Professional Documents

Culture Documents

THAI 4A GQP 21 01 2504 - Rev3

THAI 4A GQP 21 01 2504 - Rev3

Uploaded by

Bith SMG0 ratings0% found this document useful (0 votes)

26 views28 pagesOriginal Title

THAI-4A-GQP-21-01-2504_rev3

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views28 pagesTHAI 4A GQP 21 01 2504 - Rev3

THAI 4A GQP 21 01 2504 - Rev3

Uploaded by

Bith SMGCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 28

BONGKOT FIELD DEVELOPMENT PROJECT

PHASE 4A

CENTRAL FACILITIES

QPS AND FLARE TRIPOD

SS NDT PROCEDURE

& NDT TECHNICIAN CERTIFICATE

FOR

DOORS AND WINDOW

Oi as

3 | otaeto | om |! Approved for Construction He Le

2 | stmerao | se ‘see or apervet HL Po

1 | isrens0 | ve Rescued er eamments HL Po.

0 | zieo0 | sm Issued for Comments HL ro

a» | za0e000 | sw Iuaued fr DS He PO

fee | Eeowre [a O=SCRIPTION ERORGETG BAUM | APPROVAL [Generar

‘STATUS CODE : A= lssued for Comment - B = Issued for approval ~ C= Approved

TOTAL OR PARTIAL REPRODUCTION AND/OR UTILIZATION OF THIS DOCUMENT ARE FORBIDDEN

WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE OWNER

PTT Exploration and Production

i) BONGKOT FIELD DEVELOPMENT PROJECT — Phase 4A

rrguettuca ran

Saas

EI THAI-4A-GQP-21-01-2504 REVISION ‘STATUS Ee |

FTIEe : ec SERVICES

I ‘SS NDT PROCEDURE & NOT TECHNICIAN CERTIFICATE aes

al THAI-4A-GQP-21-01-2504

Doors AND WINDOW: Revision 3 os. Status:

Decumentiype: 04 Discipine: 29 Rew Oa: 01-0070 _| Page 2ef 23

GF Jop No, POG-07.0280 88 Jeb No: $5515, PTTEP Contrat No: PDG.07.0240| J

TABULATION OF REVISED PAGES

REVISIONS eo REVISIONS,

TTS les z Ze

a

52

33

54

=

56

|| a ||| na || ||] || |e af |e a > | af

x |v || ne] |e a | ne fe |e an fe fe [>

96

7

98

0

wo]

“This ccument he groper of COMPANY anal nth tore, eprdiced or dsclsedt cher wie suhaizaion fom the COMPANY.

‘8S NDT PROCEDURE & NDT TECHNICIAN CERTIFICATE

FOR

DOORS AND WINDOW

Dee Na:

‘THAI-4A-GQP-21-01-2504

Rovson 3 {ee Stats:

Document typ: OY

Dicciptne 24

Rev, Date: 01-Apr-10 rece Sof 28

IGF Jeb No. POGU7-0240

SS Job No: 85115

TEP Contrast No: POG-07.0240

TABLE OF CONTENTS

1. WP 9.2 - MAGNETIC PARTICLE INSPECTION

2. WP 9.3 - PENETRANT TESTING...

3. SS - NDT TECHNICIANS QUALIFICATION LIST & CERTIFICATE.

‘Ths aecuer she property of COMPANY k mustrot be sod, epoduces of sosad io ches wihou wuss om the COMPANY,

SPECIALIST

SERVICES

WORKS PROCEDURE

FOR

P.O. Box 2782, Dubal, UAE.

Tel ¥ 871 a3er2646

Fax +97 aaeratde

‘specsen@enirates.net ae

MAGNETIC PARTICLE INSPECTION

Document No. WP 9.2 Rev7

| 14 6x09 | Raven Sealon £7 HL

| 1G Nov 06 [Revised as mariced SH cs TAF

3 [08 Oct 04 | Revised as marked HE, CF, CAF,

“4 |"1i Dee 03 | Revised as marked Ht CF CAF,

'3_| 16 Oct 03 | Latest MPI repor raviaen Wocporated, He oF, CAF,

2 [18 Jan 00 General Updo DE car PB,

7] 02 Feb 98_| Second tesve DREAT CAF FB

[28 Oat 94 | Fist fesue DRE CAE Po

REV] DATE | DESCRIPTION PREPARED | REVIEWED | APPROVED,

SPECIALIST J MAGNETIC PaRTicte inspection [Bee [wees

vision

amnceel ea |

PAGES AFFECTED BY THIS REVISION

"T___ REVISION REVISION

PAGE [oltl2[s|[41slel7| PACE Pps

7 X[X|x x

2 ESESES x

3 X[X[X x

a XLXP XT [x] x [x]

6 x[xX[x + x [rey bal

6 X[x tT x

7 X[XPX PX | [x

Perry

FE i

[ Seeeeeea ee fey

TeCECrt

il

| Ht—H

{- et a

4

a

+ |

Jt

[

} acl MAGNETIC PARTICLE INSPECTION

SERVICES

DOCUMENT REVISION STATUS...

TABLE OF CONTENTS

1.0

2.0

3.0

4.0

50

6.0

7.0

8.0

9.0

10.0 ACCEPTANCE CRITERIA...

11.0 REPORTING.

TABLE OF CONTENTS

SCOPE

PERSONNEL QUALIFICATION...

REFERENCE...

EQUIPMENT.

SURFACE PREPARATION.

MAGNETIZATION TECHNIQUE ..

EXTENT OF COVERAGE

DEMAGNETIZATION

EVALUATION OF INDICATION ...

4.0.

2.0

3.0

4.0

SPECIALIST | MAGNETIC PARTICLE INSPECTION

SERVICES

SCOPE

This Magnetic Particle Procedure outlines the equipment, technique, surface

preparation and acceptance standard for the testing of welds and material using ‘Wet’

continuous colour contrast method, The extent of examination shall be as per project

requirements,

PERSONNEL QUALIFICATION

241.

Individual performing Magnetic Particle Inspection shall be qualified to a

minimum of Level I and Level | as per ASNT document SNT-TC-1A 2004

Edition, Level | may perform Magnetic Particle Inspection under the direct

supervision of a Level Il or Level Ill, Evaluation of Magnetic Particle

Examination shall be performed by the Level Il or Level Ill.

REFERENCE

31.

3.2.

AWS D1.1 (Latest Edition)

ASME Sec. V (Latest Edition)

3.3. GS EP STR 301 Rev. 05

3.4 AWS D1.3 (Latest Edition)

EQUIPMENT

4.1, Permanent Magnetic Yoke or Electromagnet

4.2. Black magnetic Ink (Magnaflux 7HF)

4.3. White Contrast Paint (Magnaflux WCP 2)

44, Equipment Calibration Requirement

4.4.1. Calibration shall be checked before the start of examination on a daily

basis. The magnetizing force of a yoke can be tested by determining

its liting power on’a steel plate. AC Yoke shall have the lifting power

of at least 10 Ibs. at the maximum pole spacing where they will be

used. Certified lifting weight shall be used. Calibration of yoke to be

cattied out regularly and a log book to be maintained by according to

ASME Sec V.

4.8, Consumable Contamination Requirement

4.5.1. Consumables shall be free from halogenated compound and a batch

cerfificate shall be obtained from the manufacturer to verify the same

and documented for reference.

SPECIALIST § MAGNETIC PARTICLE INSPECTION

14 Oct 09

SERVICES

5.0 SURFACE PREPARATION

5.1. Prior to examination, the surface to be examined and all adjacent areas within

at least one inch should be essentially clean, dry and free of contaminants such

as oil, grease, loose rust, loose sand, loose scale, lint, thick paint, welding flux,

and weld splatter.

5.2. Method for surface preparation may be accomplished by detergents, organic

solvents, or mechanical means such as grinding, wire brushing, etc.

5.3. When testing a local area, such as weld, the area adjacent to the surface to be

examined must also be cleaned one inch from either side.

5.4, The inspection should be cartied out once the completed welds reach its

ambient temperature and the surface preparations have been done.

6.0 MAGNETIZATION TECHNIQUE

6.4. AC Yoke or permanent magnet - Longitudinal Magnetizing Technique.

62. When it is necessary to verify the adequacy of the magnetizing field, The

magnetic particle field indicator or burmah castrol strips shall be used by

positioning the indicator on the surface fo be examined.

6.3. After preparation have been carried out, the non- magnetic white contrast paint

shall be applied to the surface following the magnetic field which does not

exceed in temperature of 135°F, and the magnetic ink will be sprayed on to the

weld area. Each part must be magnetized in at least two directions

approximately at 90° to each other.

64. A thin coat of WC paint is applied prior to testing for contrast. A sensitivity

check with burmah castrol strip shall be demonstrated with same amount of

WC coating on the strip, kept on the test surface,

6.5. The wet suspension of particles shall be sprayed on the surface whilst the

‘magnetizing force is present.

7.0 EXTENT OF COVERAGE

7.1, When using permanent magnet, the inspected area shall be considered to be

not greater than the area of the circle inscribed between the pole pieces. The

extent of coverage shali be 100% unless specified. Overlap of 10% of each

area will ensure proper magnetic coverage of the surface.

i

|

|

|

|

I

|

|

|

i

1

i

i

|

SPECIALIST §— “MAGNETIC PARTICLE INSPECTION | Doo. No. | wP 92

SERVICES Page| Oat 7

8.0

9.0

10.0

11.0

Revision | 7

Date [14 0ct08

DEMAGNETIZATION

8.1. All Ferro-magnetic material will retain some residual magnetism, the strength of

which is dependent on the retentivity of the part.

8.2. Demagnetization is required only if specified in the drawings, specifications or

purchase order.

8.3. Method for demagnetization is accomplished by subjecting the part to a fleld

equal fo or greater than that used to magnetize the part, then continuously

reversing the field direction while gradually decreasing it to zero.

EVALUATION OF INDICATIONS.

9.1. _ Discontinuities will be indicated by retention of the magnetic particles. All such

indications are not necessarily defects however, since excessive surface

roughness magnetic permeability variations (such as at the edge of heat

affected zona); may produce similar indications. If indications are believed to be

non-relevant, each type of indication shall be explored to determine if relevant

discontinuities are present. Only indications which have any dimensions greater

than 1/16 inch shall be considered relevant, Relevant indications shall be

assessed in two categories. i.e. ‘Rounded’ and ‘Linear’. A linear indication is

‘one having a length greater than three times the width,

9.2, Evaluation shall be done under visible light of minimum intensity of 1000 Lux or

100fe.

2.3, Post cleaning shall be done by grit blasting to SA 2.5 to assure removal of all

‘White contrast paint

ACCEPTANCE CRITERIA

All surfaces to be examined shall be free of:

10.1. Relevant linear indications.

10.2. Relevant rounded indications greater than 3/16 inch.

10.3. Four or more relevant rounded indications in a line separated by 1/16 inch or

less, edge fo edge.

REPORTING

11.1. NDT (MPI) Report shall clearly and unambiguously identify the component(s)

tested and the status of that component after interpretation to the relevant

acceptance criteria. All reports shall be ‘Signed-off and ‘Stamped’ by

appropriately qualified and certified technicians.

SPECIALIST § MAGNETIC PARTICLE INSPECTION [Doz No.

11.3

‘-RVICES Page

11.2.

Revision

Dato

The report shall include as a minimum the following information:

Client

Project

Contract Number

Job Number

tem

Report Number

MT Procedure Number

Weld Number

Welding Procedure

Welder Identification

Acceptance Criteria

Accept/Reject Status

Name and Signature of NDT Technician

i

Form

Form No. WP 3.1 NDT (MPI) Report Rev. 3

14 Oct 08)

S|

SERVICES

NDT (MPI) REPORT

PROM]

‘CaDERHOL

‘$5.08 N04

Lgcarion

TeuTest=n|

MATE

Tar FRocenuRe|

‘GG. INSPECTOR:

FORME) NOT (MPD REPORT REV.3 14.0508

Fosaard Oz Spx Gees ond Spe Senna asareew

0. Boxse17 Abu iol UAE

‘Spelt Seton Ari, P.O. ox 282, Out LAE,

pei onde Opertane ar Foster Yo,

HG ee se, Dab UAE.

9. bse 22,9

ran aries

Fox Tenitasriet

SSececagpecsnvecan

Wiorapaceanacen

|

pe i povneten oie uve

SERVICES Decerganiteaoe

WORKS PROCEDURE

FOR

_PENETRANT TESTING

Document No. WP 9.3 Rev 2

De, AE

DRE, CAF

PREPARED | REVIEWED | APPROV:

Pa

ZEB.

ECIALIST

PENETRANT TESTING

SERVICE;

DOCUMENT REVISION STATUS

REVISION REVISION

PAGE [TolTay2 13214) ‘PASE [o 27314

7 x] Xx

2 xx

3 x [x

4 x x

3 xX

6 x [Xx

re x

ECIALIST PENETRANT TESTING

SERVICES ee

TABLE OF CONTENTS:

DOCUMENT REVISION STATUS.

TABLE OF CONTENTS.

4.0 SCOPE

2.0 REFERENCE...

3.0 DEFINITIONS...

*

40

6 Dwell Time.

47 Removal of Exces:

Developer Application.

DOTTDADSAD

440

5.0 ACCEPTANCE,

o ©

60 RECORDS.

2.0

3.0

4.0

SPECIALIST

SERVICES

Doc. No, | WP 95

PENETRANT TESTING Revision [2

Date | 09.0ct2004

Page _[4of 6

SCOPE

This document describes the application of the non-destructive testing method of

Penetrant Testing at Specialist Services Factory and work sites.

REFERENCE

24

22

23

24

25

ASME Section V (Latest edition) Non-destructive Testing

ASNT SNT-TC-1A (Latest edition) Recommended Practice for Personnel

Qualification and certification in Non

Destructive testing.

AWS D1.1 (Latest Edition)

AWS D1.3 (Latest Edition)

GS EP STR 301 Rev.5

DEFINITIONS

NDE Inspector A qualified and certified individual who conducts the testing

as described in this document, records test results and

evaluates the same for acceptance. He shall be certified to

at least Level Il per ASNT SNT-TC-1A,

Area of interest The actual test region and adjacent area of width at least 1

inch on either side of it.

PROCEDURE

4a.

Responsibilities

The concemed production supervisor is responsible for preparation of the test

items for Penetrant Testing.

The designated Quality Control Inspector is responsible for selection of the

items or areas to be tested. This is applicable where spot testing is conducted

per project specifications.

The NDE Inspector assigned for conducting the actual test is responsible for

following this procedure and reporting of test results in approved reporting

format.

In the case of sub contractors, the QC Inspector is responsible for verifying that

the operative assigned for the job is qualified and bears valid certification.

SPECIALIST

SERVICES

42.

4.3,

44,

45.

4.6.

PENETRANT TESTING Revision.

Personnel Qualification

Personnel conducting the test and recording test results shall be qualified and

certified at least level | (per recommendations of ASNT SNT TC 1A. The Level |

operator is required to perform the test and record results in accordance with

written instructions. He may be permitted to make specific evaluations in

accordance with written instructions. The level | operator shall function under

the supervision or direction of an individual certified to at least Level Il.

Personnel involved in conducting the test, recording results and evaluating the

same against applicable acceptance standards shall be certified to at least

Level Il (per recommendations of ASNT SNT-TC 1A)

Consumables

Penetrant : Magnaflux - SKL SP1

Cleaner: Magnaflux - SKC - S

Developer: Magnaflux - SKD - $2.

The test consumables shall be in accordance with the applicable Client's

specification. This test procedure calls for the use of a visible solvent-

removable dye combination with a wet solvent-suspended developer.

The total sulphur and chlorine contents of the test consumables shall be

controlled to the requirements specified in ASME Section V. Batch Test

certificates of conformity shall be kept on file as part of the quality records in

the company.

Consumables shall be used in sets purchased from the same manufacturer.

Brands of dye and developer may not be mixed. Cleaners of different brands

may be used provided that the requirements of chlorine and sulphur limits are

complied with

Surface Preparation

The test surface and an area at least 1 inch width on either side of the test

surface shall be free of dirt, grease, rust, lint, weld spatter and other extraneous

matter which may interfere with the effectiveness of the test. If the surface to be

tested is coated with paint it shall be thoroughly cleaned off with paint thinner

and solvent cleaner to ensure that the test surface and at least 1 inch on either

side is exposed for the test.

Application of Penetrant

The dye penetrant shall be applied to the test surface to provide a thin uniform

coating over the entire area of interest and temperature shall not exceed 50°C.

Application may be done by means of spraying on, brushing or swabbing with

lint free cloth.

Dwell Time

A dwell time of at least 5 minutes (or as otherwise recommended by the

manufacturer or the applicable specification) shall be permitted to allow for

proper penetration of the dye into the discontinuities sought to be identified.

50.

6.0.

PENETRANT TESTING

4.7. Removal of Excess

After elapsement of the Dwell Time, the excess penetrant shall be removed

from the area of intetest. This shall be achieved by means of dry wipes

followed by wet wipes. Wiping is eccomplished using lint-free cloth or

absorbent tissue. Wetting as necassary is done with the cleaner.

48 Developer Application

‘The developer is applied by means of spraying on.

The application shall aim fowards imparting a thin uniform flim of developer on

the area of interest. Blotches and drips shall be avoided.

49. Observation

Development of indications shall be actively observed from the time of

application of the developer for a period of at least up fo 7 minutes.

Interpretations and evaluation may be done after this time. In any case,

observation perfods in excess of 30 minutes are not necessary.

440 Reporting

This shall be done on the format appended at the end of this document. Other

Jommats as may be approved or specified in Contractual Specifications may be

used as alternatives.

ACCEPTANCE

5.1, Acceptance of test results shall be in accordance with Clients’ specified

acoeptance standards. If not specified by the Client, the following will be the

acceptance criteria:

5.2 Linear indications in excess of 1/16” in major dimension are acceptable up to 4

in number on any test surface.

5.3 A linear indication is one in which the major dimension is equal to or excess

three times Its least dimension. Rounded indications are those which cannot be

categorized as linear indications.

RECORDS

64 The NDE (DP!) Reports shall form part of the Final Project Quelity

Documentation.

6.2 Form

Form WP 3.2 NDT (DPI) Report, Rev.3

oO

SPECIALIST

SERVICES

2.0. Box 2782, Dubal, UAE.

Ta +971 aaa7a6as

Fox S971 4aa72i4e

‘specserve@specserve.com

‘wuw-specserve.cam

NDT (DPI) REPORT

PROKECT REFORTNOL]

BeuaNaTion pave

‘ORDER NO! DEgREASER|

53.108 No. PENETRANT!|

LocaTtON DEvELoreR|

TEMTESTED: PeeTRaTion Te

Devt

MATERIAL \vewnis conomian|

SURFACE conomrion| ‘TEST TENPERATUF

bP] PROCEDURE; ‘ACCEPTANCE cReTERLA) z

raving:

Weld Result

IG. INSPECTOR:

Name:

Lovet:

Signature:

Date:

FORNWPSENDT OP REPORTREGS 197g

Registered Ofoes Spectllst Sovioes and Spedliat Services Resources,

P.0.Box S017, AtuDRGHLUAR.

‘Specialist Services Arabvan, P.O. Box 2752, Dubai, UAE.

Specialist Services Operations and Fabrication Yard,

SERVICES

P.O, Box2782, Dubel, UAE.

Tol sartaaereeas

Fox 997143472148

specsono@apecserve.com

worw speeserve.com

SPECIALIST SERVICES NDT PERSONNEL DETAILS

seta | Nanectrominnt| MEO | wots | teedate | Duedate | Renate |

——|

tae | ve | teams | Teapert

welt | wv | teamee | teaorsi

1 N. Sadiq, ‘MULTI

Teva | pF | eames | teapet

‘eel! | RT| asreba0 | aerebia

‘weit |v | amos | toate

tei | wr | 2000000 | adeeta

im Rejith Satyapatan MULTI

‘wait | Pr | 20D0009 | zo-peoa

Tova | RT| aesabo0 | oeremia

Pe

Toit | RF | vamos | crasera

3 | voncoote wun

Level tt ur (G1-Apr-08 OLApr-12,

Level It PT Ot-Apr-09 Of-Apr-12

Tova | vr | teamoa | tearert

2 | sumac. tevaii | wT | zode009 | aoccete | MULT

test | meet

‘SS NOT Technician tt R$ 28.02509

P.O, BoxG0i7, Abu Diad, UAE.

‘Specials Sendoes Arb, P.O. Box 2762, Dada. UA,

Spoctoist Senisse Oparton end Fetriaton Yor,

‘Al Quse nti! Estat, Dube, UAE.

SPECIALIST, 7.0. Box 782, Dabo, UAE,

Jol Sart 4eraee

Fax FON AUTRH0

SERVICES spaccenveG@specsariecom

‘wannepaccervacom

CERTIFICATE OF PROFICIENCY

‘This dooument congirms thst

Mr. N. SADIQ MOHIDEEN

las net requirements of transi and experience inthe non-destructive testing methods)

ed below scrrng th reqaieers of Ameen ceety fr Nondedetie

"teas, U.S.A. document SNT-TC-LA and- ‘

‘Specialist Services Written Practics.

Ho has-bcon examined accordingly and qualied to tis evel of proficiency specified baléw,

“METHOD TEEVEL |" PASSAT VAD TILE

VistAT, TESTING i pel 19, 2008 ‘Apa 1, 208i

[ MAGumnICpaRcEE |i] apart, 208) Aa OL

TESTING :

oO SENETRANTTESTING |_| Apa i200 | Ape, 200

Company fore IL Company Representative

[AGESWARAN Ba

tuamece ve HILLARY LOPES

"Fhe Na QAIQGIHSE MANAGER

ae SPECIALIST SERVICES

RRR RRR ET ae

SPECIALIST, P.O, Box 2782, Dubel, UAE.

Ta reriaaerseas

. SERVICES eedetaenoreere cee

winvshecsorve.com

CERTIFICATE OF PROFICIENCY

‘This document confirms that

‘Mr.N. SADIQ MOHIDEEN

‘Has met fequirementsoftrining ad experienc inthe non-destutive esting mathodls)

‘tat below sscondingto the requirements of Araetionn sclety fit Nondestructive

: taxing, USA, documest SNT-TC-1A oad eH

* SBR SPICES WHIEEN PERRIS:

- +» «-Hohas been examined socorngly and qulifid to the eve of roficiencyepocfed bela...

METHOD ‘LEVEL | PASSDATE ‘VALaD TLL

RADIOGRAPHIC A

||_INTERPRETATION . 0 wep, 25,2009 |Web, 24,2012 Fee

Company Level 111 7 Company Representative

: % HILLARY LOPES |

¥.NAGESWARAN QNQCHSE MANAGER

‘77 KOE Lee SPECIALIST SERVICES

‘Tapered ee Saat een and Spat Savona Haein,

cee IA ame ien rane 4 =

iPECIALIST, P.O. box 2782, Ciba UAE,

eee

SERVICES specsorve@apnesbrantom

emai

CERTIFICATE OF PROFICIENCY

‘This document confirms thet

Mr. REJITH SATHYAPALAN

Has ret requirments of training and eerie ta th non-destrctye testing method{s)

: _ - Slated below acebrding tothe equtemets of Asierian sooty fr Nondestmtiva

» testing, USA, document SNETC-IA cad

‘Specialist Servoes Witten Practice,

~Hohes been examined accordingly and qualitfed to the lovel of proficiency specified betow-

TERT Tava [RISD VADER] |

ViSUAL TESTING iia Apr 008 Tpri 9, 300 |

|

Company Lael Company Representative |

V, NAGESWARAN FE 7

Ménvvacen aso TLARY LOPES

unsnorave

rue anacmise anager

ict He ager

age pa aa wd SPR SiR, ==

P.O, Box 2782, Dubal, UAE.

Te

Fax

Specserve@speceerve.cem

“+974 43472648

+971 4aa7214s

wrwspecserve.com

CERTIFICATE OF PROFICIENCY

‘This document continms that

Mr. S, REJITH

Hes met requirements of training and experience in the non-destructive testing

“Mathod(a) stated below according to the requirements of Ameticen Society for Nondestructive

Testing,

0, 8, A.. document SNT-TC-1A and

Specialist Services Written Practice.

He bas been examined acordingly an qualified to the level of peolictency specified below:

MAGNETIC PARTICLE

TESTING ©

| Bee. 20; 2006

PENETRANT TESTING

n Dee, 20, 2006

ilo No. 78788

HILLAY

ence kOPES

SPECIALSY SenVCES

Svan

‘Company Representative

ity ofcateanesntn 20-12-2012

eterna

Regislared Oifices Spaciais! Sendeas and Spstalit Seneca Resources,

2.0. Gott 2917, Abu Dnabl, UAE.

Speck

list Sonioes Arabvan, P.O. Bot 2782, Dubal, UA.

‘Spedialst Services Operations and Fabrication Yard.

CERTIFICATE OF PROFICIENCY

‘This docamant canfinis thet

‘Mr. REIITH SATHYAPALAN:

P.O, Box282, Dube, UAE,

Tel tevt aaurzese

For Sar asraias

spacserve@spocservescom

winm-spacesrve.com

Has mst cequirements of training and experience in the noa-destractive testing method(@)

stated below nocording to the roquirements of America socity for Nondestryative

1 testing, USA, document SNT-TC-IA'end

*—agpeebinseServIEes Writer Practice

‘He has been examined accondingly aud qualified tothe lovel of proficiency specified below. att

T

verso | raven] asspare | -Varso rm

pe a ob. 25,2009 sa4012 |

‘Company Level EIT Contpany Representative

Pal

‘V. NAGESWARAN

ASNT VAC Lae

UnMT Pra vr

Flee 5008

OPES

HILLARY LOPES |

SPecwsT SERVICES

i

ageea One

P.O, Bor S917, Abu Dhabl, DAE.

i Gaclons and Spacabl Bons Resouces,

SPECIALIST

I SERVICES 1

CERTIFICATE OF PROKICIENCY |

‘This dooument confirms that

‘Mr. VIEIN GEORGE

3.0. Boe 2789, Dube, UAE.

Tol ears sserz64s

Soe FT uTaiAs

‘speeserve@apasrerve,com

vweaw.spacearvason

‘Has inet meguirements of taining and experieie in the non-destructive testing methods)

_ stated bslowe epoording to the requires of Antecigan soclcty for Nondestructive

‘testing, U.S.A, doeumment SNT-TC-1A oad °"

‘Syiecialist Services Written Practice,

‘Ho his been éxamined accordingly and qualified to ths tevel of proflfnoy specified balow.

RTHOD TRVEL | PASDATE | VAL TILE

WSGAE TESTS [Apa aos | Ape 12081

Company Lapel IE ‘Company Representative

V.NAGESWARAN

ASNTIACCE Level IL

TUT MT FT YT

le We 708

"HILLARY LOPES

BARGASE NANAGER

Sprciusr seRvCes

i

0, ox 2752, Dubal, ULE,

Tel +974 g2zrates

Foc Fert asrae

apeceerve@specservacon

wonapecservecom

CERTIFICATE OF PROFICIENCY

This document confrrs thet

. Mr. Vi

in George

‘Hes met roquiremait2 of training iid experience in the non-destructive tistingg

Method) stated b og oe eae of Amerem Society th Nondsiue

z im “OSTA, SoeiMeNESN TTC a

Specialist Services WrtteiPracticn.

He lias been exaunined accordingly and qualified tothe level of proficiency’ speaified below:

RADIOGRAPHIC testina* | at | api, 02,2006 "| Apr.dt 2009

MAGNETIC PARTICLE a Z

TESTING at | Apr.0t,2006 | apr. 04 2008

PENETRANT TESTING mt | apr.ot,2006 | Apr-01, 2009

$+ Carte for Radiograph Fim “gy eeofiee (tracts, elpingand prasare wera

V, NAGESOWARAN

“AGNT/ACCP Lovet 111

AT, UT, MT, PT AVY

File Ko. 78758

x Fiat 108

ASNTTACEE Lev GAA 7a

‘Ragiioned Offs Spaclal Savion and Saari Ravine Rawriwrbe

P.O, Box 2782, Dutal, UAE,

Tel +974 aira6ds

Fox 97a aerais + -

spscasive@specservacom

“mwowapeceares.com

SPECIALIST

SERVICES

CERTIFICATE OF PROFICIENCY

“This doouant confi tht

“My SINUM.C

“Hla metregurementsoftaining end eimorlonce in th non dectrtve testing methods)

stated belovy accdiding fo the requirements of American society hr Nondestructive

a “bekting, U.S.A,; document SNT-TC-1A end *‘*

‘Sprcatist Svions Writen Practice,

He has been xaaniced aeostingly and quilted othe level of pofitenayspectted beta,

fe "METHOD Lo PASSDATE |, VALID TELL

iE ‘VISUAL TESTING | Tea, OSA TS, ST

Company Level I Company Representative,

Y.NAGESWARAN : HILLARY LOPES

ASNT/ ACCP Le |. ONGCIHSE MANAGER

UT ARE EV SPECIALIST SERVICES.

{Saris Reson,

‘Raaiarad Onions Sasol Savas and Soom

Cc

Td sart's varzten

Fx von a3e72idg

wwaispecoervecor

‘CERTIFICATE OF PROFICIENCY

‘This document confirms that

Mr. 3INU M. C.

His met equlrements of aiing and experience ia the non destueive testing

" Misthod{) stated below accarding to the requirements of American Society for Nondestructive

Testing, U.S. A., dociment SNT-TC-1A and

Specialist Services Written Practice.

Hie has been examined!aécordingly and qualified to the level of proficiency specified below:

“Dec. 20, 2009

Company Representative

SPECIALIST SERVICES,

POBox : 2782, Tals 043472648

Fans 06472148 - DUBAI -U.AE,

aye to 20-12

yea rime 26 12-2012

Boao of

ASNT/ACCP Lovet 111,

BT, UT, MT. PT & YT

File No, 78788

xi a 19k

ASNTIAGEP LSU TE VD)

P.0.Box 2782, Dubal UAE.

sptcssrva@speesorve.com

‘Registered Oficas Speciatel Sevicas and Spdalnl Senioes Recoubet,

0. Box 9917, Abu Blatt, UAE.

‘Spetialist Services Arabvan, P.O. Bos 2782, Dube, UAE. -

‘Speclaist ewicas Operations and Fatwication Vari

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- THAI 4A GQP 21 01 2507 - Rev5Document17 pagesTHAI 4A GQP 21 01 2507 - Rev5Bith SMGNo ratings yet

- THAI 4A GQP 21 01 2505 - Rev3Document10 pagesTHAI 4A GQP 21 01 2505 - Rev3Bith SMGNo ratings yet

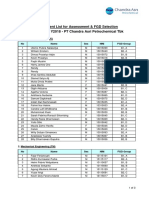

- (ITB) Pengumuman Seleksi Assessment & FGD 2018Document3 pages(ITB) Pengumuman Seleksi Assessment & FGD 2018Bith SMGNo ratings yet

- Contoh Format WIDocument2 pagesContoh Format WIBith SMGNo ratings yet

- Alpha Pinene LibDocument13 pagesAlpha Pinene LibBith SMGNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- Format Data Tim SuksesDocument1 pageFormat Data Tim SuksesBith SMGNo ratings yet

- Masterbatch Processing - PT Kasakata KimiaDocument9 pagesMasterbatch Processing - PT Kasakata KimiaBith SMGNo ratings yet