Professional Documents

Culture Documents

Error 1622

Uploaded by

Andante Agung BramastaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Error 1622

Uploaded by

Andante Agung BramastaCopyright:

Available Formats

SC-F6300 Series Revision A

3.4.4.15 INK HOLDER REPLACEMENT

A D J U S T M E N T When replacing/removing this part, refer to 4.1.2 Adjustment 1. Remove the UPPER LEFT COVER. (p194)

R E Q U IR E D

Items and the Order by Repaired Part (p329) and make sure to

perform the specified operations including required adjustment. 2. Remove the UPPER SUPPORT R COVER. (p185)

3. Remove the PANEL BOARD. (p218)

4. Remove the TOP COVER. (p176)

REQUIRED TOOL

5. Remove the MAINTENANCE COVER SENSOR. (p186)

Ink Cartridges for service (4 pcs)

6. Remove the MAINTENANVCE COVER & RIGHT ROLL COVER. (p188)

USB cable

7. Remove the FRONT COVER. (p177)

Service program

8. Remove the RIGHT LOWER COVER. (p190)

Communication driver

9. Remove the INK TANK. (p289)

PREPARATION BEFORE REPLACEMENT

1. Start the printer in the Serviceman Mode.

Turn on the printer while pressing [Menu] + [Back] + [OK].

2. Start the service program and select When replace ink holder from

ADJUSTMENT (Sequence).

3. Select Ink Holder Counter.

Press the [Run] button to reset the counter. (p364)

4. Turn off the printer.

5. Turn on the printer.

6. Discard the waste ink.

7. Turn off the printer.

8. Remove all the INK TANKs. (p289)

9. Lower the Side Cover.

10. Start the printer in the Serviceman Mode.

Turn on the printer while pressing [Menu] + [Back] + [OK].

11. Select Ink Eject.

Select All channels, and press the [Run] button to run the ink eject. (p394)

12. Turn off the printer.

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 273

Confidential 2

SC-F6300 Series Revision A

4.7 Counter Reset Table 4-10. Clear Counter Menu List

Class Item Clear Menu Name

Whenever the parts/units which have life counter are replaced, the corresponding life Main unit PF MOTOR PF Motor Counter

counter must be reset. This is important to replace those parts/units at the correct counter (Motor) APG Motor APG motor counter reset

timing.

ATC MOTOR ATC Motor Counter Reset

EXECUTION MODE Cutter motor Cutter motor counter reset

Main unit PRINT HEAD Print Head Counter

Normal mode counter (Ink DUCT CR Duct CR Counter

system)

PUMP CAP UNIT Pump Cap Unit Counter

PROCEDURE

IC HOLDER Ink Holder Counter

1. Turn the printer ON. INK TUBE Ink tube counter

2. Start the Service Program and click [FLAG CHANGE & COUNTER RESET] Main unit MAIN BOARD Main Board Exchange Counter

from the main menu. counter Power Supply Unit Replacement Date &

(Mechanism) POWER SUPPLY UNIT

Time Setting

3. Choose one of the counter reset menus to be reset.

Change Flag

4. Click [Run] to reset the counter. Initial Ink Charge Flag Initial Ink Charge Flag

Status

5. Click [Finish]. Administrator

Administrator Password Administrator Password Reset

Password

6. Restart the printer.

7. With NVRAM Viewer, verify that the counter has been reset to "0".

8. Turn the printer OFF.

C H E C K The history of the Counter Clear can be checked per counter on the

P O IN T NVRAM Viewer (P. 354).

Table 4-10. Clear Counter Menu List

Class Item Clear Menu Name

Main unit

CR MOTOR CR Motor Counter

counter (Motor)

ADJUSTMENT Counter Reset 364

Confidential 2

SC-F6300 Series Revision A

4.2.3 NVRAM Viewer Basic Operation DESCRIPTION

The following functions are provided. Life Parts Operation History

1. Displays the Life Parts Operation History

1

2. Displays the history how the printer has been used (Utilization History)

3. Displays the Error History saved in the NVRAM

4. Displays the Basic Information of the printer (such as the serial No. or the

setting values)

PROCEDURE

1. Click [Display Information] on the NVRAM Read field of the NV-RAM

BACKUP screen. Another screen of the NVRAM Viewer will be displayed.

2. Select the tab you want to check.

3. Click [Save as CSV] to save the information shown in the selected tab as CSV

file. 2 3 4 5 6

4. Click [Print] to print the information shown in the selected tab. 7

5. Click [Close] to close the screen.

Figure 4-3. [Life Parts Operation History] Screen

1 Total Print Dimension Total printed area. The unit is m2.

2 Items ---

3 Current Value Displays current values for each part or unit.

4 Limit Displays the life limit of the part if it has.

ADJUSTMENT NV-RAM BACKUP/NVRAM Viewer 354

Confidential 2

SC-F6300 Series Revision A

3.4.4.19 INK TANK/CARTRIDGE 2. Remove the two bolts that secure the INK TANK COVER.

C A U T IO N When using the INK TANKs, cleaning cartridges, and ink

cartridges for service, they should be validated by using software

(Service Program). (See P. 392 or P. 393.)

1. Open the Side Cover.

Figure 3-164. Removing the INK TANK/CARTRIDGE

3. Remove the INK TANK COVER.

Figure 3-163. Removing the INK TANK/CARTRIDGE

Figure 3-165. Removing the INK TANK/CARTRIDGE

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 289

Confidential 2

SC-F6300 Series Revision A

4. Remove the two bolts that secure the INK GUARD (TBD). 8. Remove the INK TANK.

Slider

INK TANK

Figure 3-166. Removing the INK TANK/CARTRIDGE

5. Remove the INK GUARD.

Figure 3-168. Removing the INK TANK/CARTRIDGE

Figure 3-167. Removing the INK TANK/CARTRIDGE

6. Remove the bolts that secure the INK TANKs (one each). Make sure to set the slider to the INK TANK, and then install them

together.

7. Remove the slider.

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 290

Confidential 2

SC-F6300 Series Revision A

4.12.4 Ink eject

C H E C K Due to the structure of this printer, you cannot replace only one

P O IN T tank. Therefore, replacement of the tanks should be made

according to the combinations below.

For SC-F6000 Series/SC-F6200 Series

BK and M

Y and C

For SC-B6000 Series

BK and Y

M and C

EXECUTION MODE

Serviceman Mode

PROCEDURE Figure 4-48. [Ink eject] Screen

1. Turn the printer ON in the Serviceman Mode.

Turn the power ON while pressing [Menu] + [Back] + [OK].

2. Remove either of the ink tanks, cleaning cartridges or ink cartridges of the colors

to exchange.

3. Lower the Side Cover.

4. Start the Service Program and select Ink eject.

5. Select the nozzle rows to eject (All channels or Single channel), and click the

[Run] button.

C A U T IO N Running the Ink eject function one time is not enough to prevent

ink from leaking when removing the ink tubes. Prepare paper or

cloth to wipe off leaked ink in advance or run the Ink eject function

twice in a row.

6. When finished, click [Finish].

7. Turn off the printer.

ADJUSTMENT Ink Supply Related Checks and Adjustments 394

Confidential 2

SC-F6300 Series Revision A

3.4.2.15 UPPER LEFT COVER

1. Open the PRINTER COVER.

2. Remove the five screws, and remove the UPPER LEFT COVER.

A) Silver M3x8 S-tite screw with built-in washer: 5 pcs

PRINTER COVER

A

UPPER LEFT COVER

Figure 3-35. Removing the UPPER LEFT COVER

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 194

Confidential 2

SC-F6300 Series Revision A

3.4.2.8 UPPER SUPPORT R COVER

1. Remove the two screws, and remove the UPPER SUPPORT R COVER.

UPPER SUPPORT R

A) Silver M3x8 S-tite screw with built-in washer: 2 pcs COVER

Pay attention to the positioning points. (See below figure) A

UPPER SUPPORT R

Positioning points COVER

A

Figure 3-23. Removing the UPPER SUPPORT R COVER

Positioning points

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 185

Confidential 2

SC-F6300 Series Revision A

3.4.3.7 PANEL BOARD 5. Disconnect the cable and FFC from the connectors (CN1, CN5) of the PANEL

BOARD.

1. Open the MAINTENANCE COVER.

2. Remove the two screws that secure the Panel Housing. PANEL BOARD

A) Silver M3x8 S-tite screw with built-in washer: 1 pcs

3. Slide the Panel Housing downward to disengage the four hooks. CN5

4. Remove the Panel Housing. Cable

Hooks CN1

A

Panel Housing

FFC

Hooks Figure 3-68. Removing the Panel Housing

Figure 3-67. Removing the Panel Housing

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 218

Confidential 2

SC-F6300 Series Revision A

3.4.2 Housing

Positioning point

3.4.2.1 TOP COVER

A

1. Remove the UPPER LEFT COVER. (p194)

2. Remove the UPPER SUPPORT R COVER. (p185) TOP COVER

3. Remove the screw, and remove the TOP COVER. Upper Support

Frame

A) Silver M3x8 S-tite screw with built-in washer: 1 pcs

Pay attention to the positioning points (See Figure 3-12).

Figure 3-12. Removing the TOP COVER

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 176

Confidential 2

SC-F6300 Series Revision A

3.4.2.9 MAINTENANCE COVER SENSOR

1. Open the MAINTENANCE COVER.

Pet film

2. Remove the two screws, and remove the pet film. Remove the two screws, and

remove the pet film.

A) Silver M3x8 P-tite screw with built in washer: 2 pcs

Secure the Pet film and the MAINTENANCE COVER SENSOR

with the same screw.

MAINTENANCE

COVER SENSOR

Figure 3-25. Removing the MAINTENANCE COVER SENSOR

3. Release the cable from the Cable Guide.

A

。

MAINTENANCE COVER SENSOR

Pet film

Cable Guide

Screw

together

Figure 3-24. Removing the MAINTENANCE COVER SENSOR

Cable

Figure 3-26. Removing the MAINTENANCE COVER SENSOR

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 186

Confidential 2

SC-F6300 Series Revision A

4. Pull out the cable through the gap of the MAINTENANCE COVER SENSOR,

Wrap the wire around the cable guide one time.

and then disconnect the Relay Connector.

Cable Guide MAINTENANCE COVER SENSOR

Relay Connector

Figure 3-27. Removing the MAINTENANCE COVER SENSOR

5. Remove the MAINTENANCE COVER SENSOR.

MAINTENANCE COVER SENSOR

Figure 3-28. Removing the MAINTENANCE COVER SENSOR

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 187

Confidential 2

SC-F6300 Series Revision A

3.4.2.10 MAINTENANCE COVER & RIGHT ROLL COVER

1. Remove the UPPER SUPPORT R COVER. (p185) C

B

2. Remove the MAINTENANCE COVER SENSOR. (p186)

3. Remove the Panel Housing. (p218)

4. Remove the nine screws, and remove the MAINTENANCE COVER & RIGHT

B

ROLL COVER. C

A) Silver M4x12 P-tite screw with washer: 1 pcs

B) Silver M3x8 S-tite screw with built-in washer: 5 pcs

C) Silver M3x8 P-tite screw with built-in washer: 2 pcs

D) Silver M3x10 P-tite screw with washer: 1 pcs

MAINTENANCE COVER &

RIGHT ROLL COVER

A B

Figure 3-29. Removing the MAINTENANCE COVER & RIGHT ROLL COVER

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 188

Confidential 2

SC-F6300 Series Revision A

5. Disengage the dowel on the front side, and remove the MAINTENANCE COVER

Make sure to put the MAINTENANCE COVER and the RIGHT

and RIGHT ROLL COVER at the same time. ROLL COVER together, and then install them at the same time.

MAINTENANCE COVER &

RIGHT ROLL COVER

Dowel

Figure 3-30. Removing the MAINTENANCE COVER & RIGHT ROLL COVER

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 189

Confidential 2

SC-F6300 Series Revision A

3.4.2.2 FRONT COVER

PRINTER COVER

1. Open the PRINTER COVER.

2. Remove the seven screws, and remove the FRONT COVER.

A) Silver M3x8 S-tite screw with built-in washer: 7 pcs A A A A A

To ensure the INTERLOCK SWITCH can detect the flag of

PRINTER COVE, tighten the screws which secure the FRONT

COVER while pulling the Front Frame toward you.

FRONT COVER

Figure 3-13. Removing the FRONT COVER

INTERLOCK SWITCH Front Frame

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 177

Confidential 2

SC-F6300 Series Revision A

3.4.2.11 RIGHT LOWER COVER

1. Remove the UPPER SUPPORT R COVER. (p185)

RIGHT LOWER COVER

2. Remove the MAINTENANCE COVER SENSOR. (p186)

3. Remove the PANEL BOARD. (p218) B

4. Remove the MAINTENANCE COVER & RIGHT ROLL COVER. (p188)

5. Remove the three screws, and remove the RIGHT LOWER COVER.

A) Silver M3x10 P-tite screw with washer: 1 pcs

B) Silver M3x8 S-tite screw with built-in washer: 2 pcs

Insert the two tabs of the IH COVER to the two holes on the B

RIGHT LOWER COVER. A

Pay attention to the positioning points (See below figure).

IH COVER

Tabs

Figure 3-31. Removing the RIGHT LOWER COVER

RIGHT BASE COVER

Positioning points

RIGHT LOWER

COVER

DISASSEMBLY & ASSEMBLY Disassembly and Assembly Procedure 190

Confidential 2

You might also like

- Cs-Xe9cke Cu-Xe9ckeDocument110 pagesCs-Xe9cke Cu-Xe9ckeHai NamNo ratings yet

- 88290022-798 (r03) EC 2000 User ManualDocument22 pages88290022-798 (r03) EC 2000 User ManualBilal Ijaz Sheikh100% (3)

- Instruction Guide for Service Menu FunctionsDocument6 pagesInstruction Guide for Service Menu FunctionsTolias EgwNo ratings yet

- Msa 08 VDP 1Document24 pagesMsa 08 VDP 1AbdNo ratings yet

- MP 402 Operation Panel Service - Final - 010916Document64 pagesMP 402 Operation Panel Service - Final - 010916vestaricoh scannerNo ratings yet

- Engine SectionDocument414 pagesEngine Sectionxristo xristovNo ratings yet

- Esa 415 JDocument24 pagesEsa 415 JJaermirth MelladoNo ratings yet

- NEX Series Maintenance ManualDocument123 pagesNEX Series Maintenance ManualGelu Bonea100% (5)

- Additional Functions for Deep Hole Drilling CyclesDocument30 pagesAdditional Functions for Deep Hole Drilling CyclesKapil SoodNo ratings yet

- 330 PDFsam Puritan-Bennett-700 PDFDocument139 pages330 PDFsam Puritan-Bennett-700 PDFBruna MechiNo ratings yet

- F4HFE6131Document238 pagesF4HFE6131jvega_534120100% (8)

- GDI Vertical AC Unit Preventive MaintenanceDocument4 pagesGDI Vertical AC Unit Preventive MaintenanceMousa PetrolNo ratings yet

- OldSiteOperators and ServiceEnginesTigercat FPT C87Service and RepairC87 T4f42070AENGDocument246 pagesOldSiteOperators and ServiceEnginesTigercat FPT C87Service and RepairC87 T4f42070AENGSilvio C. JarschelNo ratings yet

- Premier Remote Control ManualDocument8 pagesPremier Remote Control ManualRodrigoFaríasVelosoNo ratings yet

- Mitsubishi MSCA12YV ManualDocument32 pagesMitsubishi MSCA12YV Manualsansegundo79No ratings yet

- Remote Control Manual PDFDocument8 pagesRemote Control Manual PDFgilbert kiprutoNo ratings yet

- Accessories Filter Cartridge Lifetime Computer: Operating Manual and Spare Parts ListDocument6 pagesAccessories Filter Cartridge Lifetime Computer: Operating Manual and Spare Parts ListWilson BernalNo ratings yet

- Iveco f32Document164 pagesIveco f32jarreau kraan van derNo ratings yet

- MP6055 Operation PanelDocument63 pagesMP6055 Operation Panelcris de guzmanNo ratings yet

- Hia-717a Osp-150vad (E) Ie3Document98 pagesHia-717a Osp-150vad (E) Ie3Jorge VelazquezNo ratings yet

- N747D ManualDocument65 pagesN747D ManualAntonio NegreteNo ratings yet

- Operator'S Manual: CNC Turret Punch Press Amadan 04PcDocument62 pagesOperator'S Manual: CNC Turret Punch Press Amadan 04PcBillNo ratings yet

- Computerized Gear SystemDocument19 pagesComputerized Gear SystemK.Magenthran (UTHM)92% (12)

- CS-C28GFQ Cu-C28gfqDocument44 pagesCS-C28GFQ Cu-C28gfqPepz Rosauro NavarraNo ratings yet

- SG770 WSM-3200 Control PanelDocument13 pagesSG770 WSM-3200 Control Panelrkss100% (1)

- Service Manual: MODEL:LC-60LE631M-WH LC-60LE631X-WHDocument69 pagesService Manual: MODEL:LC-60LE631M-WH LC-60LE631X-WHAsnake TegenawNo ratings yet

- Training Material For CCWP - ACWPDocument25 pagesTraining Material For CCWP - ACWPToan NguyenNo ratings yet

- IVECOee49d2cd PDFDocument270 pagesIVECOee49d2cd PDFMouh ElobeyNo ratings yet

- BA FirstAir Control - GBDocument20 pagesBA FirstAir Control - GBMarius PapucNo ratings yet

- Iveco Nef45 tm1Document23 pagesIveco Nef45 tm1Antonio MartinNo ratings yet

- ServiceDocument51 pagesServiceAN GNo ratings yet

- NRP-2012-8C-Operation Manual (Printing Bhoteven)Document74 pagesNRP-2012-8C-Operation Manual (Printing Bhoteven)salvatorusNo ratings yet

- CJV30 Additional Pages For Maintenance Manual Jun2009 PDFDocument12 pagesCJV30 Additional Pages For Maintenance Manual Jun2009 PDFaigarsNo ratings yet

- Operator's Manual 3250: Issue 2.0Document12 pagesOperator's Manual 3250: Issue 2.0ivan sulistianNo ratings yet

- PROCESS CONER II OPERATION AND MAINTENANCE GUIDEDocument24 pagesPROCESS CONER II OPERATION AND MAINTENANCE GUIDEMd Hanif SonketNo ratings yet

- F5ae9484 9454 AgricolaDocument150 pagesF5ae9484 9454 Agricolajvega_534120No ratings yet

- Service Manual: Eride 30 Eride 30Document86 pagesService Manual: Eride 30 Eride 30tomy112No ratings yet

- f32 SeriesDocument162 pagesf32 Serieskonstantinovhy161No ratings yet

- F5ce9454 5454 9484 IndustrialDocument162 pagesF5ce9454 5454 9484 Industrialjvega_534120100% (1)

- Canon MP830 Repair Manual - CanonDocument149 pagesCanon MP830 Repair Manual - CanonJulie DealNo ratings yet

- McQuay M4AC 020-150CR Technical Manual EngDocument28 pagesMcQuay M4AC 020-150CR Technical Manual EngNanang Edy cahyonoNo ratings yet

- PR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Document50 pagesPR 9000 E - Inst Manual (E) (SG14 SE001B - Rev 20170608)Mooi Pang Ng100% (2)

- F4ce9484f AgricolaDocument132 pagesF4ce9484f Agricolajvega_534120No ratings yet

- GP605 605VsmDocument897 pagesGP605 605VsmSuvatchai TerasittivongNo ratings yet

- Cor-C1 - d766 - en - Final - 010914 (Internal Fin3180)Document34 pagesCor-C1 - d766 - en - Final - 010914 (Internal Fin3180)bengkel_ericNo ratings yet

- CP-US106180-01 Rev 4Document12 pagesCP-US106180-01 Rev 4moudar72No ratings yet

- Canon NP6045Document684 pagesCanon NP6045Endo100% (1)

- 155 17-m2 PDFDocument135 pages155 17-m2 PDFArshad Mahmood100% (1)

- Process For Setting Up The Work Tool: Testing and AdjustingDocument31 pagesProcess For Setting Up The Work Tool: Testing and AdjustingMbahdiro KolenxNo ratings yet

- F2cfe613 Fjbfe613Document518 pagesF2cfe613 Fjbfe613jvega_534120100% (3)

- Control Solutions: Atlas CopcoDocument30 pagesControl Solutions: Atlas CopcoВладислав СередаNo ratings yet

- User's Manual: Babk, CDC, CDK, HM, TM Unilog B2Document150 pagesUser's Manual: Babk, CDC, CDK, HM, TM Unilog B2MOHD NASIR KAMARUDDINNo ratings yet

- Iveco F4ge PDFDocument142 pagesIveco F4ge PDFHandy Lee67% (3)

- MITSUBISHI GENERATOR SET TECHNICAL PRESENTATIONDocument60 pagesMITSUBISHI GENERATOR SET TECHNICAL PRESENTATIONcspola50% (2)

- Canon 7161 Service ManuelDocument346 pagesCanon 7161 Service ManuelkopisanNo ratings yet

- Techspec XS enDocument2 pagesTechspec XS enpesumasinadNo ratings yet

- 1978 Damage - To Rock Tunnels From Earthquake ShakingDocument18 pages1978 Damage - To Rock Tunnels From Earthquake Shakingofelix505100% (1)

- Motion in A Straight Line: Initial PositionDocument7 pagesMotion in A Straight Line: Initial PositionEngelbert Bicoy AntodNo ratings yet

- IELTS PART 1 (Autoguardado)Document8 pagesIELTS PART 1 (Autoguardado)CARLOS CAICEDONo ratings yet

- ConclusionDocument1 pageConclusionSAVITHRINo ratings yet

- Akd 736103113213Document1 pageAkd 736103113213May'Axel RomaricNo ratings yet

- Hi Flow GroutDocument2 pagesHi Flow Groutpravi3434No ratings yet

- Razwan Iqbalcv1Document3 pagesRazwan Iqbalcv1razwaniqbalNo ratings yet

- Manual For The Implementation of International Development Cooperation Projects of SloveniaDocument7 pagesManual For The Implementation of International Development Cooperation Projects of SloveniarefikrosicNo ratings yet

- Bangladesh Labour Rights ResearchDocument29 pagesBangladesh Labour Rights ResearchMd. Hasan Ali JoyNo ratings yet

- Study of Diesel Fuel Pumps ComponentsDocument6 pagesStudy of Diesel Fuel Pumps ComponentsPro GamerssNo ratings yet

- Dynamic Arc Recognition and TerminationDocument12 pagesDynamic Arc Recognition and TerminationArun BabuNo ratings yet

- Catwalk Walk Base Plate Grouting 1Document30 pagesCatwalk Walk Base Plate Grouting 1MdShahbazAhmedNo ratings yet

- Fire Resistance UL 1709Document2 pagesFire Resistance UL 1709ednavilod100% (3)

- Beam Loader Tributary ExcelDocument2 pagesBeam Loader Tributary ExcelHari Amudhan IlanchezhianNo ratings yet

- Investingunplugged PDFDocument225 pagesInvestingunplugged PDFWilliam MercerNo ratings yet

- Magnetic Particle TestDocument4 pagesMagnetic Particle TestHarry Doble100% (1)

- 524 799 Coach - K - Coach - Knight - CaseDocument15 pages524 799 Coach - K - Coach - Knight - Casekaushalmighty100% (1)

- PCD Notes - Unit - 1Document15 pagesPCD Notes - Unit - 1Jaga DeesanNo ratings yet

- Modern Coating Additives for SustainabilityDocument8 pagesModern Coating Additives for Sustainabilitynano100% (1)

- Network Fundamentals - Chapter 4 Exam AnswersDocument4 pagesNetwork Fundamentals - Chapter 4 Exam AnswersBart AbraasNo ratings yet

- Online Auction SystemDocument29 pagesOnline Auction SystemDharmendra83% (6)

- Easergy PS100 48VDC Power SupplyDocument2 pagesEasergy PS100 48VDC Power SupplyRichard SyNo ratings yet

- Cbam Faq 1701387432Document34 pagesCbam Faq 1701387432zamarrillaNo ratings yet

- Petron Corporate PresentationDocument46 pagesPetron Corporate Presentationsivuonline0% (1)

- Superior Drummer 2 ManualDocument38 pagesSuperior Drummer 2 ManualEmmanuel MarcosNo ratings yet

- Presentation On AIR POWERED VEHICLEDocument26 pagesPresentation On AIR POWERED VEHICLEVishal SrivastavaNo ratings yet

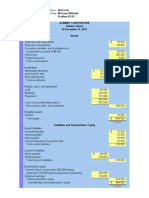

- Chapter 3 - Excel SolutionsDocument8 pagesChapter 3 - Excel SolutionsHalt DougNo ratings yet

- FINA2209 Financial Planning: Week 3: Indirect Investment and Performance MeasurementDocument43 pagesFINA2209 Financial Planning: Week 3: Indirect Investment and Performance MeasurementDylan AdrianNo ratings yet

- Final Investigative Report - MaSUDocument4 pagesFinal Investigative Report - MaSUinforumdocsNo ratings yet