Professional Documents

Culture Documents

Aggregate Planning 1 Finished

Aggregate Planning 1 Finished

Uploaded by

Md. Jihadul IslamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Planning 1 Finished

Aggregate Planning 1 Finished

Uploaded by

Md. Jihadul IslamCopyright:

Available Formats

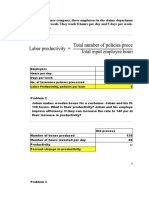

A B C D E F G H I

1 SureStep aggregate planning model

2

3 Input data Range names used:

4 Initial inventory of shoes 500 Forecasted_demand =Model!$B$36:$E$36

5 Initial number of workers 100 Inventory_after_production =Model!$B$34:$E$34

6 Regular hours/worker/month 160 Maximum_overtime_labor_hours_available =Model!$B$25:$E$25

7 Maximum overtime hours/worker/month 20 Overtime_labor_hours_used =Model!$B$23:$E$23

8 Hiring cost/worker $1,600 Production_capacity =Model!$B$32:$E$32

9 Firing cost/worker $2,000 Shoes_produced =Model!$B$30:$E$30

10 Regular wages/worker/month $1,500 Total_cost =Model!$F$46

11 Overtime wage rate/hour $13 Workers_fired =Model!$B$19:$E$19

12 Labor hours/pair of shoes 4 Workers_hired =Model!$B$18:$E$18

13 Raw material cost/pair of shoes $15

14 Holding cost/pair of shoes in inventory/month $3

15

16 Worker plan Month 1 Month 2 Month 3 Month 4 This is a model where spreadsheet layout is really important. We found it useful

to separate the model into four (related) groups: a group containing most of the

17 Workers from previous month 100 94 93 50 inputs, a group containing information about workers and their hours, a group

18 Workers hired 0 0 0 0 containing information about shoes, and a group containing monetary

information. Once you set it up this way and add appropriate labels in column A,

19 Workers fired 6 1 43 0 the "flow" of the logic is straightforward. Besides, it allows you to put the two

20 Workers available after hiring and firing 94 93 50 50 sides of constraints next to one another.

21

The decision variable cells might not be obvious. Just remember that the values of

22 Regular-time hours available 15040 14880 8000 8000 the decision variable cells should be enough to run the business. If you know the

23 Overtime labor hours used 0 80 0 0 numbers of workers hired and fired, the number of overtime hours used, and the

24 <= <= <= <= production quantities, everything else results. Try never to have decision variable

cells that are determined by the values of other decision variable cells.

25 Maximum overtime labor hours available 1880 1860 1000 1000

26 Probably the trickiest formula is the one in row 32 that involves the "production

27 Total hours for production 15040 14960 8000 8000 function," i.e., the conversion of labor hours into shoes. You have to make sure

the units are correct. The formulas in row 32 divide hours by (hours per pair of

28 shoes). The result is what we want: pairs of shoes.

29 Production plan Month 1 Month 2 Month 3 Month 4

30 Shoes produced 3760 3740 2000 1000

31 <= <= <= <=

32 Production capacity 3760 3740 2000 2000

33

34 Inventory after production 4260 5000 2000 1000

35 >= >= >= >=

36 Forecasted demand 3000 5000 2000 1000

37 Ending inventory 1260 0 0 0

38

39 Monetary outputs Month 1 Month 2 Month 3 Month 4 Totals

40 Hiring cost $0 $0 $0 $0 $0

41 Firing cost $12,000 $2,000 $86,000 $0 $100,000

42 Regular-time wages $141,000 $139,500 $75,000 $75,000 $430,500

43 Overtime wages $0 $1,040 $0 $0 $1,040

44 Raw material cost $56,400 $56,100 $30,000 $15,000 $157,500

45 Holding cost $3,780 $0 $0 $0 $3,780

46 Totals $213,180 $198,640 $191,000 $90,000 $692,820 Objective to minimize

Oneway analysis for Solver model in Model worksheet

Overtime rate (cell $B$11) values along side, output cell(s) along top

Overtime_labor_hours_used_1

Overtime_labor_hours_used_2

Overtime_labor_hours_used_3

Overtime_labor_hours_used_4

Total_cost

5

$7 1620 1660 0 0 $684,755

$9 80 1760 0 0 $691,180

$11 0 80 0 0 $692,660

$13 0 80 0 0 $692,820

$15 0 80 0 0 $692,980

$17 0 80 0 0 $693,140

$19 0 0 0 0 $693,220

$21 0 0 0 0 $693,220

As expected, as the overtime rate

increases, fewer overtime hours are used, 694000

and the total cost increases (or remains

692000

constant), as shown in the chart.

690000

688000

686000

684000

682000

680000

$7

Sensitivity of Total_cost to Overtime rate

Data for chart

When you select an output from the

dropdown list in cell $K$4, the chart

will adapt to that output.

Total_cost

684755

691180

692660

692820

692980

693140

693220

693220

Sensitivity of Total_cost to Overtime rate

694000

692000

690000

688000

686000

684000

682000

680000

$7 $9 $11 $13 $15 $17 $19 $21

Overtime rate ($B$11)

You might also like

- Practical Earned Value Analysis: 25 Project Indicators from 5 MeasurementsFrom EverandPractical Earned Value Analysis: 25 Project Indicators from 5 MeasurementsNo ratings yet

- Unit-3-Productivity Problem PDFDocument9 pagesUnit-3-Productivity Problem PDFShakil KhanNo ratings yet

- Sulphur VapoursDocument12 pagesSulphur VapoursAnvay Choudhary100% (1)

- LG4J We 9491Document406 pagesLG4J We 9491pankituna5487No ratings yet

- Visual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsFrom EverandVisual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsNo ratings yet

- 4 Th. Sem. Standard Costing Problems SolutionsDocument12 pages4 Th. Sem. Standard Costing Problems SolutionsCh Sam100% (2)

- SEC Distribution Planning Standards (DPS)Document144 pagesSEC Distribution Planning Standards (DPS)delgonzales80% (10)

- Workbook For Chemical Reactor Relief System Sizing PDFDocument256 pagesWorkbook For Chemical Reactor Relief System Sizing PDFTran Van HaiNo ratings yet

- Learning CurveDocument7 pagesLearning CurveSyed FaizanNo ratings yet

- SMDM - Project Report - LakshmiDocument26 pagesSMDM - Project Report - LakshmiKannan NNo ratings yet

- Tugas Akmen 3.2A - 3.3ADocument2 pagesTugas Akmen 3.2A - 3.3ADias AdhyaksaNo ratings yet

- EIP Book of KnowledgeDocument120 pagesEIP Book of Knowledgelarry_beeNo ratings yet

- Losses in OfcDocument26 pagesLosses in OfcdharaniNo ratings yet

- CNN Numpy 1st HandsonDocument5 pagesCNN Numpy 1st HandsonJohn Solomon100% (1)

- Mill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram ExampleDocument73 pagesMill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram Exampleسليمان مصريNo ratings yet

- CE 579 Lecture 1 Stability-Stability Vs BucklingDocument16 pagesCE 579 Lecture 1 Stability-Stability Vs BucklingbsitlerNo ratings yet

- Operations Management Final Exam - Selina Astiri - 29120184Document7 pagesOperations Management Final Exam - Selina Astiri - 29120184Selina AstiriNo ratings yet

- Green Handwritten Course Syllabus Education PresentationDocument24 pagesGreen Handwritten Course Syllabus Education PresentationCamela Jane Dela PeñaNo ratings yet

- Productivity - NotesDocument16 pagesProductivity - Notesjac bnvstaNo ratings yet

- OM Ind. Assignment AnswerDocument5 pagesOM Ind. Assignment AnswerGlobal internet100% (2)

- Questions For PracticeDocument5 pagesQuestions For PracticeKeshav GuptaNo ratings yet

- Productivity MeasurementDocument3 pagesProductivity MeasurementangelicamadscNo ratings yet

- Problem Set 12 With SolutionsDocument8 pagesProblem Set 12 With SolutionsMinh Ngọc LêNo ratings yet

- Eric Stevanus - LA28 - 2201756600Document8 pagesEric Stevanus - LA28 - 2201756600eric stevanusNo ratings yet

- CH 1 NumericalDocument10 pagesCH 1 NumericalPrabin ChaudharyNo ratings yet

- Sample Midterm PDFDocument9 pagesSample Midterm PDFErrell D. GomezNo ratings yet

- M-4 Chap. 4 OMTQM MidtermsDocument11 pagesM-4 Chap. 4 OMTQM MidtermsGelayieNo ratings yet

- Bacc232 .309 Management Accounting Assignment 1Document13 pagesBacc232 .309 Management Accounting Assignment 1TarusengaNo ratings yet

- BBA211 Vol8 JobCostingDocument10 pagesBBA211 Vol8 JobCostingAnisha SarahNo ratings yet

- Basic Pay 1000 12000 DA 200 2400 Bonus 240 2880 120 1440 Other Allowance 250 3000 1810 21720 Employer's Contribution To PFDocument15 pagesBasic Pay 1000 12000 DA 200 2400 Bonus 240 2880 120 1440 Other Allowance 250 3000 1810 21720 Employer's Contribution To PFParth VijayNo ratings yet

- Revision Module - Labour CostingDocument7 pagesRevision Module - Labour CostingRakhi AroraNo ratings yet

- Unit 2 HW Problems: Alexia Sevilla MAN3506Document3 pagesUnit 2 HW Problems: Alexia Sevilla MAN3506DyenNo ratings yet

- Sample Productivity ProblemsDocument5 pagesSample Productivity ProblemsCassia MontiNo ratings yet

- Session 4 A - Product Mix Constraints LP - Canvas - TeachingDocument37 pagesSession 4 A - Product Mix Constraints LP - Canvas - Teaching長長No ratings yet

- Productivity Class Practice Problems OM July 2019 UpdatedDocument17 pagesProductivity Class Practice Problems OM July 2019 UpdatedVinodshankar BhatNo ratings yet

- Aggregate Planning, Linear Programming and Excel SolverDocument7 pagesAggregate Planning, Linear Programming and Excel SolverekalveNo ratings yet

- Tutorial 5 - SchemeDocument4 pagesTutorial 5 - SchemeTeo ShengNo ratings yet

- Role of Work Study in Improving ProductivityDocument8 pagesRole of Work Study in Improving Productivityrub786No ratings yet

- Dwnload Full Managerial Accounting 12th Edition Warren Solutions Manual PDFDocument35 pagesDwnload Full Managerial Accounting 12th Edition Warren Solutions Manual PDFjethrohacokkbns100% (11)

- JOC (Discussion)Document10 pagesJOC (Discussion)Luisa ColumbinoNo ratings yet

- Aggregate Planning-Sales & Operations Planning: ISQA 459 Class 2Document32 pagesAggregate Planning-Sales & Operations Planning: ISQA 459 Class 2dictoNo ratings yet

- Problem Solving No.1 - HuangDocument8 pagesProblem Solving No.1 - HuangAaron HuangNo ratings yet

- CH1 CH7解答Document72 pagesCH1 CH7解答Koushik ChoudhuryNo ratings yet

- Cost Accounting Practice Quiz Chap 3-4Document7 pagesCost Accounting Practice Quiz Chap 3-4Adeline DelveyNo ratings yet

- Managerial Accounting 12th Edition Warren Solutions ManualDocument25 pagesManagerial Accounting 12th Edition Warren Solutions ManualMaryBalljswt100% (59)

- 02 Fixed Cost Manufacturing FinishedDocument6 pages02 Fixed Cost Manufacturing FinishedpankajNo ratings yet

- LABOURDocument5 pagesLABOURAtukwatse PamelaNo ratings yet

- Business Economics 29118041 Prasta Chapter 6Document5 pagesBusiness Economics 29118041 Prasta Chapter 6dum dum100% (2)

- OPMAN Prelims LessonsDocument22 pagesOPMAN Prelims LessonsEiliah MiclatNo ratings yet

- PM Sect B Test 6Document5 pagesPM Sect B Test 6FarahAin FainNo ratings yet

- Operationmanagementproblems 131216134550 Phpapp02Document86 pagesOperationmanagementproblems 131216134550 Phpapp02Mai LinhNo ratings yet

- Management Accounting CDocument5 pagesManagement Accounting CKarìũki Wa MbìgìNo ratings yet

- MICROECONOMICS ExercisesDocument2 pagesMICROECONOMICS ExercisesAdrian CorredorNo ratings yet

- 3 Process and Job Order Costing System 2019Document8 pages3 Process and Job Order Costing System 2019Abdallah SadikiNo ratings yet

- Solutions Additional ExercisesDocument87 pagesSolutions Additional Exercisesapi-3767414No ratings yet

- Combinepdf 2Document6 pagesCombinepdf 2saisandeepNo ratings yet

- Answer Scheme Acc116 Test (Jan 2021)Document4 pagesAnswer Scheme Acc116 Test (Jan 2021)Celyn Anne Jati EkongNo ratings yet

- Performance Management: Monday 9 June 2008Document9 pagesPerformance Management: Monday 9 June 2008sarkar_raNo ratings yet

- TreDocument10 pagesTremacashNo ratings yet

- Unit 4 - Job, Batch Service Costing (PDF Slides)Document51 pagesUnit 4 - Job, Batch Service Costing (PDF Slides)Ceila FerronNo ratings yet

- Lesson 10b: Aggregate Planning Finding An Optimal Production Plan Using Excel SolverDocument7 pagesLesson 10b: Aggregate Planning Finding An Optimal Production Plan Using Excel SolvervaraduNo ratings yet

- Term 1 Test 27 June 2013 Deferred Marking KeyDocument5 pagesTerm 1 Test 27 June 2013 Deferred Marking KeyPETERNo ratings yet

- JPC - LP - Class Notes - Mos 3370 - Kings - Fall 2023 - 571Document26 pagesJPC - LP - Class Notes - Mos 3370 - Kings - Fall 2023 - 571niweisheng28No ratings yet

- ProductivityDocument17 pagesProductivitygetahun2001100% (1)

- Lesson 2: Linear Programming Linear Programming - A Model That Consists of Linear Summary of Linear Programming Model Formulation StepsDocument7 pagesLesson 2: Linear Programming Linear Programming - A Model That Consists of Linear Summary of Linear Programming Model Formulation StepsStanley AquinoNo ratings yet

- CH 2 - Job Costing SystemDocument19 pagesCH 2 - Job Costing SystemDeeb. DeebNo ratings yet

- Module 1 - Productivity, Competitiveness, and Strategy (Illustrations)Document5 pagesModule 1 - Productivity, Competitiveness, and Strategy (Illustrations)Eliza Jayne Princess VizcondeNo ratings yet

- Draft Activity-ProductivityDocument3 pagesDraft Activity-ProductivityangelicamadscNo ratings yet

- Galvanic Corrosion of Zinc Anode and Copper Cathode Cell PDFDocument6 pagesGalvanic Corrosion of Zinc Anode and Copper Cathode Cell PDFsoekarnoNo ratings yet

- Potentials of Enzyme Enhanced Oil Recovery: A ReviewDocument13 pagesPotentials of Enzyme Enhanced Oil Recovery: A ReviewIbrahim SalahudinNo ratings yet

- 43 CA CPT Dec 2010 Question Paper With Answer Key 2Document6 pages43 CA CPT Dec 2010 Question Paper With Answer Key 2Vishal Gattani100% (1)

- Conductometric Titration of Mixture of AcidsDocument3 pagesConductometric Titration of Mixture of AcidsHet100% (2)

- Cpe 150 Laboratory 4: Control Structures Ii: 1 ObjectivesDocument3 pagesCpe 150 Laboratory 4: Control Structures Ii: 1 ObjectivesOsama Salim Oqla Ma'ayahNo ratings yet

- Tutorial MD II 2015 1Document1 pageTutorial MD II 2015 1rip111176No ratings yet

- The Development of A Teachers Self Efficacy Instrument For High School Physical Education TeacherDocument6 pagesThe Development of A Teachers Self Efficacy Instrument For High School Physical Education Teachercoroline0% (1)

- Introduction To Production Engineering: Somali National UniversityDocument1 pageIntroduction To Production Engineering: Somali National UniversityAbdi samad MohamedNo ratings yet

- CTMS Example - Motor Position Control ModelingDocument4 pagesCTMS Example - Motor Position Control ModelingSinggih AndreansNo ratings yet

- Retainer Brite TabletsDocument4 pagesRetainer Brite TabletsRohan BhagatNo ratings yet

- Autodesk Nastran In-CAD ComparisonDocument3 pagesAutodesk Nastran In-CAD ComparisonlsgmzNo ratings yet

- Convert The Following QuizDocument3 pagesConvert The Following Quizsammie manlapaoNo ratings yet

- MBA-BS-Recap Session Model Questions-13-07-2023-SV1Document74 pagesMBA-BS-Recap Session Model Questions-13-07-2023-SV1seyon sithamparanathanNo ratings yet

- Electromagnetic Flow Meter Elmag 200 ManualDocument39 pagesElectromagnetic Flow Meter Elmag 200 ManualmjsampaioNo ratings yet

- Floor PlansDocument11 pagesFloor PlansDaniel KoloNo ratings yet

- Managing FILESTREAM Data Win32Document9 pagesManaging FILESTREAM Data Win32bc2255No ratings yet

- IET Wiring Regulations (BS 7671:2008+A3:2015) - SECTION 702 SWIMMING Pools and Other BasinsDocument7 pagesIET Wiring Regulations (BS 7671:2008+A3:2015) - SECTION 702 SWIMMING Pools and Other BasinsBrandon LevineNo ratings yet

- Brailovskaia, Bierhoff, & Margraf, 2019Document15 pagesBrailovskaia, Bierhoff, & Margraf, 2019royNo ratings yet

- Bagas Ari Nugroho Skema Jaringan Warnet Dan ModemDocument18 pagesBagas Ari Nugroho Skema Jaringan Warnet Dan ModemAgung Agil SaputraNo ratings yet

- Class 10 SAI Science Paper 2014Document13 pagesClass 10 SAI Science Paper 2014poojaNo ratings yet