Professional Documents

Culture Documents

McLaren OTT Installation Manual

Uploaded by

RAFAEL RIBEIROOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

McLaren OTT Installation Manual

Uploaded by

RAFAEL RIBEIROCopyright:

Available Formats

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

Congratulations! You’ve just purchased a new over-the-tire track system from McLaren Industries. This

User’s Manual covers proper installation and maintenance of your V8 Series Rubber, Magnum, Diamond, or

Maximizer over-the-tire tracks.

Step 1: Read ALL instructions before installing the tracks.

Step 2: Make sure that you received all of the items shipped to you.

Step 3: Be cautious and protect yourself from harm during installation.

Step 4: Make sure the product is properly installed before operating your machine.

Though track installation is fairly simple, first time track users may require assistance. If assistance is

needed, please contact McLaren Customer Service or your authorized dealer. Your local skid steer dealer is

also an excellent source for assistance. For experienced users, the installation of the tracks takes an average

of fifteen minutes per side. However, first-time users will require more time to become familiar with the

operation of the tools in the kit and the track system. First-time users will also need to perform an initial

adjustment of the tracks to best fit the tires of the machine.

Disclaimer - Before you install and operate your skid steer loader with your new over-the-tire tracks, you

must follow the following guidelines to insure proper product operation and user safety.

MACHINE SAFETY DURING TRACK INSTALLATION AND REMOVAL

ALWAYS be sure that the boom is raised and locked when installing or uninstalling the tracks. Be sure that

other people who are not required to assist in installing/uninstalling the tracks are clear of the work area

and the loader. Make sure that the engine is also off while doing any work on the tracks.

TRACK SLACK ADJUSTMENT

Track slack should be in the range of 1” to 3”. Around 2” of slack is optimal. A looser track with a slack of

about 2” to 3” will provide for greater pin/carriage bolt life. Tracks that are too tight can damage the loader.

USE OF MCLAREN OVER-THE-TIRE TRACKS WITH FOAM-FILLED OR SOLID TIRES

Do not use foam-filled tires or solid rubber tires with McLaren over-the-tire tracks! Using solid tires with

over-the-tire tracks may damage the machine if debris gets caught between the track and the tires. The only

flat-proof tire that is recommended to work with McLaren OTT tracks is McLaren Industries’ Nu-Air Tyre®.

TIRE DAMAGE AND WEAR

Tire pressure. Make sure that the air pressure is correct. If you find a tire rating in kPa on the sidewall, to

convert to the US pounds per square inch (PSI) rating, multiply the kPa rating by 0.14504. Following is an

example of a conversion:

©Copyright McLaren Industries. All Rights Reserved. Page 1

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

Formula:

To convert kPa to PSI, multiply the kPa rating (on the Ranger tire) by 0.14504.

Example: If a Ranger tire has a kPa rating of 510. Multiply the kPa rating of 510 by 0.14504.

510 x 0.14504 = 73.9704 PSI.

Round 73.9704 up and you get 74.0 PSI

Carriage Bolt / Pin and Nut Tightness. Be sure that the nuts on the carriage bolts / pins are tight. You can

use a standard automotive air wrench to tighten any loose nuts. Alternatively, you can use a torque wrench

to tighten at a rate of 100 foot pounds. Higher torque ratings can damage or strip the bolt / nut threads. A

loose bolt can slide sideways and end up catching the sidewall of a tire and cause a puncture. A tight bolt

will prevent this from occurring.

Track-to-Tire Fit. Track-to-Tire fit is the responsibility of the machine/track owner. It is normal and

recommended that a certain amount of space exist between the tire and the inside of the track sections. Do

not run the tracks if the tires are snug inside the tracks. If the tires are snug inside the tracks, this will cause

excessive and premature tire sidewall wear and ultimately tire failure. The normal and recommended

amount of space between the tire and the inside of the tracks is 1/2” to 3/4”. This space allows for proper

release of any debris that may get caught between the tire and the inside of the tracks.

No Warranty for Any Tire Damage. Mclaren Industries does not provide warranty for any tire damage. Track

condition, fit, and machine clearance are the responsibility of the machine/track owner. (Please see the

Clearance Measurement Guide)

INSTALLATION TOOL

Do not over-tighten the installation tool when installing the over-the-tire tracks. Over tightening the

installation tool can cause damage to the tool itself, the tracks, and/or the machine. The installation tool will

break if over tightened. The tool is designed to withstand the normal pressure exerted when installing the

tracks. The installation tool is not covered by any warranty. If an installation tool breaks, a new tool may be

purchased through Mclaren Industries.

MACHINE OPERATION

Do not operate the machine if the tracks are not set to the recommended tension.

MACHINE DAMAGE

Mclaren Industries is not responsible for damage to the track owner’s machine. The machine owner is

responsible for determining that the tracks (or any related products, such as wheel spacers or boom stops)

are used within the constraints and limitations set by McLaren Industries, if purchased from McLaren

Industries, or an authorized McLaren dealer.

©Copyright McLaren Industries. All Rights Reserved. Page 2

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

BREAK-IN PERIOD

You may have to readjust the tension of your new over-the-tire tracks one (1) to three (3) times during the

first twenty (20) hours of use. This will moderate the friction between the metal components of the tracks

as-well as the friction between the tracks and tires

CARRIAGE BOLT / PIN / LINK WEAR FACTORS AND LIFE

The life of the carriage bolts / pins / links is reliant upon several factors: proper adjustment of the tracks and

track tension and work environment conditions. Soft soil will provide the longest carriage bolt/pin/link life.

The condition that is most detrimental to the life of the metal components of the tracks is sand. Sand will

wear the metal components more rapidly than any other work conditions. Sand will also greatly reduce the

life of the tracks that have rubber pads.

RETAIN THE ID PLATE

Please retain the ID plate that comes on the tracks for any future warranty issues.

©Copyright McLaren Industries. All Rights Reserved. Page 3

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

CLEARANCE MEASUREMENT GUIDE:

INSTALLATION KIT CONTENTS:

1 pc Packaging Box

1 Set of 2 Pcs of C Clamp For Universal Installation

1 pc Square Nut For V-Hook/C-Clamp (Left-Hand Thread)

1 pc Square Nut For V-Hook/ C-Clamp (Right-Hand Thread)

1 pc Allen Wrench 10 mm

1 pc 1/2" 10 mm Socket for Allen Wrench

1 pc 1/2" 19 mm Socket for Carriage Bolt

4 pcs Carriage Bolt 14 mm w/ Nut and Lock-Washer

1 pc 1/2" C Clamp Threaded Rod 12Mm

1 pc 1/2" 12 mm Socket for Threaded Rod

1 pc 1/2" 16 mm Socket For 12" OTT Rubber Pad Nut

1 pc 1/2" Ratchet

Note: Installation kit is subject to change.

©Copyright McLaren Industries. All Rights Reserved. Page 4

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

CORRECT ASSEMBLY OF C-CLAMPS AND SQUARE NUTS:

1.

Screw both C clamps onto the threaded rod. Make sure square

nuts can be screwed on to the threaded rod properly.

2.

3.

INSTALLATION INSTRUCTIONS:

Take all necessary precautions to protect yourself during installation. If necessary, install wheel spacers

and/or boom stops. Make any other adjustments to the machine as required.

Be sure you have the necessary track clearance on your machine. (Refer to the Measurement Guide IN this

manual.) You may disconnect a single track unit from the track assembly and use it to check for track

clearance before you continue with the installation. If problems with clearance occur, call McLaren

Customer Service or your authorized dealer.

NOTE: It is recommended to install one OTT Magnum is directional. When the

side at a time, as opposed to both, until track is mounted on the machine, the

you familiarize yourself with the track thick solid bar should point to the front

system. of the machine, when looking at the top

of the track.

©Copyright McLaren Industries. All Rights Reserved. Page 5

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

1. 2.

1. Make sure that both tracks are parallel to 2. To avoid serious injury or death raise and

each other and of equal distance to the lock the boom of the machine according to

machine. Remove as much slack as possible. the manufacturer’s instructions.

3. 4.

3. Slowly drive the machine over the tracks. 4. Fold the back end of tracks over the back

Stop halfway over the track chain. tire of the machine.

5. 6.

5. Fold the front end of tracks over the front tire. 6. Assemble the installation tool as described above.

NOTE: Before using the installation tool to tighten the

tracks, make sure that there is no slack bunched

between the ground and the tire - as the arrow shows

on this image. The track should be in full contact all the

way around the tire before tightening the track.

Avoid!

©Copyright McLaren Industries. All Rights Reserved. Page 6

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

7. 8.

7. Insert installation tool under the first open 8. Connect the other end of the installation tool to

section of the track. the opposite section of the track.

9. 10.

9. Put ratchet on the square end of the threaded 10. When the open track sections get close enough

rod. Use the ratchet to bring the two ends of the together, insert the ends of the dog-bone links into

track together. their respective slots.

11. 12.

11. Insert the carriage bolt on the outside of 12. Tighten the carriage bolts. You can tighten to 100

the track pounds of torque pressure or use an automotive air

gun.

13. 14.

13. Once the carriage bolts are tight, 14. Remove the installation tool from the track and

loosen the installation tool. then move the machine forward until there is an

open space to insert the carriage bolt on the inside of

the track. Tighten the bolt.

©Copyright McLaren Industries. All Rights Reserved. Page 7

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

Over-the-tire tracks are heavy. You may want to use a rope to bring the track over the tire, or if the

machine’s fenders prevent conventional installation.

Loop the

rope around

the front end

of the tire,

1. 2. 3. and tuck it

under it.

Tie one end of the rope to the Stretch the rope across the tire tread.

last pad of the track chain.

4. 5.

Drive forward enough to pull the Bring the rest of the track over the

track halfway over the rear tire. front tire.

INSTALLATION ADJUSTMENT

The suggested track sag is between 1” and 3”. The optimum slack is 2”. The pin can be locked into two

positions--- inner hole (closer to the track pad center) and outer hole (farther from the track pad center). If

more or less than 1”- 3” of sag exists, move as many pins as necessary from outer to inner hole (or vice

versa) to get the required track tension/slack.

As you can see here, this is the default adjustment of your new set of tracks. All of the links

are set to the OUTER holes. Adjusting the links by moving them to the INNER or OUTER

holes will loosen or tighten the tracks. Always make sure your tracks are at the

recommended tension prior to operating the skid steer, otherwise you may risk damaging

the machine and/or the tracks.

Each INNER hole adjustment tightens or loosens the track system by approximately 3/4".

As you can see here, the track pad in the center has been adjusted to have the link

accommodate the INNER hole. This is one INNER hole adjustment.

In this diagram, you will notice that the track pad in the center has two INNER hole

adjustments made.

This depicts an INCORRECT placement of the link. As you can see, making two INNER hole

adjustments on opposing track pads will not allow the track to operate correctly. The ears

will bind up on the curve of the tire. If the machine is run with this type of adjustment,

damage to the tracks and/or machine will occur. Please note that incorrect adjustment

voids the warranty of the product.

©Copyright McLaren Industries. All Rights Reserved. Page 8

McLaren Over-the-Tire Tracks for Skid Steer Loaders – User’s Guide & Installation Manual

THINGS TO KNOW

* The break-in period for a new set of over-the-tire track system is approximately 20 hours. During this time,

the tires will seat themselves to the tracks.

* Avoid making sharp turns until the tires have seated properly, otherwise you may damage the tires.

* Check and re-adjust the tension regularly at 100-hour intervals, this will help ensure extended tire life and

proper operation of tracks.

* For OTT Rubber we strongly recommend the tracks be rotated at 100-hour intervals or when the track

begins to have uneven wear, this will help ensure extended rubber pad life.

* When troubleshooting your tracks, take necessary precautions to protect yourself from injury (i.e. wear

gloves, lock boom, turn machine engine off, etc.)

* Contact McLaren, if there are any warranty related questions or if out-of warranty replacement parts are

needed.

* Refer to our website regularly (www.mcLarenindustries.com) for new information and additions to this

user’s guide and installation manual.

We want to hear from YOU! Have you tried something interesting with your over-the-tire tracks? Do you

have any pictures or videos of an amazing feat? Would you like a picture of YOUR machine on our website?

Tell us about it! Please contact your sales representative.

©Copyright McLaren Industries. All Rights Reserved. Page 9

You might also like

- AP Macroeconomics Review Sheet 2013Document7 pagesAP Macroeconomics Review Sheet 2013Crystal Farmer100% (4)

- Pricelist Computer AccessoriesDocument17 pagesPricelist Computer AccessoriesAyyasamr0% (2)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Manitou 2003 Sherman Service ManualDocument8 pagesManitou 2003 Sherman Service Manualmarcos2808No ratings yet

- Instruction Manual For Cam Shaft Kit: (Exclusive For Bore-Up)Document5 pagesInstruction Manual For Cam Shaft Kit: (Exclusive For Bore-Up)Louis100% (2)

- DC4160 Technical HandbookDocument210 pagesDC4160 Technical HandbookANH LÊ100% (4)

- Bicycle Engine Kit Installation Guide - Raw 80ccDocument9 pagesBicycle Engine Kit Installation Guide - Raw 80ccSokitome0% (1)

- Design of Steel TowerDocument31 pagesDesign of Steel Towerudara89% (9)

- 1999 Coda Expert Crank InstructionsDocument8 pages1999 Coda Expert Crank InstructionsaPaCz42No ratings yet

- Tm9-2610-200-14 US Army Tire ManualDocument207 pagesTm9-2610-200-14 US Army Tire Manualr17g100% (1)

- Manual de Panther T8 2013Document347 pagesManual de Panther T8 2013Anonymous Hd32bhqNo ratings yet

- QuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service ManualDocument9 pagesQuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service Manualjengandxb100% (2)

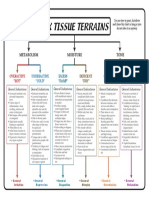

- 6 Tissue Terrains ColorDocument1 page6 Tissue Terrains Colorஆ.க.கோ. இராஜேஷ்வரக் கோன்No ratings yet

- Insider TradingDocument49 pagesInsider Tradinghakec100% (1)

- Re Kyc Form For Nri Amp Pio CustomersDocument3 pagesRe Kyc Form For Nri Amp Pio CustomerskishoreperlaNo ratings yet

- Manitou 2001 Magnum Service ManualDocument12 pagesManitou 2001 Magnum Service ManualEdha AliNo ratings yet

- BFGoodrich Truck Tires Data BookDocument20 pagesBFGoodrich Truck Tires Data Bookluis eduardo corzo enriquezNo ratings yet

- 625-43 - 825-42K Supertrack Kit (Rev. 04-2015)Document6 pages625-43 - 825-42K Supertrack Kit (Rev. 04-2015)George finkleNo ratings yet

- 04 Skareb EngDocument4 pages04 Skareb EngAlvin ArcturianNo ratings yet

- Camshaft Installation and Degreeing Procedure: InstructionsDocument12 pagesCamshaft Installation and Degreeing Procedure: Instructionsluokla7No ratings yet

- 131 T2el 01 A - Oil Catch Can Kit, Install GuideDocument6 pages131 T2el 01 A - Oil Catch Can Kit, Install GuidejorgeNo ratings yet

- Front Disc Brake Pads Replacement PDFDocument4 pagesFront Disc Brake Pads Replacement PDFY. Vásquez0% (1)

- BFGoodrich Truck Tires Data BookDocument22 pagesBFGoodrich Truck Tires Data BookSantiago UrgilesNo ratings yet

- Avid User Manual Bb7Document2 pagesAvid User Manual Bb7Elizabeth Soares BourneNo ratings yet

- DA50 Manual July 12 2012Document10 pagesDA50 Manual July 12 2012Jorge José Figueiredo SiqueiraNo ratings yet

- 001 Electric BrakesDocument5 pages001 Electric BrakesHamza AlkafreNo ratings yet

- Manitou 1999 SX Service ManualDocument16 pagesManitou 1999 SX Service ManualSonoinformaticaNo ratings yet

- Section 4 - Cam Followers/Tappets - Group 04Document9 pagesSection 4 - Cam Followers/Tappets - Group 04Miodrag HuberNo ratings yet

- Truck Tire Data BookDocument130 pagesTruck Tire Data Bookrashom0099088No ratings yet

- Troll Fork Instructions: Condition 3Document3 pagesTroll Fork Instructions: Condition 3VÍCTOR VINUESA CAÑASNo ratings yet

- TT4100 Ops Manual 990039Document23 pagesTT4100 Ops Manual 990039farid said errahmaniNo ratings yet

- Honda Accord Tow Bar FittingDocument2 pagesHonda Accord Tow Bar FittingpppeterthepigNo ratings yet

- Corvette Body Complete Manual 3823KBDocument41 pagesCorvette Body Complete Manual 3823KBCoolbreeze1224100% (1)

- User Instructions Bull Wheel Liners 4-2010Document8 pagesUser Instructions Bull Wheel Liners 4-2010Alexander SladeNo ratings yet

- RS Reba User ManualDocument63 pagesRS Reba User ManualRadu Nica0% (1)

- Emission Containment Seal: ForewordDocument8 pagesEmission Containment Seal: ForewordAnonymous 4MwmDaNbNo ratings yet

- Bolt Torque Sequence PDFDocument2 pagesBolt Torque Sequence PDFmilNo ratings yet

- Rev A Durospeed GuideDocument15 pagesRev A Durospeed GuideCamilo Arroyave JNo ratings yet

- AXL - AxlesDocument7 pagesAXL - AxlesDavid GaciaNo ratings yet

- Rear Drum Brakes: Section: 4E2Document12 pagesRear Drum Brakes: Section: 4E2Rafael HernandezNo ratings yet

- 08 Byg Cast Blades BrochureDocument22 pages08 Byg Cast Blades BrochureAvaa AmgaaNo ratings yet

- ATV Clutch Setups V6.7Document16 pagesATV Clutch Setups V6.7Luis BaracchiNo ratings yet

- Tyre Degradation On Mobile Elevating Work Platforms Guidance DocumentDocument3 pagesTyre Degradation On Mobile Elevating Work Platforms Guidance DocumentbugseNo ratings yet

- Rock Shox Judy FilesDocument84 pagesRock Shox Judy FilesIvan PuškadijaNo ratings yet

- Wheels BinderDocument60 pagesWheels BinderGuillermo AlfonsoNo ratings yet

- Hughes Torque Converter Installation InstructionsDocument3 pagesHughes Torque Converter Installation InstructionsMichael VasquezNo ratings yet

- Dv300 STD MMDocument40 pagesDv300 STD MMjacklyn ade putraNo ratings yet

- POWERBLOCDocument17 pagesPOWERBLOCcyril DESPRATNo ratings yet

- Geith - Acople Ec460bDocument25 pagesGeith - Acople Ec460bjrincon26No ratings yet

- Despiece Polipasto Manual CycloneDocument40 pagesDespiece Polipasto Manual CyclonearmandoNo ratings yet

- Motor B411 Turbo MitsubishiDocument1 pageMotor B411 Turbo MitsubishiCarlos Alberto Lau SosaNo ratings yet

- Jc60evo ManualDocument12 pagesJc60evo ManualGerman ParamoNo ratings yet

- Roller Rocker InstructionsDocument4 pagesRoller Rocker InstructionsDamien DrakeNo ratings yet

- Trooper Brake DisksDocument3 pagesTrooper Brake DisksJairo SoriaNo ratings yet

- Brake Drum RefinishingDocument1 pageBrake Drum RefinishingY. VásquezNo ratings yet

- Inter BrakeDocument1 pageInter BrakedovlikusNo ratings yet

- Camisa de CilindroDocument16 pagesCamisa de CilindroFelipe CarranzaNo ratings yet

- V-SB 3902801e - Disc Brake Wear and DamageDocument28 pagesV-SB 3902801e - Disc Brake Wear and DamageAtul ScNo ratings yet

- MAN ShaftErrosion SL2008-498Document18 pagesMAN ShaftErrosion SL2008-498flipflop12100% (1)

- Suspension Fork: User ManualDocument84 pagesSuspension Fork: User ManualJose GarciaNo ratings yet

- Installation Instructions For 97 03 Ford F150 2wdDocument8 pagesInstallation Instructions For 97 03 Ford F150 2wdMike CollepardiNo ratings yet

- 001-012 Camshaft Gear (Camshaft Installed) : InstallDocument3 pages001-012 Camshaft Gear (Camshaft Installed) : InstallNaing Min HtunNo ratings yet

- PVL Ignition Installation & Operating Instructions: Warning!!Document4 pagesPVL Ignition Installation & Operating Instructions: Warning!!nenadNo ratings yet

- Tyre Degradation Mew PsDocument3 pagesTyre Degradation Mew PsTatak Bay AhmedNo ratings yet

- Textar Fitting Instructions enDocument8 pagesTextar Fitting Instructions enKhristina StefanovaNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Ammann Av26-2 01Document8 pagesAmmann Av26-2 01RAFAEL RIBEIRONo ratings yet

- 2006 English PE Catalogue 60Hz-USADocument27 pages2006 English PE Catalogue 60Hz-USARAFAEL RIBEIRONo ratings yet

- GBL22D 42D SoundproofDocument2 pagesGBL22D 42D SoundproofRAFAEL RIBEIRONo ratings yet

- Catalogo PE 50 HZ 2006 ING Secondo Aggiornamento 72DPIDocument36 pagesCatalogo PE 50 HZ 2006 ING Secondo Aggiornamento 72DPIRAFAEL RIBEIRONo ratings yet

- GBW15-22-30-45P SoundproofDocument2 pagesGBW15-22-30-45P SoundproofRAFAEL RIBEIRONo ratings yet

- Protection of Information Systems: © The Institute of Chartered Accountants of IndiaDocument28 pagesProtection of Information Systems: © The Institute of Chartered Accountants of Indiajonnajon92-1No ratings yet

- O Rei Esta Voltando (Mara Lima) - Score and PartsDocument41 pagesO Rei Esta Voltando (Mara Lima) - Score and PartsSidionir FalcheteNo ratings yet

- Crazy in Love-KadebostanyDocument2 pagesCrazy in Love-Kadebostanyvikas kumawatNo ratings yet

- SEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDocument3 pagesSEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDaniel TamisenNo ratings yet

- Major Orientation Reflection PaperDocument2 pagesMajor Orientation Reflection PaperNessNo ratings yet

- Experimentation, Orgasms, and The Rise of Anal Sex. - by William Saletan - SDocument13 pagesExperimentation, Orgasms, and The Rise of Anal Sex. - by William Saletan - Saweawerwerwe100% (1)

- 1991 Indianapolis 500 - WikipediaDocument48 pages1991 Indianapolis 500 - WikipediabNo ratings yet

- Shotlist and Script For Eco Friendly WorldDocument3 pagesShotlist and Script For Eco Friendly Worldapi-426197673No ratings yet

- Architecture Firms: CCBA DesignsDocument1 pageArchitecture Firms: CCBA DesignspallaviNo ratings yet

- Las 9Document14 pagesLas 9HisokaNo ratings yet

- In The Garden of Beasts by Erik Larson - Reading Group GuideDocument9 pagesIn The Garden of Beasts by Erik Larson - Reading Group GuideCrown Publishing Group100% (1)

- M-346 Flight Test ProgrammeDocument10 pagesM-346 Flight Test ProgrammecoralonsoNo ratings yet

- PEST AnalysisDocument5 pagesPEST Analysisacheron_pNo ratings yet

- CPDDocument9 pagesCPDMeigy NitalessyNo ratings yet

- Cot 2Document9 pagesCot 2Wowie J CruzatNo ratings yet

- Finned Surfaces: Name:Mohamed Hassan Soliman ID:190513 DR - Mohamed HassanDocument7 pagesFinned Surfaces: Name:Mohamed Hassan Soliman ID:190513 DR - Mohamed HassanMohamed HassanNo ratings yet

- This Study Resource Was: Management Consultancy June Dane Yuri D. Abieras BSA-5Document5 pagesThis Study Resource Was: Management Consultancy June Dane Yuri D. Abieras BSA-5Jicell FerrerNo ratings yet

- 2 Obstacle Avoiding Robot PDFDocument7 pages2 Obstacle Avoiding Robot PDFRaj AryanNo ratings yet

- 01building Services Design ProcessDocument38 pages01building Services Design ProcessBen MusimaneNo ratings yet

- Site Analysis Requirements PDFDocument24 pagesSite Analysis Requirements PDFmuthukumar0% (1)

- Always Sunny SpecDocument35 pagesAlways Sunny SpecSamuel KapustNo ratings yet

- WILDVALLEY SHIPPING CO V CaDocument2 pagesWILDVALLEY SHIPPING CO V CaChariNo ratings yet

- Assignment Two CartoonsDocument3 pagesAssignment Two CartoonsAbraham Kang100% (1)