Professional Documents

Culture Documents

BEP Black and Grey Tank Sender Ts1

Uploaded by

artemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BEP Black and Grey Tank Sender Ts1

Uploaded by

artemCopyright:

Available Formats

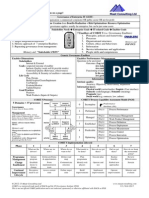

TS1

Ultrasonic Tank Sender

Installation and Operating Instructions

For TS1 Firmware v3.8

INST-TS1-V13 Page 1

18/11/10

Downloaded from www.Manualslib.com manuals search engine

Table of Contents

1. FEATURES ....................................................................................................... 3

2. SPECIFICATIONS ............................................................................................ 3

3. DIMENSIONS.................................................................................................... 4

4. MOUNTING AND INSTALLATION ................................................................... 5

5. WIRING ............................................................................................................. 9

6. PROGRAMMING AND SETUP....................................................................... 10

7. PROBLEM SOLVING ..................................................................................... 10

8. FREQUENTLY ASKED QUESTIONS ............................................................ 11

Important TS1 Installation Issues

1. The sender must not be mounted closer than 150mm from the

centre of the sender to sides of the tank, baffles or other intrusions.

2. Only use on tanks greater than 200mm in depth.

3. Sender must be mounted parallel to the surface of the liquid.

4. Do not install on flexible tanks that may bulge/distort as fluid levels

change.

5. Check unit is calibrated to suit tank shape, depth and fluid type.

6. Make sure that sender protrusion is NOT in contact with any

object including sealants when mounted.

7. Use gasket and fittings as provided.

8. Mount above deepest point of the tank.

INST-TS1-V13 Page 2

18/11/10

Downloaded from www.Manualslib.com manuals search engine

1. Features

12V and 24V operation

Extremely low profile only 20mm high once mounted

Operating distance of 0mm to 2000mm maximum

Programmable tank dimensions via windows application

Linear and non linear tank calibration at 5 levels

Supports metal and plastic tanks

Supports tanks wall thickness up to 6mm (or larger if spacer is used and top limit

adjusted)

Industry standard SAE-5 stud mounting pattern with gasket seal and washers.

Supports analogue gauge types 10-180, 300-10, 240-33

Supports Digital meter that require 0-5 volt inputs

Operating temperature range of 4°c to 65°c

2. Specifications

Electrical

10VMIN to 32VMAX DC.

Ignition protected to ISO 8846

Fire Resistance tested to ABYC, US Coast guard and ISO10088

Output types: Analogue 10-180, 300-10, 240-33 ohm gauges and 0-5volt

Environmental

Resistant to Petrol, Diesel, Water, and Chemical Toilet.

Maximum Tank depths

Operating distance of 0mm to 1100mm for Petrol tanks

Operating distance of 0mm to 2000mm for Water tanks

Operating distance of 0mm to 2000mm for Diesel tanks

Operating distance of 0mm to 1500mm at 55°c

Note: Liquids that may have a sound absorbing surface will limit tank depth or in the worst

case provide no return signal eg. foam bubbles or porous sludge.

Permanent liquid surfaces that are more than 3 degree’s off level will have a tank depth de-

rating effect.

Liquids that have higher viscosities than water (e.g. oil) may not propagate liquid ripples that

create a strong return signal. This will also have a tank depth de-rating effect.

Don’t use on tanks shallower than 200mm in depth as angular reflections will reduce

accuracy.

INST-TS1-V13 Page 3

18/11/10

Downloaded from www.Manualslib.com manuals search engine

3. Dimensions

19.64 [3/4"]

95.35 [3 3/4"]

ACOUSTIC

PROTRUSION

8.9 [3/8"]

95.35 [3 3/4"]

84.88 [3 5/16"]

INST-TS1-V13 Page 4

18/11/10

Downloaded from www.Manualslib.com manuals search engine

4. Mounting and Installation

68°

Ø5 [Ø3/16"]

72

°

80°

]

Ø42 [Ø1 5/8"] R27 [R1 1/16"

VERY IMPORTANT:

°

72

DIAMETER MUST NOT BE

LESS THAN Ø42mm

68°

INDICATES CUTOUT

GLUE

BARRIER

GASKET RING

TANK ACOUSTIC TANK

LID PROTRUSION LID

4.5mm 4.5mm

42mm

IMPORTANT

SIDE WALLS OF ACOUSTIC PROTRUSION MUST BE NO

CLOSER THAN 4.5mm TO THE TANK SIDES OF THE

CUTOUT HOLE

The acoustic protrusion should be positioned in the tank aperture in the centre of the

hole. The protrusion should ideally be protruding into the tank and not be recessed in the

hole. See drawing above.

For tightening screws ensure base and washers are sitting flat. Tighten screw until screw

head makes contact with the washer, and then tighten another 2 full turns.

Maximum torque for the mounting screws is 0.5 Newton meter.

Note: Drawing is not to scale. Please use the tank gasket as a template and make sure

the tank hole is 42mm.

INST-TS1-V13 Page 5

18/11/10

Downloaded from www.Manualslib.com manuals search engine

Case 1

TS1 must be mounted at the deepest tank point!

It is recommended the sender is mounted in the middle of the tank, this is particularly

important on low or no baffled tanks that are mounted in moving vehicles or vessels. This

allows the TS1 to average waves of fluid to the correct level when the depth is varying due to

wave slop.

Case 2

TS1 must be mounted at least 150mm from a vertical tank baffle, tank walls and piping.

INST-TS1-V13 Page 6

18/11/10

Downloaded from www.Manualslib.com manuals search engine

Case 3

Correct BEP Gasket must be used!

Use 5 washers provided, washers must be placed under screw heads to prevent rubber lid

damage.

Case 4

Acoustic protrusion must not touch the tank frame!

Case 5

TS1 must be mounted so it can see the bottom of the tank if the liquid is to be measured to

the bottom.

INST-TS1-V13 Page 7

18/11/10

Downloaded from www.Manualslib.com manuals search engine

Case 6

Inlet and Outlet piping must go in at least ⅔rds of the way in to the tank on grey and black

water tanks to stop water turbulence when filling.

Case 7

Do not fit the TS1 with a tube.

Case 8

Ensure bolts and mounting holes are aligned properly to keep plastic body isolated

acoustically from tank. Do not over tighten the screws.

INST-TS1-V13 Page 8

18/11/10

Downloaded from www.Manualslib.com manuals search engine

5. Wiring

Power must be removed before TS1 is connected to the system. Ensure wiring is

correct or else damage may occur rendering the device inoperable.

OUTPUT (GREEN)

OUTPUT (GREEN)

NEG (BLACK)

NEG (BLACK)

POS (RED)

POS (RED)

(GAUGE SHOULD HAVE DROPPING RESISTOR)

USE 24V RATED GAUGES FOR 24V SYSTEMS

G (S)

POS

POS

BAR

BAR

NEG

NEG

BAR

BAR

-

-

12V

12V

+

INST-TS1-V13 Page 9

18/11/10

Downloaded from www.Manualslib.com manuals search engine

6. Programming and Setup

TS1 Tank Sender Interface Box + USB-to-Serial Converter Cable

Computer with USB Port

(BEP P/N TS1) (BEP P/N TS1-PK)

Please visit the BEP website for the programming software.

7. Problem Solving

Water Tanks

After long periods of no use, condensation will build up on the roof of the water tank and the

sender face. If the water droplets are large, the sender will not be able to read the contents

of the tank accurately. This will clear with normal boat or RV use.

Waste Tanks

Large amounts of foam bubble on the surface of the liquid caused by detergents or washing

powders will result in the sender not receiving reflected sound pulses back from the liquid

surface, instead these will be absorbed by the bubbles until they disperse. Then normal

operation will resume.

INST-TS1-V13 Page 10

18/11/10

Downloaded from www.Manualslib.com manuals search engine

8. Frequently Asked Questions

Q: What is the signal update period?

A: Signal is updated in real time.

Q: Why is the tank level stuck on one value?

A: When the sender cannot measure a valid tank level, the sender will recover the last good

reading of the tank level from its own memory. This will be sent to the monitor until a new

valid level is found.

Q: Is the TS1 ignition protected?

A: The TS1 is ignition protected and approved. It is fully potted.

Q: On power up, the analogue gauge goes full scale then back to empty. After 5 seconds it

shows the correct level.

A: This is normal for a 10 – 180ohm analogue gauge.

Q: On power up, the analogue gauge goes full scale and then back to the correct level.

A: This is normal for a 240 – 33ohm analogue gauge.

Q: The gauge is reading full all the time.

A: 1. The most common problem is that the acoustic protrusion is touching the tank.

2. The incorrect gasket has been used specified gasket is a Cork/viton mix.

3. The sender is to close to the side of the tank.

4. There is an obstruction in the tank.

5. The mounting screws are not isolated acoustically from body (see. Case 8)

Q: Is the sender sensitive to electrical interference. Should we use shielded cable?

A: There is no need to use shielded cable, unless you are running a long distance and near

appliance cables that radiate noise.

Q: What is the maximum distance between sender and meter?

A: 50 metres.

Q: What support is there for the product?

A: Updates will be placed on BEP website.

Q: Why is the meter reading incorrect when tank is empty?

A: There must be some fluid covering the bottom of the tank for sender to receive a valid

return signal.

Q: What is the beam angle of the sender?

A: 300mm at 2M depth

Q: Can I use a sealant with the TS1 and gasket

A: Yes, but ensure sealant does not get on to protrusion. Also, do not over tighten screws

for purpose of providing a tighter seal. The screws should be tightened until there is

contact between screw head and washer, then another 2 full turns.

INST-TS1-V13 Page 11

18/11/10

Downloaded from www.Manualslib.com manuals search engine

BEP MARINE

55 Paul Matthews Road,

Albany, Auckland 0632

New Zealand

PO Box 101739 NSMC

Phone (+649)4157261

Fax. (+649)4159327

www.bepmarine.com

E-mail: enquiries@bepmarine.com

Please visit our website for the latest International Distributor List

INST-TS1-V13 Page 12

18/11/10

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- BEP Marine TS1 Ultrasonic Sender User Manual enDocument12 pagesBEP Marine TS1 Ultrasonic Sender User Manual enfranciscoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Komac Compactor: Operation and Maintenance Parts ManualDocument32 pagesKomac Compactor: Operation and Maintenance Parts Manualhenry vegaNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Brother Hi TapDocument6 pagesBrother Hi TapMohd Asri TaipNo ratings yet

- JFEBEAR Running Manual (Rev.2)Document13 pagesJFEBEAR Running Manual (Rev.2)Cong BuiNo ratings yet

- Verti Drain 7212 AeratorDocument55 pagesVerti Drain 7212 AeratorBojan KitanovskiNo ratings yet

- Workshop SmallDocument35 pagesWorkshop Smallesteban marinkovicNo ratings yet

- Tap SPDOpInstDocument6 pagesTap SPDOpInstjschaudtNo ratings yet

- MODEL 82206 Bare Reel Series "Q": Owner/Operator ManualDocument9 pagesMODEL 82206 Bare Reel Series "Q": Owner/Operator ManualLuis Carlos González LondoñoNo ratings yet

- BsdcatalogDocument2 pagesBsdcatalogrickbolgerNo ratings yet

- M806 ManualDocument21 pagesM806 ManualcoinsertelcaNo ratings yet

- Desmi Terminator Weir Skimmer: Operators ManualDocument30 pagesDesmi Terminator Weir Skimmer: Operators Manualhalf clanNo ratings yet

- PP1184 DocDocument60 pagesPP1184 DocJean Pierre NKUNZIMANANo ratings yet

- Protect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationDocument4 pagesProtect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationBurak YILMAZNo ratings yet

- Design, Machining and Installation ManualDocument49 pagesDesign, Machining and Installation ManualmayaNo ratings yet

- Manual Lewmar V700Document20 pagesManual Lewmar V700Eduardo Dantas LobãoNo ratings yet

- 07 Hydraulic HoseDocument18 pages07 Hydraulic HoseVilius BukysNo ratings yet

- 4 - Rubber Element SpecDocument4 pages4 - Rubber Element Speclich_tran01No ratings yet

- SY-5 Manual enDocument7 pagesSY-5 Manual entienNo ratings yet

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- PS120 Series: Fuel Strainer/PrefiltersDocument4 pagesPS120 Series: Fuel Strainer/PrefiltersZoelkifli mansyurNo ratings yet

- Rotametro KeyDocument2 pagesRotametro Keydocumentos.envirotestNo ratings yet

- Denison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationDocument35 pagesDenison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationZoran Jankov100% (1)

- Appendices V2Document76 pagesAppendices V2Nikola AngjelkovskiNo ratings yet

- AppendicesDocument69 pagesAppendicesIvan CanoNo ratings yet

- 20-1700 Slips CMSDocument7 pages20-1700 Slips CMSRahul M.RNo ratings yet

- TNB223RevC - FleXinspect M Application NotesDocument10 pagesTNB223RevC - FleXinspect M Application NotesGiuseppeNo ratings yet

- Manual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsDocument2 pagesManual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsMax SdNo ratings yet

- KESSEL - Oil / Fuel Separator KESSEL - Coalescence SeparatorDocument16 pagesKESSEL - Oil / Fuel Separator KESSEL - Coalescence SeparatorsterlingNo ratings yet

- Quick Couplers Mechanical Hydraulic 068700 PDFDocument26 pagesQuick Couplers Mechanical Hydraulic 068700 PDFSTEVHEN MARTHINNo ratings yet

- INDECO Service Manual PDFDocument61 pagesINDECO Service Manual PDFANTONIO LUGOCAL100% (3)

- Flange Spreader: Parts List and Operating Instructions ForDocument6 pagesFlange Spreader: Parts List and Operating Instructions ForTitanplyNo ratings yet

- KinetrolDocument8 pagesKinetrolimbasdNo ratings yet

- Design V260 Rotary Pipeline Ball ValveDocument16 pagesDesign V260 Rotary Pipeline Ball ValveTomás MercadoNo ratings yet

- Globe ValveDocument17 pagesGlobe Valveachmad firmanyahNo ratings yet

- Bomba Hidro Microcool GIANTDocument12 pagesBomba Hidro Microcool GIANTDiego VelezNo ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsmahesh_eilNo ratings yet

- Sterilmatic: Digital Electric Sterilizer Installation - Operation - MaintenanceDocument21 pagesSterilmatic: Digital Electric Sterilizer Installation - Operation - MaintenanceNoel GarciaNo ratings yet

- 08 6.H Pressure VesselDocument32 pages08 6.H Pressure VesselstargaxxxxNo ratings yet

- Flange Spreader: Parts List and Operating Instructions ForDocument6 pagesFlange Spreader: Parts List and Operating Instructions ForTitanplyNo ratings yet

- Operating, Service, and Maintenance Manual: Model Rph-20,000 Series Industrial Planetary WinchDocument20 pagesOperating, Service, and Maintenance Manual: Model Rph-20,000 Series Industrial Planetary WinchBoogi Andika TamamiNo ratings yet

- Minerbolter Class NotesDocument10 pagesMinerbolter Class NotesSivalya SivaramanNo ratings yet

- User Instructions Bull Wheel Liners 4-2010Document8 pagesUser Instructions Bull Wheel Liners 4-2010Alexander SladeNo ratings yet

- Lake Flow Meter Quick ManualDocument20 pagesLake Flow Meter Quick ManualSaint JossNo ratings yet

- Komatsu OilsDocument200 pagesKomatsu OilsBrian Careel100% (1)

- 3raico Engineers BlowersDocument9 pages3raico Engineers Blowerssunilhasabnis@gmail.comNo ratings yet

- Manual BS 1000853 4 USDocument12 pagesManual BS 1000853 4 USRao ImranNo ratings yet

- 4 Marine Design Machining TENMATDocument49 pages4 Marine Design Machining TENMATWalter JosephNo ratings yet

- Packet H Chain SawsDocument8 pagesPacket H Chain SawsForum PompieriiNo ratings yet

- BT Series Owners Manual - CombinedDocument142 pagesBT Series Owners Manual - Combinedalejandro777_eNo ratings yet

- 4 Marine Design Machining TENMATDocument49 pages4 Marine Design Machining TENMATDanar BayuNo ratings yet

- Victor 1 IngleseDocument15 pagesVictor 1 IngleseReijean Alexfer Dos Santos SantosNo ratings yet

- WEBTROL SP Series Self-Priming Centrifugal PumpDocument8 pagesWEBTROL SP Series Self-Priming Centrifugal PumpSilvan ZupancNo ratings yet

- StrainersDocument4 pagesStrainersSharun SureshNo ratings yet

- Elcometer - SAGMETER 4270-ManualDocument9 pagesElcometer - SAGMETER 4270-ManualRıdvan SürmeliNo ratings yet

- Installation, Maintenance and Operating Instruction Manual For Forged Stainless Steel Actuators "S" SeriesDocument12 pagesInstallation, Maintenance and Operating Instruction Manual For Forged Stainless Steel Actuators "S" Serieskarmen kroflicNo ratings yet

- Aicd WFTDocument2 pagesAicd WFTCláudio VirgílioNo ratings yet

- PP 1184 US Quick Reference Guide Lo Res1Document60 pagesPP 1184 US Quick Reference Guide Lo Res1Bud ParizekNo ratings yet

- COBIT 5 Foundation Exam Revision On A PageDocument1 pageCOBIT 5 Foundation Exam Revision On A PageSergiö Montoya100% (1)

- When Technology and Humanity Cross: Reflect On The Following QuestionsDocument3 pagesWhen Technology and Humanity Cross: Reflect On The Following QuestionsRICKIE MAE MERISNo ratings yet

- LGS AP20 AutoPole DS 953384 0722 en LRDocument2 pagesLGS AP20 AutoPole DS 953384 0722 en LRDébora BarahonaNo ratings yet

- Air Cooled Package York Ysb 1112 CDocument2 pagesAir Cooled Package York Ysb 1112 CStevler SheNo ratings yet

- LCD S830 Manual Control Panel User Manual The Latest Version 2018Document7 pagesLCD S830 Manual Control Panel User Manual The Latest Version 2018suresh08072172No ratings yet

- Ansible BasicsDocument48 pagesAnsible Basicsshrinath bhat0% (1)

- Airborne InternetDocument14 pagesAirborne InternetChaudhari SendhaNo ratings yet

- Error in HTTP RECEIVE 1 PDFDocument3 pagesError in HTTP RECEIVE 1 PDFKumud RanjanNo ratings yet

- Mediastrategy & Christian WitnessDocument284 pagesMediastrategy & Christian WitnessDan HenrichNo ratings yet

- Women Safety Device With GPS, GSM and Health Monitoring SystemDocument3 pagesWomen Safety Device With GPS, GSM and Health Monitoring SystemPavan VNo ratings yet

- Ijsred V5i3p21Document11 pagesIjsred V5i3p21Samuel AbraghamNo ratings yet

- User Manual: Element T6 Max Bluetooth SpeakerDocument51 pagesUser Manual: Element T6 Max Bluetooth SpeakerAung Thu LinnNo ratings yet

- Part1 Chapter2 FAB and Photolithography EE3165 EE3425 EE4051Document52 pagesPart1 Chapter2 FAB and Photolithography EE3165 EE3425 EE4051Minh Phan QuangNo ratings yet

- 3 Axis Milling Machine PDFDocument5 pages3 Axis Milling Machine PDFAnuj MathurNo ratings yet

- Design and Analysis of IoT-Based Intelligent Robot For Real-Time Monitoring and ControlDocument13 pagesDesign and Analysis of IoT-Based Intelligent Robot For Real-Time Monitoring and Controlhamed razaNo ratings yet

- Class X Chapter 1 Internet BasicDocument27 pagesClass X Chapter 1 Internet BasicMack TripathiNo ratings yet

- Pioneering Practices For New Product DevelopmentDocument7 pagesPioneering Practices For New Product Developmentparthaj97No ratings yet

- Health Management Different Approaches SolutionsDocument508 pagesHealth Management Different Approaches SolutionsمرتديلامرتديلاNo ratings yet

- Analytics Certification Exam AnswersDocument17 pagesAnalytics Certification Exam AnswersWahyuni SalmanNo ratings yet

- Generator Protection: Syllabus Rotor Faults, DifferentialDocument21 pagesGenerator Protection: Syllabus Rotor Faults, DifferentialPratham VaghelaNo ratings yet

- Fyp 1Document26 pagesFyp 1Taha RahatNo ratings yet

- Flyer Sheet MetalDocument8 pagesFlyer Sheet MetalBG2012No ratings yet

- Slayer Exciters Tesla Coils Everything You Need ToDocument5 pagesSlayer Exciters Tesla Coils Everything You Need ToiamtheescottiewallaceNo ratings yet

- ATPL AGK Systems Questions BankDocument90 pagesATPL AGK Systems Questions BankadiNo ratings yet

- Anyconnect VPN ManualDocument10 pagesAnyconnect VPN ManualKapilNo ratings yet

- 3ds Max 2018 Help - Additional Keyboard Commands - AutodeskDocument2 pages3ds Max 2018 Help - Additional Keyboard Commands - Autodeskbackupsanthosh21 dataNo ratings yet

- Dynamitron - October 2016 - WebDocument12 pagesDynamitron - October 2016 - WebChilmy Coklat SusuNo ratings yet

- Grade 7 Holiday AssignmentDocument55 pagesGrade 7 Holiday AssignmentJavya JaneNo ratings yet

- Introduction To MBSD - NotesDocument783 pagesIntroduction To MBSD - NotesMidhun DavisNo ratings yet