600#- 900# , PN 64-160 25.50 25.50

7.4 Installation of valve 1500#- 2500# , PN 250-320 28.56 28.56

7.5 Installation of valve incl. drive 8.16 8.16

7.6 Installation of wafer-type valve 8.16 8.16

8.1 Pressure testing : hydrostatic/pneumatic 0.87 0.87

You might also like

- DACE Labour Norms Plastic Piping Tables V2Document3 pagesDACE Labour Norms Plastic Piping Tables V2Amir AbazaNo ratings yet

- DACE Calculatie PrefDocument37 pagesDACE Calculatie PrefIzzet BozkurtNo ratings yet

- WFF - FlangesDocument5 pagesWFF - Flangesbaskaran vNo ratings yet

- Circular Bolt Group Base Plate DesignDocument3 pagesCircular Bolt Group Base Plate DesignChong Wee LinNo ratings yet

- NRF 206 Pemex 2008 FDocument17 pagesNRF 206 Pemex 2008 FJavier GarcíaNo ratings yet

- 2006 National Standard Plumbing Code ILLUSTRATED 397&398Document2 pages2006 National Standard Plumbing Code ILLUSTRATED 397&398Hussain Al SanonaNo ratings yet

- 1 Pipe Supply 13,775,013.8 2 Fitting Supply 2,196,295.0: Summary of Works Item - No Item Description Contract AmountDocument11 pages1 Pipe Supply 13,775,013.8 2 Fitting Supply 2,196,295.0: Summary of Works Item - No Item Description Contract AmountAbi DemeNo ratings yet

- Weight of Piping MaterialDocument9 pagesWeight of Piping Materialviny22No ratings yet

- Fittings & Valves Equivalent LengthsDocument2 pagesFittings & Valves Equivalent LengthsSanthosh Kumar33% (3)

- Design CalDocument19 pagesDesign CalneelNo ratings yet

- Design Gambar Scaffolding 2021Document3 pagesDesign Gambar Scaffolding 2021Unggul NugratamaNo ratings yet

- Quotation ForDocument4 pagesQuotation ForAnsaf AskyNo ratings yet

- Tee EqualDocument3 pagesTee EqualJirakom LimmongkolkulNo ratings yet

- Documents - Pub Pipe Span With Point LoadsDocument75 pagesDocuments - Pub Pipe Span With Point LoadsThanhNo ratings yet

- Stiudiu 1010351 1Document7 pagesStiudiu 1010351 1Simion MariusNo ratings yet

- 4 Storey 8 CL (Standard Footing) - FinalDocument106 pages4 Storey 8 CL (Standard Footing) - FinalKaren Balisacan Segundo RuizNo ratings yet

- ACPDB Wire Sizing ReportDocument5 pagesACPDB Wire Sizing ReportJM AndresNo ratings yet

- Duct EstimatesDocument25 pagesDuct EstimatesRhowelle TibayNo ratings yet

- Bronze Relief Valve DN10 DN15 DN20Document2 pagesBronze Relief Valve DN10 DN15 DN20billNo ratings yet

- ProductSpec 9810019228RAWFRAME20HBS21Document54 pagesProductSpec 9810019228RAWFRAME20HBS21Gabriel MorosanuNo ratings yet

- Lap Joint Stub Ends-ANSI B16.9Document1 pageLap Joint Stub Ends-ANSI B16.9Sachin HolkarNo ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Type of Steel and SpsDocument7 pagesType of Steel and Spschaitanya bholeNo ratings yet

- Valves & Fittings Equivalent LengthsDocument5 pagesValves & Fittings Equivalent LengthsCzarSASNo ratings yet

- Class 125 Cast Bronze Swing Check Valve Screwed Ends: Kitz Fig: RDocument1 pageClass 125 Cast Bronze Swing Check Valve Screwed Ends: Kitz Fig: Rnvhoang0185No ratings yet

- Weight of Piping Materials in KG Weight of Piping Materials in KGDocument18 pagesWeight of Piping Materials in KG Weight of Piping Materials in KGJeevan DasNo ratings yet

- Metal Fabrication Pipe Cost Estimation SheetDocument1 pageMetal Fabrication Pipe Cost Estimation SheettunlinooNo ratings yet

- PCB CharacteristicsDocument7 pagesPCB Characteristicssanthoshkvs2005No ratings yet

- Hammer Lug Union SpecificationDocument16 pagesHammer Lug Union Specificationashved505100% (1)

- Supply of Pipe and Fittings BlankDocument7 pagesSupply of Pipe and Fittings BlankMiko AbiNo ratings yet

- Ke AkrDocument1 pageKe Akrnvhoang0185No ratings yet

- Tightening Torque: EngineDocument4 pagesTightening Torque: EngineJaziel Lopez ReyesNo ratings yet

- Lap Joint Stub End PDFDocument2 pagesLap Joint Stub End PDFBowo Edhi WibowoNo ratings yet

- nrcs142p2 - 024468 (Autoguardado)Document1 pagenrcs142p2 - 024468 (Autoguardado)Luis RamirezNo ratings yet

- Forged Steel FittingsDocument12 pagesForged Steel FittingsHong Trung DuongNo ratings yet

- Motor Wire CalculatorDocument6 pagesMotor Wire CalculatorFausto SelettiNo ratings yet

- Wire Sizing and Impedance Calculations for Three ACPDB CircuitsDocument3 pagesWire Sizing and Impedance Calculations for Three ACPDB CircuitsJM AndresNo ratings yet

- Description VA Meters Size of Wire Z/305 AMP VD %VDDocument3 pagesDescription VA Meters Size of Wire Z/305 AMP VD %VDJM AndresNo ratings yet

- Swaged and Lightweight Welding NozzlesDocument5 pagesSwaged and Lightweight Welding NozzlesDries VandezandeNo ratings yet

- Lightweight Welding Nozzles Ordering GuideDocument10 pagesLightweight Welding Nozzles Ordering GuideDries VandezandeNo ratings yet

- Flanges: SI SMEDocument16 pagesFlanges: SI SMEbalaNo ratings yet

- Swaged and Lightweight Welding NozzlesDocument2 pagesSwaged and Lightweight Welding NozzlesDries VandezandeNo ratings yet

- Stainless Steel Flexible Hose AssembliesDocument10 pagesStainless Steel Flexible Hose AssembliesDkdkkdNo ratings yet

- Ta BBV LF: Balancing ValvesDocument12 pagesTa BBV LF: Balancing ValvesDanZel DanNo ratings yet

- Fast Engineer For Pipe - Fittings and FLGDocument212 pagesFast Engineer For Pipe - Fittings and FLGsipannusNo ratings yet

- Spherical Bearings 140107045033 Phpapp02 PDFDocument3 pagesSpherical Bearings 140107045033 Phpapp02 PDFRaja Sekaran SajjaNo ratings yet

- Cutting and Welding Nozzles GuideDocument4 pagesCutting and Welding Nozzles GuideDries VandezandeNo ratings yet

- ExtractPage14 PDFDocument2 pagesExtractPage14 PDFDries VandezandeNo ratings yet

- Cutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Document2 pagesCutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Dries VandezandeNo ratings yet

- ExtractPage14 15 PDFDocument2 pagesExtractPage14 15 PDFDries VandezandeNo ratings yet

- ESAB ExtractPage15-16cDocument9 pagesESAB ExtractPage15-16cDries VandezandeNo ratings yet

- Description VA Meters Size of Wire Z/305 AMP VD %VDDocument5 pagesDescription VA Meters Size of Wire Z/305 AMP VD %VDJM AndresNo ratings yet

- K-511-V, FLW SWTDocument2 pagesK-511-V, FLW SWTamir shokrNo ratings yet

- Wire sizing chart for electrical circuitsDocument3 pagesWire sizing chart for electrical circuitsJM AndresNo ratings yet

- Ductile and Cast Iron Flanged Fittings Dimensions and SpecsDocument16 pagesDuctile and Cast Iron Flanged Fittings Dimensions and SpecsAhmed AbdoNo ratings yet