Professional Documents

Culture Documents

2008-02 - ICAF Installation Manual CWC 1.0 Eng

Uploaded by

gennaroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2008-02 - ICAF Installation Manual CWC 1.0 Eng

Uploaded by

gennaroCopyright:

Available Formats

INSTALLATION MANUAL

Anodes

ICAF System

(MGPS)

IMPRESSED CURRENT ANTI FOULING

Corrosion & Water-Control bv Page 2

ICAF Installation manuals CWC 1.0 Eng.

Corros

sion & Water

r-Conttrol b.v

v.

P.O. Box 47

P

NL-2750

0 AA Moeerkapellle

The

e Netherllands

Tel. (+3

31) 79 - 5931295

5

Fax: (+3

31) 79 - 593187

71

Websitee:

www

w.corros

sion.nl

Genneral em

mail :

info@corrosion.nl

Serrvice em

mail :

servic

ce@corroosion.nl

Corrosion & Water-Control bv

C Page

P 3

I

ICAF Installa

ation manua

als CWC 1.0 Eng.

Corrosion & Water-Control bv Page 4

ICAF Installation manuals CWC 1.0 Eng.

Index

1 Installation of the ICAF system 7

1.A ICAF anode description 7

1.B Boxcoolers 8

1.C Sea water intake 10

1.D Strainers 12

2 Cable Feed Through (CFT) 15

3 Power Unit 16

4 Connection – Anode to Plugbox 17

5 Connection – Plugbox to Digital Processing Unit 17

6 Current requirements 17

Att. A - d0 Anode (CT Cofferdam) 18

Att. B - d1 Anode 19

Att. C - d2 Anode 20

Att. D - d3 Anode 21

Att. E - d4 Anode 22

Att. F - Installation for Ø60 - Ø70 mm anodes 23

Att. G - Installation for Ø80 - Ø90 – Ø100 mm anodes 24

Att. H - Installation d0 M20 25

Att. I - Installation d0 M30 26

Att. J - Installation d0 + NW125 CT Cofferdam M20 27

Att. K - Installation d0 + NW125 CT Cofferdam M30 28

Att. L - Installation d0 + NW150 CT Cofferdam 29

Att. M - Tightening torques 30

Att. = Attachment

Corrosion & Water-Control bv Page 5

ICAF Installation manuals CWC 1.0 Eng.

Corrosion & Water-Control bv Page 6

ICAF Installation manuals CWC 1.0 Eng.

1 Installation of the ICAF system

An ICAF system can be applied on Boxcoolers, Sea water intakes, Strainers and other

cooling systems that need protection from fouling.

* This installation manual is for all the applications as mentioned

above. Please use the part that is suitable for your system.

Locations for anodes are determined by the yard / owners in collaboration with the

engineers of Corrosion & Water-Control bv. The anodes must be mounted according

the mounting specifications of Corrosion & Water-Control bv.

Corrosion & Water-Control bv can supply these mounting specification if needed. The

positions of the boxcoolers are determined by the yard / Owner.

1.A ICAF anode description

Example :

Cu-70/1200d3

Cu = Material of the anode:

Cu = Copper;

Al = Aluminium;

Fe = Iron.

70 = Diameter of the anode (Ø 70mm)

1200 = Length of the anode (1200mm)

d3 = Quantity of support rings

Corrosion & Water-Control bv Page 7

ICAF Installation manuals CWC 1.0 Eng.

1.B Boxcoolers

Anodes must be mounted in support rings, on angle steel supports, with the help of U-

clamp fixings. The angle steel supports are welded between the boxcooler frames. The

amount of angle steel supports depends on the anode length.

• Drill holes for the u-clamp fixings in the steel angle supports, before welding the

steel angle supports in the seachest;

• Weld the steel angle supports on a suitable location underneath the boxcooler inside

the boxcooler chest, according the installation drawings attached to this manual.

The steel angle supports should be welded perpendicular to the length of the

boxcooler. Now the anodes and cathode plates can be installed linear to the

boxcooler (length). The anodes should be centred underneath the boxcooler,

according the installation drawings attached to this manual.

• Weld the cathode plates on the steel angle supports. The cathode plates must be

aligned with the anodes. The minimal cathode plate length is equal to the anode

length.

The dimensions of the cathode plates are:

Ø60 & Ø70 mm anodes = 80 x 8 x anode length (mm);

Ø80, Ø90 & Ø100 mm anodes = 120 x 12 x anode length (mm).

* Note :

All welds should meet structures classification society rules.

* Attention :

The cathode plates and steel angle supports are yard delivery.

* Attention :

Do not coat the cathode plates. This can cause malfunction.

Corrosion & Water-Control bv will not guarantee the protection

against fouling if the cathode plates are coated.

• Slide the support rings over the anodes and mount them on the steel angle supports

with the u-clamps. Centre the anodes under the boxcooler before tightening the u

clamps. The support rings must be centred on the angle supports. Tighten the u-

clamp bolts to secure the anodes.

For the tightening torques we refer to Attachment M.

U-clamp Support ring

Cathode

plate

Anode

Angle steel

Sideview of boxcooler with ICAF Sectional view of boxcooler

anodes. with ICAF anodes.

Fig. 1

Corrosion & Water-Control bv Page 8

ICAF Installation manuals CWC 1.0 Eng.

* Attention :

The dimensions of the steel angle support, whereto the support rings

are mounted, cannot be bigger than 50mm (See fig. 2). If the steel

angle support is bigger it can cause system malfunction.

Corrosion & Water-Control bv will not guarantee the protection

against fouling if the steel angle supports are bigger than 50mm.

Support ring

U-clamp

Sideview of boxcooler with ICAF

anodes.

Maximal allowed

dimension is 50mm

Fig. 2

Corrosion & Water-Control bv Page 9

ICAF Installation manuals CWC 1.0 Eng.

1.C Sea water intake

The anodes must be mounted inside the seachest in such a way that the anodes are in

front of the suction pipe. If 2 anodes are delivered (Copper, Aluminium or Iron) the copper

anode should always be mounted closest to the suction side (See Fig. 3).

Copper anode

Aluminium / Iron anode

Water inlet

Crossover

pipe Inlet grid

Sea Chest

Water Balast Tank

Fig. 3 Inlet grid

• Before cutting a hole in the seachest surface, make sure that the positions of the

counter flange are determined so that the anode(s) will fit inside the seachest. Also

make sure that the anodes are positioned in front of sea water inlet pipe.

• Cut a hole in the seachest with the same diameter as the diameter of the counter

flange;

• Weld the counter flange into the seachest (See Fig. 4). The surface of the counter

flange must be equal to the seachest surface.

* Note :

All welds should meet structures classification society rules.

• After welding the counter flange into the sea chest surface clean the surface and coat

the counter flange with the ships paint system. Make sure that the threaded studs

are not coated. Also paint the top part of the CT cofferdam construction with the

ships paint system. Do not coat the anode surface.

* Attention :

Do not coat the anode surface. This can cause malfunction.

Corrosion & Water-Control bv will not guarantee the protection

against fouling if the anodes are coated.

* Attention :

Do not coat the threaded studs. The nuts for tightening the top part

cannot be fixed to the studs if paint is on the threaded studs.

• After the paint of the CT cofferdam is dried please place the gasket (See Fig. 4)

before mounting the top part of the CT cofferdam construction to the counter flange.

* Attention :

Make sure that the area where the gasket makes contact with both

flanges is clean and has a flat surface in order to guarantee a water

tight connection.

Corrosion & Water-Control bv Page 10

ICAF Installation manuals CWC 1.0 Eng.

Minimal space between Nuts

the flanges is 25mm. Washers

Top part

with anode

Gasket

Counter flange

Counter flange surfase

must be welded equally

to the welded surface.

Fig. 4

• After fixing the top part to the counter flange please fix the washers and nuts to the

threaded studs and tighten the nuts according the torque as described in

attachments M.

• Open the lid of the cofferdam top part and connect the anode cable to the M8 bolt

inside.

• Close the lid of the cofferdam top part and tighten the M6 bolt on top of the lid using

the torque as described in Attachment M.

• Please tighten the cable gland cup according the torque as described in

attachments M.

• Connect the anode cable to the corresponding terminal inside the plug box.

• The system is now ready for use.

* Attention :

The CT cofferdam construction and anodes are delivery of CWC.

Corrosion & Water-Control bv Page 11

ICAF Installation manuals CWC 1.0 Eng.

1.D Strainers

• First determine the positions of the anode(s) on the strainer cover and check if the

anode(s) fit inside the strainer basket.

• The anodes must be mounted inside the strainer in such a way that the anodes are

inside the strainer basket. When 1 anode is delivered the anode must be positioned

in the centre of the strainer basket. If 2 anodes are delivered (Copper, Aluminium or

Iron) the copper anode should always be mounted closest to the suction side (See

Fig. 5).

Copper anode

Strainer top plate

Outlet Inner diam.

Inlet

Position single anode =

Basket center strainer basket

Strainer

Fig. 5

If 2 anodes are used, the positions are determined by using the following calculation:

The pitch of where the anodes must be mounted is calculated as follows :

Mounting pitch = Internal diameter of the basket x 0,5 (See Fig. 6)

Example :

The internal diameter of the basket is Ø 600mm.

Mounting pitch = Ø 600mm x 0,5 => Ø 300mm.

Copper anode

Aluminium / Iron anode

Outlet Strainer top plate Pitch anodes (2x)

0,5 x Inner diam.

basket

Inlet Inner diam.

Basket

Strainer

Fig. 6

Corrosion & Water-Control bv Page 12

ICAF Installation manuals CWC 1.0 Eng.

• Before making a hole in the strainer cover please check the diameter of the anode

stud (Ø 20mm / Ø 30mm). If the diameter is Ø 20mm please make a hole of

Ø 24mm (+0,2mm) and if the stud is Ø 30mm make a hole of Ø 38mm (+0,2mm).

• The isolator tube must be shortened in order to tighten the anode assembly to the

strainer cover. The size of the isolator tube must be adjusted to the thickness of the

strainer cover minus 4 mm (measured above the top gasket). (see Fig. 7)

Example :

The strainer cover thickness is 15mm.

Isolator tube length = 15mm – 4mm => 11mm

* When a CT cofferdam is used it is not necessary to shorten the

isolator tube.

Strainer cover

thickness - 4mm

Isolator tube

Top gasket

Isolator Bottom gasket

Anode

Fig. 7

• Mount the anodes on the strainer cover and tighten the mounting bolts. For the

tightening torques we refer to attachment M.

• Place the strainer cover on top of the strainer and tighten the strainer bolts according

suppliers standard.

• Connect the anode cable to the M8 bolt on the anode stud.

• Connect the anode cable to the corresponding terminal inside the plug box.

• The system is now ready for use.

A strainer anode can also be deliver with a CT cofferdam construction (See Fig. 8). This is

usually requested when the strainer is very big and the strainer cover is too heavy to be

lifted. The installation of a CT cofferdam is described in chapter 1.C Sea water intake.

The advantage of using a CT cofferdam is that when the anodes need replacement, the

strainer cover does not need to be lifted.

Corrosion & Water-Control bv Page 13

ICAF Installation manuals CWC 1.0 Eng.

Copper anode

Aluminium / Iron anode

Strainer top plate

Outlet Pitch anodes

0,5 x Inner diam.

basket

Inlet Inner diam.

Basket

Strainer

Fig. 8

If, for some reasons, it is impractical to fit a component in the specified position. Please

contact a Corrosion & Water-Control bv representative for advise with determining a

new suitable location.

Corrosion & Water-Control bv Page 14

ICAF Installation manuals CWC 1.0 Eng.

2 Cable Feed Through (CFT)

Hull plating

Feed through socket

Cable gland NPT 1/2"

Anode cable

Use treat sealant when

tighting inside the feed

trough socket

(Versagem / Loctite)

Fig. 9

• A Ø38mm hole must be made in order to mount the feed through socket. If possible

place the hole as close to the anode as possible.

• Remove the cable glands from the feed through socket (ANSI) and secure it by a

continuous filled weld. Weld on the inside and also on the outside of the hull plating.

• Each individual anode requires one Cable Feed Through (CFT).

• Install the anodes, with the use of the delivered support rings and the U-clamps, on

the angle steel supports.

• Make sure that the anode cable is not damaged. If the cable is damaged it can cause

short circuit or leakage. If the cable is damaged please contact a Corrosion &

Water-Control bv representative for advice. Prior to transport, the cables of the

anodes are pressurized to check against leakage.

• Re-install the cable glands in the feed through construction and secure them by

using the Loctite or Versachem thread sealant.

• Pass the anode cable through the cable gland and tighten the screw cap fully.

For the tightening torques we refer to Attachment M.

• When the distance between the anode and feed-trough is longer than 20 cm the

cable must be secured in the sea chest to avoid damage.

* Note :

All welds should meet structures classification society rules.

* Note :

When tightening the cable with tie-wraps, only use 100% plastic tie-

wraps. This is to avoid damage to the cable.

* Note :

Make sure, there is enough space available below the anode rack. If

the anodes need replacement, space is needed in order to mount the

anodes.

Corrosion & Water-Control bv Page 15

ICAF Installation manuals CWC 1.0 Eng.

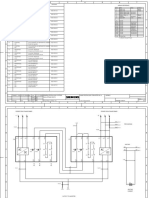

3 Power Unit

The power unit is equipped with:

• Power supply;

• Anode control prints (ACP);

• DPU (Touch screen operation);

• Primary and secondary fuses;

• Connection terminals;

• On / off main switch.

The main power supply for the power unit must be connected to the primary terminal

marked with L1 and N.

Each anode connection has its own specific cable (colour / number). The cable of the

anode must correspond with terminal number inside the DPU. The data for the anodes and

terminals is given by Corrosion & Water-Control bv.

Power unit

Menu

ICAF ICCP

m

i p ress ed cu rre nt m

i p re sse d curre nt

an t fi o ul n

i g syst em c at ho dic p rot ect o

i n

Plugbox

Cable feed through

1

Power cable Multicore cable Anode cable

Grounding cable

Anode cable

Alarm cable

Anode

Multicore cable Anode cable

Anode cable

Fig. 10

Corrosion & Water-Control bv Page 16

ICAF Installation manuals CWC 1.0 Eng.

4 Connection – Anode to Plugbox

The cable from the anodes must be connected via the cable feed through to the terminals

inside the plugbox. Please make use of the pre-installed cable glands and terminals.

A plugbox 4/1 means :

4 anode cable in (input) and 1 multicore cable out (output).

Corrosion & Water-Control bv can supply plugboxes with 1 to 10 inputs.

5 Connection – Plugbox to Digital Processing Unit

From the terminals in the plugbox, a multi-core cable must be connected to the

corresponding terminals in the DPU. Double check the multicore cable if the cables on both

end correspond with the correct terminals.

The powerunit is pre installed with a ground cable. The yard should prepared a connection

on the structures hull to connect a cable to.

6 Current requirements

The current requirements of each output / anode are pre-programmed by Corrosion &

Water-Control bv.

Corrosion & Water-Control bv Page 17

ICAF Installation manuals CWC 1.0 Eng.

Att. A - d0 Anode (CT Cofferdam)

d0 Anode (CT Cofferdam)

Mounting bolt M20 or M30.

M20 or M30 depents on the

anode thickness.

L

D

The CT Cofferdams are designed for mounting the D0 anode

inside a sea chest. A CT cofferdam can be delevered by CWC.

For more detaled information we refer you to the specific

mounting method.

CT Cofferdam

Anode length - (mm)

The length of these anode are from

L

350 mm up to 1200 mm

Anode Ø (mm)

Ø 60

Ø 70

Ø 80

Ø 90

Ø 100

Ø 120

Ø 150

Corrosion & Water-Control bv Page 18

ICAF Installation manuals CWC 1.0 Eng.

Att. B - d1 Anode

d1 Anode

Mounting bolt M20 or M30.

M20 or M30 depents on the

anode thickness.

L

D

0,2 x L

Anode length - (mm)

500

550

600

650

700

750

800

850

900

950

1000

1050

1100

1150

1200

1250

Anode Ø (mm)

Ø 60

Ø 70

Ø 80

Ø 90

Ø 100

Corrosion & Water-Control bv Page 19

ICAF Installation manuals CWC 1.0 Eng.

Att. C - d2 Anode

d2 Anode

L 6 Mtr.

D

0,2 x L 0,2 x L

Anode length - (mm)

500

550

600

650

700

750

800

850

900

950

1000

1050

Anode Ø (mm)

Ø 60

Ø 70

Ø 80

Ø 100

Ø 90

Corrosion & Water-Control bv Page 20

ICAF Installation manuals CWC 1.0 Eng.

Att. D - d3 Anode

d3 Anode

L 6 Mtr.

D

0,2 x L 0,2 x L

0,5 x L

Anode length (mm)

1100

1150

1200

1250

1300

1350

1400

1450

1500

1550

1600

1650

1700

Anode Ø (mm)

Ø 60

Ø 70

Ø 80

Ø 100

Ø 90

Corrosion & Water-Control bv Page 21

ICAF Installation manuals CWC 1.0 Eng.

Att. E - d4 Anode

d4 Anode

L 6 Mtr.

0,2 x L 0,2 x L

D

0,4 x L 0,4 x L

Anode length - (mm)

1750

1800

1850

1900

1950

2000

Anode Ø (mm)

Ø 60

Ø 70

Ø 80

Ø 100

Ø 90

Corrosion & Water-Control bv Page 22

ICAF Installation manuals CWC 1.0 Eng.

Att. F - Installation for Ø60 - Ø70 mm anodes

Installation Ø 60 - Ø 70 mm Anode

A Section A-A

50 - 200 mm

B

DETAIL A

Third anode support is

A deivered when anodes are

longer than 1050 mm.

Section B-B

Anode cable to plugbox

Cable Feed Through

DETAIL A

Isolator U-clamp

Angle steel Cathode plate

50 x 50 x 8 mm 80 x 8 mm Steel

89 Anode

M10

75

Attention :

150

The dimensions of the steel angle support,

whereto the support rings are mounted, may not

be bigger than 50mm.

The cathode plates and steel angle supports are

yard delivery.

Do not coat the cathode plates.

Do not over-tighten the nuts on the U-clamps, as

the support rings (isolation rings) are made of

plastic. All bolt and cable gland must be tightened

with a torque wrench.

We refer to Att. M for the tightening torques.

When tightening the cable with tie-wraps, only

use 100% plastic tie-wraps.

Make sure, there is enough space available below

the anode rack. If the anodes need to be replaced

space is needed to mount the anodes easily.

Corrosion & Water-Control bv Page 23

ICAF Installation manuals CWC 1.0 Eng.

Att. G - Installation for Ø80 - Ø90 – Ø100 mm anodes

Installation Ø80 - Ø90 - Ø100 mm Anode

A Section A-A

50 - 200 mm

B

DETAIL A Third anode support is

A deivered when anodes are

longer than 1050 mm.

Section B-B

Anode cable to plugbox

Cable Feed Through

DETAIL A

Isolator U-clamp

Cathode plate

120 x 12 mm Steel

Angle steel

50 x 50 x 8 mm

126 Anode

M12

115

Attention :

230

The dimensions of the steel angle support,

whereto the support rings are mounted, may not

be bigger than 50mm.

The cathode plates and steel angle supports are

yard delivery.

Do not coat the cathode plates.

Do not over-tighten the nuts on the U-clamps, as

the support rings (isolation rings) are made of

plastic. All bolt and cable gland must be tightened

with a torque wrench.

We refer to Att. M for the tightening torques.

When tightening the cable with tie-wraps, only

use 100% plastic tie-wraps.

Make sure, there is enough space available below

the anode rack. If the anodes need to be replaced

space is needed to mount the anodes easily.

Corrosion & Water-Control bv Page 24

ICAF Installation manuals CWC 1.0 Eng.

Att. H - Installation d0 M20

Installation d0 anodes M20

M20

Detail A

Strainer cover

Ø60 - Ø90

Detail A

M8 Bolt

washer

Stud

Nut M20

Washer

PVC Washer

Gasket

Before mounting a do anode, with a M20 Attention :

stud, to the cover of the strainer a hole Before mounting the do anode, with a M20 stud,

of Ø 24mm must be drilled. to the cover of the strainer a hole of Ø 24mm

must be drilled.

All bolt and cable gland must be tightened with

a torque wrench. We refer to Att. M for the

tightening torques.

Ø24

Corrosion & Water-Control bv Page 25

ICAF Installation manuals CWC 1.0 Eng.

Att. I - Installation d0 M30

Installation d0 anodes M30

M30

Detail A

Strainer cover

Ø80 - Ø150

Detail A

M8 Bolt washer

Stud Low nut M30

Nut M30

Washer

PVC Washer

Gasket

Before mounting a do anode, with a M30 Attention :

stud, to the cover of the strainer a hole Before mounting the do anode, with a M30 stud,

of Ø 38mm must be drilled. to the cover of the strainer a hole of Ø 38mm

must be drilled.

All bolt and cable gland must be tightened with

a torque wrench. We refer to Att. M for the

tightening torques.

Ø38

Corrosion & Water-Control bv Page 26

ICAF Installation manuals CWC 1.0 Eng.

Att. J - Installation d0 + NW125 CT Cofferdam M20

Installation d0 anodes

(CT Cofferdam NW125)

M20

Ø115

Detail A

Cover

Gasket

Stud Cable gland

154

Washer Nut M16

Top flange 22mm

Gasket

Gasket Bottom flange 22mm

Detail A

M8 Bolt

washer

Stud

Nut M20

Washer

Ø60 - Ø90 PVC Washer

Gasket

Ø250

Bottom flange Attention :

Weld the bottom flange in position.

All welds should meet structures classification

society rules.

All bolt and cable gland must be tightened with

a torque wrench. We refer to Att. M for the

tightening torques.

Ø140 22

Ø250

Corrosion & Water-Control bv Page 27

ICAF Installation manuals CWC 1.0 Eng.

Att. K - Installation d0 + NW125 CT Cofferdam M30

Installation d0 anodes

(CT Cofferdam NW125)

M30

Ø115

Detail A

Cover

Gasket

Stud Cable gland

154

Washer Nut M16

Top flange 22mm

Gasket

Gasket Bottom flange 22mm

Detail A

M8 Bolt washer

Stud Low nut M30

Nut M30

Washer

Ø80 - Ø120 PVC Washer

Gasket

Ø250

Bottom flange Attention :

Weld the bottom flange in position.

All welds should meet structures classification

society rules.

All bolt and cable gland must be tightened with

a torque wrench. We refer to Att. M for the

tightening torques.

Ø140 22

Ø250

Corrosion & Water-Control bv Page 28

ICAF Installation manuals CWC 1.0 Eng.

Att. L - Installation d0 + NW150 CT Cofferdam

Installation d0 anodes

(CT Cofferdam NW150)

Ø115

Detail A

Cover

Gasket

Stud Cable gland M32

158

Washer Nut M20

Top flange 20mm

Gasket

Bottom flange 20mm

Gasket

Detail A

M8 Bolt washer

Stud Low nut M30

Nut M30

Washer

Ø150 PVC Washer

Gasket

Ø285

Bottom flange Attention :

Weld the bottom flange in position.

All welds should meet structures classification

society rules.

All bolt and cable gland must be tightened with

a torque wrench. We refer to Att. M for the

tightening torques.

168 22

285

Corrosion & Water-Control bv Page 29

ICAF Installation manuals CWC 1.0 Eng.

Att. M - Tightening torques

CFT cable gland NPT ½” 70 Nm

CFT cable gland cup “ 25 Nm

M32 cable gland M32 x 1,5 100 Nm

M32 cable gland cup “ 70 Nm

Studs CT Cofferdam NW 125 M16 (8x) 80 Nm

Studs CT Cofferdam NW 125 M20 (8x) 100 Nm

U-clamp M10 20 Nm

U-clamp M12 35 Nm

Anode Ø

do stud M20 Nut 60 75 Nm

70 75 Nm

80 75 Nm

90 75 Nm

M30 Nut 80 100 Nm

90 100 Nm

100 120 Nm

120 140 Nm

150 180 Nm

M30 Low nut - 100 Nm

Corrosion & Water-Control bv Page 30

ICAF Installation manuals CWC 1.0 Eng.

You might also like

- Manual ICAF 2947 Skandi Achiever V02-83215Document19 pagesManual ICAF 2947 Skandi Achiever V02-83215João Pedro Parada MacielNo ratings yet

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveFkrmcofmfmNo ratings yet

- Cathodic Protection For PipelinesDocument18 pagesCathodic Protection For Pipelineskaushikgreat100% (3)

- Series D1VW Characteristics: Directional Control ValveDocument8 pagesSeries D1VW Characteristics: Directional Control ValveJas SumNo ratings yet

- Series D1MW Characteristics: Technical FeaturesDocument6 pagesSeries D1MW Characteristics: Technical FeaturesНикола КолаковићNo ratings yet

- La WbsebDocument11 pagesLa WbsebPritamNo ratings yet

- Specification No. CSC-72/DH/UH/P&D/2012-2013Document27 pagesSpecification No. CSC-72/DH/UH/P&D/2012-2013ahmedNo ratings yet

- CapacitorDocument48 pagesCapacitorgoobcheNo ratings yet

- LIGHTNING ARRESTORS - Rev 2Document11 pagesLIGHTNING ARRESTORS - Rev 2kajale.shrikantNo ratings yet

- Cathodic Protection Electrolytic AntifoulingDocument8 pagesCathodic Protection Electrolytic Antifoulingcatalintoader1969No ratings yet

- CA110061 - NB906 - ICCP ManualDocument74 pagesCA110061 - NB906 - ICCP ManualBùi Công Lộc100% (1)

- 3 KTA DesignguideDocument32 pages3 KTA Designguideodin_auerNo ratings yet

- Cathelco: C-Shield IccpDocument75 pagesCathelco: C-Shield IccpJuan Carlos ZavalaNo ratings yet

- 45SAFETY Interlock SwitchesDocument8 pages45SAFETY Interlock SwitchesAndreina DelgadoNo ratings yet

- FF Works - CAPDocument8 pagesFF Works - CAPEngy AhmedNo ratings yet

- AC03 Safety (AC03..CS) : Vishay DraloricDocument3 pagesAC03 Safety (AC03..CS) : Vishay Draloricyenassiri278No ratings yet

- Pgcil SpecsDocument90 pagesPgcil SpecsNirmal Wires100% (1)

- Danfoss CoilsDocument22 pagesDanfoss CoilsDaniel TovarNo ratings yet

- TDS ARGO HYTOS Coils For Solenoid Operated Valves EngDocument18 pagesTDS ARGO HYTOS Coils For Solenoid Operated Valves Engandres ramosNo ratings yet

- Kontaktor Shcneider K - LC3K06M7Document6 pagesKontaktor Shcneider K - LC3K06M7lailatul maftukhaNo ratings yet

- ENG DS OMI 2 Pole Series Relay Data Sheet E 0411Document3 pagesENG DS OMI 2 Pole Series Relay Data Sheet E 0411letterniNo ratings yet

- P0050S MGPSDocument21 pagesP0050S MGPSDmytro 1No ratings yet

- NM8N HVDocument28 pagesNM8N HVRana Awais KhanNo ratings yet

- Iso-Phase Bus Duct Typical MaintenanceDocument18 pagesIso-Phase Bus Duct Typical MaintenancesulemankhalidNo ratings yet

- Saturno 3 Counter EjectorDocument10 pagesSaturno 3 Counter Ejectorarmando olivaresNo ratings yet

- MV ConnexDocument76 pagesMV ConnexPartha BiswasNo ratings yet

- Denon Avr-2310 PDFDocument169 pagesDenon Avr-2310 PDFboroda241067% (3)

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- Solenoide Ode - GenebreDocument10 pagesSolenoide Ode - GenebreRenzo Huarcaya HuaraccNo ratings yet

- Fall Arresst For Standing Seams RoofingDocument18 pagesFall Arresst For Standing Seams RoofingDoug WeirNo ratings yet

- Cathelco Evac ICPP ManualDocument85 pagesCathelco Evac ICPP ManualВладимир ПетрукNo ratings yet

- Series D1Vw 8 Watt Characteristics: Distributed and Standardised Installation TechDocument6 pagesSeries D1Vw 8 Watt Characteristics: Distributed and Standardised Installation TechDollinho AmiguinhoNo ratings yet

- Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130Document2 pagesOde Solenoid Valve 21wa3z0b130 - 21wa4z0b130Uno MariconNo ratings yet

- Woehner PortafusiblesDocument5 pagesWoehner PortafusiblesmerdaNo ratings yet

- F-050 Impressed Current SystemDocument80 pagesF-050 Impressed Current SystemВасиль Гудзь100% (1)

- 02.06.05 3-Way Valve 1240 6519 - enDocument6 pages02.06.05 3-Way Valve 1240 6519 - enabuya3kubmNo ratings yet

- DS6 - DS9 - Technical DatasheetDocument3 pagesDS6 - DS9 - Technical Datasheetcarlos martinezNo ratings yet

- 776 ICCP Installation Manual 33383N PDFDocument95 pages776 ICCP Installation Manual 33383N PDFDmitrii Pustoshkin67% (3)

- D3W Stand - UKDocument8 pagesD3W Stand - UKYosmell Fritzan Paz UrbizagasteguiNo ratings yet

- LC 40le810eDocument83 pagesLC 40le810eToni222No ratings yet

- Victaulic Flexible Hose Connecting To Dry Barrel SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Dry Barrel SprinklerOwais AhmedNo ratings yet

- 3/2-Way Direct Mounting Pilot ValveDocument3 pages3/2-Way Direct Mounting Pilot ValveTan Chee KwangNo ratings yet

- Pcb001nda 1Document2 pagesPcb001nda 1junaid ahmadNo ratings yet

- Sonnenschein SOLAR BLOCKDocument7 pagesSonnenschein SOLAR BLOCKCalincit0No ratings yet

- CHANNEL6COILVOLTAGE24VDCDocument2 pagesCHANNEL6COILVOLTAGE24VDCDee RajaNo ratings yet

- NW FlangeDocument11 pagesNW FlangeStanley PeterNo ratings yet

- 03-000-R1 Alternative DC Power Systems SummaryDocument20 pages03-000-R1 Alternative DC Power Systems Summaryengr khanNo ratings yet

- Mps & Itt - Spiral SteelDocument23 pagesMps & Itt - Spiral SteelSiswo YuwonoNo ratings yet

- 11kV 22kV AB Switch With Polymer Insulator 31.08.2020Document18 pages11kV 22kV AB Switch With Polymer Insulator 31.08.2020SunilkumarNo ratings yet

- 03 Bushing-Cedaspa Type FDocument7 pages03 Bushing-Cedaspa Type FKatherine SmithNo ratings yet

- Marine Growth Preventing Device Instr Manu - M-9-20Document22 pagesMarine Growth Preventing Device Instr Manu - M-9-20Gokul SureshNo ratings yet

- OsiSense XC Standard - XCKJ167ADocument8 pagesOsiSense XC Standard - XCKJ167AgmatweakNo ratings yet

- MW610 2S MGPSDocument19 pagesMW610 2S MGPSkodrys100% (1)

- Safety Standard Recognized, C900, Encapsulated, AC Type, X1 400 VAC/Y2 250 VAC (Industrial Grade)Document17 pagesSafety Standard Recognized, C900, Encapsulated, AC Type, X1 400 VAC/Y2 250 VAC (Industrial Grade)cacalot93No ratings yet

- DMRDocument8 pagesDMRaks2205No ratings yet

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Document2 pagesSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniNo ratings yet

- 07 - Installation of ACS1000Document18 pages07 - Installation of ACS1000Canaril VictóriaNo ratings yet

- Ordering Code: HA 8007 11/2014 Coils For Solenoid Operated ValvesDocument18 pagesOrdering Code: HA 8007 11/2014 Coils For Solenoid Operated ValvesOleksandr U.No ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- X00364-1003-4A Main Propulsion Thruster No. 4Document24 pagesX00364-1003-4A Main Propulsion Thruster No. 4gennaroNo ratings yet

- Carlyle Service ManualDocument124 pagesCarlyle Service Manualrlynch3394% (16)

- Triton® XLX 35 Computer ControlDocument273 pagesTriton® XLX 35 Computer ControlgennaroNo ratings yet

- Hmi Tp177a Tp177b Op177b Operating Instructions en US en-USDocument380 pagesHmi Tp177a Tp177b Op177b Operating Instructions en US en-USSting EyesNo ratings yet

- User Manual NovDocument578 pagesUser Manual Novgennaro100% (1)

- ODIM HP Manual-OversideDocument111 pagesODIM HP Manual-OversidegennaroNo ratings yet

- EHV Bladder Accumulators RangeDocument16 pagesEHV Bladder Accumulators RangegennaroNo ratings yet

- Carrier 90MA404-931 Pièces DétachéesDocument43 pagesCarrier 90MA404-931 Pièces DétachéesBibene MakitaNo ratings yet

- 3BSE020923R5001 A en S800 I O - General Information and Inst PDFDocument284 pages3BSE020923R5001 A en S800 I O - General Information and Inst PDFRavenShieldXNo ratings yet

- Seatex MRU: User's ManualDocument104 pagesSeatex MRU: User's ManualAlexGrigorjevNo ratings yet

- NAVTEXDocument88 pagesNAVTEXAlex SkriabikovNo ratings yet

- Hipapa Kongsberg 501 NuovoDocument57 pagesHipapa Kongsberg 501 NuovogennaroNo ratings yet

- Operator's Manual DI16 EMS - PDE Eng Issue 2083248Document59 pagesOperator's Manual DI16 EMS - PDE Eng Issue 2083248gennaroNo ratings yet

- Curriculum Vitae: Maria BeihaghiDocument19 pagesCurriculum Vitae: Maria BeihaghiSamuel Embiza TadesseNo ratings yet

- Take Home ExamDocument10 pagesTake Home ExamRaine PiliinNo ratings yet

- Electric CircuitsDocument7 pagesElectric CircuitsEzio AuditoreNo ratings yet

- Act Action Active Actively: Professional English Ii Unit IiDocument3 pagesAct Action Active Actively: Professional English Ii Unit IiCamila Ruiz GasparNo ratings yet

- 362100deff40258 Exde03 35Document44 pages362100deff40258 Exde03 35Daniel SdNo ratings yet

- Chase Evan Oliphant BiographyDocument1 pageChase Evan Oliphant Biographyapi-248803155No ratings yet

- FEM Lab 1 2011Document20 pagesFEM Lab 1 2011droessaert_stijnNo ratings yet

- Drum Brakes RT: According To DIN 15435Document1 pageDrum Brakes RT: According To DIN 15435LukaNo ratings yet

- Prof Ed QuestionsDocument35 pagesProf Ed QuestionsKatrina BautistaNo ratings yet

- PuzzlesDocument9 pagesPuzzlespraveen_1288No ratings yet

- Literary, Photo Story, OpinionDocument9 pagesLiterary, Photo Story, OpinionMaya BabaoNo ratings yet

- SN 74 Ls 245Document19 pagesSN 74 Ls 245Luisdceo LggNo ratings yet

- Timings To Avoid Based On Ghatak Chakra - Mariocean@gmail - Com - GmailDocument3 pagesTimings To Avoid Based On Ghatak Chakra - Mariocean@gmail - Com - GmailMariana SantosNo ratings yet

- Road Check List Borrow ExcavationDocument2 pagesRoad Check List Borrow Excavationklp_kedarpNo ratings yet

- Lecture 8 Data Sources in GISDocument32 pagesLecture 8 Data Sources in GISkhakhamasetiNo ratings yet

- 2022 01 MED21A T1-Assessment QestionPaperDocument4 pages2022 01 MED21A T1-Assessment QestionPaperIshmael MvunyiswaNo ratings yet

- College For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityDocument2 pagesCollege For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityLove JcwNo ratings yet

- ASME Y14.5 2009 Vs 2018 Comparison ChartDocument1 pageASME Y14.5 2009 Vs 2018 Comparison ChartShiban TripathyNo ratings yet

- Calculating Speed Time and Distance (3) .PPT 3rd Quarter Math 6Document25 pagesCalculating Speed Time and Distance (3) .PPT 3rd Quarter Math 6Wilma Ganit BalasNo ratings yet

- Truth About Reptilian Alien RacesDocument12 pagesTruth About Reptilian Alien RacesSuripeddi Koundinya60% (5)

- 2018 (Vuorien Et Al)Document20 pages2018 (Vuorien Et Al)gowthami mNo ratings yet

- Myp Unit 3 PlannerDocument6 pagesMyp Unit 3 PlannerTarique MasoodNo ratings yet

- Physics (Mass, Weight and Density)Document2 pagesPhysics (Mass, Weight and Density)TVNo ratings yet

- MODULE 2 The Nature of The Human PersonDocument8 pagesMODULE 2 The Nature of The Human PersonMary Grace Lobina ColamboNo ratings yet

- DI Saturday Essays For ENGR 102Document2 pagesDI Saturday Essays For ENGR 102Amber ChungNo ratings yet

- SC WD 1 WashHandsFlyerFormatted JacobHahn Report 1Document3 pagesSC WD 1 WashHandsFlyerFormatted JacobHahn Report 1jackson leeNo ratings yet

- The Earth's Movements PDFDocument37 pagesThe Earth's Movements PDFEnola PearlNo ratings yet

- Mathematics: Quarter 1 - Module 4: Properties of Operations On The Set of IntegersDocument25 pagesMathematics: Quarter 1 - Module 4: Properties of Operations On The Set of Integersarnel paghacian100% (1)

- ALFA ThermostatDocument1 pageALFA ThermostatTamilarasi SambathNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program Descriptionnamasral100% (3)