Professional Documents

Culture Documents

CNG Dispenser

CNG Dispenser

Uploaded by

sale Service0 ratings0% found this document useful (0 votes)

9 views11 pagesOriginal Title

cng-dispenser

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views11 pagesCNG Dispenser

CNG Dispenser

Uploaded by

sale ServiceCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

ra

Is Our Commitment

oma

D.V. Des:

&

, Chairman

MISSION STATEMENT

We strive to be a leading gobal player in the field of

Pressure Regulating Valves, Systems & Technology.

We strive to be an organization which is knowledge-based,

progressive, innovative and profitable. Catering to the

needs of customers through high-quality and cost-effective

products & services is our drive for excellence. Being

concerned for people & safety, we are a disciplined

& dedicated work force practicing participative style of

leadership and management to achieve progress,

prosperity and happiness.

COREVALUES

In our journey of striving for excellence, we ensure that our

values are always firmly rooted to establish a strong global

foundation enhancing a promising future. We are:

‘# — Anorganisation havingrespect for every individual

© Anorganisation where passion and commitmentis the

driving force

© Anorganisation where tustand freedom empowersall

the people associated with us

Anorganisation encouraging a culture of learning and.

adaptability

An organisation that excels beyond boundaries

through teamwork

® — Anorganisation where customer focusis at the core of

allactivities

Established in 1973, Nirmal became the pioneer of Self Actuated Pressure Control Valves and Allied Process Control

Systems and Solutions. Nirmal offers its expertise globally to all major industries namely Oll & Gas, Petrochemical &

Refineries, Pharmaceutical, Steel & Power, Food & Dairy, Plastic and Nuclear Power Industries. Today, Nirmal has been

successfully established.as the "Expertise that delivers”.

At Nirmal, we are fully equipped to cater to the ever changing needs of our discerning customers. Be it investing in R&D or

adhering to world-class quality standards, we have always strived to come up with innovative and customized solutions that

help our customers scale newhorizons.

At Nirmal, we believe that our responsibilities are not just limited to delivering customized products. We are equally involved

in each stage of the process from product planning and manufacturing to execution along with timely and regular follow-up

sessions post delivery.

With each product supply, Nirmal offers a formal ‘Product instruction & After Sales Commissioning Suppor’, which includes

value added features such as 0 &M manual, comprehensive literature & customer training programme. A Technical Support

Teamis always available to answer any queries regarding our products & services. We also conduct various training programs

foryoung engineers of the industry as we believe that with the rignt knowledge, the youth today can transform our tomorrow.

GLOBAL STANDARD OF EXCELLENCE

QUALITY ASSURANCE

The Quality Assurance system of Nirmal ensures that innovative solutions are delivered through processes which are:

assessed, approved & certified to ISO 9001:2015 Quality Assurance Standard. Strict adherence to procedures by

isciplined and dedicated work force and internal audits, guarantee that the quality system is implemented across al stages,

{rom incoming raw materials to final test and delivery. Occupational health and safety management system of Nirmal is

certified to BS OHSAS 18001 : 2007 standard which ensures to control and improve health and safety performance. We are

also certified to ISO 14001:2015 Standard which specifies the requirements for an environmental management system

thatan organization can use to enhance its environmental performance. One of the most prestigious accolades eared is the

U&R Stamp Certification which authorizes the use of the symbol of American Society of Mechanical Engineers (ASME). It

‘assures customers that the stamped products are builtin accordance with the applicable rules of the ASME Boiler and

Pressure Vessel Code. Nirmal s the first Indian manufacturer to getits products certified with stringent European Standards

EN-334 & EN-14382 for Pressure Regulators and Safety Shut Off Valves ensuring world-class product performance &

accuracy. We have also received ASME/UV/NB Certification for our Safety Relief Valves. Our TTS Series Flame Arrestor with

Pressure & Vacuum Relief Valve are type - approved according to ATEX Directive 94/9/EC and B.S EN ISO 16852 by SGS

Baseefa UK.

cenriricare cenviricate

180 9001:2015 150 a4001:2025 ‘98 o1tSAS 18001 - 2007 ASME Cereation

‘ASME U Stamp Centcate ASMER Stamp Cerise PeDy97/23/E0 (CE & Type Test

Conical to EN 354 6 14382

Nirmat's 60,000 sq. feet unit at Asangaon comprises

state-of-the-art equipment like Overhead Crane,

Hydra, NC Band Saw Machine, High Pressure

Compressor, VMC, HMC & CNC Machining Centers,

Automatic Welding (Saw) Machine, Shrink Packing

Machine, Foam Packing Machine etc.

High Pressure Compressor Automate Welding Machine CoN macrine

Being a quality conscious company, testing is an

‘area we lay special emphasis on. Our testing

facilities include Computerised Flow Test Lab, CMM

Test, Ultrasonic Test, Magnetic Particle Test,

Pneumatic High Pressure Test Setup upto 700 Bare,

Helium Leak Test, Spring Load Test, D.P.Test, Hydro

Test, Radiography, PMITestetc

CComputerises Flow Test Lab

OMM Tost Automated Pressure Regulstor Test Setup PMI Test

Nemal offers complete Gas Condtoning

System for Power Pants & Frizes as wellas

‘Gas Conatuoning Equipments

nook out Onum:

Muttioyeione / Demistertype

© Fite Separators:

Vane Pack /Fiterlement

© QOEC:- Quick OpeningEné osures

© Gas Pre Heaters: Electric / Gas Fired

Water Bath /Steam Heater

© Coalescer Fiters for fine liquid panicles

removal

© Natural Gas Odorisers By pase &

Injection Type

Equipments & Pressure Vessels are

fabricated as perASMESECVI DIV 1.

ur fact is also authorized to use ASME

Vand stamp,

Nirmal specialzes in offering. one-stop

solutions for design, development,

rmanufaetxe, instalation & commissioning of

Pre-fabricated skids for natural ges

transmission and dsinbutton applications,

hich nade:

.

+

.

.

City Gate Stations (66s)

District Regulating Stations (ORS)

Indust! Pressure Regulating Stations

(prs)

Metering & Regulating Stations (MRS)

foroommercial&industal installations

Fiscal and Secondary Orifes / RPO /

Turbine / Uttrasonie-based Metering

‘Skids Compliant to AGA Standards with

Flow Computer RTU SCADAOptions

(CNG High Pressure Skids

(ONG Dispensers

The Standards used for Manufacturing of

these Stations are:

+ ANSIBSL.S:

\e1D 13

evaztes

+ euiz279

The Configurations for these Stations can be

customizedas:-

+ TWIN-STREAMHOTSTAND-BY

‘+ ACTIVE-MONITOR & WORKING

MONITOR

1 53 Series Gas Presaure Regulator

We are the fst in India to manufacture Gas

Pressure Regulators with PED/ST/23/EC

complance certfeation and also Type Test

cette to EN 324 for Pressure Reguletors.

© Activemonitorconfiguation suitability

$ Twopatn control &fastresponse

© Sizerengngtrom4”to6"

°

End connection options fom ANSI 150%

toANs!600# class

© Tigit smut offcapabitty

© Easyoniine maintenance

# Double stage pilot contol which can

handle high variations in inlet pressure

‘without affecting the accuracy of outlet

controtied pressure

© Integral slam shut-off option with over

pressure &under-pressurecutoff

© pecuracy cass: uptoACA

© Inlet pressure: 2 Bargto 100 Barg

Outetpressure: 0.5 Bargt0 60 Borg

© Accesso more than thee decades of

cengineeringsotivon espeence

© Bonet krowedge of gas transmission

‘&distibuton appeation engnoonng

© Professional appication engineers

to assist you from concept to

commissioning

© complete station manufacturedin our

‘nm foctoy & fuly tested in ou

computerized fowtestlab

LS

‘SHA Sones Slam Shut Vaive 181 Series Gas Pressure Regulator

We are the frst in nds to manufacture Gas ‘These regulators ae best suited for industial, Integral wo stage pressure reduction

Slam Shut Valves with PED/97/23/EC commercial gas burner applications & — @ s4esura'make regulator

‘compliance corication an combustion systems. The regulators maintain

pie cae aes, Se VERE as nat Integral over pressure / under pressure

conti ‘constant Outlet Pressure with niet Pressure.

Wel t0 EN 24382. stant Outlet th ne re keen ee

Integral Over Pressure & Under Pressure Siam

© Sweranging tom 4”106" oriaae enti © Normal capaety2.5 SCMHto 80 SMH

# Endconnection options from ANSI 150# Pie hi Bel one ors car iia

toANS|6O0# class © Sirerangingttom 1/2"t02" atrightangle

© Owtet pressure 20 to 300 mbar (with

bickresponse ess than 2 seconds © End connection options Screwed /

ocinmuuaee . different springs)

Fangecto ANSI504#to600# class

# Manual resetting with the tever -

mechanism setpointadjustingsorewis temper proot

© Capabiity with special tim design Easyonline mainenence jomestic Meter Regula

4 Buin pressure equalisation which ean @ Tightshut-offeapability

becarried outbyslightlytumingthe reset @ orientaionin'360*cirection

lever. No separate by-pass arrangement

‘orequalzng vate is required ory ei prcretins pie fon 25.

Fy to180

Remote signals canbe proved optional

A These pressure regulators can regulate

“# over pressure and under pressure shut fatale sec earahieeaer

tfoptions avaliable

.

Inlet pressure up to 100 Bang

© Optional regulators with inbuilt stam

© utietpressure:0.3 Bargto34 Barg

shutvales arealsoavaliable

Accuracy class: uptoAG 4

Max Inlet Pressure-200 mbar

‘uwletPressur:-15~25 mbar

End Connection:-DN2O, 24" BSPT

Accuracy: Upto AG - 5

Integrated with UPCO Device.

CComptingioT/SPIPRSI3

Flow Capacty 2.5 SMH

PRODUCTS FOR PROCESS INDUSTRIES

Self Actuated Upstream & Downstream Pressure Control Valves. Relief Valves for Safety

Thermal & Emergency Relief

Direct Acting & Pilot Opereted Regulators for accurate pressure contro in a variety of ;

appheaton: © ody sine & Comnectons: "to 24°,

Screwed / Flanged 10 ANS! 150#

# Tentsnatoncapabi

he " to1500#

ato Manian

© Ten Shut orrcapadity

“© Body Size& Connections: 4"to16" Screwed Flanged to ANSI1S0# /3008 /600#

19008715008 © Ange Woe Spring Loesea

+ win ocwthout over reseue/ Under pressure Cutoff upto 10" Seeanduptorating Gobo Body Spring Loaded saphragm

of1500# ‘ype for propotonate pressure relet

© ForDovinsteamorUpstear Pressure Cont © Pooperated fr higher ret capacity

a ow et poets

# Wide Rangeof Flow &Differemtial Pressure Capability

DMB Series Drect Acting _OH Series Set Actuated BA Soros Dioot Acting

Proseure Regulator High Pressure Convo Pressure Regulstors for ——

aos for prossure upto pressure upto 100 Bars EP Sees Plot operated Pressure Reliet

250 Bare valves

ASME/UV/NB Certified Safety Relief Valves

‘SR.O7 Safety RolefVobe SRS Saety Rie Vave |S Safety Rede Valve Fomuator

Screwed Ranged

© Vokesize:1°(0025)- Inet soutetSze:¥s't0 Inlet Oulet Sie: 34"t0

8y0N200) a5 as

© Inlet Rating: 1508, 3008, @ Pressure Rating: 150# to Pressure Rating: 1508 to

600#, 900%, 1500# & | 25008 28008

28008

© oer Rating: 2508 &

2008

© End conection: Rangod

(spor AMSE 816.5)

© nice & Mounting

Dimension: As per API 526

© Maxim Set Proscure:

ifr Putsing Ine ms

414 Bar @ 38'C Centrifuge Puig & nerising Syst

PRODUCTS FOR PROCESS INDUSTRIES

Inert Gas Blanketing ‘Tank Protection Devices:

Turnkey Solutions forTank Blanketing & Tank Nimal also provides various safety dewees

Protection Devices compiyingtoAP12000. fram their enhanced product ine tomake the

Nevers. Dianketing system fooiproo.

# Minimise vaporlosses ofcostysoWvents @ VacuumRellet Vane

iste ge oresrTults Wel gh eae ecs, cae ta

coneianan ramensndor * Pai Mt WC

combustion/fire hazard

‘© Optimum protection of storagetanktrom _BeatherValves:

‘excess pressure orvacuum Breather Valve i.e. Pressure eum

@ Prevents ingress ofa anc moisture into YYacuum Relit Valve

tank =

Features

# Turkey solution for blanketing —

system with safety devices along with r

nitrogen. high pressure reducing ———

station, for storage tanks, reactors,

Acontriuges

# Simple easy 10 maintain and reliable 7

design considering AP! 2000 _ :

‘ener

ow 20 port ono ensues vey Emerfncy Rt on Vent

fo Ose consimpton & 6G sr ange risen topo

inne ofeosue tte

‘Han spe of response to poet the

isnieitteeaet seen .

1 han atom sca whee exe

tw se poss il opera

bandage

1 Stans matelseecton conpatie

‘erences

We also provide Contieuous Blanketing &

Purging System for Safe Operation of =

Ccontiuge

Flame Arvestors:

Tank Glonketing Regulators: “ype tested at CMRI testing cll, Dhanbad,

Minimum Set Pressure 1/4" Wg forfame quencing

61 Senos Direct Acting Regulator Hydrogen Pressure Reducing

Sation with Safety Shut-off

ATEX certified TTS Series

Flame Arrestor with Pressure

& Vacuum Relief Valve:

4 T19- Sotios is neny ances pessre anc

acum‘ aivefortigh flow capacities with

Acombinssfame tester uni.

© ms can be usee ab protective este

tending ATEX in ates subject to explain

© ype - Approved according to ATEX Dietve

94/910 and BS EV ISO 26882 by SOS

BaveotaU.

High Pressure Reducing

Station with Safety Shut Off

We offer complete Gas Cylinder Manifold &

High Pressure Reducing. Stations for

Nitrogen, Hycrogen, Carbon Dioxide, Ongen,

‘gon, Ammonia, Chlorine and other Gases

vith folowing features:

# shia mounted, ready to use package

© ‘Tho stage pressure reduction ensuring

constant outlet pressure respective of

extensive variation in inet pressure and

flowrate

© Completely sf actuated system without

auillary power requirement

.

With overpressure shut-off in-built for

safe operation without manual

intervention

°

‘Short payback period as high censcity

typical two stage reduction allows

‘maximum tization of gas from the

Cylinder /Totey

Hydrogen Pressure Reducing

Station with Safety Shut-off

NETWORK

Corporate Office - Mumbai

[Nirmal industria Controls Pvt: Ld.

Fret Floor, Senco, 8.5. Road

‘Mulund (#9, Mumbai - 200 080

hs +91-22-67746200, +91-22-25608668

Fan $9120.28682771

Enel nfo@amaindusties com

Website: wi nimsincustes com

Asangaon Factory

Nirmal dst! Controls Pot. id.

Suney No. 136/10) Asongaon (W),

Dist Thane, Maharastra, Ie = 424 602

Pas +91-2527-661000

Fee +91.2527-661020

International Sales.

‘Megan Services DMCC

PO.Bax 283581 Dubai Ut No 2308,

Sumetan Bay Tower. Pet No x2,

Jumeirah Lakes Towers,

Dube, UAE, P+ 9744 aS6O7e?

mai: saesiomeganintemstionsl.0¢

International Representatives

‘Abu Dhabi tar Saudi Arabia

Potro Mile East Pevoser Contols sas Al Jood

£ Communications WL “Fading Establishment

South Korea Nigeria ‘oman

eumgang S21 Co. id. Faeongae Uimted ovis acing UC

Malaysia Taiwan Bangladesh

Hammer Engngemng San. ad, Feleantemational Corporation|

‘Cocos Marveting onsutants Pvt. Ui,

National Representatives,

[Emboe Marketing Services SRG Engineering Pvt Lt.

‘Mr Ravindra Shah - Drecor NM Samer Buda - rector

Ph: #91-22.67977135 Phe +91-11-27356580

Fas: $91-22.67977135 Fax +91-1-27359633

Mobi: +01 9324620827 Male: +91 9810027898

Ena sales@embeein nai info@stgengneerngin

Hyderabad Bangalore

‘Bhavani Automation olution Seaton Sales,

Mec Shiakamar- Drecter

Ph: 491-40-24757057

Far: +91.40-66828407 Fa: +080-22243501

Moble: #91 9548299611 oie: +91.96450 07880

Ena ephiydorabod@grallcom Email solos@seatonsales.com

Me S.N. vatan Managing Director

Ph: $080-222134658222140200/ 61125072 Ph: + 044.64577181,

Nima

INDUSTRIAL CONTROLS PVE TD.

Expertise that delivers

Vadodara Indo

Incl Engineers, ‘Suptha Marketing

‘Me Vay Langata - Diector Mi Nin Choudhar -Dieetoe

Ph: +91-265-2310816 Pr: +91-731-2503432

Fox: +91-265-231492 Fax +91-731-4062761

Moble: +91 9825153564 — Vobie: +91 9626032731

nati inia@nelindacom Ema: sutha@arteimalin

Cchonnat

Servats

Me. Katyanaraman - vector

Mobi: +94 840116010

Emel: senolsmas@gmalcom

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

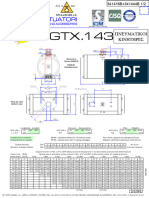

- Pneumatic Actuator GTX143Document2 pagesPneumatic Actuator GTX143sale ServiceNo ratings yet

- Pneumatic Actuators (UNIMECH)Document4 pagesPneumatic Actuators (UNIMECH)sale ServiceNo ratings yet

- 카다로그20221123Document1 page카다로그20221123sale ServiceNo ratings yet

- OI ERHARD Diaphragm Valves DN15 300 Manually Operated ENDocument23 pagesOI ERHARD Diaphragm Valves DN15 300 Manually Operated ENsale ServiceNo ratings yet