Professional Documents

Culture Documents

8300 Furse 15 A 082 085

Uploaded by

challu conandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8300 Furse 15 A 082 085

Uploaded by

challu conandCopyright:

Available Formats

Earthing

Introduction

Furse earthing components are manufactured to meet exacting British, European

and International standards to ensure robust, long lasting performance in even

the harshest soil conditions.

All components are designed to withstand mechanical Furse earthing and equipotential bonding products offer the

damage and the thermal and electromechanical stresses from surest solution to this problem.

the earth fault and leakage currents expected within an

installation. From pipe clamps and metalwork bonds to connect to

accessible metal parts, to low resistance copper conductor

These components, combined together, form the earth and high quality earth rods for the earthing arrangement -

termination system - the vital system for dispersing those Furse products are designed to perform.

dangerous lightning and fault currents safely and effectively

into the ground. And where our standard range doesn’t quite fit your

requirements, with full design and manufacturing capability

Following National & International standards, we recommend we can design a special component to suit.

a single integrated earth termination system for a structure,

combining lightning protection earthing with power and Special component design and manufacture

telecommunication system earthing. Our standard range is designed to meet the vast

majority of earthing applications. However, on occasion,

This integrated approach ensures all systems are you may have the need for a non-standard part, for example

appropriately cross-bonded and earthed, to fully safeguard where connecting large copper cable or tape to a rod, or to

against the risk of voltage differences which might otherwise metalwork.

give rise to flashover or electric shock.

Where this is the case, our technical engineering team can

design a special component to your needs, which on approval

can be manufactured in the quantity specified for the project.

6/2 Total Solution to Earthing & Lightning Protection | 9AKK106354A3360

6

Total Solution to Earthing & Lightning Protection | 9AKK106354A3360 6/3

Earthing

Product selection guide

Product selection guide - Earthing In addition to the conductors, earth rods and plates or any

No. Type Section / Page No. combination thereof can be used to achieve an effective earth

1. Conductors 3/1 depending on the site conditions.

2. Earth rods 7/4

3. Earth plates 7/10 2 2. Earth rods

4. FurseWELD exothermic welding 9/2 Earth rods take advantage of lower

5. Compression connectors 8/23 resistivity soils at greater depths than

6. Mechanical clamps 8/2 normal excavation will allow.

7. Earth inspection pits 7/9

8. Earth bars 8/18 3. Earth plates

9. Earth electrode backfills 7/11 Earth plates are used to attain an effective

3

earth in shallow soils with underlying rocks

or in locations with large amounts of

buried services. They can also provide

Earthing protection at potentially dangerous places

e.g. HV switching positions.

6

An effective earthing system is a fundamental requirement

of any modern structure or system for operational and/or

Main aspects and individual components of an earthing system

safety reasons. Without such a system, the safety of

a structure, the equipment contained within it and its

occupants are compromised.

Earthing systems typically fall into (but are not limited to) one

of the following categories:

–– Power generation, transmission and distribution

–– Lightning protection

– – Control of undesirable static electricity

– – Telecommunications

The following schematic illustrates the key elements of an

effective earthing system.

Conductors and earth electrodes

As with lightning protection, the first choice faced by the 8

designer of an earthing system is the type of conductor to be

4 8

used. The correct choice of conductor is extremely important, 1

whether it be a simple below ground electrode or a complex

2

computer room signal reference grid.

1

1. Conductors 4

We offer three types of conductor:

– Flat tape

5

– Solid circular

– Stranded cable

1

It is important that earthing conductors should be correctly

sized for their application, as they may be required to carry a 5

considerable current for several seconds. A range of conductor

materials is available. Above ground, copper, aluminium and

steel may be used. Below ground, copper is the most common

choice due to its high resistance to corrosion.

6/4 Total Solution to Earthing & Lightning Protection | 9AKK106354A3360

Connectors and terminations FurseWELD connections allow conductors to carry higher

currents than other types of connections. They will

An effective earthing system relies on joints and connections never loosen, are highly conductive and have excellent

to have good electrical conductivity with high mechanical corrosion resistance.

strength. Poorly chosen or badly installed joints and

connectors can compromise the safe operation of an earthing 5 5. Compression connectors

system. We offer a range of connectors and termination For applications where exothermic

methods to suit a wide range of applications: welding is not appropriate for creating

permanent connections, compression

4

4. FurseWELD exothermic welding connectors may be used.

A simple, self-contained method of

forming high quality electrical connections Compression connectors produce very

which requires no external power or robust joints which can be buried in the

heat source. Connections are made using ground or in concrete.

the high temperature reaction of

powdered copper oxide and aluminium. 6. Mechanical clamps

6

6

Where permanent connections are not

appropriate, mechanical clamps offer the

ideal solution. These are typically used on

smaller scale installations where periodic

This illustration is designed to demonstrate the main aspects and

individual components of an earthing system. It is not disconnection for testing is required.

intended to represent an actual scheme conforming to a particular

code of practice. The drawing is not to scale. All Furse mechanical clamps are

manufactured from high copper content

alloy. They have high mechanical

strength, excellent corrosion resistance

and conductivity.

1

7

7. Earth inspection pits

Regular inspection and testing of the

earthing system is essential. Inspection

pits allow easy access to earth

electrodes and conductors to facilitate

this procedure.

8

8. Earth bars

Earth bars are an efficient and

convenient way of providing a common

3

earth point. Integral disconnecting

1 links mean the earth bars can be isolated

3 for testing purposes.

9

9. Earth electrode backfills

7 Earth electrode backfills are to be used

in areas where required resistance

6

1 levels are difficult to achieve. These

2

products effectively act to increase the

electrode’s surface area thus lowering its

resistance to earth.

9 2

Total Solution to Earthing & Lightning Protection | 9AKK106354A3360 6/5

You might also like

- Grounding Systems: EM 1110-2-3006 30 Jun 94Document4 pagesGrounding Systems: EM 1110-2-3006 30 Jun 94Rizwan RaoNo ratings yet

- Earthing PDFDocument24 pagesEarthing PDFCharu DuggalNo ratings yet

- EarthingDocument24 pagesEarthingJothimanikkam SomasundaramNo ratings yet

- Code of Practice For Earthing & Bonding System PDFDocument9 pagesCode of Practice For Earthing & Bonding System PDFAQIBNo ratings yet

- Earth 2Document25 pagesEarth 2Vikas Srivastav75% (4)

- Grounding TechniquesDocument28 pagesGrounding Techniquesricardo martinezNo ratings yet

- Construction Earthing ManualDocument23 pagesConstruction Earthing Manualactionjackmod100% (1)

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocument10 pagesGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationNur FajarNo ratings yet

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocument10 pagesGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationNur FajarNo ratings yet

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocument10 pagesGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationbdikicNo ratings yet

- Earthing System: 6.1 PurposeDocument12 pagesEarthing System: 6.1 PurposeRenan RossaNo ratings yet

- Guidelines For GroundingDocument11 pagesGuidelines For Groundingparrastevens930No ratings yet

- Buried Installation of Optic Fiber Cable: Application NotesDocument19 pagesBuried Installation of Optic Fiber Cable: Application NotesAli AbdulaleemNo ratings yet

- Pocket Book On Ring Earth & Maintenance Free Earth PDFDocument32 pagesPocket Book On Ring Earth & Maintenance Free Earth PDFRohit KumarNo ratings yet

- Earthing Construction ManualDocument22 pagesEarthing Construction Manualjeb13No ratings yet

- Earthing System PDFDocument24 pagesEarthing System PDFasexyguyNo ratings yet

- earthing-bondingDocument19 pagesearthing-bondingMohamoud MuseNo ratings yet

- Designing of HV Power Substation and LayoutDocument6 pagesDesigning of HV Power Substation and LayoutRagavanNo ratings yet

- Design of Earthing in Underground Substation Using ETAP With ConstraintsDocument6 pagesDesign of Earthing in Underground Substation Using ETAP With ConstraintsEditor IJTSRDNo ratings yet

- Simulation of Cathodic Protection System Using Matlab: March 2013Document14 pagesSimulation of Cathodic Protection System Using Matlab: March 2013adnantanNo ratings yet

- Chem RodDocument2 pagesChem RodKOUDJIL Mohamed0% (1)

- Earthing Guide NCS Rev 2 - 01 - 2Document18 pagesEarthing Guide NCS Rev 2 - 01 - 2andcrisdanmatNo ratings yet

- Earthing System GuideDocument23 pagesEarthing System GuideGopal KhatriNo ratings yet

- The GEAFOL Basic - Compact Power, Convincing Data: Answers For EnergyDocument6 pagesThe GEAFOL Basic - Compact Power, Convincing Data: Answers For EnergyMohamed ElnahNo ratings yet

- Rdso SPN 197-2008, Earthing and Bonding SystemDocument10 pagesRdso SPN 197-2008, Earthing and Bonding SystemdipenkhandhediyaNo ratings yet

- دراسة مصورة لنظام التاريضDocument10 pagesدراسة مصورة لنظام التاريضdheyab farajNo ratings yet

- Earthing BY MR. ALIMIDocument21 pagesEarthing BY MR. ALIMIHeidar KarrarNo ratings yet

- 02 Pe 05 21 5-11Document8 pages02 Pe 05 21 5-11delta conceptNo ratings yet

- Ham Station GroundingDocument33 pagesHam Station GroundingakaNo ratings yet

- Earth Ground Testing TechniqueDocument24 pagesEarth Ground Testing TechniqueMohd Zamri Abu BakarNo ratings yet

- 02 Pe 05 21 5-11Document8 pages02 Pe 05 21 5-11AlairNo ratings yet

- Grounding and Ground Fault Protection of Multiple GeneratorsDocument5 pagesGrounding and Ground Fault Protection of Multiple Generatorsmanirup_tce0% (1)

- A Practical Approach For Determining The Grounding Grid PDFDocument6 pagesA Practical Approach For Determining The Grounding Grid PDFOscar ZambranoNo ratings yet

- Design of Earthing System For A Substation: A Case StudyDocument6 pagesDesign of Earthing System For A Substation: A Case StudyHimanshu RanjanNo ratings yet

- Bently Housings For Prox Datasheet 141599tDocument19 pagesBently Housings For Prox Datasheet 141599tCecep AtmegaNo ratings yet

- Priciples Testing Methods EtcDocument5 pagesPriciples Testing Methods EtcMuhammad SajidNo ratings yet

- EARTHING PresentationDocument15 pagesEARTHING PresentationsemajamesNo ratings yet

- Keywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDocument6 pagesKeywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDebasish RahaNo ratings yet

- Electrical Block2Document36 pagesElectrical Block2NUSRAT AKHTARNo ratings yet

- Design of Earthing System For 400 KV AC Substation: A Case StudyDocument13 pagesDesign of Earthing System For 400 KV AC Substation: A Case StudySunilNo ratings yet

- Cathodic Protection Catalog: The Contractors ChoiceDocument40 pagesCathodic Protection Catalog: The Contractors ChoiceHatemS.MashaGbehNo ratings yet

- NaseerA alhabobiandShahadF AbedDocument14 pagesNaseerA alhabobiandShahadF AbedJorge LunaNo ratings yet

- NBC ComparisonDocument19 pagesNBC ComparisonAshish TiwariNo ratings yet

- The Earthing of Zenner BarrierDocument4 pagesThe Earthing of Zenner BarrierFatholla SalehiNo ratings yet

- Substation Earthing Design: Akshay PatilDocument6 pagesSubstation Earthing Design: Akshay PatilSunil SinghNo ratings yet

- Earth Mat Design For 132/33Kv Substation in Rivers State Using ETAPDocument15 pagesEarth Mat Design For 132/33Kv Substation in Rivers State Using ETAPTafadzwa MurwiraNo ratings yet

- Government of India-Ministry of RailwaysDocument24 pagesGovernment of India-Ministry of RailwaysAkramNo ratings yet

- CP System DesignDocument8 pagesCP System Designvchui34No ratings yet

- Grounding and Overvoltage Protection IP 16-4-1: ScopeDocument11 pagesGrounding and Overvoltage Protection IP 16-4-1: ScopeMara LiceoNo ratings yet

- Optimisationof Earthing Systemin Industrial PlantDocument6 pagesOptimisationof Earthing Systemin Industrial Plantjamye wolduNo ratings yet

- Reasoned DocumentDocument9 pagesReasoned DocumentRajesh meenaNo ratings yet

- Experiment No. 4 Study of Various Types of EarthingDocument14 pagesExperiment No. 4 Study of Various Types of EarthingJude JohnNo ratings yet

- 22 Standard Earthing Philosophy of GETCO R 2 25-0-711Document4 pages22 Standard Earthing Philosophy of GETCO R 2 25-0-711Ramesh AnanthanarayananNo ratings yet

- Underground Cable Fault Distance Detector Using ATmega328 MicrocontrollerDocument7 pagesUnderground Cable Fault Distance Detector Using ATmega328 MicrocontrollerregecartNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Fundamentals of Fault Current and Grounding in Electrical SystemsFrom EverandFundamentals of Fault Current and Grounding in Electrical SystemsRating: 4 out of 5 stars4/5 (3)

- Welding ReportDocument15 pagesWelding ReportSamNo ratings yet

- GTO Block Diagram FinalDocument2 pagesGTO Block Diagram Finalamit guinNo ratings yet

- General Catalogue: Technical Features DocumentationDocument1 pageGeneral Catalogue: Technical Features DocumentationYalem AlemayehuNo ratings yet

- FlightplanDocument25 pagesFlightplanErlendur PetersenNo ratings yet

- AMI Pen TestingDocument10 pagesAMI Pen TestingcutenemesisNo ratings yet

- OEM Connections Sensor +5 Volt Supply #4Document2 pagesOEM Connections Sensor +5 Volt Supply #4ibrahem100% (2)

- Byv10ed 600pDocument10 pagesByv10ed 600pdavid.gjeorgevskiNo ratings yet

- NASA - Obtain Coordinates of NACADocument27 pagesNASA - Obtain Coordinates of NACATiago CandeiasNo ratings yet

- Double Disc Gate ValveDocument12 pagesDouble Disc Gate Valveshafeeqm3086No ratings yet

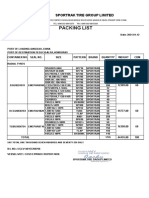

- Packing List: Sportrak Tire Group LimitedDocument1 pagePacking List: Sportrak Tire Group Limitedissa lamarNo ratings yet

- SAP HCI DevGuideDocument168 pagesSAP HCI DevGuideSrinivasan SriNo ratings yet

- Pneumatic Can Crusher SystemDocument21 pagesPneumatic Can Crusher Systemkamleshm2No ratings yet

- E060701020025 PDFDocument6 pagesE060701020025 PDFمنير أحمدNo ratings yet

- AIR Modeller 2019-04-05 83Document68 pagesAIR Modeller 2019-04-05 83Tomeu Llompart100% (8)

- G 9Document10 pagesG 9Phiw TabuzoNo ratings yet

- Coil Caliburn GDocument1 pageCoil Caliburn GLukman Arsyanto WibowoNo ratings yet

- OP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGDocument76 pagesOP100 D & OC 100 D - Spare Parts Manual 12 - 2002 - ENGRafael CastroNo ratings yet

- Chapter 09 Flow Measurement Applications Aps Compatibility ModeDocument12 pagesChapter 09 Flow Measurement Applications Aps Compatibility ModeBig BangNo ratings yet

- Green Mark Manager 6 May 2019Document1 pageGreen Mark Manager 6 May 2019Haider Tyebally TyeballyNo ratings yet

- QCD-FS-G.Annex Rev2015 PDFDocument1 pageQCD-FS-G.Annex Rev2015 PDFvhin84No ratings yet

- Parts Guide Manual: Bizhub PRO 951 A4EwDocument257 pagesParts Guide Manual: Bizhub PRO 951 A4EwYessica MontenegroNo ratings yet

- 1.-Which Was Not One of The Problems With The First Metal Detectors?Document3 pages1.-Which Was Not One of The Problems With The First Metal Detectors?virginia González HernándezNo ratings yet

- Guide-To Visual InspectionDocument25 pagesGuide-To Visual InspectionMatthew ShieldsNo ratings yet

- General notes and location planDocument1 pageGeneral notes and location planRamith De SilvaNo ratings yet

- Press Note Safety Training For Power Grid Team by KEC International LTDDocument2 pagesPress Note Safety Training For Power Grid Team by KEC International LTDManish GuptaNo ratings yet

- 9fa ProbsDocument12 pages9fa ProbsMarbz Al MonteNo ratings yet

- 1.2. Modular Programming - En-UsDocument12 pages1.2. Modular Programming - En-UsChandrasekhar K100% (1)

- Modified o and G Slides 2Document21 pagesModified o and G Slides 2Salam FaithNo ratings yet

- Project: Inventory Management System For Music Store: SynopsisDocument7 pagesProject: Inventory Management System For Music Store: SynopsisSoumitra ChakravartyNo ratings yet