Professional Documents

Culture Documents

3.2 Thawing Methods - Breakout Session

Uploaded by

Arylle Arpia0 ratings0% found this document useful (0 votes)

9 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pages3.2 Thawing Methods - Breakout Session

Uploaded by

Arylle ArpiaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Thawing Methods

Breakout Session

c. It will take longer to cook frozen products.

1. Introduction d. Always thoroughly check the temperature

In this toolbox talk you (a supervisor or manager of food of the food prior to service.

and beverage operations) will discuss the importance of 3. Running water

correctly thawing food ensuring that growth of pathogens in This process should only be performed as an

PHF minimised. emergency measure as it creates additional food

safety risks and increases water consumption.

To facilitate this toolbox talk, it maybe helpful to carry out

the talk near an area that food is thawing. You can then a. The temperature of the water must be

indicate correctly labelled food products and demonstrate 21°C (70°F) or below.

relevant process. b. Separate different food types.

c. Thawed PHF must be fully submerged.

Engage in a two-way discussion with your team using key

d. The flow of cold, potable water in the sink

points, selected questions and answers on this sheet.

must be strong enough to remove all loose

2. Key points particles.

e. The temperature of thawed portions of

Background Information ready-to-eat food must be closely

• Freezing food does not kill bacteria, it slows their monitored so they do not rise into the TDZ

growth or 'puts them to sleep'. (Temperature Danger Zone).

• Thawing food means changing frozen food to a soft f. In the case of thawed portions of a raw

or liquid state. animal food, do not allow the temperature

• As the food and bacteria heats up, the bacteria will to rise into the TDZ for more than 4 hours.

begin multiplying again, so it is very important for

the thawing process to be controlled.

Advanced Planning

It is very important to know the time it takes for the product

Methods of Thawing food to defrost. Planning is a fundamental step in the thawing

There are several approved ways to thaw food in a safe operation.

way: The benefits of advanced planning:

1. Refrigeration or in thawing cabinets: • Avoid emergency defrosting.

a. Items should be placed on the bottom • Accurate product quantities.

shelf, covered or protected. • Correct stock rotation.

b. Use ‘run-off trays’ to prevent food resting • Avoid unnecessary food waste.

in liquid. • Save money.

c. Labels should be used recording the

Monitoring Thawing Food

product name and the date the thawing

started. Thawing requires constant monitoring by everyone in your

d. To be kept below 5°C (41°F) Costa and team to prevent harmful bacteria multiplying.

Aida flagged vessels: 4°C (39°F). Process for monitoring thawing food:

2. As a part of the cooking process 1. Check temperature during the thaw.

a. By grilling, deep fat frying or using a 2. Check the temperature of the defrosting unit (if

microwave oven. used).

b. Usually used with processed/readymade 3. Check the condition of the food once completely

foods such as burgers, sausages, pizzas thawed.

etc.

Thawing Methods

Breakout Session

4. Check the temperature of the cooked food to

ensure it is safe for consumption.

3. Test your team’s knowledge

Select questions from the list below for discussion with your

team with an emphasis on the issues you have recently

observed in your workplace.

1. What happens to the food during the thawing process?

A: It changes from a solid to a soft or liquid state.

2. Why is it important that the thawing process is carefully

controlled?

A: As the food warms up, so does the bacteria within

the food causing it to multiply.

3. List 3 methods of thawing food.

A: Refrigeration or in thawing cabinets, cooking and

running water.

4. What are the considerations when thawing food in a

refrigerator?

A: Place food on the bottom shelf, use run-off trays,

label and keep below 5°C (41°F) Costa and Aida

flagged vessels: 4°C (39°F).

5. When should the ‘running water’ method be used?

A: Only in an emergency.

6. What considerations should you make when using the

‘running water’ thawing method?

A: Water must be below 21°C (70°F), keep different food

separated, closely monitor the food temperature so it

doesn’t rise into the TDZ and the flow of cold potable

water in the sink must be strong enough to remove all

loose particles.

7. Why is it important to plan the thawing in advance?

A: Avoid emergency defrosting, accurate quantities,

correct stock rotation, avoid food and money waste.

8. When thawing portions of a raw animal food, how long

is it allowed to rise into the TDZ for?

A: 4 hours.

You might also like

- Freeze Drying Mastery For Beginners: Complete Guide to Long-Term Food Storage, Save Money, Reduce Waste and Keep Your Pantry StockedFrom EverandFreeze Drying Mastery For Beginners: Complete Guide to Long-Term Food Storage, Save Money, Reduce Waste and Keep Your Pantry StockedNo ratings yet

- Safe food handling stepsDocument2 pagesSafe food handling stepsGerma ComandaNo ratings yet

- Thawing Food SafelyDocument15 pagesThawing Food SafelySamiksha SinghNo ratings yet

- Paleo Canning And Preserving Recipes Three Ps of Preserving – Pick, Prepare, and PreserveFrom EverandPaleo Canning And Preserving Recipes Three Ps of Preserving – Pick, Prepare, and PreserveNo ratings yet

- SAFE DEFROSTINGDocument2 pagesSAFE DEFROSTINGCherieNo ratings yet

- SAFE DEFROSTINGDocument2 pagesSAFE DEFROSTINGSarfraz EPIC ConsultingNo ratings yet

- Storing Sandwiches March 18Document22 pagesStoring Sandwiches March 18hirarivera07No ratings yet

- 4+K3+SOP+Frozen+Food+Storage+&+Thawing+Procedure PDF+Document2 pages4+K3+SOP+Frozen+Food+Storage+&+Thawing+Procedure PDF+AbhishekNo ratings yet

- SEAFOOD SAFETY QUALITY Partial PDFDocument15 pagesSEAFOOD SAFETY QUALITY Partial PDFLarraine Chaste PonteresNo ratings yet

- SITHKOP005 Coordinate Cooking OperationDocument8 pagesSITHKOP005 Coordinate Cooking OperationBaljeet SinghNo ratings yet

- Food Product FlowDocument12 pagesFood Product FlowDal.giNo ratings yet

- SITHKOP005 Coordinate Cooking OperationDocument7 pagesSITHKOP005 Coordinate Cooking Operationbijay rai100% (3)

- Assessment 1 SITHKOP005 - Coordinate Cooking Operations Questioning - Quiz Answer The Following QuestionsDocument17 pagesAssessment 1 SITHKOP005 - Coordinate Cooking Operations Questioning - Quiz Answer The Following QuestionsbeyNo ratings yet

- Cooling and Reheating - FINALDocument1 pageCooling and Reheating - FINALMMNo ratings yet

- DDDDocument2 pagesDDDJheann Flestado SapicoNo ratings yet

- Learning Module: Surigao State College of TechnologyDocument6 pagesLearning Module: Surigao State College of TechnologyRegine YuNo ratings yet

- Template Food Control Plan Revised Sous Vide SectionDocument7 pagesTemplate Food Control Plan Revised Sous Vide SectionAtlasLiu100% (1)

- Module 4 - ProductionDocument28 pagesModule 4 - ProductionMonish DoifodeNo ratings yet

- HH Inspection Observations List JUNODocument6 pagesHH Inspection Observations List JUNOmohamed hathilNo ratings yet

- Rsfs 2019 Lesson 4Document14 pagesRsfs 2019 Lesson 4RICHARD C. DIZONNo ratings yet

- Food FlowDocument15 pagesFood FlowJessa CapangpanganNo ratings yet

- Four Safe Methods to Thaw FoodsDocument2 pagesFour Safe Methods to Thaw FoodsJheann Flestado SapicoNo ratings yet

- COOKERY Store SandwichesDocument16 pagesCOOKERY Store SandwichesJessie James Bendicio VirtuosoNo ratings yet

- TLE Cookery10 Week4Document4 pagesTLE Cookery10 Week4Dru Sour Orange TreeNo ratings yet

- Cook-Chill Food PreservationDocument30 pagesCook-Chill Food PreservationChan MichaelNo ratings yet

- Thermal Processing of Food PDFDocument23 pagesThermal Processing of Food PDFthanhtl_hugolataNo ratings yet

- Safe Thawing MethodsDocument3 pagesSafe Thawing MethodsfaisalNo ratings yet

- Introduction To Food Science and Food Systems 2nd Edition Parker Solutions ManualDocument10 pagesIntroduction To Food Science and Food Systems 2nd Edition Parker Solutions Manualquandiendjv100% (27)

- Chapter 8 - Servsafe - 6e EditedDocument6 pagesChapter 8 - Servsafe - 6e Editeddevvy anneNo ratings yet

- Activities: SITHCCC101 Use Food Preparation EquipmentDocument9 pagesActivities: SITHCCC101 Use Food Preparation EquipmentRekha SainiNo ratings yet

- Thermal Processing of FoodDocument23 pagesThermal Processing of FoodDharanibalan PNo ratings yet

- Cooking Meat Cuts: Techniques for Tenderizing and Preparing Different Meat CutsDocument4 pagesCooking Meat Cuts: Techniques for Tenderizing and Preparing Different Meat CutsYuki100% (1)

- Hygiene RulesDocument7 pagesHygiene Rulesskylife1106No ratings yet

- Christmas Soup Saftey HandoutDocument2 pagesChristmas Soup Saftey Handoutapi-449956571No ratings yet

- GRADE 10 2nd Quarter 3rd WeekDocument5 pagesGRADE 10 2nd Quarter 3rd WeekJOHN LUZADASNo ratings yet

- Food Safety Rules - A3 PosterDocument1 pageFood Safety Rules - A3 PosterBhavana BhattNo ratings yet

- Module 13 Thermal ApplicationDocument15 pagesModule 13 Thermal ApplicationMitchille Getizo100% (1)

- Kitchen Session 1a Workplan AssessmentDocument45 pagesKitchen Session 1a Workplan AssessmentWey WahNo ratings yet

- 6800ghp 8 Defrosting fsghp00803pdfDocument4 pages6800ghp 8 Defrosting fsghp00803pdfchiheb maaloulNo ratings yet

- MRNB Hyg 0010 Freezer TemperatureDocument3 pagesMRNB Hyg 0010 Freezer Temperaturecowboy1966No ratings yet

- Hazard Analysis: Hat Is It OwdowedoitDocument8 pagesHazard Analysis: Hat Is It OwdowedoitHazarNo ratings yet

- Q4 HE Cookery 9 Week6Document3 pagesQ4 HE Cookery 9 Week6Nicole PanoNo ratings yet

- Chapter 4 Heat Treatment (B)Document22 pagesChapter 4 Heat Treatment (B)NURUL BALQIS DZULKIFLINo ratings yet

- Control Time and Temperature Abuse to Keep Food SafeDocument7 pagesControl Time and Temperature Abuse to Keep Food SafeJea Sumaylo HamoNo ratings yet

- High Temperature Food PreservationDocument28 pagesHigh Temperature Food PreservationDuy NguyenNo ratings yet

- Kitchen AssessmentDocument41 pagesKitchen AssessmentAMAN MIGLANINo ratings yet

- Food Safety RulesDocument1 pageFood Safety RulesSubbarao MallampalliNo ratings yet

- Sitxinv002 Maintain The Quality of Perishable Items: Activity 1ADocument8 pagesSitxinv002 Maintain The Quality of Perishable Items: Activity 1ANancy VermaNo ratings yet

- Apw Cookery 9 Las q3 Week7Document12 pagesApw Cookery 9 Las q3 Week7Jeric VolosoNo ratings yet

- Canning BasicsDocument4 pagesCanning BasicsJuno CambayaNo ratings yet

- Thawing FoodDocument2 pagesThawing FoodAddress HotelNo ratings yet

- Tle10 He Cookery q2 Mod4 Storingvegetabledishes v3 (62 Pages)Document53 pagesTle10 He Cookery q2 Mod4 Storingvegetabledishes v3 (62 Pages)Marilyn Lamigo BristolNo ratings yet

- Storing Desserts Safely and ProperlyDocument6 pagesStoring Desserts Safely and ProperlyMichelle Ann LuzonNo ratings yet

- Blanching Enzyme Inactivation in VegetablesDocument5 pagesBlanching Enzyme Inactivation in Vegetablesemilia emiliaNo ratings yet

- Final Cookery12 q3 Module 4Document14 pagesFinal Cookery12 q3 Module 4Elle Gatch50% (2)

- RSOP25 Cooling FoodDocument2 pagesRSOP25 Cooling FoodjessidreyesNo ratings yet

- Stainless Steel Food Dehydrator Operating ManualDocument12 pagesStainless Steel Food Dehydrator Operating ManualJhoselyn GuachaláxoNo ratings yet

- Writing A Food Safety Plan PDFDocument17 pagesWriting A Food Safety Plan PDFFitri RamadhaniNo ratings yet

- Food Flow PDFDocument10 pagesFood Flow PDFWeendel VenturaNo ratings yet

- 3.1 Food Provisions - Breakout SessionDocument3 pages3.1 Food Provisions - Breakout SessionArylle ArpiaNo ratings yet

- Phy2 11 - 12 Q3 0202 FDDocument21 pagesPhy2 11 - 12 Q3 0202 FDArylle Arpia100% (1)

- Stress and Coping Strategies Among StudentsDocument5 pagesStress and Coping Strategies Among StudentsArylle ArpiaNo ratings yet

- PT Gen Chem 2 Q4Document4 pagesPT Gen Chem 2 Q4Arylle ArpiaNo ratings yet

- Introduction To The Philosophy of Man What Is Philosophy?Document2 pagesIntroduction To The Philosophy of Man What Is Philosophy?Arylle ArpiaNo ratings yet

- Duty Manager Checklist Ensures Smooth OperationsDocument3 pagesDuty Manager Checklist Ensures Smooth OperationsRevo RichNo ratings yet

- Tree of Life Center US: Slow Oxidizer ProfileDocument2 pagesTree of Life Center US: Slow Oxidizer ProfileAnne Marie GordonNo ratings yet

- Oryzanol 3.1TKDocument23 pagesOryzanol 3.1TKmd.kamrul hasan riadNo ratings yet

- History of chocolate drinkDocument3 pagesHistory of chocolate drinkjavierNo ratings yet

- Comparatives & SuperlativesDocument5 pagesComparatives & SuperlativesMaria Eugenia Gomez GabrielliNo ratings yet

- H2B ManualDocument50 pagesH2B ManualLylyneNo ratings yet

- Little-Ants-Big-Plan Eng BOOKLET V12022.08.31T155802+0000Document10 pagesLittle-Ants-Big-Plan Eng BOOKLET V12022.08.31T155802+0000Vone MoresNo ratings yet

- 30 Day Fitness Challenge: Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7Document4 pages30 Day Fitness Challenge: Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7Xytus100% (2)

- 05-Quiz 1Document16 pages05-Quiz 1Rose Ann Bagalawis AquinoNo ratings yet

- Adventurous Journey Recommended Kit ListDocument1 pageAdventurous Journey Recommended Kit ListimanuelcNo ratings yet

- Nutritional and Pharmacological Properties of TamarindusDocument6 pagesNutritional and Pharmacological Properties of TamarindusHazel Michelle Cañas MartínezNo ratings yet

- EVOLVE Level 1 Grammar ChartsDocument12 pagesEVOLVE Level 1 Grammar ChartsLiliana Amanda Lema LarraguibelNo ratings yet

- MD - Tanveer IslamDocument89 pagesMD - Tanveer IslamAbdullah KhanNo ratings yet

- Plants Extract As An Alternative Ink ForDocument14 pagesPlants Extract As An Alternative Ink ForBO4-MAGYAYA, NIEL JAY M.No ratings yet

- Nothing To Lose by Fei Tian Ye Xiang (MTL)Document507 pagesNothing To Lose by Fei Tian Ye Xiang (MTL)Thea ClonesNo ratings yet

- 04 Legacy A2 Unit 4Document9 pages04 Legacy A2 Unit 4HristoMilushevNo ratings yet

- CBSE-Cls6-Separation of Substances NotesDocument12 pagesCBSE-Cls6-Separation of Substances NotesPankaj KumarNo ratings yet

- STOWAGE FACTOR LIST DRY BULK CARGO PT HaDocument8 pagesSTOWAGE FACTOR LIST DRY BULK CARGO PT HaGerente MLGINo ratings yet

- QuotesDocument12 pagesQuotesKripalu Madhava DasNo ratings yet

- Coca-Cola India Case Study AssignmentDocument24 pagesCoca-Cola India Case Study AssignmentRishab MaheshwariNo ratings yet

- Group Members Project DetailsDocument30 pagesGroup Members Project DetailsNehal Thakkar100% (1)

- Dish Washer ManuelDocument32 pagesDish Washer ManuelretishambatNo ratings yet

- Assignment On BCG Matrix of Coca-ColaDocument14 pagesAssignment On BCG Matrix of Coca-ColaChamodya ThathsaraniNo ratings yet

- Study - Id115028 - FMCG Market in Saudi ArabiaDocument33 pagesStudy - Id115028 - FMCG Market in Saudi ArabiaAshish ManchandaNo ratings yet

- The Coca-Cola Company.: in Plant Training at HCCBPL, WadaDocument69 pagesThe Coca-Cola Company.: in Plant Training at HCCBPL, WadaAmol WarghadeNo ratings yet

- 泰國飲食文化Document19 pages泰國飲食文化黃鈺棠No ratings yet

- The Role of Nurses and Nutrition in Healthy PatientsDocument1 pageThe Role of Nurses and Nutrition in Healthy Patientsamal abdulrahmanNo ratings yet

- Foodyz Technologies - Rc1801239: Restaurant Partner Enrolment Form For Online Food Ordering ServicesDocument4 pagesFoodyz Technologies - Rc1801239: Restaurant Partner Enrolment Form For Online Food Ordering ServicesAsemotaiykeNo ratings yet

- W1-L1-FAQ - Scope of Human NutritionDocument3 pagesW1-L1-FAQ - Scope of Human NutritionIshita SinghNo ratings yet

- Smart Choice 1 Woork BookDocument90 pagesSmart Choice 1 Woork BookDiana SilvaNo ratings yet

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideFrom EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideRating: 4 out of 5 stars4/5 (6)

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsFrom EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsNo ratings yet

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 5 out of 5 stars5/5 (4)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomFrom EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomRating: 4 out of 5 stars4/5 (1)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterFrom EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterRating: 3.5 out of 5 stars3.5/5 (487)

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayFrom EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayRating: 4 out of 5 stars4/5 (10)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldFrom EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldRating: 3.5 out of 5 stars3.5/5 (5)

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayFrom EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayRating: 4 out of 5 stars4/5 (4)

- Keto Friendly Recipes: Easy Keto For Busy PeopleFrom EverandKeto Friendly Recipes: Easy Keto For Busy PeopleRating: 3.5 out of 5 stars3.5/5 (2)

- Tacos, Tortas, And Tamales: Flavors from the Griddles, Pots, and Streetside Kitchens of MexicoFrom EverandTacos, Tortas, And Tamales: Flavors from the Griddles, Pots, and Streetside Kitchens of MexicoNo ratings yet

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyFrom EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyRating: 4 out of 5 stars4/5 (11)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoFrom EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoNo ratings yet

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingFrom EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingNo ratings yet

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingFrom EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingRating: 4 out of 5 stars4/5 (3)

- Binging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsFrom EverandBinging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsNo ratings yet

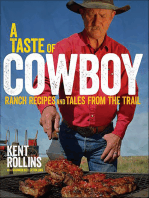

- A Taste of Cowboy: Ranch Recipes and Tales from the TrailFrom EverandA Taste of Cowboy: Ranch Recipes and Tales from the TrailRating: 4.5 out of 5 stars4.5/5 (3)

- Rice, Noodle, Fish: Deep Travels Through Japan's Food CultureFrom EverandRice, Noodle, Fish: Deep Travels Through Japan's Food CultureRating: 4 out of 5 stars4/5 (20)

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthFrom EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthRating: 2 out of 5 stars2/5 (1)

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingFrom EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingRating: 4 out of 5 stars4/5 (9)

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyFrom EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyRating: 4 out of 5 stars4/5 (1)

- Heirloom Kitchen: Heritage Recipes & Family Stories from the Tables of Immigrant WomenFrom EverandHeirloom Kitchen: Heritage Recipes & Family Stories from the Tables of Immigrant WomenRating: 4.5 out of 5 stars4.5/5 (3)