Professional Documents

Culture Documents

1B1

Uploaded by

William ChengOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1B1

Uploaded by

William ChengCopyright:

Available Formats

COMPANY DATA

Story: 1F

JOB NO. CALC BY

PROJECT CHECKED BY B1(1200x1500)

Len = 13.500 m

Storey: 1F, Beam Mark: B1, Etabs Label: B555

CB3 B94

Section = 1200x1500, Length(Span) = 13.500 m

Concrete : C45, fcu = 45, Cover: = 40 mm, Main Bars: GRADE 500, Strirrup: GRADE 500

Modification: Tens Bar Steel Ratio : 0.30, Compr Bar Steel Ratio: 0.30

Area Factor: Top Bar Area Ratio : 1.00, Bot Bar Area Ratio: 1.00

Beam Type = Main Beam; ps,min = 0.30; As,min = 5400 C18 Label = B555 B680 B557

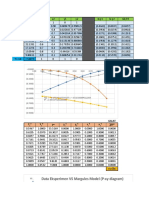

Hogging Moment Calculations Moment & Shear Diagram

Dist Mmax Case d d1 d2 K1 K x d1/x Fsc la z At Ac Ac2 Ator At2 At3 ps

0.75 -7493.7 (2) 1400 60 100 0.156 0.071 268 0.22 435 0.91 1279 13464 0 0 0 13464 13464 0.75

2.00 -3898.7 (2) 1440 60 60 0.156 0.035 160 0.38 435 0.95 1368 6551 0 0 0 6551 6551 0.36

2.00 -3898.7 (2) 1440 60 60 0.156 0.035 160 0.38 435 0.95 1368 6551 0 0 0 6551 6551 0.36 0.75 2.34 4.00 6.75 8.63 10.67 11.52 13.50

2.34 -3033.8 (2) 1440 60 60 0.156 0.027 160 0.38 435 0.95 1368 5098 0 0 0 5098 5400 0.30

3.94 -14.4 (280) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 24 0 0 0 24 5400 0.30

4.00 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

4.00 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

0.75 2.34 4.00 6.75 8.63 10.67 11.52 13.50

5.53 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

6.75 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

6.75 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30 AST = 13464 AST = 5400 AST = 5400

7.13 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

11T40 11T32 11T32

8.63 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

8.63 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30 11T32 11T40+2T32 11T40

8.72 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

10.31 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30 ASB = 5400 ASB = 13932 ASB = 11516

10.67 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30 ASVV = 2988 ASVV = 2123 ASVV = 2302

ASVT = 0 ASVT = 0 ASVT = 0

10.67 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

ASV = 2988 ASV = 2123 ASV = 2302

11.52 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30 1T10-150(1LEGS) 1T10-250(1LEGS) 1T10-250(1LEGS)

11.52 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30 ASTT = 0 ASTT = 0 ASTT = 0

11.91 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

13.50 -733.2 (181) 1440 60 60 0.156 0.007 160 0.38 435 0.95 1368 1232 0 0 0 1232 5400 0.30

Shear and Torsion Calculations

Sagging Moment Calculations

Dist Vmax Case Tmax As d1 ps vc vr vu vtmin v vt v+vt (v+vt)/vu Av/s At/s Avt/s As,tor

0.75 -2992.0 (2) 5.7 13464 100 0.75 0.70 0.43 5.37 0.40 1.78 0.01 1.79 0.33 2988 0 2988 0

Dist Mmax Case d d1 d2 K1 K x d1/x Fsc la z At Ac Ac2 Ator At2 At3 ps

2.00 -2793.8 (2) 4.7 6551 60 0.36 0.55 0.43 5.37 0.40 1.62 0.01 1.62 0.30 2946 0 2946 0

0.75 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

2.00 -2568.1 (2) 1.6 6551 60 0.36 0.55 0.43 5.37 0.40 1.49 0.00 1.49 0.28 2585 0 2585 0

2.00 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

2.34 -2508.0 (2) 1.6 5400 60 0.30 0.51 0.43 5.37 0.40 1.45 0.00 1.45 0.27 2584 0 2584 0

2.00 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

3.94 -2219.1 (2) 1.6 5400 60 0.30 0.51 0.43 5.37 0.40 1.28 0.00 1.29 0.24 2123 0 2123 0

2.34 0.0 (0) 1440 60 60 0.156 0.000 160 0.38 435 0.95 1368 0 0 0 0 0 5400 0.30

4.00 -2208.3 (2) 1.6 5400 60 0.30 0.51 0.43 5.37 0.40 1.28 0.00 1.28 0.24 2105 0 2105 0

3.94 1539.9 (109) 1440 60 60 0.156 0.014 160 0.38 435 0.95 1368 2588 0 0 0 2588 5400 0.30

4.00 -1948.8 (2) 6.6 5400 60 0.30 0.51 0.43 5.37 0.40 1.13 0.01 1.14 0.21 1691 0 1691 0

4.00 1639.0 (109) 1440 60 60 0.156 0.015 160 0.38 435 0.95 1368 2754 0 0 0 2754 5400 0.30

5.53 -1675.3 (2) 6.6 6559 60 0.36 0.55 0.43 5.37 0.40 0.97 0.01 0.98 0.18 0 0 1194 0

4.00 1639.0 (109) 1440 60 60 0.156 0.015 160 0.38 435 0.95 1368 2754 0 0 0 2754 5400 0.30

6.75 -1458.1 (2) 6.6 9856 60 0.55 0.63 0.43 5.37 0.40 0.84 0.01 0.85 0.16 0 0 1194 0

5.53 3903.3 (1) 1440 60 60 0.156 0.035 160 0.38 435 0.95 1368 6559 0 0 0 6559 6559 0.36

6.75 -1194.3 (2) 33.9 9856 60 0.55 0.63 0.43 5.37 0.40 0.69 0.04 0.73 0.14 0 0 1194 0

6.75 5795.7 (1) 1440 60 60 0.156 0.052 196 0.31 435 0.94 1352 9856 0 0 0 9856 9856 0.55

7.13 -1126.3 (2) 33.9 10648 60 0.59 0.65 0.43 5.37 0.40 0.65 0.04 0.69 0.13 0 0 1194 0

6.75 5795.7 (1) 1440 60 60 0.156 0.052 196 0.31 435 0.94 1352 9856 0 0 0 9856 9856 0.55

8.63 -907.8 (2) 33.9 13932 100 0.77 0.71 0.43 5.37 0.40 0.54 0.04 0.58 0.11 0 0 1194 0

7.13 6228.4 (1) 1440 60 60 0.156 0.056 212 0.28 435 0.93 1345 10648 0 0 0 10648 10648 0.59

8.63 870.5 (109) 11.0 13932 100 0.77 0.71 0.43 5.37 0.40 0.52 0.01 0.53 0.10 0 0 1194 0

8.63 7728.9 (1) 1400 60 100 0.156 0.073 277 0.22 435 0.91 1275 13932 0 0 0 13932 13932 0.77

8.72 876.3 (109) 11.0 13830 100 0.77 0.70 0.43 5.37 0.40 0.52 0.01 0.54 0.10 0 0 1194 0

8.63 7728.9 (1) 1400 60 100 0.156 0.073 277 0.22 435 0.91 1275 13932 0 0 0 13932 13932 0.77

10.31 996.6 (109) 11.0 11516 60 0.64 0.66 0.43 5.37 0.40 0.58 0.01 0.59 0.11 0 0 1194 0

8.72 7677.6 (1) 1400 60 100 0.156 0.073 275 0.22 435 0.91 1276 13830 0 0 0 13830 13830 0.77

10.67 1022.8 (109) 11.0 11049 60 0.61 0.65 0.43 5.37 0.40 0.59 0.01 0.61 0.11 0 0 1194 0

10.31 6697.2 (1) 1440 60 60 0.156 0.060 229 0.26 435 0.93 1337 11516 0 0 0 11516 11516 0.64

10.67 1079.0 (109) 18.2 11048 60 0.61 0.65 0.43 5.37 0.40 0.62 0.02 0.65 0.12 0 0 1194 0

10.67 6445.6 (1) 1440 60 60 0.156 0.058 220 0.27 435 0.93 1341 11049 0 0 0 11049 11049 0.61

11.52 1136.3 (109) 18.2 9747 60 0.54 0.63 0.43 5.37 0.40 0.66 0.02 0.68 0.13 0 0 1194 0

10.67 6445.3 (1) 1440 60 60 0.156 0.058 220 0.27 435 0.93 1341 11048 0 0 0 11048 11048 0.61

11.52 2144.1 (1) 18.2 9745 60 0.54 0.63 0.43 5.37 0.40 1.24 0.02 1.26 0.24 1694 0 1694 0

11.52 5735.6 (1) 1440 60 60 0.156 0.051 194 0.31 435 0.94 1353 9747 0 0 0 9747 9747 0.54

11.91 2176.7 (1) 18.2 8264 60 0.46 0.59 0.43 5.37 0.40 1.26 0.02 1.28 0.24 1839 0 1839 0

11.52 5734.6 (1) 1440 60 60 0.156 0.051 194 0.31 435 0.94 1353 9745 0 0 0 9745 9745 0.54

13.50 2331.2 (1) 18.2 5400 60 0.30 0.51 0.43 5.37 0.40 1.35 0.02 1.37 0.26 2302 0 2302 0

11.91 4910.6 (1) 1440 60 60 0.156 0.044 164 0.37 435 0.95 1366 8264 0 0 0 8264 8264 0.46

13.50 1403.3 (1) 1440 60 60 0.156 0.013 160 0.38 435 0.95 1368 2358 0 0 0 2358 5400 0.30

Span-Depth Ratio Calculations

Max Moment, M 7728.90 Support condition Continuous

Beam Span 12.750 m Effective Depth 1400 mm

Basic span / depth ratio 26.00 Modified span / depth ratio 20.39

M / bd^2 3.29 Ast,provide / Ast,req 1.00

Service steel stress, fs 333.33 MPa 100Ac.prov / bd 0.30

Tens. reinf. modification factor 0.836 Comp. reinf. modification factor 1.091

Allowable span / depth ratio 18.60 Actual span / depth ratio 9.11

Allow SD ratio > Actual SD Ratio Okay (0.49)

You might also like

- Amal 8.5 BHADocument18 pagesAmal 8.5 BHAMuhammadAskariNo ratings yet

- Amal 12.25 BHADocument19 pagesAmal 12.25 BHAMuhammadAskariNo ratings yet

- Untuk Membuat Tikungan SCS Dibutuhkan Hitungan: 1. ES 2. RC Pakai 3. Sudut Circle 4. Sudut Spiral RC Pakai 180Document9 pagesUntuk Membuat Tikungan SCS Dibutuhkan Hitungan: 1. ES 2. RC Pakai 3. Sudut Circle 4. Sudut Spiral RC Pakai 180Djunaedi MarsetoNo ratings yet

- E030 - 2016 - IqmDocument4 pagesE030 - 2016 - IqmJilber Flores RamosNo ratings yet

- Lab 05Document8 pagesLab 05Ernesto ZavaletaNo ratings yet

- Orden 0: Experiencia 1Document20 pagesOrden 0: Experiencia 1abelNo ratings yet

- Tabelul Cu Date Experimentale Nr. CRTDocument6 pagesTabelul Cu Date Experimentale Nr. CRTSabadîș DenisaNo ratings yet

- Co (MG/L) : A% Exponential (A %)Document35 pagesCo (MG/L) : A% Exponential (A %)Οδυσσεας ΚοψιδαςNo ratings yet

- STRESS STRAIN MODEL V2 - AluminumDocument11 pagesSTRESS STRAIN MODEL V2 - AluminumRay FaiersNo ratings yet

- Ambion: Wearnes CambionDocument2 pagesAmbion: Wearnes CambionalexanderNo ratings yet

- Settlement AnalysisDocument3 pagesSettlement AnalysisNoe H. MoralesNo ratings yet

- MatematicaDocument46 pagesMatematicaKen HPNo ratings yet

- Nozzle Load TableDocument14 pagesNozzle Load TableHossein FarhadiNo ratings yet

- Yasir 20201019 Invpac DetailDocument2 pagesYasir 20201019 Invpac Detailypr123321No ratings yet

- Lo Ad (P) : KG N (MM)Document9 pagesLo Ad (P) : KG N (MM)Muhammad Husnain IjazNo ratings yet

- Cylinder Force CalculationDocument2 pagesCylinder Force CalculationPriyanka RautNo ratings yet

- V2Document12 pagesV2ZatAdiktifNo ratings yet

- TODO1Document18 pagesTODO1JorgeVillenaNo ratings yet

- PreferenceSharesDocument1 pagePreferenceSharesTiso Blackstar GroupNo ratings yet

- Assignment 2 Final Version1Document78 pagesAssignment 2 Final Version1Christopher Bayo DaramolaNo ratings yet

- Ejercicios IO ACA 2Document36 pagesEjercicios IO ACA 2CRISTIAN CAMILO RUIZ ABAUNZANo ratings yet

- DN027B Led3nw L100 SQDocument1 pageDN027B Led3nw L100 SQHaianh PhamNo ratings yet

- Trabajo Analisis 2Document84 pagesTrabajo Analisis 2jenry alexander casas sernaqueNo ratings yet

- Preference Shares - March 26 2018Document1 pagePreference Shares - March 26 2018Tiso Blackstar GroupNo ratings yet

- 109P0424J3013 SanyoDocument4 pages109P0424J3013 SanyoFrancisco edward Guerrero ticonaNo ratings yet

- PreferenceShares - February 20 2018Document1 pagePreferenceShares - February 20 2018Tiso Blackstar GroupNo ratings yet

- Polar Fineza: Axis Title Axis TitleDocument4 pagesPolar Fineza: Axis Title Axis TitleUriel Gallegos PérezNo ratings yet

- Aa - 1604 DNL JDGDocument17 pagesAa - 1604 DNL JDGangel salvadeoNo ratings yet

- Aca 2 InvestigacionesDocument37 pagesAca 2 InvestigacionesCRISTIAN CAMILO RUIZ ABAUNZANo ratings yet

- DATA SONDIR / DCPT (Dynamic Cone Penetration Test) : Depth Depth DepthDocument3 pagesDATA SONDIR / DCPT (Dynamic Cone Penetration Test) : Depth Depth DepthAndita Tri BudiantoNo ratings yet

- Final Col Terrece Floor Floting Pour - 1Document28 pagesFinal Col Terrece Floor Floting Pour - 1sanjeevNo ratings yet

- Graficos TP9Document2 pagesGraficos TP9AnsleNo ratings yet

- Uas MJ Invest PM 2020 (Kunci)Document2 pagesUas MJ Invest PM 2020 (Kunci)YanjNo ratings yet

- ChemostatDocument10 pagesChemostatFrancesco FerellaNo ratings yet

- ST-06 Machine Room Bottom Plan Reinforcement Details of "MERCADO" Sec-80 GGNDocument46 pagesST-06 Machine Room Bottom Plan Reinforcement Details of "MERCADO" Sec-80 GGNRAKESH KUMARNo ratings yet

- Trabajo #15 de Marcos Por El Metodo de RigidezDocument8 pagesTrabajo #15 de Marcos Por El Metodo de RigidezEnrique SersiNo ratings yet

- DIVERSDocument3 pagesDIVERSAbdenacer DjabriNo ratings yet

- Design ChartDocument2 pagesDesign ChartFrederick TanNo ratings yet

- GH - 2023 - HydraulicTests - 01 - Harbleidy Ibarra IbarraDocument87 pagesGH - 2023 - HydraulicTests - 01 - Harbleidy Ibarra IbarraHarbleidy Ibarra IbarraNo ratings yet

- Calibr of RMC 18+900 - 8thDocument10 pagesCalibr of RMC 18+900 - 8thaashish patidarNo ratings yet

- Plantilla-Armadura 3D Analisis Estructural Metodo MatricialDocument49 pagesPlantilla-Armadura 3D Analisis Estructural Metodo MatricialRaul DelgadoNo ratings yet

- 5000 Cs Culvert Analysis Report: Project NotesDocument9 pages5000 Cs Culvert Analysis Report: Project NotesFahad ZulfiqarNo ratings yet

- 2.1.2 Spatial Response Plot: Angle: - 45°, Frequency Range: (100 HZ, 4000 HZ) (From Current Selection)Document2 pages2.1.2 Spatial Response Plot: Angle: - 45°, Frequency Range: (100 HZ, 4000 HZ) (From Current Selection)oscaracostaNo ratings yet

- Problema 01.-: Ovidio Serrano ZeladaDocument11 pagesProblema 01.-: Ovidio Serrano ZeladaMarcos Luis Chuquilin VergaraNo ratings yet

- Volume 1Document2 pagesVolume 1MeetNo ratings yet

- Determinação Da Taxa Mínima de Armadura de Flexão em Vigas Com Seção RetangularDocument9 pagesDeterminação Da Taxa Mínima de Armadura de Flexão em Vigas Com Seção RetangularPatrícia MouraNo ratings yet

- Influencelines Lineas de InfluenciaDocument6 pagesInfluencelines Lineas de Influenciakari20sNo ratings yet

- PreferenceShares Metals - February 28 2018Document1 pagePreferenceShares Metals - February 28 2018Tiso Blackstar GroupNo ratings yet

- TUGAS 3 KESFAS A - 05191056 - Pradhitya Dwijati WibowoDocument10 pagesTUGAS 3 KESFAS A - 05191056 - Pradhitya Dwijati WibowoArlieNo ratings yet

- HospitalisationDocument33 pagesHospitalisationLes élites d'économieNo ratings yet

- Part 1 Volumetric MethodDocument4 pagesPart 1 Volumetric Methodanas 1No ratings yet

- Result Marcet 2Document4 pagesResult Marcet 2Ahmed Qutb AkmalNo ratings yet

- Buckley - Leverett (Practico)Document5 pagesBuckley - Leverett (Practico)Juan Carlos GarecaNo ratings yet

- Result Marcet 2Document4 pagesResult Marcet 2Ahmed Qutb AkmalNo ratings yet

- Duct Size Duct Size Velocity Duct Loss Pressure Pressure Length Width (Equiv Round) Airflow Velocity Pressure Length Coeff. Loss Per 100ft LossDocument1 pageDuct Size Duct Size Velocity Duct Loss Pressure Pressure Length Width (Equiv Round) Airflow Velocity Pressure Length Coeff. Loss Per 100ft LossAzher ANo ratings yet

- 5000 Cs Culvert Analysis Report: Project NotesDocument9 pages5000 Cs Culvert Analysis Report: Project NotesFahad ZulfiqarNo ratings yet

- Job 5Document10 pagesJob 5Janita SiddiquiNo ratings yet

- Tatt Agrotek BDocument17 pagesTatt Agrotek BJun AdityaNo ratings yet

- Tabel Pengamatan Eksperimen Interferometer Fabry-PerotDocument3 pagesTabel Pengamatan Eksperimen Interferometer Fabry-Perotmaul ataNo ratings yet

- CHEM Reviewer Grade 12Document3 pagesCHEM Reviewer Grade 12RaphaelNo ratings yet

- Module 2 Reading - Ross, 2006 PDFDocument20 pagesModule 2 Reading - Ross, 2006 PDFMacky AguilarNo ratings yet

- 101 - System ArgumentsDocument16 pages101 - System ArgumentsMurali VarathanNo ratings yet

- No FamilyDocument46 pagesNo FamilyWindsurfingFinnNo ratings yet

- Bhomavat 2009Document8 pagesBhomavat 2009Jing XueNo ratings yet

- Compartir Which-Food-Am-I - Students Taller 2Document1 pageCompartir Which-Food-Am-I - Students Taller 2Daniela MellizoNo ratings yet

- AdaptabilityDocument3 pagesAdaptabilityfarah hanimNo ratings yet

- GreeceDocument15 pagesGreeceapi-357620775No ratings yet

- In These Studies, The Domains of Care and Justice or Their Associated Values Were Most Important From The Participants'Document4 pagesIn These Studies, The Domains of Care and Justice or Their Associated Values Were Most Important From The Participants'Amenah SagapanNo ratings yet

- English QN PaperDocument8 pagesEnglish QN PaperLini DasanNo ratings yet

- De 7Document12 pagesDe 7Nhã Trần ĐứcNo ratings yet

- Removal GuideDocument16 pagesRemoval Guidegk8rfcmc9hNo ratings yet

- The Influence of Abbasid Empire and Community Needs in The Development of Ḥadīth Literature and Islamic ProphetologyDocument9 pagesThe Influence of Abbasid Empire and Community Needs in The Development of Ḥadīth Literature and Islamic ProphetologylmdwdwdqkNo ratings yet

- The Post Humanist ApproachDocument17 pagesThe Post Humanist ApproachfajarsusantoNo ratings yet

- List of AcquisitionsDocument1,058 pagesList of AcquisitionsBrix ArriolaNo ratings yet

- Top Attorneys 2019Document14 pagesTop Attorneys 2019Arlington MagazineNo ratings yet

- 2010 Revised Manual of Regulations For Private Schools in Basic Education I. General ProvisionsDocument21 pages2010 Revised Manual of Regulations For Private Schools in Basic Education I. General ProvisionsAnnalyn EndrinalNo ratings yet

- Sawit-Sumbermas-Sarana TBK Billingual 31 Des 20 Released1617291310Document158 pagesSawit-Sumbermas-Sarana TBK Billingual 31 Des 20 Released1617291310Ade FajarNo ratings yet

- MKTG Plann Final PageDocument28 pagesMKTG Plann Final Pageacs_89No ratings yet

- Slides NPTEL BlockchainTechnologyApplicationsDocument596 pagesSlides NPTEL BlockchainTechnologyApplicationsVeeresh PatelNo ratings yet

- 15 & 16. LSCM - Planning and Managing Inventories in A SC - Aggregating Multiple Products in A Single OrderDocument49 pages15 & 16. LSCM - Planning and Managing Inventories in A SC - Aggregating Multiple Products in A Single OrderAKASH RAJNo ratings yet

- PONLINE System Overview V5 eDocument5 pagesPONLINE System Overview V5 emanskebe6121No ratings yet

- Alphawave IP - Phase I - L2Document12 pagesAlphawave IP - Phase I - L2extortionchloride610No ratings yet

- 507 33 Powerpoint-Slides DRCS Ch20Document21 pages507 33 Powerpoint-Slides DRCS Ch20Anil Basnet100% (1)

- Coconut Rice PuddingDocument2 pagesCoconut Rice PuddingTommy TunaNo ratings yet

- Pe Long QuizDocument3 pagesPe Long QuizRehyna Relos CrudaNo ratings yet

- General Knowledge About PakistanDocument8 pagesGeneral Knowledge About PakistanShahzeb AliNo ratings yet

- Progress Test 4 PDFDocument6 pagesProgress Test 4 PDFPabloNo ratings yet

- UHW Kaiser Local Agreement 2012-2016Document414 pagesUHW Kaiser Local Agreement 2012-2016seiuuhw60% (5)

- Baby Food Indonesia Euromonitor International - AnalysisDocument13 pagesBaby Food Indonesia Euromonitor International - AnalysisJaysun AlumkalNo ratings yet