Professional Documents

Culture Documents

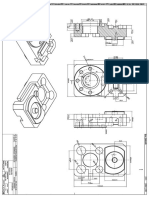

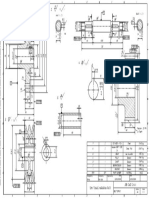

Power Transmission Assy A

Uploaded by

hilmikock1423Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Transmission Assy A

Uploaded by

hilmikock1423Copyright:

Available Formats

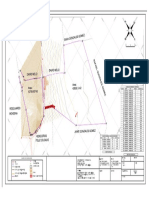

24

N8 20

1

R1

6 VIEW X

10

N8

2

R6 15

R1

0

0.05 A

N7

N6

2-M10

N7

0.05 A

69

6 12 X 90

N6

R6

R4

R6 6P9

A

0.03 A 12

0

18H7

0.00

21 +- 0.10

144

112

36

72

96

24 52 30

N6

68

15

R26

R3 A

A

N7

48

N7 11 6

N7

R10

24H7

36H7

30H7

144

102

42

48

90

120

10

N6

N7

N6

R12

R80

N6

N7

R6 10

N6

R3 R6 R3 40

10

R10

N7

28

N7

R1

R6

6

12 10

N7

0.03 A

A 5x 11 20 2

6

A-A

10

19

129

8 1 Bush Brass / Dia 24x19

140

7 2 Stud Steel / M10x48

N6

6 1 Bush Brass / Dia 30x30

N6

6 8 30 30

GENERAL NOTES:

2 1 Vee Pulley Alumunium / Dia 144x28

1. Deburr All Sharp Edge 0.5x45 or R0.3

15 7 2. Unspecified Chamfer 1x45 1 1 Bracket Cast Iron / Dia 144x140

16 28 3. Unspecified Radii of Fillets R0.5 Item Qty Part Name Material / Dimension Remark

24H7

36f7

4. General Tolerance:

24H7

30f7

- Fundamental Tolerancing Principle ISO 8185 41th. WorldSkills Competition - London, UK 2011

M10

- Casting = ISO 8015 - CT10

- Machining = ISO 2768 - mK TRADE 05 : Mech. Engineering Design - CAD

48

- Geometrical Tolerance = ISO 1101 Project Name Units

30 19 5. Side Angle 1 mm

POWER TRANSMISSION ASSY A.N.Silmi Scale

1:1

Task Time Sheet

2D & 3D ASSEMBLY DRAWING 1/2

You might also like

- Aluminium Alloy 2014 - 2014A - Aircraft MaterialsDocument3 pagesAluminium Alloy 2014 - 2014A - Aircraft MaterialscelsribeiroNo ratings yet

- Profit and Loss Projection, 1yrDocument1 pageProfit and Loss Projection, 1yrhowieg43100% (2)

- Basic Concepts of Iron and Steel MakingDocument644 pagesBasic Concepts of Iron and Steel Makingclaudia100% (7)

- Riser DesignDocument4 pagesRiser DesignJiggy Jick100% (1)

- Welding Map & NDE Map JTBDocument7 pagesWelding Map & NDE Map JTBFarhan PutraNo ratings yet

- Etching Specialty AlloysDocument6 pagesEtching Specialty AlloysNitin100% (1)

- Flywheel PDFDocument1 pageFlywheel PDFedward santiago buitrago aguirreNo ratings yet

- DOC-20230410-WA0007.Document1 pageDOC-20230410-WA0007.Ragul0042No ratings yet

- Universidad Nacional de Colombia-Fac - Ing Empalmes Brayan C. AngaritaDocument1 pageUniversidad Nacional de Colombia-Fac - Ing Empalmes Brayan C. AngaritaBrayan AngaritaNo ratings yet

- 244-46 Rev BDocument1 page244-46 Rev BDeepak DasNo ratings yet

- Moving Pin Knob Assembly DrawingDocument1 pageMoving Pin Knob Assembly DrawingAdam FitriNo ratings yet

- Bearing Housing Drawing PDFDocument1 pageBearing Housing Drawing PDFtostes_brNo ratings yet

- ITEM-9: Document StatusDocument1 pageITEM-9: Document StatusNitinNo ratings yet

- 428 05634 O DRW en - 1 BallDocument1 page428 05634 O DRW en - 1 BallJose Maria HernandezNo ratings yet

- Nps A838Document1 pageNps A838FranGigaNo ratings yet

- 5.N8 Body Screw Assembly DrawingDocument2 pages5.N8 Body Screw Assembly Drawingpolman cad08No ratings yet

- Manufatura ModelagemDocument4 pagesManufatura ModelagemArlan FNNo ratings yet

- BELT DRIVE 25 Jan 2024Document1 pageBELT DRIVE 25 Jan 2024bimaditya281No ratings yet

- FL3B-434-M-2073-0.0 (434T010) D1 Filtrate TankDocument1 pageFL3B-434-M-2073-0.0 (434T010) D1 Filtrate TanknyaptoNo ratings yet

- Final 2 RevisiDocument1 pageFinal 2 Revisisatya_saptaadisetyapNo ratings yet

- Crank PDFDocument1 pageCrank PDFPhap NguyenNo ratings yet

- Machine Afzar Shams: Bearing HousingDocument8 pagesMachine Afzar Shams: Bearing HousingmasoodkamaliNo ratings yet

- DRW SOHO AK Blok A, B, C-LAYOUTDocument1 pageDRW SOHO AK Blok A, B, C-LAYOUTAdji ShonNo ratings yet

- Khulna - Circle RHD ROAD NETWORK, Bangladesh .Document1 pageKhulna - Circle RHD ROAD NETWORK, Bangladesh .Salman HaiderNo ratings yet

- G ClampDocument3 pagesG ClampFRESKABIO0% (1)

- Bearing Stand PDFDocument1 pageBearing Stand PDFËďdýsson ČhüqűïîanaNo ratings yet

- Grundig-Beko Delta dps-174bp PsuDocument3 pagesGrundig-Beko Delta dps-174bp PsuMy USERNAME100% (1)

- Laporan Praktikum 2Document15 pagesLaporan Praktikum 2Dimas PrasNo ratings yet

- John Ric Plate 5Document1 pageJohn Ric Plate 5Mark Adrian TagabanNo ratings yet

- Mid STA.2+342.91Document1 pageMid STA.2+342.91Julian SandovalNo ratings yet

- Crankrod PDFDocument1 pageCrankrod PDFjose lfmNo ratings yet

- Horizontal Beam Engine with Centrifugal PumpDocument1 pageHorizontal Beam Engine with Centrifugal PumpQTG channelNo ratings yet

- ACAD-LLANCAY v4-Model-KM 0+576.00-0+953.88Document1 pageACAD-LLANCAY v4-Model-KM 0+576.00-0+953.88Moral PedroNo ratings yet

- Sensor mounting bracket dimensionsDocument1 pageSensor mounting bracket dimensionsChandru ChristurajNo ratings yet

- Esquema Eletronico Ups East Bivolt - 600 - 1200va-Parte2Document1 pageEsquema Eletronico Ups East Bivolt - 600 - 1200va-Parte2Armandinho CaveroNo ratings yet

- Notes:: Produced by An Autodesk Student VersionDocument1 pageNotes:: Produced by An Autodesk Student VersionFredy Quispe SotoNo ratings yet

- Connection piece assembly drawingDocument1 pageConnection piece assembly drawingStefan MilojevicNo ratings yet

- DTS Sheet 2 ComponentDocument1 pageDTS Sheet 2 ComponenthimanshuNo ratings yet

- ITEM-11 ITEM-12: Document StatusDocument1 pageITEM-11 ITEM-12: Document StatusNitinNo ratings yet

- LBP and DBP Floor Plan GFDocument1 pageLBP and DBP Floor Plan GFKarl Anton ClementeNo ratings yet

- R2 SECTION: Sta. 0+000 - Sta. 1+100: Scale A1: 1/1500, A3: 1/3000 Ring 2 - 1Document12 pagesR2 SECTION: Sta. 0+000 - Sta. 1+100: Scale A1: 1/1500, A3: 1/3000 Ring 2 - 1ကိုနေဝင်းNo ratings yet

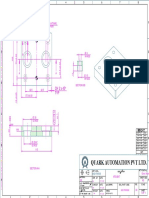

- 2 X 45° CH TYP: Drn. by Date Date CHKD - by Date Aprd - by Rev. Sheet Size MaterialDocument1 page2 X 45° CH TYP: Drn. by Date Date CHKD - by Date Aprd - by Rev. Sheet Size MaterialQUARK AUTOMATIONNo ratings yet

- Hardened steel components face hardened to 58 HRCDocument1 pageHardened steel components face hardened to 58 HRCChandru ChristurajNo ratings yet

- Digital LED Clock SchematicsDocument1 pageDigital LED Clock Schematicsnuvr100% (1)

- FRB02A010102Document1 pageFRB02A010102Chandru ChristurajNo ratings yet

- Folding stool design drawingDocument1 pageFolding stool design drawingsoorajssNo ratings yet

- At GN4Document1 pageAt GN4jazzvivekNo ratings yet

- Toughining Upto 40-45 HRC: Thread RelifDocument1 pageToughining Upto 40-45 HRC: Thread RelifChandru ChristurajNo ratings yet

- 2 - G Clamp - IdwDocument1 page2 - G Clamp - IdwMisfalah MusicNo ratings yet

- BC Window SheetDocument1 pageBC Window SheetSubhankan JainNo ratings yet

- 11kv and LV Pin InsulatorsDocument1 page11kv and LV Pin InsulatorsMosa Elnaid ElnaidNo ratings yet

- Part Drawing Sheet1Document1 pagePart Drawing Sheet1Shrikrushna MaliNo ratings yet

- Indigenous land rights in ColombiaDocument1 pageIndigenous land rights in ColombiaTopografia ConstrupresenteNo ratings yet

- Plano Predio Santa Helena - El Abra-PliegoDocument1 pagePlano Predio Santa Helena - El Abra-PliegoJorge RicoNo ratings yet

- Stepper Datasheetsfsahj PDFDocument1 pageStepper Datasheetsfsahj PDFpatil_ameyaNo ratings yet

- Gargallo Dibujos-IIDocument318 pagesGargallo Dibujos-IIMarisa Carreras AbeniaNo ratings yet

- Document Status: If in Doubt AskDocument1 pageDocument Status: If in Doubt AskNitinNo ratings yet

- Crankshaft CounterweightDocument1 pageCrankshaft CounterweightCốGắngNàoNo ratings yet

- Guide Post MGP MisumiDocument1 pageGuide Post MGP MisumiMarcus ViniciusNo ratings yet

- 2tda180503 SH01 CDocument1 page2tda180503 SH01 CnightmanmxNo ratings yet

- Tanklenmen 218-A1 ModelDocument1 pageTanklenmen 218-A1 ModelJisoo KimNo ratings yet

- IoiuyDocument4 pagesIoiuyAul FiNo ratings yet

- VCC1 Voltage Regulator CircuitDocument1 pageVCC1 Voltage Regulator Circuityako15110% (1)

- Part Drawing Sheet2Document1 pagePart Drawing Sheet2Shrikrushna MaliNo ratings yet

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Daftar PustakaDocument4 pagesDaftar PustakavgestantyoNo ratings yet

- Torque CalculatorDocument4 pagesTorque CalculatorNityananda Permadi TjokrodimurtiNo ratings yet

- Guy JollyDocument24 pagesGuy JollyAndres Fitria FarrelNo ratings yet

- ELECTRODE SELECTION GUIDEDocument9 pagesELECTRODE SELECTION GUIDERehan sheikhNo ratings yet

- Information and Safety Rules en 2012Document4 pagesInformation and Safety Rules en 2012nqh2009No ratings yet

- TMT Bar - Thermomechanical ProcessingDocument1 pageTMT Bar - Thermomechanical Processingsmallik3No ratings yet

- Flot Lab TA MicroscDocument10 pagesFlot Lab TA MicroscLaura B. AlvarezNo ratings yet

- Sae J404-2000 PDFDocument5 pagesSae J404-2000 PDF2601220150379No ratings yet

- FFS Pitting As Per API 510Document7 pagesFFS Pitting As Per API 510Hares SlalNo ratings yet

- Tool Materials PDFDocument34 pagesTool Materials PDFAvadhoot RajurkarNo ratings yet

- Perspectives of a European Steel Producer on SA 387 gr.11Document29 pagesPerspectives of a European Steel Producer on SA 387 gr.11Ali VarmazyarNo ratings yet

- Carbon Steel Metallography StudyDocument5 pagesCarbon Steel Metallography Studyanne200390100% (1)

- Manual de Aceros Inoxidables EspecialesDocument12 pagesManual de Aceros Inoxidables EspecialesErick OlavarriaNo ratings yet

- Grit Comparison Chart PDFDocument3 pagesGrit Comparison Chart PDFdanyNo ratings yet

- Glass Manufacturing ProcessDocument2 pagesGlass Manufacturing ProcessNur Aulia S100% (2)

- Solidification ProcessingDocument14 pagesSolidification ProcessingTrupti Ranjan DasNo ratings yet

- PDocument4 pagesPIca zaharaNo ratings yet

- Underground hydrant, fire hose, and connection equipmentDocument1 pageUnderground hydrant, fire hose, and connection equipmentchinitnNo ratings yet

- Holdax EnglishDocument8 pagesHoldax EnglishChris MrozoskyNo ratings yet

- JBIL Steel Manufacturer ProfileDocument17 pagesJBIL Steel Manufacturer ProfileShashwat OmarNo ratings yet

- BMET GROUP 3 Welding-2Document4 pagesBMET GROUP 3 Welding-2Alhaj MassoudNo ratings yet

- BS en 1011-5Document14 pagesBS en 1011-5Peter TvardzíkNo ratings yet

- Steel Wire, High Tensile Strength, Cold Drawn: Standard Specification ForDocument3 pagesSteel Wire, High Tensile Strength, Cold Drawn: Standard Specification ForAkkiNo ratings yet

- Efecto de La Temperatura Del Hipoclorito de SodioDocument4 pagesEfecto de La Temperatura Del Hipoclorito de SodioMarriano DarinoNo ratings yet

- Ams 4911LDocument7 pagesAms 4911Ljamesdong1120No ratings yet