Professional Documents

Culture Documents

V4.0 PCB Design Typical Layout Characteristics

V4.0 PCB Design Typical Layout Characteristics

Uploaded by

Красимир ГеоргиOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V4.0 PCB Design Typical Layout Characteristics

V4.0 PCB Design Typical Layout Characteristics

Uploaded by

Красимир ГеоргиCopyright:

Available Formats

PRECISION POINT

Electronics &

Software

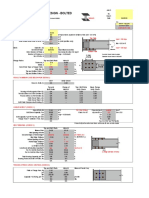

PCB DESIGN: TYPICAL LAYOUT CHARACTERISTICS 1/1

Introduction

The ever-increasing requirements for small volume

envelopes contribute to integrating electronics to the

mechanical design. Although there are numerous solutions

this sheet provides the JPE standard in designing PCB’s.

Electrical layout characteristics

• Guidelines for outer layers (top/bottom), but also

suitable for inner layers

• Copper base thickness: 18 𝑢𝑚

• Suitable for PCB thickness of: ≤ 2.4 𝑚𝑚 PCB build up

Finished Hole Dia A standard buildup of a 4-layer, thickness of 1.55 𝑚𝑚:

Trace Width

Silkscreen (Bottom)

TRACE-PAD Solder Mask (Bottom)

Copper (Bottom) 18 [um]

Prepreg 180 [um]

Prepreg 180 [um]

Copper (Inner Layer 2) 35 [um]

A A B Base FR4 710 [um]

OAR

TRACE-TRACE

PAD-Hole

EDGE - TRACE

PAD-PAD

Copper (Inner Layer 1) 35 [um]

A = Plated Through Hole (PTH) Prepreg 180 [um]

B = Non-Plated Through Hole (NPTH) Prepreg 180 [um]

OAR = Outer Annular Ring

Copper (Top) 18 [um]

Solder Mask (Top)

Type Minimal Recomm. Note

Silkscreen (Top)

Recommended values:

Trace Width 0.15 𝑚𝑚

see “PCB trace widths” In a 2-layer design, the Copper Inner and Prepreg layers are

Edge-Trace 0.45 𝑚𝑚 1.0 𝑚𝑚 left out but the base FR4 is thicker.

Trace-Trace 0.15 𝑚𝑚 0.35 𝑚𝑚

Trace-Pad 0.15 𝑚𝑚 0.35 𝑚𝑚

Pad-Pad 0.15 𝑚𝑚 0.5 𝑚𝑚 Mechanical design characteristics

Pad-Hole 0.20 𝑚𝑚 0.5 𝑚𝑚 Also for Trace-Hole Type Value Note

Initial drill hole ø will be 𝑚𝑖𝑛: 5 𝑥 5 𝑚𝑚 PCB does not have

PCB Dimensions

Finished hole +0.1 𝑚𝑚 to 𝑚𝑎𝑥: 425 𝑥 425 𝑚𝑚 to be rectangular!

0.25 𝑚𝑚

ø for PTH accommodate through 1.55 𝑚𝑚 Industry standard

hole plating Also a standard for

Board thickness 1.00 𝑚𝑚

Finished hole ceramic PCBs

0.35 𝑚𝑚

ø for NPTH 2.00 𝑚𝑚 Heavy components

OAR PTH 0.125 𝑚𝑚 0.35 𝑚𝑚 Width for slots 𝑚𝑖𝑛. 0.5 𝑚𝑚

For non-plated hole but Radius inside

OAR NPTH 0.30 𝑚𝑚 0.5 𝑚𝑚 𝑚𝑖𝑛. 1.0 𝑚𝑚

with pad on top/bottom corners PCB edge

A PTH to connect traces Drill size

Via ø 0.45 𝑚𝑚 0.6 𝑚𝑚 0.05 𝑚𝑚

from/to different layers increments

End-size drill ø NPTH:

±0.05 𝑚𝑚

PCB trace widths

End-size drill ø PTH:

• Copper base thickness: 18 𝑢𝑚 ±0.1 𝑚𝑚

• Temperature rise of trace: ≤ 15℃ Standard Contour dim. : ±0.2 𝑚𝑚

• Ambient temperature: ~25℃ tolerances Position contour / holes:

±0.2 𝑚𝑚

• For outer layer traces only (top/bottom) Slot dimensions:

width: ±0.1 𝑚𝑚

Signal type Minimal Recommended Application length: ±0.2 𝑚𝑚

Low voltage DC Good solderability,

Low current 0.5 𝑚𝑚 1.0 𝑚𝑚

power supply lines HAL Lead-free for standard PCB

Mains, high power thickness

High current 1.5 𝑚𝑚 ≥ 2.5 𝑚𝑚 Surface finish on

DC Flat surface, for

I/O, logic, solderable pads and

ENIG (chem. Ni/Au) connectors and

Digital 0.2 𝑚𝑚 0.5 𝑚𝑚 microcontroller, traces

contacts, expensive

CPLD Immersion Silver Flat surface, long

ADC, low power op- (chem. Ag) shelf life, cheap

Analog 0.5 𝑚𝑚 0.8 𝑚𝑚

amps

Disclaimer: www.jpe.nl

The information in this document is correct to the best of

our knowledge. The author and publisher disclaim any

liability in connection with the use of this information.

You might also like

- Drilling Engineering: Bottom Hole Assembly (BHA)Document41 pagesDrilling Engineering: Bottom Hole Assembly (BHA)djeramNo ratings yet

- E4.3.1-2-3-4-5 - PTB-4-2019 PDFDocument17 pagesE4.3.1-2-3-4-5 - PTB-4-2019 PDFEdison CasallasNo ratings yet

- AISC LRFD Moment Connections BoltedDocument531 pagesAISC LRFD Moment Connections BoltedManoj JaiswalNo ratings yet

- Bottom Hole Assembly (BHA) : Presented by Mahmoud Mohamed Ali Ahmed Abdel Aziz RabieDocument47 pagesBottom Hole Assembly (BHA) : Presented by Mahmoud Mohamed Ali Ahmed Abdel Aziz RabieArturo Elizondo100% (1)

- PDC Dull GradingDocument52 pagesPDC Dull GradingimampranadipaNo ratings yet

- Appendix 3 Example Report E9Document3 pagesAppendix 3 Example Report E9Laith SalmanNo ratings yet

- Dull Grading BesteBitDocument52 pagesDull Grading BesteBitJohn SzNo ratings yet

- Design Data Sheet For Air ReceiverDocument3 pagesDesign Data Sheet For Air ReceivergksakthiNo ratings yet

- PRO2 01eDocument14 pagesPRO2 01eghita_gabrielNo ratings yet

- Drill Bit Fundamentals: Schlumberger TrainingDocument50 pagesDrill Bit Fundamentals: Schlumberger TrainingJGRENDON2004100% (1)

- EXAMPLE Nozzle Calculations Using ASME VIII Div 2 Appendix 1-10Document16 pagesEXAMPLE Nozzle Calculations Using ASME VIII Div 2 Appendix 1-10jtai1983No ratings yet

- Spyglass CDCDocument3 pagesSpyglass CDC林文榮No ratings yet

- Computer Organization, Unit 1 & 2Document198 pagesComputer Organization, Unit 1 & 2NamanRungtaNo ratings yet

- SMART HELMET USING ARDUINO B.Tech Project ReportDocument52 pagesSMART HELMET USING ARDUINO B.Tech Project ReportMohan Khedkar77% (47)

- Threading Inserts: Now in To Conquer ISO S MaterialsDocument32 pagesThreading Inserts: Now in To Conquer ISO S MaterialsAchmad Arifudin HidayatullohNo ratings yet

- SmartPCB Plant-Specification-Mar-2017 PDFDocument1 pageSmartPCB Plant-Specification-Mar-2017 PDFsmsarmadNo ratings yet

- PlasticBGA SMTAssembly Issues From FreescaleDocument77 pagesPlasticBGA SMTAssembly Issues From FreescaleAntonio Arr100% (1)

- Clamp Design Baher 1651934316Document10 pagesClamp Design Baher 1651934316Muhammad Zun Nooren BangashNo ratings yet

- Product Catalog: PBGA IC Substrate PCBDocument6 pagesProduct Catalog: PBGA IC Substrate PCBhhaiddaoNo ratings yet

- Extruded Outlet HeaderDocument2 pagesExtruded Outlet Headermario salazarNo ratings yet

- Nine9 30 45 60 90 Degree Engraving ToolsDocument16 pagesNine9 30 45 60 90 Degree Engraving ToolsLuthier37No ratings yet

- HE Design CalculationsDocument166 pagesHE Design CalculationsdinakaranpatelNo ratings yet

- Mechanical Clamp Baher 1650482617Document10 pagesMechanical Clamp Baher 1650482617MAT-LIONNo ratings yet

- Drilling Overview: Bottom Hole Assembly (BHA)Document41 pagesDrilling Overview: Bottom Hole Assembly (BHA)Sunny ChaubeyNo ratings yet

- Turning Handbook: General Turning - Parting and Grooving - ThreadingDocument53 pagesTurning Handbook: General Turning - Parting and Grooving - ThreadingMindrila BogdanNo ratings yet

- 5.0 Tension-Members (1) BENG17-1Document20 pages5.0 Tension-Members (1) BENG17-1Erick Elvis ThomassNo ratings yet

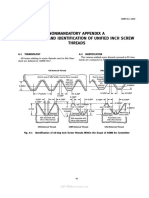

- Nonmandatory Appendix A Terminology and Identification of Unified Inch Screw ThreadsDocument2 pagesNonmandatory Appendix A Terminology and Identification of Unified Inch Screw ThreadsMarcelo KleinNo ratings yet

- PCB Manufacturing Table 1Document1 pagePCB Manufacturing Table 1Solomon AndreiNo ratings yet

- How To Design PCB StackupDocument4 pagesHow To Design PCB StackupPhạm Văn TưởngNo ratings yet

- Basic Design Rules 0423 CBT enDocument8 pagesBasic Design Rules 0423 CBT enAuslanderNo ratings yet

- Operadora Cicsa S.A. de C.V.: Swecomex Calle 5 No. 899 Zona Industrial 44940 Guadalajara Jalisco MexicoDocument45 pagesOperadora Cicsa S.A. de C.V.: Swecomex Calle 5 No. 899 Zona Industrial 44940 Guadalajara Jalisco Mexicoabryant633777No ratings yet

- 15mm Upright SprinklerDocument1 page15mm Upright SprinklerCost RootsNo ratings yet

- UN Internal Screw Thread: in Practice It Is Necessary To Provide For Some Threading ToolDocument4 pagesUN Internal Screw Thread: in Practice It Is Necessary To Provide For Some Threading ToolGuillermo ArteagaNo ratings yet

- Data Sheet: 1N4728A 1N4764ADocument5 pagesData Sheet: 1N4728A 1N4764AAnkitNo ratings yet

- 1N4728A PanJitInternationalDocument5 pages1N4728A PanJitInternationalPablo AllosiaNo ratings yet

- 3.2 Hole Making Selection and Application - DrillingDocument61 pages3.2 Hole Making Selection and Application - DrillingBaljeet SinghNo ratings yet

- DEUTSCH FDBA Series Filter Connectors: NAS1599BDocument5 pagesDEUTSCH FDBA Series Filter Connectors: NAS1599BNevinNo ratings yet

- Documento - MX Comp1Document10 pagesDocumento - MX Comp1Mangesh BanaleNo ratings yet

- TAP GuhringDocument2 pagesTAP GuhringErhanNo ratings yet

- KMT BoringDocument37 pagesKMT BoringNARENDER SINGHNo ratings yet

- China Guanghan Petroleum 2 FZ 35-35 RAMSDocument1 pageChina Guanghan Petroleum 2 FZ 35-35 RAMSTiffany DacinoNo ratings yet

- Design Rules Basic CBT en PDFDocument8 pagesDesign Rules Basic CBT en PDFVICTOR MARCOSNo ratings yet

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavNo ratings yet

- 3 Single Coils - 1 Volume 2 Tones - 5 Way Blade: Location For Ground (Earth) ConnectionsDocument1 page3 Single Coils - 1 Volume 2 Tones - 5 Way Blade: Location For Ground (Earth) ConnectionsMike CivnodaNo ratings yet

- Ludwig Phase II CloneDocument15 pagesLudwig Phase II CloneEmmanuel SanzNo ratings yet

- Hitachi Micro (EMM)Document24 pagesHitachi Micro (EMM)brianNo ratings yet

- TZ Seals: SNL Plummer Block Housing Seal Data SheetDocument4 pagesTZ Seals: SNL Plummer Block Housing Seal Data SheetShajib RasheedNo ratings yet

- Fig. Slab Typical Detail: Lapping Area (Bottom Bar Only) 2h 2hDocument1 pageFig. Slab Typical Detail: Lapping Area (Bottom Bar Only) 2h 2hWai Yar AungNo ratings yet

- Panasonic-Matsushita Thermal Cutoff 139-C PDFDocument8 pagesPanasonic-Matsushita Thermal Cutoff 139-C PDFDanGibbsNo ratings yet

- Erix Tool Catalog English Metric Print-2Document32 pagesErix Tool Catalog English Metric Print-2RupertNo ratings yet

- Ch4 SheetMetalDocument10 pagesCh4 SheetMetalmaurya21No ratings yet

- AISC 13ed LRFD Bolted Moment Connections Post r4Document504 pagesAISC 13ed LRFD Bolted Moment Connections Post r4Amresh KumarNo ratings yet

- Merkel U-Ring T 18: MaterialDocument5 pagesMerkel U-Ring T 18: MaterialRakesh CheeliNo ratings yet

- 423-U SlotMill SeriesDocument28 pages423-U SlotMill Seriespapa bianNo ratings yet

- S-0000-13A0-101 B Specification For PaintingDocument6 pagesS-0000-13A0-101 B Specification For PaintingAgus Hendra PramujiNo ratings yet

- TLA-6T214ALF For Lenovo T420Document34 pagesTLA-6T214ALF For Lenovo T420Ramdas KambleNo ratings yet

- Engineering Drawing StandardDocument59 pagesEngineering Drawing StandardYuva Raj AnandNo ratings yet

- 4Document47 pages4mohamed nageebNo ratings yet

- E - Linear Slot Diffusers PDFDocument17 pagesE - Linear Slot Diffusers PDFabdullah khanNo ratings yet

- Flow Chart Diagram SymbolsDocument4 pagesFlow Chart Diagram SymbolshimanshuNo ratings yet

- Laporan: Nama Kelompok: Ariesta Ayuning Fitri (1041160019) Goliat Galih Satria (1041160013)Document9 pagesLaporan: Nama Kelompok: Ariesta Ayuning Fitri (1041160019) Goliat Galih Satria (1041160013)Goliat GalihNo ratings yet

- Id SD Catalog eDocument4 pagesId SD Catalog ealltheloveintheworldNo ratings yet

- Ch.12 Programmable Logic ControllersDocument7 pagesCh.12 Programmable Logic ControllersMy QNNo ratings yet

- Lecture Notes On Electronics CircuitsDocument54 pagesLecture Notes On Electronics CircuitsKashif AhmedNo ratings yet

- Technical Specifications: Version 1.0 March 2001Document4 pagesTechnical Specifications: Version 1.0 March 2001Ge SuNo ratings yet

- Ad Hoc TestingDocument19 pagesAd Hoc TestingSridhar SachinNo ratings yet

- NF-268 User ManualDocument6 pagesNF-268 User ManualEmerson Wanderley BragaNo ratings yet

- 350 Fall 12 FinalDocument10 pages350 Fall 12 Finalchuck212No ratings yet

- IC-RX7 BrochureDocument2 pagesIC-RX7 BrochurerhandalfNo ratings yet

- Ece Seminar TopicsDocument17 pagesEce Seminar TopicsKrishna Chaitanya GorleNo ratings yet

- Voltage Controller of DC-DC Buck Boost Converter With Proposed PID ControllerDocument5 pagesVoltage Controller of DC-DC Buck Boost Converter With Proposed PID ControllerAbdul HafeezNo ratings yet

- CPF Maintenance ManualDocument269 pagesCPF Maintenance ManualmarquezgaunaNo ratings yet

- DCT/IDCT Implementation With Loeffler AlgorithmDocument5 pagesDCT/IDCT Implementation With Loeffler AlgorithmInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- QMS250 IDocument2 pagesQMS250 IVenugopal Venu100% (1)

- Study Equivalent: On The Electrical Circuit Models of Polluted Outdoor InsulatorsDocument4 pagesStudy Equivalent: On The Electrical Circuit Models of Polluted Outdoor InsulatorsKamello AssisNo ratings yet

- Radiance 19 FMMI User ManualDocument28 pagesRadiance 19 FMMI User ManualAlejandro de la CruzNo ratings yet

- Sangean ATS803A ModDocument43 pagesSangean ATS803A ModAntonius HaryantoNo ratings yet

- Shyam Ac Performance of Nano ElectronicsDocument30 pagesShyam Ac Performance of Nano Electronicsapi-3827000100% (1)

- DCSE2000 Network Foundation AnswersDocument5 pagesDCSE2000 Network Foundation AnswersOttmar Gallwitz50% (2)

- QIHAN Catalogo enDocument16 pagesQIHAN Catalogo enzonahiphopNo ratings yet

- 6.012 Microelectronic Devices and Circuits: MIT, Spring 2007Document22 pages6.012 Microelectronic Devices and Circuits: MIT, Spring 2007Shubhra DixitNo ratings yet

- Lab Basic ElecDocument12 pagesLab Basic Elecren rNo ratings yet

- Part 1B, DR S.W. MooreDocument16 pagesPart 1B, DR S.W. MooreElliottRosenthal100% (3)

- A Guide For Using PTM and The CPC 100 To Test TransformersDocument56 pagesA Guide For Using PTM and The CPC 100 To Test TransformersSalah SalahNo ratings yet

- A Simple Vending Machine: VLSI Design and Embedded System (VDES) - 2015Document18 pagesA Simple Vending Machine: VLSI Design and Embedded System (VDES) - 2015mpsingh2200No ratings yet