Professional Documents

Culture Documents

API 653 Above Ground Storage Tanks Inspector 08-July-2023

Uploaded by

RAVICopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 653 Above Ground Storage Tanks Inspector 08-July-2023

Uploaded by

RAVICopyright:

Available Formats

API 653

Above Ground Storage Tank

Inspector

Gavade Institute of Nondestructive Testing & Training (GINDT)

710/3A Ground Floor, Swami Vivekananda Road, Angol, Belgaum-590 006, Karnataka State, India

2 minutes walkable distance from 34 No Marathi Government School Bus Stop

Phone No: +091-831-2484060, Mobile No: +091-9632916690

Email: gindtbelgaum@gmail.com , Website: www.gindt.org

API 653 - Aboveground Storage Tank Inspector (In-service Inspection)

1. API Standard 653, Tank Inspection, Repair, Alteration, and Reconstruction, 5th Edition, November 2014,

Addendum 1 (April 2018), Addendum 2 (May 2020), Errata 1 (March 2020)

2. API Recommended Practice 571, Damage Mechanisms Affecting Fixed Equipment in the Refining

Industry, 3rd Edition, March 2020

3. API Recommended Practice 575, Inspection Practices for Atmospheric and Low-pressure Storage Tanks,

4th Edition, July 2020

4. API Recommended Practice 576, Inspection of Pressure-relieving Devices, 4th Edition, April 2017.

(Sections 4.3.2 and 6.6 only)

5. API Recommended Practice 577, Welding Processes, Inspection, and Metallurgy, 3rd Edition, October

2020.

6. API Standard 650, Welded Tanks for Oil Storage, 13th Edition, March 2020 with Errata 1 (January 2021)

7. API Recommended Practice 651, Cathodic Protection of Aboveground Petroleum Storage Tanks,

4th Edition, September 2014.

8. API Recommended Practice 652, Lining of Aboveground Petroleum Storage Tank Bottoms, 5th Edition,

May 2020

American Society of Mechanical Engineers (ASME), Boiler and Pressure Vessel Code (BPVC), 2021 Edition

I. Section V, Nondestructive Examination, Articles 1, 2, 6, 7 and 23 (Section SE-797 only)

II. Section IX, Qualification Standard for Welding, Brazing, and Fusing Procedures; Welders; Brazers; and

Welding, Brazing, and Fusing Operators, (Welding only)

Contact us for Preparatory Training – Training Coordinator

Gavade Institute of Nondestructive Testing & Training (GINDT)

710/3A Ground Floor, Swami Vivekananda Road

Angol, Belgaum - 590 006

Karnataka State, INDIA (भारत )

Phone No.:+091-0831-2484060

Mobile No.:+091-9632916690

Email: gindtbelgaum@gmail.com

sunilgavade@rediffmail.com

Website: www.gindt.org

Format No. GINDT/PT/API-653 Revision: 03 Draft Revision Date: 08-July-2023

Gavade Institute of Nondestructive Testing & Training (GINDT) Page 1 of 7

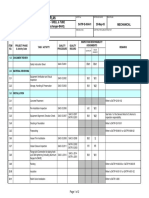

Details of Examination API-ICP Examination Schedule - 2023

Examination Window Program Schedule/Duration Application Deadline

10-March-2023

API 653 - Aboveground

to 7.5 Hours 06-January-2023

Storage Tank Inspector

31-March-2023

14-July-2023

API 653 - Aboveground

to 7.5 Hours 12-May-2023

Storage Tank Inspector

04-August-2023

03-November-2023

API 653 - Aboveground

to 7.5 Hours 01-September-2023

Storage Tank Inspector

24-November-2023

Exam Structure

The API 653 exam day is 7.5 hours long - a short tutorial session, 2.75 hours for the closed-book

portion, a 45-minute lunch break and 3.75 hours for the open-book portion.

There are 170 questions on the API 653 exam, of which only 140 are scored. The remaining 30 are

pretest questions.

There are 110 closed-book questions and 60 open-book questions.

Preparatory Training from: 11-February-2023 to 20-February-2023

Preparatory Training from: 01-June-2023 to 10-June-2023

Preparatory Training from: 19 to 29 October, 2023

Indian Rupees INR 28,000/- + GST @ 18%

GST No. 29AANFG1207A2ZT

SAC Code: 999293 Commercial training and coaching services

API-ICP 2023 Examination Fees with CODE’s and Standard’s Books

Note: Purchase the Codes and Standards for your examination as per the applicable Effective Sheet

API-ICP Main Individual Certification Program API-510 API-570 API-653

ICP-Examination Fees in USD $ 940 940 940

Codes and Standards in USD $ 1,161 1,418 1,542

Total in USD $ 2,101 2,358 2,482

Gavade Institute of Nondestructive Testing & Training (GINDT) Page 2 of 7

API 653

API Standard 653, Tank Inspection, Repair, Alteration, and Reconstruction, 5th Edition, November

2014, Addendum 1 (April 2018), Addendum 2 (May 2020), Errata 1 (March 2020)

This standard covers steel storage tanks built to API 650 and its predecessor API 12C. It provides

minimum requirements for maintaining the integrity of such tanks after they have been placed in

service and addresses inspection, repair, alteration, relocation, and reconstruction.

The scope is limited to the tank foundation, bottom, shell, structure, roof, attached appurtenances,

and nozzles to the face of the first flange, first threaded joint, or first welding-end connection. Many

of the design, welding, examination, and material requirements of API 650 can be applied in the

maintenance inspection, rating, repair, and alteration of in-service tanks. In the case of apparent

conflicts between the requirements of this standard and API 650 or its predecessor API 12C, this

standard shall govern for tanks that have been placed in service.

This standard employs the principles of API 650; however, storage tank owner/operators, based on

consideration of specific construction and operating details, may apply this standard to any steel

tank constructed in accordance with a tank specification.

This standard is intended for use by organizations that maintain or have access to engineering and

inspection personnel technically trained and experienced in tank design, fabrication, repair,

construction, and inspection.

This standard does not contain rules or guidelines to cover all the varied conditions which may occur

in an existing tank. When design and construction details are not given, and are not available in the

as-built standard, details that will provide a level of integrity equal to the level provided by the

current edition of API 650 must be used.

This standard recognizes fitness-for-service assessment concepts for evaluating in-service

degradation of pressure containing components. API 579-1/ASME FFS-1, Fitness-For-Service,

provides detailed assessment procedures or acceptance criteria for specific types of degradation

referenced in this standard. When this standard does not provide specific evaluation procedures or

acceptance criteria for a specific type of degradation or when this standard explicitly allows the use

of fitness-for-service criteria, API 579-1/ASME FFS-1 may be used to evaluate the various types of

degradation or test requirements addressed in this standard.

Gavade Institute of Nondestructive Testing & Training (GINDT) Page 3 of 7

API Standard 650, Welded Tanks for Oil Storage, 13th Edition, March 2020 with Errata 1 (January 2021)

This standard establishes minimum requirements for material, design, fabrication, erection, and

inspection for vertical, cylindrical, aboveground, closed- and open-top, welded storage tanks in

various sizes and capacities for internal pressures approximating atmospheric pressure (internal

pressures not exceeding the weight of the roof plates), but a higher internal pressure is permitted

when additional requirements are met. This standard applies only to tanks whose entire bottom is

uniformly supported and to tanks in non-refrigerated service that have a maximum design

temperature of 93 °C (200 °F) or less.

This standard provides industry with tanks of adequate safety and reasonable economy for use in

the storage of petroleum, petroleum products, and other liquid products. This standard does not

present or establish a fixed series of allowable tank sizes; instead, it is intended to permit the

Purchaser to select whatever size tank may best meet their needs. This standard is intended to help

Purchasers and Manufacturers in ordering, fabricating, and erecting tanks; it is not intended to

prohibit Purchasers and Manufacturers from purchasing or fabricating tanks that meet

specifications other than those contained in this standard.

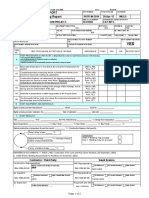

Following are “11” types of the Corrosion and Damage Mechanisms Affecting Fixed Equipment in

the Refining Industry, 3rd Edition, March 2020 as per API 571

Section 2 Terms and Definitions

Sr. No. Clause Mechanisms

1 3.8 Atmospheric Corrosion

2 3.11 Brittle Fracture

3 3.14 Caustic Corrosion

4 3.15 Caustic Stress Corrosion Cracking (Caustic Embrittlement)

5 3.17 Chloride Stress Corrosion Cracking

6 3.22 Corrosion Under insulation (CUI)

7 3.43 Mechanical Fatigue (Including Vibration-induced Fatigue)

8 3.45 Microbiologically Influenced Corrosion (MIC)

9 3.57 Soil Corrosion

10 3.58 Sour Water Corrosion (Acidic)

11 3.62 Sulfuric Acid Corrosion

Gavade Institute of Nondestructive Testing & Training (GINDT) Page 4 of 7

What you will going to learn?

The topics covered include:

Detailed explanations of all the information covered in the API 653 'Body of Knowledge' including ASME

welding requirements for storage tanks sections IX Welding and API 650 Welded Tanks for Oil Storage.

ASME Non-destructive testing principles and application of section V

Storage tank design review API 650, weld sizes, tank nozzle reinforcement, brittle fracture, weld efficiency

factors, post weld heat treatment; API 653 inspection, repair alteration and reconstruction of tanks,

inspection intervals, inspection requirements, relationships to ASME codes

Corrosion, minimum thickness determination and remaining life calculations; inspection and degradation

mechanisms of API 575, cathodic protection and internal coatings for storage tanks. Safety and preparation

issues on tank floors for repair and MFL-Magnetic Flux Leakage for floors scanning.

Inspection and degradation mechanisms of Above Ground Storage Tanks corrosion and cracking mechanisms,

erosion, common corrodents and Damage Mechanisms, Corrosion Under Insulation (CUI), Erosion/Erosion –

Corrosion.

What else should you know?

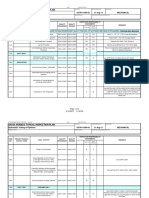

Entry Requirements for API Examinations

You must be employed by or under contract to an authorized inspection agency or owner/user organization

as defined in API 653 - Aboveground Storage Tank Inspector (In-service Inspection), Section 1.5.4

You must satisfy one of the combinations of education and experience for the certification you are applying

for:

1) A Bachelor of Engineering or Technology {BE or B.Engg./B.Tech./AMIE (India) } or a Bachelor of Science in

Engineering or BS in Science or higher in engineering, with minimum of 1 years’ experience and skills in

supervision or performance of inspection activities of piping systems as described in API 653.

2) Two-year degree or certificate in engineering or technology, with minimum of 2 years' experience and

skills in design, repair, construction, operation, or inspection of piping systems, of which one year must

be in supervision performance of inspection activities as described in API 653.

3) High school diploma or equivalent, or 3 Year Diploma in Mechanical Engineering or Metallurgy with a

minimum of 3 years’ experience and have the same skills as listed in item 2.

4) Have 5 or more years’ experience and same skills as listed in item 2. Conversant with the Oil and Gas

Refineries shutdown or Process Plant Inspector or Inspection Engineer – Welded Tanks for Oil Storage

(In-service or New Construction activities or Repair of API-650 Welded Tanks for Oil Storage)

Gavade Institute of Nondestructive Testing & Training (GINDT) Page 5 of 7

Sunil B. Gavade

Training Instructor Mr. Sunil B. Gavade is Mechanical Engineer and with more than 30 years of experience in

Steel Plant, Pipes manufacturing mills, Steel Plates, Forges Shop, Foundry, Pumps and Valves, Water

Treatment Plant, Desalination Plants, Petrochemical Plant, Oil and Gas Refineries, Fabrication of Heavy

Engineering equipment for Nuclear Power - Steam Generator and Oil and Gas refineries equipment such as

Coal Gasifier-CGPP, Vacuum distillation column, VDU, CDU, Atmospheric Column, Heavy Naphtha Stripper,

Light Kero Stripper, Heavy Kero Stripper. LGO Stripper, HGO Stripper, Naphtha Stabilizer, Vacuum Column,

Heat Exchangers, Fired Heater. Aluminum Plant, Inspection of Boilers and Pressure Vessels for Various

Thermal and Nuclear Power Plants, Nuclear Power PFBR- Prototype Fast Breeder Reactor, Nuclear Steam

Generators. Specialist in Piping, valves, materials and codes and standards. Inspection Engineer for

Petrochemical Plant and handling the Corrosion and Metallurgical studies for Oil Refineries and Petrochemical

Plant. Piping Engineering from IIT-Mumbai, Powai, Mumba-400072

ASME Code Stamp work for “S”, “U”, “U2,”U3”, “PP”,”N”,”NPT” and “R” NBBI Repair of Process

equipment’s. Familiar with The National Board Inspection Code (NBIC) NB 23 Part-1 to Part-4

Having vide experience in carrying out In‐service inspection of Oil Refineries and Petrochemical Plant.

RLA - FFS. Pressure Vessels, Heat Exchangers, Piping and Above Ground Storage Tanks.

RBI-Risk Based Inspection and AIMS-Asset integrity management system Oil Refineries and Petrochemical

Plant.

ROB-Railway over Bridge and RUB-Railway under Bridge, Flyover Bridge, Welding, NDT Testing and Training.

Lead Auditor for QMS ISO 9001:2015 and API Spec. Q1 Practitioner for Oil and Gas QMS and API Monogram

related work. Experience in API Specification, API Monograms and 20 SCM-Supply Chain Management

System.

API Spec Q1 9th Edition by the American Petroleum Institute (API) titled "Specification for Quality

Management System Requirements for Manufacturing Organizations for the Petroleum and Natural Gas

Industry".

ISO 29001:2020

Petroleum, petrochemical and natural gas industries — Sector-specific quality management systems —

Requirements for product and service supply organizations.

ISO 19443:2018 Nuclear energy sector

Quality management systems — Specific requirements for the application of ISO 9001:2015 by organizations

in the supply chain of the Nuclear energy sector supplying products and services important to nuclear safety

(ITNS)

API 20 Series – Supply Chain Management (SCM)

• Specification 20A: Castings for use in the Petroleum and Natural Gas Industry.

• Specification 20B: Open Die Forgings for use in the Petroleum and Natural Gas Industry.

• Specification 20C: Closed Die Forgings for use in the Petroleum and Natural Gas Industry.

• Specification 20D: Qualification of Nondestructive Testing Operations for use in the Petroleum and

Natural Gas Industry.

• Specification 20E: Specification for Low Alloy Steel Bolting for Pressure Containing Gas Equipment.

Gavade Institute of Nondestructive Testing & Training (GINDT) Page 6 of 7

• Specification 20F: Specification for CRA Steel Bolting for Pressure Containing Gas Equipment.

• Specification 20G: Welding services used in the Petroleum and Natural Gas Industry.

• Specification 20H: Heat treat services used in the Petroleum and Natural Gas Industry.

• Specification 20I: Quality requirements for Distributors of Raw materials for use in the Petroleum and

Natural Gas Industry.

ISO 3834-1:2021

Quality requirements for fusion welding of metallic materials — Part 1: Criteria for the selection of the

appropriate level of quality requirements

ISO 3834-2:2021

Quality requirements for fusion welding of metallic materials — Part 2: Comprehensive quality requirements

ISO 3834-3:2021

Quality requirements for fusion welding of metallic materials — Part 3: Standard quality requirements

ISO 3834-4:2021

Quality requirements for fusion welding of metallic materials — Part 4: Elementary quality requirements

EN 15085 (Welding of Railway Vehicles and Components) and certification Process

Certification process, Classification, Fabrication, Inspection and certification requirements of the Welding

Manufacturers for Welding of Railway Vehicles and Components

Indian Railways Guidelines as per

BS 110 (R) Guideline of Fabrication of steel girders for Construction Field Engineer

Edition: March, 2016 (With Addendum & Corrigendum of July, 2017)

Issued by : B&S Directorate

RDSO-Research Designs and Standards Organisation, Lucknow-226011, Uttar Pradesh, INDIA

Work Location: SWR-South Western Railways, Hubli Division, Kusgal Road ROB-Railway Over Bridge, INDIA

Inspection of Fabricated Aluminum Coach for Indian Railways as per the requirements of

LHB-Linke Hofmann Busch

Welding Inspection of Aluminum Plates and relevant NDT Inspection.

WPQ-Welder Performance Qualification

WOPQ-Welding Operator Performance Qualification

New Construction Inspection of API 650 API-650 Welded Tanks for Oil Storage and

API Standard 653, Tank Inspection, Repair, Alteration, and Reconstruction, 5th Edition, November 2014,

Addendum 1 (April 2018), Addendum 2 (May 2020), Errata 1 (March 2020)

AWS-American Welding Society, SME-Subject Matter Expert-Welding

Format No. GINDT/PT/API-653 Revision:03 Draft Revision Date: 08-July-2023

Gavade Institute of Nondestructive Testing & Training (GINDT) Page 7 of 7

You might also like

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Essential Weld Fit-Up ChecksDocument10 pagesEssential Weld Fit-Up ChecksManoj KumarNo ratings yet

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Document2 pages1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDocument2 pagesSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- API 653 Integrated TrainingDocument97 pagesAPI 653 Integrated TrainingHesam MazaheriNo ratings yet

- ARAMCO QM Number listDocument3 pagesARAMCO QM Number listMohamed Yousuf Syed MohamedNo ratings yet

- Assessment 1 API 570Document5 pagesAssessment 1 API 570Mohamed ZainNo ratings yet

- Sis Book Asme IxDocument107 pagesSis Book Asme IxHamza AlamNo ratings yet

- Sa 263Document8 pagesSa 263Wagner Renato AraújoNo ratings yet

- 1st April 2021 653 PaperDocument7 pages1st April 2021 653 Papermohamed haMEEM100% (1)

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Repairing Corroded Tank Bottoms Safely and Cost EffectivelyDocument5 pagesRepairing Corroded Tank Bottoms Safely and Cost EffectivelylsatchithananthanNo ratings yet

- Lockhart 653Document7 pagesLockhart 653oluninjaaNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- SAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FDocument2 pagesSAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FAnonymous S9qBDVky100% (1)

- Interview Ques & Ans - KNPCDocument8 pagesInterview Ques & Ans - KNPCStephen RajNo ratings yet

- NBIC Part 2 PDFDocument12 pagesNBIC Part 2 PDFjhonjimenez87No ratings yet

- CKRC API 653 WORKBOOK MODULE 2 AIT Rev 1Document18 pagesCKRC API 653 WORKBOOK MODULE 2 AIT Rev 1CHANDRA BHUSHAN KESARI100% (1)

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- API RP 577 Welding InspectionDocument7 pagesAPI RP 577 Welding InspectionLuthfi ArdiansyahNo ratings yet

- API653 - Guidelines - 653 Certification - ExamDocument11 pagesAPI653 - Guidelines - 653 Certification - ExamirfanlarikhotmailcomNo ratings yet

- Lap Patch Notes (Printed)Document5 pagesLap Patch Notes (Printed)JeganeswaranNo ratings yet

- VBTDocument5 pagesVBTMohdHuzairiRusliNo ratings yet

- Scope of API 650 API 620 & API 653Document3 pagesScope of API 650 API 620 & API 653Dinesh Kumar SNo ratings yet

- Assessment of Weld Misalignment and Shell Distortion: Quest Integrity October 2015Document31 pagesAssessment of Weld Misalignment and Shell Distortion: Quest Integrity October 2015امين100% (1)

- Weekly Welder ReportDocument2 pagesWeekly Welder Reportkarthi51289No ratings yet

- API 650 12th - 2013Document4 pagesAPI 650 12th - 2013mohamed100% (1)

- API 653 Quiz 1Document3 pagesAPI 653 Quiz 1fazeel mohammedNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- API 653 PREPARATION/ REPONSES N°06 close bookDocument3 pagesAPI 653 PREPARATION/ REPONSES N°06 close bookkorichiNo ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- Exam July 2021Document16 pagesExam July 202101280724321 Helmy100% (1)

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsDocument6 pagesConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanNo ratings yet

- Practice Questions For API RP 577Document10 pagesPractice Questions For API RP 577vamsikrishnaNo ratings yet

- General Mechanical-2 PDFDocument6 pagesGeneral Mechanical-2 PDFAhmed Shaban KotbNo ratings yet

- API 650 & API 653 TrainingDocument56 pagesAPI 650 & API 653 TrainingSalah JallaliNo ratings yet

- API 510 Petrosync Course PDFDocument301 pagesAPI 510 Petrosync Course PDFAkramKassis100% (1)

- TK®-236 Physical Properties: 1. HardnessDocument2 pagesTK®-236 Physical Properties: 1. HardnessSaradhi MedapureddyNo ratings yet

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 Mechkarthi51289No ratings yet

- TDS PDF Intertherm - 751CSADocument4 pagesTDS PDF Intertherm - 751CSAwilliam sukyonoNo ratings yet

- Saudi Aramco Pressure Testing ProcedureDocument21 pagesSaudi Aramco Pressure Testing ProcedureDilshad AhemadNo ratings yet

- SAES X 500 Cathodic ProtectionDocument8 pagesSAES X 500 Cathodic ProtectionAbdul Khader HassanNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Damage Mechanisms For API 653Document10 pagesDamage Mechanisms For API 653Saran KumarNo ratings yet

- UL-142 R912 Installation InstructionsDocument4 pagesUL-142 R912 Installation InstructionsRodrigoNo ratings yet

- Welding Inspection: Course Reference WIS 5Document31 pagesWelding Inspection: Course Reference WIS 5venkyNo ratings yet

- Api 653 Daily Points To Recall (Day 3)Document2 pagesApi 653 Daily Points To Recall (Day 3)Naveed Ahmed100% (1)

- Cswip Div 9 03 General Inspector 4th Edition Jan 2008Document12 pagesCswip Div 9 03 General Inspector 4th Edition Jan 2008obinnaNo ratings yet

- Sa 6717Document1 pageSa 6717biplabpal2009No ratings yet

- 2-Questions API 650 Question N°02 2022Document3 pages2-Questions API 650 Question N°02 2022korichiNo ratings yet

- ASME VIII Div 1 PWHT RulesDocument5 pagesASME VIII Div 1 PWHT RulesEr Manish JadaunNo ratings yet

- TOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1Document1 pageTOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1kokaanilkumarNo ratings yet

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- 2021-API 570 Piping Inspector Preparation Course BROCHUREDocument8 pages2021-API 570 Piping Inspector Preparation Course BROCHUREMarzuqi A. Halim100% (1)

- Saudi Aramco Standards: WeldingDocument12 pagesSaudi Aramco Standards: WeldingGEORGE IVANNo ratings yet

- API 653 Above Ground Storage Tank InspectorDocument2 pagesAPI 653 Above Ground Storage Tank InspectorMohamed Hichem Guesmi0% (1)

- Pages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningDocument2 pagesPages From NSH-SAOMPP-QCP-PI-021 Hydratight Procedure For Flange Hydraulic Torque TighteningRajis Rahim100% (1)

- Cryogenic and Refrigerated Tank Projects ListDocument6 pagesCryogenic and Refrigerated Tank Projects ListAndrzejNo ratings yet

- CCME-TANK TIPS - Tank Tips 1 On Storage Tank Systems For Petroleum ProductsDocument56 pagesCCME-TANK TIPS - Tank Tips 1 On Storage Tank Systems For Petroleum ProductsPubcrawlNo ratings yet

- Ips e in 100Document87 pagesIps e in 100charleselitb92No ratings yet

- G LIT API-650-Tanks PDFDocument2 pagesG LIT API-650-Tanks PDFAlexanderNo ratings yet

- Improving Rural Dairy Farming Through Milk Value Chain AnalysisDocument58 pagesImproving Rural Dairy Farming Through Milk Value Chain AnalysisBasideu ByinajuNo ratings yet

- API 653 Exam Study Sheet QuestionsDocument0 pagesAPI 653 Exam Study Sheet QuestionsYasser Abd El Fattah100% (1)

- VaporVac System SpecificationsDocument5 pagesVaporVac System SpecificationsEnrique ArmandoNo ratings yet

- LNG Permit To ConstructDocument78 pagesLNG Permit To ConstructAly Sera100% (1)

- API Mpms ListDocument5 pagesAPI Mpms Listhtutswe75% (4)

- 1416-MC-DBS-101 - Mechanical Design Basis - R1Document19 pages1416-MC-DBS-101 - Mechanical Design Basis - R1KrunalNo ratings yet

- Training Api 653 - October - 2022Document1 pageTraining Api 653 - October - 2022Leon PanjaitanNo ratings yet

- Atmospheric Tank Fire Protection GuideDocument51 pagesAtmospheric Tank Fire Protection GuideEki RamadhaniNo ratings yet

- Chapter 5Document20 pagesChapter 5Fathi ShokryNo ratings yet

- Ruggerini RD 210 270Document85 pagesRuggerini RD 210 270BobCav100% (2)

- 116 - CMEC - MEPP - PMC - Provisional Approval of Test - Coupons, Method Statement & WPS-PQRDocument34 pages116 - CMEC - MEPP - PMC - Provisional Approval of Test - Coupons, Method Statement & WPS-PQRAbubakar lawan moduNo ratings yet

- 20070906presentation of Sondex CsDocument21 pages20070906presentation of Sondex CsAnonymous DFCmFkDNo ratings yet

- EEMUA 159 Reading ChecklistDocument3 pagesEEMUA 159 Reading ChecklistbacabacabacaNo ratings yet

- API 652 LiningDocument4 pagesAPI 652 LiningMohammed YoussefNo ratings yet

- EHS Guidelines For LNG Facilities - World Bank GroupDocument19 pagesEHS Guidelines For LNG Facilities - World Bank GroupJafar KhanNo ratings yet

- Pipeline Investigation ReportDocument34 pagesPipeline Investigation ReportaliNo ratings yet

- LNG BasicsDocument14 pagesLNG BasicsAnil Kumar MohapatraNo ratings yet

- Nit 1005 Mab Amd 1Document95 pagesNit 1005 Mab Amd 1Pradeep KumarNo ratings yet

- Inspection of Storage TankDocument19 pagesInspection of Storage TanknovazhaiNo ratings yet

- Simplify BOG Recondenser Design and OperationDocument8 pagesSimplify BOG Recondenser Design and OperationWilfredo Suarez TorresNo ratings yet

- Oil Storage Tank TypesDocument6 pagesOil Storage Tank TypescathlenNo ratings yet

- BS en 14620-4 2006Document34 pagesBS en 14620-4 2006Quat Le DinhNo ratings yet

- 20191010-JSP 317 Part 2 v6.3 Word Ver ODocument336 pages20191010-JSP 317 Part 2 v6.3 Word Ver OM.A.NNo ratings yet

- Changes To API 650 Twelfth EditionDocument3 pagesChanges To API 650 Twelfth EditionHimanshu SharmaNo ratings yet

- RFEvaluation LPGPool Fire Heat FluxDocument44 pagesRFEvaluation LPGPool Fire Heat FluxKanchan KhetanNo ratings yet

- Safety Data Sheet: Section 1 - Product and Company IdentificationDocument10 pagesSafety Data Sheet: Section 1 - Product and Company IdentificationakramNo ratings yet