Professional Documents

Culture Documents

CMS Casing Slip Operating Manual

Uploaded by

Rahul M.ROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CMS Casing Slip Operating Manual

Uploaded by

Rahul M.RCopyright:

Available Formats

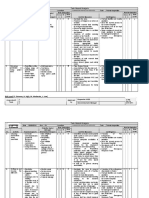

CMS CASING SLIPS

OPERATING PROCEDURE MANUAL

Doc. 20-1700 Rev E (09/13/2005)

CMS Casing Slip Operating Procedure Manual

TABLE OF CONTENTS

Section Page

1 - Introduction 2

1.1 Purpose

1.2 Description

2 - Operation 3

2.1 Preperation

2.2 Operation

3 - Maintenance 4

3.1 Inspection

3.2 Lubricants

4 - Shop Repairs 5

4.1 Changing Inserts

4.1 Slip Disassembly

Certificate of Warranty and Guarantee to Quality 6

Doc. 20-1700 Rev E (09/13/2005)

CMS Casing Slip Operating Procedure Manual

1

1 - INTRODUCTION

1.1 PURPOSE

This technical manual contains operation and maintenance Instructions for AOT "CMSXL" &

"CMS-3" casing slips with complete parts breakdown. It provides a guide for proper field use,

disassembly and repair.

1.2 DESCRIPTION

The "CMS" series consist of two models of casing slips. The "CMSXL" which has a 4" taper

per ft. And the "cms-3" which has a 3" taper per ft. Both slips have a 13 1/2" gripping length,

and can handle a wide range of casing & conductor pipe with the proper number of segments

and inserts.

MODEL RANGE

CMSXL 6 5/8" - 30"

CMS-3 9 5/8" - 30"

CPS 24” - 36”

CPS-3 24” -36”

Any overloading of the recommended rating or misuse of this equipment can

cause serious injury or death.

Doc. 20-1700 Rev E (09/13/2005)

CMS Casing Slip Operating Procedure Manual

2

2 - OPERATION

2.1 PREPARATION

In order for the "CMS" series of casing slips to operate properly, it is necessary to install the

proper number of segments and size of inserts corresponding to the size of the O.D. It is to

catch. Follow the procedures in section 4 – Shop repairs.

2.2 OPERATION

• After installation of the proper size of inserts in the casing slip, the slip is ready for

service. The back of the slips and ID

• The bowl should be cleaned and greased before use, and daily during use.

• To set the slips, move the drill string to the desired location and allow it to come to a

complete stop. Place the slips into the tapered bowl or spider, gently lower the pipe,

which will allow the slips to wedge into the bowl or spider and hold the pipe from

moving.

• When lifting slips out of the bowl firmly grip and apply inward pressure to the front

handles of the slip as the pipe is lifted. Then, let the upward movement of the pipe lift

the slip out of the bowl. Once the slip is clear of the bowl pull on rear handles of slip to

clear the bowl.

CAUTION:

• Be sure to use the handles provided on the slip assemblies for raising the slip

assembly in and out of the bowl.

• Be sure drill string is at a complete stop before setting the slips into the bowl. This will

cause the slips to be overloaded and can cause damage to the slips. Do not use slips

as a backup.

• Make sure the slips are used with the proper size of inserts and slip backs are cleaned

and greased daily. Also be sure that the taper on the slip matches the taper on the

bowl.

Doc. 20-1700 Rev E (09/13/2005)

CMS Casing Slip Operating Procedure Manual

3

3 - MAINTENANCE

Practice safety at all times when servicing the equipment and use approved

safety methods, material and tools. Always wear protective gear for eyes,

head and hands.

3.1 INSPECTION

To insure optimum performance from the "CMS" series of casing slips, the following checks

should be made once a week.

• Check for worn hinge pins and handle pins and replace as necessary.

• Check inserts for wear and replace as necessary.

• Slips should undergo a magnetic particle inspection a minimum of once a month, when

in use and after every job.

• Slip backs should be checked with a straight edge weekly.

3.2 LUBRICATIONS

Lubricate the slip regularly during usage and storage to prevent corrosion. Use an extreme

pressure, multi-purpose, lithium base grease of no. 1 or no. 2 consistency and multi-weight

motor oil. When the tool is in use, lubricate the slip according to the following schedule or

annually while in storage.

Daily: Clean and grease slip backs and bowl ID.

Weekly:

• Grease hinge pins.

• Remove inserts and Grease insert slots.

Doc. 20-1700 Rev E (09/13/2005)

CMS Casing Slip Operating Procedure Manual

4

4 - SHOP REPAIRS

4.1 CHANGING INSERTS.

To replace worn inserts or change sizes:

1. Remove cotter keys holding in inserts.

Always wear eye protection when removing or replacing inserts to protect

against chip fragments.

2. Using a brass punch and hammer, drive out the inserts.

Always install the proper size inserts for the tubular to be used on.

3. Clean and grease the insert slots before installing new inserts.

4. Install insert retainer cotter keys.

4.2 SLIP DISASSEMBLY:

1. Remove hinge pin cotters and hinge pins.

2. Remove inserts (See Section 4 Changing Inserts.)

3. After inspecting all parts for cracks and wear, replace defective parts and reassemble

in reverse order.

Due to the complex metallurgy in AOT "CMS" casing slips welding should be

performed only by AOT or an authorized repair agent.

Doc. 20-1700 Rev E (09/13/2005)

CMS Casing Slip Operating Procedure Manual

5

CERTIFICATE OF WARRANTY AND GUARANTEE TO QUALITY

Seller warrants all materials, products and supplies manufactured or furnished by it to be free

from defects in material and workmanship, under normal use and service, when installed,

used and serviced in the manner provided and intended by seller for a period of twelve (12)

months after installation or delivery, whichever shall occur first. Seller’s obligations under this

warranty are expressly limited to repair or replacement, at its option, of any materials,

products or supplies returned to seller’s plant, New Iberia, Louisiana, and which are

determined by seller to be defective. All freight charges for return and reshipment shall be

paid by customer. A new warranty period shall not be established for repaired or replaced

materials, products or supplies; such items shall remain under warranty only for the

remainder of the warranty period on the original materials, products or supplies. This is the

sole warranty of seller and no other warranty is applicable, either expresses or implied, in fact

or by law, including any warranty as to merchantability or fitness for a particular use or

purpose.

In case of goods or parts not wholly of seller’s manufacture, seller shall make available to the

customer whatever warranty or guaranty is extended to seller for such goods or parts by the

supplier or manufacturer thereof.

Seller will not assume responsibility or liability for any repairs, rebuilding, welding or heat

treating done to its material, products or supplies outside of seller’s plants, such work shall

void any all warranties. All parts used in the manufacture and/or final assembly of seller’s

materials, products and supplies are necessary for both safety and operational performance.

Omission of any part or failure to replace any part may result in a malfunction and a

consequent safety hazard for which seller disclaims any responsibility or liability for injuries or

damage as a result thereof.

Buyer’s sole and only remedy in regard to any defective materials, products or supplies shall

be the repair or replacement thereof as herein provided, and seller shall not be liable for any

consequential, special, incidental or punitive damages resulting from or caused by any

defective materials, products or supplies.

Doc. 20-1700 Rev E (09/13/2005)

CMS Casing Slip Operating Procedure Manual

6

You might also like

- 4HK1 & 6HK1 ManualDocument352 pages4HK1 & 6HK1 Manuallionkinghd94% (104)

- Manual Taller EC25N2Document461 pagesManual Taller EC25N2Claudio AndrésNo ratings yet

- Hibon Tri Lobe Blower Manual PDFDocument55 pagesHibon Tri Lobe Blower Manual PDFtayyabeme100% (1)

- 9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFDocument68 pages9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFcoelhoclaudios100% (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- SG Operation ManualDocument51 pagesSG Operation ManualEdin Raul Yalle Rafael100% (1)

- Foote-Jones 8000 Series Gear Reducer ManualDocument20 pagesFoote-Jones 8000 Series Gear Reducer ManualbwelzNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Sap Product Costing Configuration DocumentDocument16 pagesSap Product Costing Configuration Documentguru_vkg75% (4)

- Hibon Tri Lobe Blower ManualDocument55 pagesHibon Tri Lobe Blower Manualmsaqibraza9350% (2)

- Thomas & Ely (1996) - "Making Differences Matter: A New Paradigm For Managing Diversity," Harvard Business ReviewDocument2 pagesThomas & Ely (1996) - "Making Differences Matter: A New Paradigm For Managing Diversity," Harvard Business ReviewEdison Bitencourt de Almeida100% (1)

- 20-1701 Slips DCSDocument7 pages20-1701 Slips DCSRahul M.RNo ratings yet

- Installation, Operation and Maintenance of Airflex@ CM Marine ClutchDocument12 pagesInstallation, Operation and Maintenance of Airflex@ CM Marine Clutchaiyubi2No ratings yet

- BVM Corporation Maintenance Manual: Casing Slips "CMSXL"Document5 pagesBVM Corporation Maintenance Manual: Casing Slips "CMSXL"Ali mohammadNo ratings yet

- Manual Drill Collar S-R-LDocument6 pagesManual Drill Collar S-R-LJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- SD Slip ManualDocument9 pagesSD Slip ManualGregory StewartNo ratings yet

- Type DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar PumpDocument43 pagesType DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar Pumpkprasad_56900No ratings yet

- 70 - 75 - 80 - 90 - 100 - 115 HPDocument3 pages70 - 75 - 80 - 90 - 100 - 115 HPLorenzoGabrielSilvaDonosoNo ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsandres castroNo ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsmahesh_eilNo ratings yet

- Iom SCTDocument71 pagesIom SCTSaikat PurkaitNo ratings yet

- Fork ArmDocument26 pagesFork ArmtulogmulatNo ratings yet

- User Instructions Bull Wheel Liners 4-2010Document8 pagesUser Instructions Bull Wheel Liners 4-2010Alexander SladeNo ratings yet

- Machine Maintenance.: General Workshop ProceduresDocument23 pagesMachine Maintenance.: General Workshop Proceduresvld7rpmNo ratings yet

- Installation and maintenance instructions for John Crane seal models 670 and 680Document6 pagesInstallation and maintenance instructions for John Crane seal models 670 and 680Steve EbenezerNo ratings yet

- Mechanical Seal Installation InstructionDocument4 pagesMechanical Seal Installation InstructionSandi AslanNo ratings yet

- Manual de Seleção e Manutenção de Soprador IndustrialDocument39 pagesManual de Seleção e Manutenção de Soprador IndustrialEleno RibeiroNo ratings yet

- Chapter 2 Machine Maintenance.: General Workshop ProceduresDocument22 pagesChapter 2 Machine Maintenance.: General Workshop ProcedureswillifenlonNo ratings yet

- Operation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyDocument25 pagesOperation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanySaif MohammadNo ratings yet

- Mechanical Liquid Meter: Owners Installation, Operation, and Safety ManualDocument32 pagesMechanical Liquid Meter: Owners Installation, Operation, and Safety ManualRodolfo Trujillo TrejoNo ratings yet

- SD-010404-01 - Test Stump Operating ManualDocument15 pagesSD-010404-01 - Test Stump Operating ManualFam Escalante OnofreNo ratings yet

- Click Wrench RepairDocument31 pagesClick Wrench RepairTu PhamNo ratings yet

- Industrial Training Report Diesel Locomotive Works Varanasi: Mechanical Engineering DepartmentDocument19 pagesIndustrial Training Report Diesel Locomotive Works Varanasi: Mechanical Engineering DepartmentVeer PatelNo ratings yet

- Pump Maintenance Procedures 1Document7 pagesPump Maintenance Procedures 1Shraddha Raut100% (1)

- MM01001 enDocument32 pagesMM01001 enmahmoud yarahmadiNo ratings yet

- Hammer Crusher User ManualDocument10 pagesHammer Crusher User ManualJuan MoralesNo ratings yet

- Double Suction Split Case PumpsDocument27 pagesDouble Suction Split Case PumpsgbogboiweNo ratings yet

- Flowserve Seal - ISC2 - Install - LTRDocument8 pagesFlowserve Seal - ISC2 - Install - LTRjame11inNo ratings yet

- Boilers: 9-1. Minimum Maintenance Activities For BoilersDocument12 pagesBoilers: 9-1. Minimum Maintenance Activities For BoilersLacshay ShekharNo ratings yet

- Installation Operation and Maintenance GuideDocument21 pagesInstallation Operation and Maintenance GuideAscencio RubenNo ratings yet

- Sam Industries PumpDocument52 pagesSam Industries PumpHunney KotiyaNo ratings yet

- Hibon Blower Manual Installation GuideDocument55 pagesHibon Blower Manual Installation GuideRicardo RGNo ratings yet

- 1 PDFDocument41 pages1 PDFChan Peng SwanNo ratings yet

- EGV ManualDocument15 pagesEGV ManualT.MuthuvijayapandiNo ratings yet

- Pantograph Isolator Maintenance ManualDocument32 pagesPantograph Isolator Maintenance ManualVishnu ShankerNo ratings yet

- 9853 1082 01 Overhauling Instructions COP 2550CR-CRLDocument66 pages9853 1082 01 Overhauling Instructions COP 2550CR-CRLTien Vi NguyenNo ratings yet

- Maintaining Flowline EquipmentDocument23 pagesMaintaining Flowline Equipmentralph100% (1)

- Manual controlador EC25N2Document199 pagesManual controlador EC25N2Claudio Galvez RojasNo ratings yet

- Camflex-II Instruction NyDocument24 pagesCamflex-II Instruction NyCarlos Castillo100% (1)

- NOV - Rotary Slips ManualDocument7 pagesNOV - Rotary Slips ManualbenkaouhaNo ratings yet

- Technical Manual Rotary ValveDocument8 pagesTechnical Manual Rotary ValvexichengrenNo ratings yet

- 25d Double Searmer ManualDocument21 pages25d Double Searmer Manuallisya liputoNo ratings yet

- Idler Service Manual 2016-08-31Document8 pagesIdler Service Manual 2016-08-31Sergio Rodrigo Miranda GuajardoNo ratings yet

- Mould UPKEEPDocument6 pagesMould UPKEEPvinayakNo ratings yet

- 8' MPV User's Manual For Side Port PDFDocument20 pages8' MPV User's Manual For Side Port PDFdavibrenoNo ratings yet

- Installation Lubrication and Maintenance Instructions for Spiral Bevel Helical ReducerDocument21 pagesInstallation Lubrication and Maintenance Instructions for Spiral Bevel Helical Reducerbwelz100% (1)

- QuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualDocument21 pagesQuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service Manualshashiraj50% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- 20-1708 Elevator SJDocument10 pages20-1708 Elevator SJRahul M.RNo ratings yet

- NOV HT Manual Tong-50006190 MAN 001-Rev GDocument68 pagesNOV HT Manual Tong-50006190 MAN 001-Rev GRahul M.R100% (1)

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- JSA TubularDocument4 pagesJSA TubularRahul M.RNo ratings yet

- Damaged / Lost Equipment Report: Date Division MIS Country Der No. KSADocument1 pageDamaged / Lost Equipment Report: Date Division MIS Country Der No. KSARahul M.RNo ratings yet

- SW One DXP Cost Sheet (4.5BHK+Utility) Phase 1Document1 pageSW One DXP Cost Sheet (4.5BHK+Utility) Phase 1assetcafe7No ratings yet

- Fundamentals of Organizational Communication: A01 - SHOC0079 - 09 - SE - FM - Indd 1 08/04/14 4:27 PMDocument26 pagesFundamentals of Organizational Communication: A01 - SHOC0079 - 09 - SE - FM - Indd 1 08/04/14 4:27 PMDaniel PaloNo ratings yet

- V - 62 Caroni, Trinidad, Tuesday 14th March, 2023-Price $1.00 N - 39Document17 pagesV - 62 Caroni, Trinidad, Tuesday 14th March, 2023-Price $1.00 N - 39ERSKINE LONEYNo ratings yet

- Question Papers of 5th SemDocument15 pagesQuestion Papers of 5th SemGautam RoyNo ratings yet

- FindsDocument8 pagesFindsdan4oNo ratings yet

- DP Clean Tech BrochureDocument16 pagesDP Clean Tech BrochurebhasinbNo ratings yet

- Complacency - Safety Toolbox Talks Meeting TopicsDocument2 pagesComplacency - Safety Toolbox Talks Meeting TopicsqhseNo ratings yet

- GMCC Rotary Compressor Manual Provides Technical DetailsDocument24 pagesGMCC Rotary Compressor Manual Provides Technical Detailsyeancarlo sequera0% (1)

- Talk About Amway CompanyDocument18 pagesTalk About Amway CompanyHoàng Huy NguyễnNo ratings yet

- Course Syllabus Outline OBLI 2nd SEM AY 2021 2022 For The ClassDocument8 pagesCourse Syllabus Outline OBLI 2nd SEM AY 2021 2022 For The ClassJULLIAN PAOLO UMALINo ratings yet

- Subject Outlines MIHM 2016 V20.1Document75 pagesSubject Outlines MIHM 2016 V20.1Rahul Yadav100% (1)

- PT Djarum Company Profile DocumentDocument18 pagesPT Djarum Company Profile DocumentAri SetiadiNo ratings yet

- NOIDA 2021 HandbookDocument59 pagesNOIDA 2021 HandbookpremprakashtransportNo ratings yet

- Chapter 26 - Incremental AnalysisDocument34 pagesChapter 26 - Incremental AnalysisLe H KhangNo ratings yet

- IFRS IntroductionDocument44 pagesIFRS Introductionpadm0% (1)

- 9 Strategic Parterning and CollaborativeDocument50 pages9 Strategic Parterning and CollaborativeSafdar PervaizNo ratings yet

- LBC Express TungpalanDocument20 pagesLBC Express TungpalanJohn Henry BartolomeNo ratings yet

- Ariana Villanueva ResumeDocument1 pageAriana Villanueva Resumeariana villanuevaNo ratings yet

- New 1st Semester English (MCO-01,04,05,21) M.com AssignmentDocument8 pagesNew 1st Semester English (MCO-01,04,05,21) M.com AssignmentRajni KumariNo ratings yet

- Final Output in Intermediate Accounting Problems on Shareholders' EquityDocument15 pagesFinal Output in Intermediate Accounting Problems on Shareholders' Equityennaira 06No ratings yet

- Management Information Question Bank by Icaew 2013Document241 pagesManagement Information Question Bank by Icaew 2013Mộc LanNo ratings yet

- Public RelationDocument14 pagesPublic RelationWahyu RinaNo ratings yet

- Best Buy's Positioning and Competitive AdvantagesDocument16 pagesBest Buy's Positioning and Competitive AdvantagesJobin GeorgeNo ratings yet

- Marketing Management Course SyllausDocument5 pagesMarketing Management Course SyllausAhmed FathelbabNo ratings yet

- Marks and Spencer: A Retail HistoryDocument11 pagesMarks and Spencer: A Retail HistorysteffijasperNo ratings yet

- Mawdsley - From Billions To Trillions - Financing The SDGs in A World Beyond AidDocument5 pagesMawdsley - From Billions To Trillions - Financing The SDGs in A World Beyond AidCodruța Mihaela HăinealăNo ratings yet

- Supplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksDocument3 pagesSupplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksdysonNo ratings yet

- Vertical and Horizantal Analysis of Ultratech CementDocument12 pagesVertical and Horizantal Analysis of Ultratech Cementthamil marpanNo ratings yet