Professional Documents

Culture Documents

Section R804 Cold-Formed Steel Roof Framing

Section R804 Cold-Formed Steel Roof Framing

Uploaded by

Phú Nguyễn0 ratings0% found this document useful (0 votes)

7 views22 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views22 pagesSection R804 Cold-Formed Steel Roof Framing

Section R804 Cold-Formed Steel Roof Framing

Uploaded by

Phú NguyễnCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

522, 7:94 PM ‘Section R804 Cold-Fored Stee! Roof Framing

‘Section R804 Cold-Formed Stoo! Roof Framing

R804.1 Gener

Elements shall be straight and free of any defects that would significantly affect ther stuctural performance. Cold-formed stee! roof framing

‘members shall bein accordance with the requirements ofthis section,

£R804.1.1 Applicability Limits

‘The provisions of ths section shal control the construction of cold-frmed steel roof framing fo buildings not greater than 60 feet (18 288

mm) perpendicular tothe joist, rafter or truss span, not greater than 40 feet (12 192 mm) in width paral tothe joist span or russ, less than

for equal to three stories above grade plane and with rot slopes not less than 3:12 (25-percent slope) or greater than 12:12 (100-percent

slope). Cold-ormed steel roo framing constructed in accardance withthe provisions of this section shall be limited to sites where the

Lliate design wind speed is less than 140 miles per hour (63 mis), Exposure Category B or C, and the ground snow load is less than oF

‘equal to 70 pounds per square foot (3350 Pa).

R804.1.41 Alternate Applications

Cole-formed steel rot and ceiling raming for buildings exceeding the applicability mits of Section R804. 1.1 is permited tobe designed

‘and constructed in accordance with AIS! S230, subject othe limits therein,

£R804.1.2 In-Line Framing

CCole-formed steel oof tring constructed in accordance with Section R804 shall be located in line with the tol

‘S240, Section B1.2.3,

ances specified in AIS!

R804.2 Structural Framing

\Load-bearing, coldormed steel rool framing members shal be in accordance with this section,

£R804.2.1 Material

Load-bearing, cold-ormed steel framing members shall be cold formed to shape from structural quay sheet stee! complying with the

requirements of AISI $240, Section AS,

£R804.2.2 Corrosion Protection

‘Load-bearing, cold formed steel framing shall have a protective coating complying with AISI $240, Section Ad,

£R804.2.3 Dimension, Thicknoss and Material Grado

‘Load-bearing, cold-ormed stee! root framing members shall comply wth AISI S230, Section Ad.3 and material grade requirements as

specified in AISI $290, Section A&.4

£R804.2.4 Identification

‘Load-bearing, cold-ormed stee! framing members shall meet the product identicaton requirements of AISI S240, Section AS.S.

'R804.2.5 Fastoning Requirements

‘Screws fr stelo-stee connections shal be installed with a minimum edge distance and center4o-center spacing of "pinch (12.7 mm

shallbese-ling tapping and shall conform to ASTM C1513, Stuctral sheathing shall be attached to coldfrmed see oo afters with

minimum No. 8 se. riling tapping Screws that conform to ASTM C1513. Screws for attaching structural sheathing to cold formed ste! root

framing shall have a minimum head ciameter of 0.292 inch (7.4 mm) with countersunk heads and shal be installed with @ minimum edge

distance of inch (9.5 mm). Gypsum Boars ceilings shalbe attached to coe-ormed steel its wih minimum No, 6 screws conforming

ASTM C954 of ASTM C1513 wih a bugle-headalye an shall be installed in accordance wih Section REDS. For all connections, screws

hntps:/up.codesiviower_exportjurs_keylcoloradolpubint residential code_202%/retiRA04 sree

‘Section R804 Cold-Fored Stee! Roof Framing

tend through the steel not fewer than three exposed threads. Fasteners shall have rust-nhibitve coating suitable fr the installation

In which they are Being used, of be manufacture fram material nat susceptible to corrosion,

'R804.2.6 Wob Holes, Wob Hole Reinforcing and Web Hole Patching

Web holes in roof or ceiling joists shall comply withthe conditions as prescribed in AIS! $230, Section A4.5. Web holes not in conformance

to the conditions of AISI $230, Section A4.5 shal be reinforced in accordance with the provisions of AISI $230, Section A4.6 or patched in

‘accordance with the provisions of AIS! $230, Section AA 7,

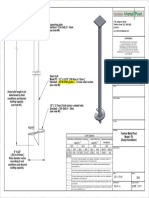

R804.3 Roof Construction

CCold-formed steel roof systems constructed in accordance with the provisions of this section shall consist of both celing joists and rafters in

accordance with Figure R804.3 and fastened in accordance with Table REO4.3

304.8 mm, 1 mil = 0.0254 mm,

FIGURE R804.3,

COLD-FORMED STEEL ROOF CONSTRUCTION

‘TABLE R804.3

ROOF FRAMING FASTENING SCHEDULE®®

hntps:/up.codesiviower_exportjurs_keylcoloradolpubint residential code_202%/retiRA04 22

822, 7:94 PM ‘Section R804 Cold-Formed Stee! Roof Framing

Roo seating (tate stan barr phos oat No. ctee ‘oe. onedgesand 10 ater por

2 at gai er 8.

‘Utne Doan We Seed empty ang

conrarestermes | et

sewcrgin) | Se | eae |< [aw | caw

For Si: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 pound per square foot = 0.0479 kPa, 1 mil = 0.0254 mm.

a, Screws are a minimum No. 10 unless noted otherwise.

b. Indicated number of screws shall be applied through the flanges of the truss or ceiling joist or through each leg of a

‘54 mil lip angle. See Section R804.3.8 for additional requirements to resist uplift forces.

£R804.3.1 Colling Joists

CColé-formed steel cling joists shal be in accordance with this section.

R804.3.4.1 Minimum Celling Joist Size

CCeling joist size and thickness shal be determined in accordance with the limits set forth in Tables R804 3.1,1(1) and R804 3.1.1(2).

When determining the size of ceiling joists, the lateral support ofthe top flange shall be classified as unbraced, braced at midspan or

braced at thcd points in accordance with Section REO4 3.1.3, Where sheathing material is attached tothe top fange of celing joists or

here the bracing is spaced closer than at third points ofthe joist, the "third point” values from Tables RBO4.3.1.1(1) and RBOS.3.1.1(2)

shall be used

hnups:iup.codes/viower_exportjurs_keylcoloradolpubint residential code_202"vretRB04 22

ovsza, 7:34 PM ‘Section R804 Cold-Formed Stee Root Framing

Cling joists shall havea bearing suppor length of nat les than 11/, inches (38mm) and shal be connected to oot rafters (heel

Joint) with No, 10 screws in accordance with Figure R8O4 21.1 and Table RBOA 3.1.13).

Where continuous joists are framed across interior beating supports, the interior beating supports shall be located within 24 inches

(610 mm) of midspan ofthe celing joist, and the individual spans shall not exceed the applicable spans in Tables R8O4.3.1.1(1) and

R808 3.1112)

\Where the attic i to be used as an occupied space, the celing joists shall be designed in accordance with Section R505,

TABLE R804.3.1.1(1)

CEILING JOIST SPANS 10 PSF LIVE LOAD (NO ATTIC STORAGE)*:

tps:

Jup.codesviower_exporijurs_koylcoloradoipubiint residential code_202'etR804 ana

522, 7:36 PM Sextion R804 Cold-Formed Steel Roof Framing

[ALLOWABLE SPAN footnote)

‘tara Support ot Top (Compression Fange

weuseroesionarion | unoracea | Misspan racing | Thirpoit Bracing

cetng Jost Specing nes)

For Sk: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 mil = 0.0254 mm, 1 pound per square foot = 0.0479 kPa.

2, Deflection criterion: L/240 for total loads.

b. Celling dead load = § psf.

hitpssup.codesiewer_exporvjurs_Keyicloradolpubin, residential code_202%ie1iR804

522, 7:94 PM ‘Section R804 Cold-Fored Stee! Roof Framing

©. Minimum Grade 33 ksi steel shall be used for 33 mil and 43 mil thicknesses. Minimum Grade 60 ksi steel shall

bbe used for 54 and 68 mil thicknesses.

4d. Listed allowable spans are not applicable for 350 162-33, 550 162-33, 5508 162-43 and 800816243

Continuous joist members.

TABLE R804.3.4.1(2)

CEILING JOIST SPANS 20 PSF LIVE LOAD (LIMITED ATTIC STORAGE}*®S¢

hnups:iup.codes/viower_exportjurs_keylcoloradolpubint residential code_202"vretRB04

522, 7:36 PM Sextion R804 Cold-Formed Steel Roof Framing

[ALLOWABLE SPAN footnote)

‘tara Support ot Top (Compression Fange

cetg Jost Spocing Gnces)

For Sk: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 mil = 0.0254 mm, 1 pound per square foot = 0.0479 kPa.

2, Deflection criterion: L/240 for total loads.

. Celling deal load = 5 pst.

hitpssup.codesiewer_exporvjurs_Keyicloradolpubin, residential code_202%ie1iR804 tee

522, 7:94 PM

©. Minimum Grade 33 ksi steel shall be used for 33 mil and 43 mil thicknesses. Minimum Grade 60 ksi steel shall

bbe used for 54 and 68 mil thicknesses.

Section R804 Cold-Formed Steel Root

arming

4d. Listed allowable spans are not applicable for 360 162-33, 350162-43, 550S162-33, $50S162-43 and

8008162-43 continuous joist members,

TABLE R804.3.4.1(3)

NUMBER OF SCREWS REQUIRED FOR CEILING JOIST TO ROOF RAFTER CONNECTION®

atang wit feat

For Si: 1 foot = 304.8 mm, 1 pound per square foot = 0.0479kPa,

1. Screws shall be No. 10.

hitpssup.codesiewer_exporvjurs_Keyicloradolpubin, residential code_202%ie1iR804

522, 7:94 PM ‘Section R804 Cold-Fored Steel Roof Framing

ceimiasoist ——+| rack

FASTEN RAFTER TO

GAILING JOIST WaT

MaNMUMANO. 10 SCREWS

‘AS REQURRED OR THROUGH

CLPANGLE, PLATE OR OTHER,

[APPROVED CONNECTOR

FASTEN ROOF TO WALL

‘TRACK WITH2 NO. 10;

‘SCREWS THROUGH CEILING

JOIST FLANGES, 54 MIL CUP,

[ANGLE (MINIMUM, STEEL

PLATE OR OTHER.

‘APPROVED CONNECTOR

For Si: 4 mil = 0.0254 mm.

FIGURE R804.3.1.1

JOIST TO RAFTER CONNECTION

‘The bottom flanges of cling joists shal be laterally braced by the application of gypsum board or continuous sleel straps installed

perpendicular to the jist un in accordance with one of the following:

1. Gypsum board shall be fastened with No. 6 screws in accordance with Section R702.

2, Stee! straps with a minimum size of 1" inches by 33 mils (88 mm by 0.84 mm) shall be Installed ata maximum spacing

(of 4 feet (1219 mm), Straps shall be fastened fo te bottom flange at each jist with one No. 8 screw and shall be

fastened to blocking with two No. 8 screws. Blocking shall be installed between joists at a maximum spacing of 12 feet

(3658 mm) measured along a line of continuous strapping (perpendicular tothe joist run), and at the termination of all

siraps.

R808.3.1.3 6

ling Joist Top Flange Bracing

‘The top flanges of coling joists shall be laterally braced as required by Tablos R8O4 3.1.1(1) and R804 3.1.1(2), in accordance with one

(ofthe folowing

1. Minimum 33-mil (0.84 mm) C-shaped member in accordance with Figure R604 3.1.3(1,

2. Minimum 33-mil (0.84 mm) track section in accordance with Figure R8Q4.3.1.3(1)

3. Minimum 33-mil (0.84 mm) hat section in accordance with Figure R8O4.3.1.3(1)

hntps:/up.codesiviower_exportjurs_keylcoloradolpubint residential code_202%/retiRA04 92

522, 7:94 PM ‘Section R804 Cold-Fored Stee! Roof Framing

4. Minimum 54m (1.37 men) 1ginch (38 mm) cold-olled channel section in accordance with Figure RBOA.3.1:3(1)

5. Minimum 17-inch by 83-ni(38.mm by 0.84 mm) continuous steel strap in accordance with Figure R8O4.3.15(2).

Lateral bracing shall be installed perpendicular to the ceiling joists and shal be fastened tothe top flange ofeach jist with one No. 8

‘sorew. Blocking shal be installed between joists inline wth bracing at a maximum spacing of 12 feet (2658 mm) measured

perpendicular to the joists, Ends of lateral bracing shall be attached to blocking or anchored toa stable building component with two No,

screws,

BRACING. USE 1 NO. 8 SCREW TO EACH JOIST.

[AT SPLICE LOCATIONS, EITHER LAP MEMBERS,

‘AS SHOWN OR ABUT. WITH 2 NO. 8 SCREWS

EACH END OF EACH MEMBER.

FIGURE R804.3.1.3(1)

CEILING JOIST TOP FLANGE BRACING WITH C-SHAPED, TRACK OR COLD-ROLLED CHANNEL

For Si: 1 foot = 304.8 mm,

hntps:/up.codesiviower_exportjurs_keylcoloradolpubint residential code_202%/retiRA04 s0n22

522, 7:94 PM ‘Section R804 Cold-Fored Stee! Roof Framing

FIGURE R804.3.1.3(2)

CEILING JOIST TOP FLANGE BRACING WITH CONTINUOUS STEEL STRAP AND BLOCKING

R804.3.4.4Colling Joist Splicing

‘Spices in celing joists shall be permited, if celing jis splices are supported at interior bearing points and are constructed in

‘accordance with Figure R804 3.1.4. The number of screws on each side ofthe splice shall be the same as required forthe heel joint

‘connection in Table R8O4 3,1.1(3)

C-SHAPE OR TRACK

SECTION WITH

MINIMUM SIZE AND

THICKNESS AS

CEILING JOIST

CEILING JOIST

NUMBER OF SCREWS:

(ON EACH SIDE OF

SPLICE SHALL BE THE

‘SAME AS REQUIRED

FOR THE HEEL JOINT

CONNECTION

CEILING JOIST

TRACK

LOAD-BEARING STUD

FIGURE R604.3.1.4

‘SPLICED CEILING JOISTS

£R804.3.2 Roof Rafters:

(Colé-formed steel roof rafters shall be in accordance with this section,

R804.3.2.1 Minimum Roof Rafter Sizos

Roof rafter size and thickness shall be determined in accordance withthe limits set forth in Table RO4.3.2.1(1) based on the horizontal

projection of the roof rafter span, For determination of roof rafter sizes, reduction of roof spans shall be permited where a roof rafter

hnups:iup.codes/viower_exportjurs_keylcoloradolpubint residential code_202"vretRB04 see

522, 7:94 PM

‘support brace is installed in accordance with Section REOA.3.2.2. The reduced roof rafter span shall be taken as the larger ofthe

‘Section R804 Cold-Fored Stee! Roof Framing

distances from the roof rafter support brace tothe ridge oto the heel measured horizontally.

For the purpose of determining roof rafter sizes in Table R804 3.2.11, umate design wind speeds shall be converted fo equivalent

‘ground snow loads in accordance wih Table R804 3 2.1(2), Roof rafter sizes shal be based on the higher ofthe ground snow load or

‘he equivalent snow load converted from the ulimate design wind speed

TABLE R804.3.2.1(1)

ROOF RAFTER SPANS®:.c.d

(testnctes)

‘round snow nas

on

tiers)

Ca zee | war | 20a | arse | arse | ae | wee | er

For Sk: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 pound per square foot =

4. Table provides maximum horizontal rafter spans in feet and inches for slopes between 3:12 and 12:12

0479 kPa,

b. Deflection criteria: L/240 for live loads and L/180 for total loads.

hnups:iup.codes/viower_exportjurs_keylcoloradolpubint residential code_202"vretRB04

ran2

522, 7:94 PM

12pst.

4d, Grade 33 ksi steel is permitted to be used for 33 mil and 43 mil thicknesses. Grade 50 ksi stee! shall be used

for §4 and 68 mil thicknesses,

ULTIMATE DESIGN WIND SPEED TO EQUIVALENT SNOW LOAD CONVERSION

Sextion R804 Cold-Formed Steel Roof

TABLE R804.3.2.1(2)

[EQUWALENT GROUND SNOW LOND pe)

txoorure | winsspeeaineny | a2 ] a2 | saz | oz | 212 | or2 | one | sore | aise | oe

For SI: 1 mile per hour = 0.447 mis, 1 pound per square foot = 0.0479 kPa

R804.3.2.1.1 Eave Overhang

ave overhangs shall not exceed 24 inches (610 mm) measured horizontal

R804.3.2.1.2 Rake Overhangs

Rake overhangs shall not exceed the limitations provided for Option 1 or 2 in Figure REO4.3.2.1.2. Outlookers at gable endwalls

shall be installed in accordance with Figure RBO4 3.2.1.2. The required strength for uplit connectors required for Option 1 shall be

determined in accordance with AISI $230, Table F-4

hitpssup.codesiewer_exporvjurs_Keyicloradolpubin, residential code_202%ie1iR804

r922

522, 7:94 PM

3505162-33 BLOCKING

BETWEEN OUTLOOKERS

W/#8 SCREWS @ 6" 0.c. —_—*]

TO WALLTRACK

(MIN.3 SCREWS EACH)

2-88 SCREWS

(OUTLOOKER TO —~

‘WALL TRACK)

WALL SHEATHING

GABLE END

WALL STUD,

1-0" MAX

‘Section R804 Cold-Fored Stee! Roof Framing

OPTION #1

_ #8 SCREWS @ 6" 0.C. MAX

_—~ (REF. AISI $230 TABLE F2-5)

1-0" MIN el —

ROOF RAFTERS.

\\ 3508162-33 (W/O HOLES)

\_ OUTLOOK RAFTERS.

ALIGN WITH EACH GABLE

WALL STUD.

UPLIFT ANCHOR ATTACHED TO

\\_ EACH OUTLOOKER AND GABLE

WALL STUD. (REF. AISI S230 TABLE

F3-4 FOR REQUIRED CONNECTION

STRENGTH)

OPTION #2

(NOT APPLICABLE FOR WIND SPEEDS > 130 mph)

or Max

(ste NOTE)

#8 SCREWS @ 6" 0.C. "MAX’ —

(REF. AISI $230 TABLE F2-5)

3505162-33 @ 2'-0" 0.¢.

W/CONTINUOUS TRACK

EACH END.

2-#8 SCREWS.

TO EACH STUD

WALL SHEATHING

GABLE END a

WALL STUD

1-0" MIN —+}

ROOF RAFTER

NOTE: ROOF SHEATHING JOINTS PARALLEL TO THE

GABLE ENDWALL ARE NOT PERMITTED IN THIS REGION

UNLESS AN APPROVED TENSION TIE IS PROVIDED.

For Si: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 mile per hour = 1.6 kph.

tps:

Jup.codesviower_exporijurs_koylcoloradoipubiint residential code_202'etR804

swiee

522, 7:94 PM ‘Section R804 Cold-Fored Stee! Roof Framing

FIGURE R806.3.2.1.2

GABLE ENDWALL OVERHANG DETAILS

R804.3.2.2 Roof Rafter Support Braco

Where used to reduce roof rafter spans in determining rof rafter sizes, a roof rafter support brace shall meet all of he folowing

conditions

1. Minimum 3508 162-83 C-shaped brace member with maximum length of 8 feet (2438 mm)

2. Minimum brace member slope of 45 degrees (0.785 rad) to the horizontal

5. Minimum connection of brave toa oot rater and ceing joist wth four No.10 srews at each end.

4. Maximum 8 inches (152 mm) between bracelesiling joist connection and load-bearing wall below

5. Each root rafter support brave greater than 4 feet (1219 mm) in length, shall be braced witha supplemental brace having

‘@ minimum size of 9508 162-38 or $507 162-33 such thatthe maximum unsupported length ofthe oof rafter support

brace is 4 feet (1219 mm). The supplemental brace shall be continuous and shall be connected to each roo rafter

‘support brace using two No. 8 screws,

R804.3.2.3 Roof Rafter Splice

Roof raters shall not be spliced,

R804.3.2.4 Roof Rafter to Ceiling Joist and Ridge Member Connection

Roof raters shall be connected toa parallel cling jist o form a continuous tie between exterior walls in accordance with Figure

RBO4.3.1.1 and Table R8O4.3.1.1(3). Ceiling joists shall be connected tothe lop track ofthe load-bearing wall in accordance with Table

R804 3, ether withthe required number of No. 10 screws applied through the flange ofthe celing joist or by using @ 54-mil (1.37 mm)

Clip angle withthe required number of No.10 screws in each leg. Roof rafters shall be connected ta @ ridge member with a minimum 2-

inch by 2snch (51 mm by 51 mm) clip angle fastened with No. 10 screws to the ridge member in accordance with Figure R804.3.2.4 and

“Table R804.3.2 4. The clip angle shall have a stee! thickness equivalent o or greater than the root rafter thickness and shall extend the

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5808)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HLC - TLC - FO - 07 - G052-N18-BC2A Amend-S-Appendix Roof Connection Design - Parapet To Console Beam ConnectionDocument4 pagesHLC - TLC - FO - 07 - G052-N18-BC2A Amend-S-Appendix Roof Connection Design - Parapet To Console Beam ConnectionPhú NguyễnNo ratings yet

- HLC - TLC - FO - 08 - G28 - APPENDIX M - Roof Parapet Design Report-RevCDocument56 pagesHLC - TLC - FO - 08 - G28 - APPENDIX M - Roof Parapet Design Report-RevCPhú NguyễnNo ratings yet

- 1700, Setlakwe Street Thetford Mines (QC) G6G 8B2 Canada: ConfidentialDocument1 page1700, Setlakwe Street Thetford Mines (QC) G6G 8B2 Canada: ConfidentialPhú NguyễnNo ratings yet

- Safety Factors For Pile TestingDocument7 pagesSafety Factors For Pile TestingPhú NguyễnNo ratings yet

- Fire Design of Steel Members: Kathryn R LewisDocument178 pagesFire Design of Steel Members: Kathryn R LewisPhú NguyễnNo ratings yet

- HLC - TLC - DR - 12 - S0088 - Balcony Lifting Frame - Typical BalconyDocument1 pageHLC - TLC - DR - 12 - S0088 - Balcony Lifting Frame - Typical BalconyPhú NguyễnNo ratings yet