0% found this document useful (0 votes)

37K views14 pagesTesla Cybertruck Application

tesla ct beast app

Uploaded by

Joey KlenderCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

37K views14 pagesTesla Cybertruck Application

tesla ct beast app

Uploaded by

Joey KlenderCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

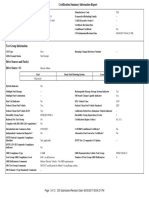

- COMMUNICATIONS

- FACILITIES, EQUIPMENT and TEST PROCEDURES

- LABELS

- GENERAL TECHNICAL DESCRIPTION

- STARTING AND SHIFTING SCHEDULES

- CALIFORNIA REQUIREMENTS