Professional Documents

Culture Documents

TWIX 1 230V - Instruction Manual

Uploaded by

Keval MistryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TWIX 1 230V - Instruction Manual

Uploaded by

Keval MistryCopyright:

Available Formats

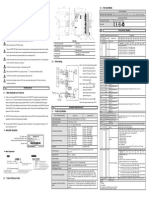

TWIX-1-230V RELAY OUTPUTS

selec Operating Instructions Number of Relay Outputs 4

INSTALLATION INSTRUCTIONS

CAUTION

Output Type NO contact type 1. This equipment, being built-in-type, normally becomes

OP481-V02

a part of the main control panel and the terminals do not

5A @28VDC (Resistive)

FEATURES Output Current

remain accessible to the user after installation.

2. Conductors must not come in contact with the internal

5A @240VAC (Resistive)

circuitry of the equipment else it may lead to a safety

Ø

PLC with built-in HMI hazard that may endanger life or cause electrical shock

Ø

Configurable LED display

Response Time 10ms to the operator.

Ø

RS485 based communication with MODBUS RTU 3. Circuit breaker or mains switch must be installed

Life Expectancy 30000 operation at full load between the power source and supply terminals to

protocol

facilitate power 'ON' or ‘OFF' function.

Isolation No 4. The equipment shall not be installed in environmental

conditions other than those specified in this manual.

Existence of common points between channels 1 COM for 4 Relay Outputs 5. Since this equipment forms part of the main control

panel, its output terminals get connected to the host

equipment. Such equipment shall also comply to EMI /

48mm x 96mm ANALOG INPUTS EMC and safety requirements like CE standard

procedure.

SPECIFICATIONS TC Type RTD Type 7. T h e r m a l d i s s i p a t i o n o f e q u i p m e n t i s m e t t h r o u g h

ventilation holes provided on housing of equipment.

Top Red – 8 digits (7 segment) Number of channels 1 (user selectable) Obstruction of these ventilation holes may lead to a

safety hazard.

Display Bottom Green – 6 digits (7 segment) J, K, T, R, S, C, E, B, N, 8. The output terminals shall be loaded strictly as per the

values / range specified by the manufacturer.

8 LED's (4 Red + 4 Green) Sensor type L, U, W, PLATINEL II, PT100

MILLIVOLT (-5 to 65mV) ELECTRICAL PRECAUTIONS DURING USE

No. of Keys 5 (4-user configurable) Electrical noise generated by switching of inductive

Measurement Range As per sensor selection 0

-99 C to 850 C

0 loads can create momentary disruption, erratic display,

Supply Voltage 230V AC (90 - 270 V AC) latch up, data loss or permanent damage to the

Type of input Non-differential instrument.

Sensor Supply (SS) 10V, 50mA To reduce noise :

Temperature Resolution 0 Use of Selec make Snubber across load is

0.1 C recommended.

FUNCTIONAL SPECIFICATIONS (CPU) Snubber Part no. : SNUBBER

Digital Resolution for MILLIVOLT 12 bits NA NOTE : Below mentioned diagram is applicable only for

Windows based user friendly SELPRO software for

Programming Language 230V relay outputs.

ladder logic programming. Input impedance in signal range 560 kΩ 750 kΩ

0

Program Memory : 112 kB Analog input error at 25 C 0.25% of full scale ±1 C

0

0.1% of full scale ±1 C

0

Data Memory : 16 kB Absolute input range 5V NA

Memory

EEPROM Memory : 2 kB

Non linearity 0.25% of full scale ±1 C

0

0.1% of full scale ±1 C

0

VAR_INOUT & VAROUTPUT TYPE Variable :-

Max 120 bytes retention Conversion time 100 ms Typical Connections For Loads :

Scan Time Typical 1ms For load current < 0.5A For bigger loads use

Protection against polarity inversion Yes NA interposing relay / contactor

Timer On delay, Timer Off delay, Pulse Timer,

Function Blocks Channel isolation No

24V DC / L N / GND 24V DC / L N / GND

Special Timer, Up/Down Counter, PID control etc. PLC

PLC

Memory Retention 10 Years PLC PLC Contactor

COMMUNICATION LOAD C NO

DIGITAL INPUTS 1 C NO

0

* = 90 Phase shift signals

Communication Port RS485 Slave R C

R C

L N Snubber

Number of Digital Inputs 6 (Including 2 Fast Input) Snubber C

Communication Protocol MODBUS RTU LOAD

L N

Unidirectional / Bidirectional / Quadrature /

Operating Modes (user configurable) 9600, 19200, 38400, 57600, 115200 NOTE : A) Use snubber as shown above to increase life of

Dual Unidirectional / None internal relay.

Baud Rate (user configurable via software and hardware)

B) Use separate shielded wires for inputs.

MODE Default = 19200 (Preferred ladder downloading at 19200)

Channel DI

UNI BI QUAD DUAL UNI None MECHANICAL INSTALLATION

ENVIRONMENTAL CONDITIONS

I0 Rate Totalizer Rate Totalizer 1st input *

1

Rate Totalizer Digital Input Outline Dimensions (in mm) Panel Cutout (in mm)

Operating Temperature 0 to 55 C

0

FC0

I1 Digital Input Direction 2nd input *1 Totalizer Digital Input Storage Temperature -20 to 70 C

o

46

45

50

Operating Range 5 ~ 30V DC Humidity (non-condensing) 95%

Input current 3 mA @10V Mounting Panel Mounted 98 3 76 92

For installing the controller

Level 1 Level 0 <3V DC Weight Approx. 240 gms 1. Prepare the panel cutout with proper dimensions as

Action Level shown above.

Level 0 Level 1 ≤ 5V DC

SAFETY PRECAUTIONS 2. Fix the unit into the cutout. Insert the clamp from both

sides and tighten the screws.

Digital Input mode Typical 1ms (based on ladder scan time)

Response Time

Fast Input mode 100µsec CAUTION

Input Impedance 7.5 kΩ The equipment in its installed state must not come in proximity to

any heating sources, caustic vapors, oils, steam or other unwanted

Debounce Time 0 ~ 255 ms (Default = 10 ms) process by products.

Maximum counting Frequency (Fast Input) 5kHz

Protection against polarity Inversions Yes Doc. name : OP INST TWIX-1-230V OP481-V02(Page 1 of 2)

EMC Guidelines : MENU DESCRIPTION CALIBRATION CERTIFICATE

1. Use proper input power cables with shortest connections

OP481-V02

and twisted type.

2. Layout of connecting cables shall be away from any Model :- TWIX-1-230V

internal EMI source.

PLC Stop mode Claimed Accuracy :- For TC :0.25% of full Scale ± 1°C

MAINTENANCE :

1. To avoid blockage of ventilation holes, clean the

User HMI mode 1234 For RTD :0.1% of full Scale ± 1°C

For V & I :0.5% of full Scale

1234

equipment regularly using a soft cloth. Internal

2. Do not use Isopropyl alcohol or any other organic ENT (Press 3sec.) SET (Press 3sec.)

Solvents for cleaning.

menu

mode ENT

Internal Menu

Row 1 : Bootloader version

Traceability :-

50X25

1234

WIRING INSTRUCTIONS 1234 Row 2 : SELPRO Software version (Version number is subject to change)

CAUTION

1. To prevent risk of electric shock, power supply to the Scan time

equipment must be kept OFF while wiring.

SET

ROW1 : Ladder scan time in MS for the application downloaded.

2. Terminals and electrically charged parts must not be 1234

touched when the power is ON. 1234 ROW2 : Millisecond (unit)

3. Wiring shall be done strictly according to the terminal

This Units Has Been verified For All functional parameters mentioned in Operating Instruction.

Press ENT to go to previous screen

layout provided in the operating manual.

4. To eliminate electromagnetic interference use short wire Communication settings

F1

with adequate ratings and twists of equal size.

1234

Row1 : Slave ID and Baudrate Analog Parameters [For Applicable Product]

5. The power supply connection cable must have a cross

section of 1sq.mm or greater and insulation capacity of at

1234 Row2 : Word length(8), Parity (N=None) and Stop bits (2)

least 1.5KV. To configure communication settings : The Calibration of this unit has been verified at the following value for selection channels :-

SET : Edit enable (Press for 3 sec.)

F1 : Shift cursor position

F2 : Decrement value Analog Input :- CH0 CH1 CH2 CH3 CH4 CH5

FUNCTIONAL DETAILS F3 : Increment value

ENT : Save value

TWIX-1-230V is a PLC with built in HMI. The user can TC

configure the product using SELPRO software.

SELPRO has two sections :

1. Ladder logic programming section

F2

Digital Input Status RTD

2. Selec Machine Interface, used for configuration of LED Row 1 : Status of DI0/DI1/DI2/DI3

HMI. 1234

For details of the software, please refer to the software user

1234 LED Row 2 : Status of DI4/DI5 AI

manual.

Digital Output Status AV

F3

INTERNAL PINOUT FOR COMMUNICATION RS485 PORT 1234

1234

LED Row 1 : Status of DO0 /DO1/DO2/ DO3

NOTE : Analog Input/Analog Output Has Been Verified At the following Value :

PIN DESCRIPTION

1 RS485+ (Slave) Enter Bootloader mode Calibration Display Calibration Display

Sensor Sensor

6 Pin 2 Temp(°C) Value(°C) Value Value

Power ON After 3sec. release

Jack No Ladder

3 Device 35.0

35.0

ENT (Pressed)

4 Bootloader mode

PIN 1

5

K Voltage 0.000 0.000

700.0 700.0

RS485– (Slave)

(VDC)

6 ACCESSORIES (To be ordered separately) SERVICE DETAILS 10.000 10.000

This device contains no user serviceable parts and 1350.0 1350.0

WIRING DIAGRAM ORDER CODE DESCRIPTION requires special equipment and specialized engineers for

repair.

USB to RS485 cable

TC + / RTD1

TC / RTD2

AC-USB-RS485-03

(6 pin jack for downloading)

Please contact service center for repair on the following 0.0 0.0

SENSOR

numbers : Tel. No. : + 91-7498077172 ;

Email : service@selec.com 0.000 0.000

NTC

AC-USB-RS485-02 * USB to RS485 cable (2 pin open wire) NO WARRANTY ON UNIT DAMAGED DUE TO WRONG POWER SUPPLY. PT100 Current

500.0 500.0

1 2 3 4 5 6 7 8 9 10 ACH-004 RJ25 (6-pin) cable (mA) 20.000 20.000

I5 I4 I3 I2 I1 I0 GND SS (Specifications are subject to change, since development is a

FC0 AC-IOEXP-03 Port Expansion adapter 800.0 800.0

21 RTD3 10V 22 + continuous process.)

Note: * Along with ACH-004 & AC-IOEXP-03 for networking

Selec Controls Pvt. Ltd., India

11 12 13 14 15 16 17 18 19 20 The thermocouple/RTD curves are Linearized in this microprocessor based product ,

NO0 NO1 NO2 NO3 COM

Factory Address : and hence the value interpolated between the readings shown above are also equally accurate,

L N

EL-27/1, Electronic Zone, TTC Industrial Area, MIDC, Mahape, at every point in the curve.

LOAD

LOAD

LOAD

LOAD

Navi Mumbai - 400 710, INDIA.

Tel. No. : +91-22-41 418 419/430 | Fax No. : +91-22-28471733 Product Calibration Is Traceable to NABL Standard.

Toll free : 1800 227 353 (BSNL/MTNL Subscribers only) Unit is accepted as accuracy is within the specified limit of claimed accuracy and certifiedis valid

NOTE : When DIs are to be connected to External SMPS,

then 0V of Ext. SMPS should be looped with SS- of PLC Website : www.selec.com | Email : sales@selec.com up to one year from the date of issue.

Doc. name : OP INST TWIX-1-230V OP481-V02(Page 2 of 2)

You might also like

- Earthing Design TestingDocument2 pagesEarthing Design Testingblp26No ratings yet

- ABB - 4 Biggest MistakesDocument7 pagesABB - 4 Biggest MistakesAnargha BhattacharyaNo ratings yet

- ABB Navigator 600Document96 pagesABB Navigator 600lequydueu100% (1)

- Avinash Adluri PTE JourneyDocument6 pagesAvinash Adluri PTE Journeydarpan.groverNo ratings yet

- Advamce Diploma in Industrial Safety & Security Management (FF)Document21 pagesAdvamce Diploma in Industrial Safety & Security Management (FF)Dr Shabbir75% (4)

- Laboratory Activity 1: Do and See The Surface Tension: 1. Describe The Shape of The Water On Top of The Coin. (5 Points)Document3 pagesLaboratory Activity 1: Do and See The Surface Tension: 1. Describe The Shape of The Water On Top of The Coin. (5 Points)Clarence Bautista100% (2)

- State of Nature Alternatives 1 2 3Document10 pagesState of Nature Alternatives 1 2 3Michael Allen RodrigoNo ratings yet

- D4643Document5 pagesD4643Ruddy EspejoNo ratings yet

- Wiring Diagram Selection: Y004.868/003/en Issue 1.16 Page 1/5Document5 pagesWiring Diagram Selection: Y004.868/003/en Issue 1.16 Page 1/5Medjahdi RafikNo ratings yet

- 2CSC400002D0208Document751 pages2CSC400002D0208Pedro BortotNo ratings yet

- Motor technical specificationsDocument2 pagesMotor technical specificationsmishtinilNo ratings yet

- Selpro DatasheetDocument2 pagesSelpro Datasheetnieav280No ratings yet

- Functional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualDocument24 pagesFunctional Safety Switch Amplifier KFD2-SR2-Ex .W (.LB) : ManualPaul Ramos CarcaustoNo ratings yet

- SLC 220 UniversalDocument4 pagesSLC 220 UniversalRaja Ram67% (3)

- EM1000/EM1200 Energy Meter: Va Va1 Va2 Va3 W W1 W2 W3Document4 pagesEM1000/EM1200 Energy Meter: Va Va1 Va2 Va3 W W1 W2 W3Imamul HaqueNo ratings yet

- DB Range Catg - 2016 - v11 PDFDocument24 pagesDB Range Catg - 2016 - v11 PDFchaitanyaomronNo ratings yet

- Delta PLC Temp ModuleDocument2 pagesDelta PLC Temp ModuleSohail ANo ratings yet

- ElettroDocument16 pagesElettroNikhil RajanNo ratings yet

- Manual For 3-Disp-Jumbo-USL PDFDocument9 pagesManual For 3-Disp-Jumbo-USL PDFYogesh RamdasiNo ratings yet

- NEMA Motor Manual Section on AccessoriesDocument16 pagesNEMA Motor Manual Section on AccessoriesDelfinshNo ratings yet

- Muc 5 52003821.58084010 59902230Document16 pagesMuc 5 52003821.58084010 59902230zhou NickyNo ratings yet

- ABB TransformatoriDocument1 pageABB TransformatoridgngNo ratings yet

- Digital Output Unit Technical SpecificationsDocument10 pagesDigital Output Unit Technical SpecificationsRio YuwandiNo ratings yet

- WW-MFR2 (Multifunction Relay)Document4 pagesWW-MFR2 (Multifunction Relay)KT MENONNo ratings yet

- 1008S User ManualDocument38 pages1008S User ManualHardev Singh100% (1)

- 21h4e1b4 Annunciator KeyboardDocument12 pages21h4e1b4 Annunciator KeyboardCHRISTIANABGNo ratings yet

- Arduino, Components, Sensors Product List with PricesDocument3 pagesArduino, Components, Sensors Product List with PricesuyaiekanemNo ratings yet

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocument24 pagesTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNo ratings yet

- 5040 - MASIBUS CONTROLLER User - Manual PDFDocument53 pages5040 - MASIBUS CONTROLLER User - Manual PDFYUYWEGDYNo ratings yet

- P-I Transducer - P200-P290 PDFDocument4 pagesP-I Transducer - P200-P290 PDFman_y2kNo ratings yet

- Micro ScannerDocument2 pagesMicro ScannerArun KumarNo ratings yet

- Temperature Indicator 409-4IN User's ManualDocument34 pagesTemperature Indicator 409-4IN User's Manualaayush715100% (1)

- Pressure Transmitter Data SheetDocument2 pagesPressure Transmitter Data SheetzethramNo ratings yet

- Earthing PitDocument4 pagesEarthing PitChaitanya ShakyaNo ratings yet

- Atv31 (E)Document220 pagesAtv31 (E)Santos Zosimo Ocas GoicocheaNo ratings yet

- PECON Condense Catalogue 2013Document36 pagesPECON Condense Catalogue 2013Manoj AggarwalNo ratings yet

- Pressure & Temperature Switch RT SeriesDocument4 pagesPressure & Temperature Switch RT SeriesVivek Vous AimeNo ratings yet

- Masibus Tcs 4050m - Loop Calibrator - Cb-2 - tcs4050m - r2 - 0110Document2 pagesMasibus Tcs 4050m - Loop Calibrator - Cb-2 - tcs4050m - r2 - 0110kazishahNo ratings yet

- Powerguard Heavy DutyDocument12 pagesPowerguard Heavy DutyOdion Usunobun Julius100% (1)

- LV Fuse Holders BS Type SelectionDocument2 pagesLV Fuse Holders BS Type Selectionavishai04No ratings yet

- 2-Wire RH+T Transmitters with Dual LCD and IP65 ProtectionDocument6 pages2-Wire RH+T Transmitters with Dual LCD and IP65 ProtectionRavi Kant GuptaNo ratings yet

- 21A Solenoid Valves Series DatasheetDocument40 pages21A Solenoid Valves Series Datasheetportusan2000No ratings yet

- Rish em 1320-30-40 Multifunction MetersDocument8 pagesRish em 1320-30-40 Multifunction Metersswapnil patkar100% (1)

- ContactorsType MN00 Ac ContactorDocument2 pagesContactorsType MN00 Ac ContactorDivyanshu MittalNo ratings yet

- Maxlinks ADocument89 pagesMaxlinks ADeepak GuptaNo ratings yet

- Dissolved Oxygen Analyzer User ManualDocument92 pagesDissolved Oxygen Analyzer User ManualABVSAINo ratings yet

- Man FL10Document54 pagesMan FL10BiljanaKovacevic100% (1)

- Rudolf RTXDocument15 pagesRudolf RTXNuengruthai WeerawattanaNo ratings yet

- Practical File of PLC and SCADADocument17 pagesPractical File of PLC and SCADAvara prasadNo ratings yet

- Trivector Meter ER300PDocument4 pagesTrivector Meter ER300PAnonymous q8EusUCNo ratings yet

- Control Gear Price ListDocument15 pagesControl Gear Price ListShubham GuptaNo ratings yet

- BMS Shop Drawing - LCP-R-01 - UERCCDocument16 pagesBMS Shop Drawing - LCP-R-01 - UERCCmahmoudramadan007No ratings yet

- CDTTSDocument2 pagesCDTTSAnonymous m65TTcfOT100% (1)

- OGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistDocument2 pagesOGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistTaylor100% (1)

- Masibus 85XX+ - R3F - 0219 ScannerDocument4 pagesMasibus 85XX+ - R3F - 0219 ScannerchinnathambijNo ratings yet

- TWIX-1 MNLDocument2 pagesTWIX-1 MNLsrboghe651665No ratings yet

- TC244Document4 pagesTC244rama_subbuNo ratings yet

- PROGRAMMABLE ANNUNCIATORDocument4 pagesPROGRAMMABLE ANNUNCIATORSudipto MajumderNo ratings yet

- Controlador TC544 Manual:operaciónDocument3 pagesControlador TC544 Manual:operaciónMartin GaonaNo ratings yet

- Controller: Important: Retain These InstructionsDocument12 pagesController: Important: Retain These InstructionsAnonymous XYAPaxjbYNo ratings yet

- PR-14D Operating Instructions: 144 X 144 X 50 MMDocument2 pagesPR-14D Operating Instructions: 144 X 144 X 50 MMMladen MuskinjaNo ratings yet

- UT450 Standard Type (Model UT450-0 or UT450-3) or Heating/Cooling Type (Model UT450-2) UT450 Position Proportional Type (Model UT450-1 or UT450-4)Document1 pageUT450 Standard Type (Model UT450-0 or UT450-3) or Heating/Cooling Type (Model UT450-2) UT450 Position Proportional Type (Model UT450-1 or UT450-4)neyebNo ratings yet

- Upustvo Za Regulator PR-14DDocument2 pagesUpustvo Za Regulator PR-14DMarko KosanovićNo ratings yet

- 21modulo Smart OneDocument2 pages21modulo Smart OnePedroNo ratings yet

- 21 ModuloDocument2 pages21 ModulosuryaNo ratings yet

- TWIX-1 MNLDocument2 pagesTWIX-1 MNLsrboghe651665No ratings yet

- Controllogix XT 5573 Processor 8Mb Catalogue NoDocument2 pagesControllogix XT 5573 Processor 8Mb Catalogue NoKeval MistryNo ratings yet

- EliteDocument1 pageEliteKeval MistryNo ratings yet

- Premier 300 PDFDocument2 pagesPremier 300 PDFNath AtanuNo ratings yet

- Premier 300 PDFDocument2 pagesPremier 300 PDFNath AtanuNo ratings yet

- 105 Cau Hoi Trac Nghiem Tieng Anh Lop 12 Co Dap An Va Loi Giai Chi Tiet 2023Document15 pages105 Cau Hoi Trac Nghiem Tieng Anh Lop 12 Co Dap An Va Loi Giai Chi Tiet 2023UnknownNo ratings yet

- Algorithms to calculate, compare, and determine valuesDocument3 pagesAlgorithms to calculate, compare, and determine valuesLee Anne AngelesNo ratings yet

- Vol 5, No 2 November, Pp. 99-111 P-ISSN 2549-4880, E-ISSN 2614-1310 Journal DOI: WebsiteDocument11 pagesVol 5, No 2 November, Pp. 99-111 P-ISSN 2549-4880, E-ISSN 2614-1310 Journal DOI: WebsiteSyarah RamadhaniNo ratings yet

- Adequacy and Utilization of Instructional Resources For Skills Acquisiton in BrickDocument5 pagesAdequacy and Utilization of Instructional Resources For Skills Acquisiton in BrickSaidu NingiNo ratings yet

- Disputed Paternity and DNA Testing in IndiaDocument14 pagesDisputed Paternity and DNA Testing in IndiaAtulya Singh ChauhanNo ratings yet

- Guide to designing a strong research proposalDocument11 pagesGuide to designing a strong research proposalmayo ABIOYENo ratings yet

- Lecture 3Document10 pagesLecture 3Dr. Saad Saffah HresheeNo ratings yet

- Central Force Motion/kepler ProblemDocument5 pagesCentral Force Motion/kepler ProblemHel HelNo ratings yet

- SAT Practice Test 1 Combined PDFDocument122 pagesSAT Practice Test 1 Combined PDFRay728No ratings yet

- Procurement of Land in Indonesia: Challenges and Solutions in the Legal Sociological PerspectiveDocument12 pagesProcurement of Land in Indonesia: Challenges and Solutions in the Legal Sociological PerspectiveFrans OleyNo ratings yet

- UntitledDocument76 pagesUntitledjaiNo ratings yet

- ME 554 Problem Set-04 Nozzle Theory-Part-2Document1 pageME 554 Problem Set-04 Nozzle Theory-Part-2rahul prakashNo ratings yet

- FAO Fisheries & Aquaculture - Cultured Aquatic Species Information Programme - Penaeus Vannamei (Boone, 1931)Document14 pagesFAO Fisheries & Aquaculture - Cultured Aquatic Species Information Programme - Penaeus Vannamei (Boone, 1931)Dalis FaNo ratings yet

- Leadership and Management ModuleDocument6 pagesLeadership and Management ModuleMichael AngelesNo ratings yet

- GH04.Key Word TransformationDocument6 pagesGH04.Key Word TransformationViệt Hà Nguyễn BùiNo ratings yet

- m2 Arithmetic SequenceDocument9 pagesm2 Arithmetic Sequenceedmund roseteNo ratings yet

- Statistics For Biology and Health: M. Gail K. Krickeberg J. M. Samet A. Tsiatis W. WongDocument579 pagesStatistics For Biology and Health: M. Gail K. Krickeberg J. M. Samet A. Tsiatis W. WongViníciusSeixasNo ratings yet

- Bms PCC and RCC PDFDocument27 pagesBms PCC and RCC PDFKeshav SethiNo ratings yet

- Galileo Reading ComprehensionDocument3 pagesGalileo Reading ComprehensionAcademic AdvisorNo ratings yet

- Apollo / Saturn V: Insert Disk Q and The Fold OverDocument4 pagesApollo / Saturn V: Insert Disk Q and The Fold OverRob ClarkNo ratings yet

- Probability and Statistics Tutorial for EQT 272Document2 pagesProbability and Statistics Tutorial for EQT 272Jared KuyislNo ratings yet

- Matsim: A Matpower and Simulink Based Tool For Power System Dynamics Course EducationDocument6 pagesMatsim: A Matpower and Simulink Based Tool For Power System Dynamics Course EducationJavad RahmanifardNo ratings yet

- Energy Resources Conversion and Utilization: Liq-Liq Extract. & Other Liq-Liq Op. and EquipDocument3 pagesEnergy Resources Conversion and Utilization: Liq-Liq Extract. & Other Liq-Liq Op. and EquipyanyanNo ratings yet

- (Reuters Institute For The Study of Journalism) James Painter - Climate Change in The Media - Reporting Risk and Uncertainty-I. B. Tauris (2013)Document192 pages(Reuters Institute For The Study of Journalism) James Painter - Climate Change in The Media - Reporting Risk and Uncertainty-I. B. Tauris (2013)Thomas Ravelly Batista dos SantosNo ratings yet

- Change formatting and styles in a Word documentDocument3 pagesChange formatting and styles in a Word documentquanganhto2003No ratings yet