Professional Documents

Culture Documents

FARO Quantum M Tech Sheet

Uploaded by

Andr EkmeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FARO Quantum M Tech Sheet

Uploaded by

Andr EkmeCopyright:

Available Formats

FARO® QuantumM FaroArm®

The Standard for Cost-Effective Factory lnspection

CERTIFIED TO MEET THE MOST RIGOROUS ISO

10360-12:2016 MEASUREMENT STANDARD

Quantum Arms are the first Arms in the market that

are certified against ISO 10360-12:2016, setting

a new industry performance bar, and ensuring

maximum measurement consistency and reliability.

INNOVATIVE DESIGN FOR HIGHEST

PERFORMANCE AND FACTORY STRESS-TESTED

FOR RELIABILITY

An all-new design ensures superior performance

and confidence in measurement results in every

working environment, while the FaroBlu featuring

blue laser technology ensures best-in-class scanning

capability. Every Quantum is tested for ruggedness

and is factory-ready to ensure accuracy and

performance.

EXCELLENT ERGONOMICS AND USABILITY

New ergonomic design, overall weight optimization,

combined with new features such as tool-less

quick change, kinematic intelligent probes,

provide unequaled freedom of movement and an

unparalleled measurement experience.

HIGH SPEED WIRELESS OPERATION

(ROBUST WI-FI®)

New sophisticated and robust electronic design

delivers superior reliability and guarantees optimal

wireless operation for scanning and probing,

allowing unmatched reach across the manufacturing

floor.

EXTENDED BATTERY USE

Dual hot-swappable batteries support prolonged

cable-free operation of the device, making it easy to

The FARO QuantumM FaroArm is a portable coordinate measuring machine (PCMM) go to the part without the need for external power.

that meets the most rigorous ISO 10360-12:2016 measurement standard in the world

– an industry first. It is ideal for companies that want to maximize their manufacturing FAROBLU™ LASER LINE PROBE HD

productivity, reduce scrap and waste and improve their production and quality control

efficiencies. The FAROBlu Laser Line Probe HD leverages

optically-superior blue laser technology. The blue

The Quantum is extremely durable and has been tested to withstand the harshest

M

laser has a shorter wavelength than a red laser,

shop-floor environments. Additionally, it delivers market-leading reliability, portability,

and delivers improved scanning results with higher

and ergonomics along with plug-and-play 3D laser scanning integration with optically-

resolution, thanks to its ability to discover smaller

superior FAROBlu™ technology.

details in an object. The blue laser also provides a

MOST COMMON APPLICATIONS: Alignment • Dimensional Analysis • CAD-Based 50% reduction in speckle noise compared to a red

Inspection • First Article Inspection • Incoming Inspection • In-Process Inspection • On laser. Speckle noise is proportional to wavelength

Machine Inspection • Part Inspection • Final Inspection • Reverse Engineering • Tool and degrades measurement accuracy.

Building & Setup

TYPICAL INDUSTRIES: Aerospace: Part Inspection and Certification, Alignment, Tool &

Mold Certification, Reverse Engineering • Automotive: Tool Building and Certification,

Alignment, Part Inspection, Reverse Engineering • Metal Fabrication: First Article

Inspection, Periodic Part Inspection • Molding/Tool & Die: Mold and Die Inspection,

Prototype Part Scanning

FARO® QuantumM

www.faro.com

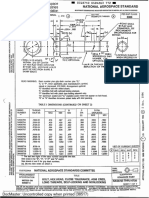

PERFORMANCE SPECIFICATIONS

Contact Measurement (Arm)*

Measurement range SPAT 1

EUNI

2

PSIZE3 PFORM4 LDIA5

6 axis 7 axis 6 axis 7 axis 6 axis 7 axis 6 axis 7 axis 6 axis 7 axis

0.018mm 0.028mm 0.012mm 0.020mm 0.034mm

QuantumM 1.5m (4.9ft) (0.0007in) (0.0011in) (0.0005in) (0.0008in) (0.0013in)

0.026mm 0.028mm 0.038mm 0.042mm 0.018mm 0.020mm 0.030mm 0.035mm 0.045mm 0.060mm

QuantumM 2.5m (8.2ft) (0.0010in) (0.0011in) (0.0015in) (0.0017in) (0.0007in) (0.0008in) (0.0012in) (0.0014in) (0.0018in) (0.0024in)

0.044mm 0.055mm 0.066mm 0.085mm 0.030mm 0.040mm 0.050mm 0.060mm 0.080mm 0.110mm

QuantumM 3.5m (11.5ft) (0.0017in) (0.0022in) (0.0026in) (0.0033in) (0.0012in) (0.0016in) (0.0020in) (0.0024in) (0.0031in) (0.0043in)

0.053mm 0.065mm 0.078mm 0.100mm 0.034mm 0.040mm 0.060mm 0.080mm 0.096mm 0.132mm

QuantumM 4.0m (13.1ft) (0.0021in) (0.0026in) (0.0031in) (0.0039in) (0.0013in) (0.0016in) (0.0024in) (0.0031in) (0.0038in) (0.0052in)

Non-Contact Measurement (ScanArm)** All values represent MPE (Maximum Permissible Error) 1

SPAT – Single Point Articulation Test

* Contact Measurement (Arm): In accordance with ISO ² EUNI – Distance Error between two points

comparing measured vs nominal values

Measurement range LDIA5 10360-12 3

PSIZE – Sphere Probing Size Error comparing

** Non-Contact Measurement (ScanArm): Full System measured vs nominal values

QuantumM 2.5m (8.2ft) 0.063mm (0.0025in) performance in accordance with ISO 10360-8 Annex D 4

PFORM – Sphere Probing Form Error

5

LDIA – Sphere Location Diameter Error (Diameter

QuantumM 3.5m (11.5ft) 0.100mm (0.0039in) of the spherical zone containing the centers of a

sphere measured from multiple orientations)

QuantumM 4.0m (13.1ft) 0.115mm (0.0045in)

HARDWARE SPECIFICATIONS

Operating temp range: 10°C - 40°C (50°F - 104°F) Operating humidity range: 95%, non-condensing

Temperature rate: 3°C/5min (5.4°F/5min) Power supply: Universal worldwide voltage;

100-240VAC; 47/63Hz

FARO LASER LINE PROBE SPECIFICATIONS

Accuracy: ±25μm (±0.001in) Minimum point spacing: 40μm (0.0015in)

Repeatability: 25μm, 2σ (0.001in) Scan rate: 300 frames/second, 300 fps x 2,000

points/line = 600,000 points/sec

Stand-off: 115mm (4.5in)

Laser: Class 2M

Depth of field: 115mm (4.5in)

Weight: 485g (1.1lb)

Effective scan width: Near field 80mm (3.1in)

Far field 150mm (5.9in) Accuracy and repeatability specified at Full Field of View (FOV)

Points per line: 2,000 points/line

Certifications: Meets OSHA requirements, NRTL TÜV SÜD C-US Listed, Complies with Electronic Code of Federal Regulations 47 CFR PART 15,

17 CFR Parts 240 and 249b-Conflict Material, 21 CFR 1040 Performance standards For Light-Emitting Products, and 10 CFR Part 430 -Department

of Energy; Energy Conservation for External Power Supplies. Complies with the following EC Directives: 93/68/EEC CE Marking; 2014/30/EU

Electrical Equipment; 2014/53/EU Radio Equipment Directive; 2011/65/EU RoHS2; 2002/96/EC WEEE; 2006/66/EC WEEE; 2006/66/EC Batteries

and Accumulators; 2014/35/EU Low Voltage Directive; 2009/125/EC Ecodesign requirement. Conforms to the following standards: EN 61010-

1:2010 / CSA-C22.2 No. 61010-1; EN 61326-1:2013 EMC; ETSI EN 300 328 V2.1.1; ETSI 301 489-1 V1.9.2; ETSI 301 489-17 V2.2.1; ETSI EN

62311:2008; IEEE 802.11 b/g; FCC Part 15.247 (WLAN and Bluetooth); Japanese Radio Law MPT No. 37 Ordinance (MIC classification WW); UN T1-T8;

IEC 62133 2nd ed.; IEC 60825-1:2014 ed3.0; FDA (CDRH) 21 CFR 1040.10 / ANSI 2136.1-2007; EN 50581:2012; 21 CFR 1002 (Records & Reports); 21

CFR 1010 (Performance Standards).

Shock and Vibrations Testing per International Electrotechnical Commission (IEC) Standards: IEC 60068-2-6; IEC 60068-2-64; IEC 60068-2-27

Extreme Temperature Cycling (-20°C to 60°C). Based on: IEC 60068-2-1; MIL-STD-81 OG; ISTA

www.faro.com

Freecall 00 800 3276 7253

info.emea@faro.com

Revised: 11 Sep. 2017 | © 2017 FARO | EU-04REF201-774-EN

You might also like

- 04REF101-092 - Techsheet - FARO QuantumS FaroArm - ALL - AP - SG-Dec2018Document2 pages04REF101-092 - Techsheet - FARO QuantumS FaroArm - ALL - AP - SG-Dec2018Ta quoc dungNo ratings yet

- How Will The 5900 Meet My Needs?: Engineered For PrecisionDocument1 pageHow Will The 5900 Meet My Needs?: Engineered For PrecisionAnkit ChaurasiaNo ratings yet

- Dimension FastScan Pro Atomic Force Microscope Brochure BRUKERDocument8 pagesDimension FastScan Pro Atomic Force Microscope Brochure BRUKERsahar vahdatifarNo ratings yet

- Collaborative Robots Brochure - enDocument13 pagesCollaborative Robots Brochure - enNgộ Không TônNo ratings yet

- Simple, Reliable Compliance: Signature Compact S-30Document4 pagesSimple, Reliable Compliance: Signature Compact S-30KARLA CORDOBANo ratings yet

- Precisa Ep225sm DRDocument6 pagesPrecisa Ep225sm DREdwinNo ratings yet

- Faro Laser Scanner Focus 350Document2 pagesFaro Laser Scanner Focus 350malchukNo ratings yet

- VUMAN-E3 BrochureDocument16 pagesVUMAN-E3 Brochurealmir karahodzicNo ratings yet

- Rocklabs-Brochure PulverisersDocument7 pagesRocklabs-Brochure PulverisersSilvio Insulza ChoqueNo ratings yet

- Techsheet Faro Focus S M Laser ScannerDocument2 pagesTechsheet Faro Focus S M Laser ScannerAlexandra GaTorresNo ratings yet

- MAR ONYX Catalogo Industrial Tyres MPT 2020 ENG WebDocument23 pagesMAR ONYX Catalogo Industrial Tyres MPT 2020 ENG WebЕвгенийNo ratings yet

- Roxar 2600 Multiphase Flow MeterDocument30 pagesRoxar 2600 Multiphase Flow MeterOmar Al SousliNo ratings yet

- Agilent Nano Indenter G300: Data SheetDocument4 pagesAgilent Nano Indenter G300: Data Sheetgursharan singhNo ratings yet

- Pressure - Brochure FOXBORODocument8 pagesPressure - Brochure FOXBOROray griffitNo ratings yet

- Speedtec Pulse RangeDocument33 pagesSpeedtec Pulse RangeVăn BáNo ratings yet

- Global Line: Versatile Coordinate Measuring MachinesDocument9 pagesGlobal Line: Versatile Coordinate Measuring MachinesMauricio SilvaNo ratings yet

- Endura AZ30 Features FlyerDocument3 pagesEndura AZ30 Features FlyerCarlos Andrés Vargas OsornoNo ratings yet

- Faro Focus M 70 Tech Sheet - 0Document2 pagesFaro Focus M 70 Tech Sheet - 0Mahmoud GaberNo ratings yet

- TANGO Flyer ENDocument2 pagesTANGO Flyer ENpaula.bugheanuNo ratings yet

- Cxdi-Rf Wireless B1Document3 pagesCxdi-Rf Wireless B1zoir qodirovNo ratings yet

- The World's First Pocket Sized NIR SpectrometerDocument2 pagesThe World's First Pocket Sized NIR SpectrometerJUAN JOSE TUR MOYANo ratings yet

- GSRe BrochureDocument10 pagesGSRe Brochures98460No ratings yet

- Performance + Reliability + Flexibility. It All Adds Up To PowerDocument4 pagesPerformance + Reliability + Flexibility. It All Adds Up To PowerCamel FangNo ratings yet

- Faro Laser Scanner Focus 70Document2 pagesFaro Laser Scanner Focus 70malchukNo ratings yet

- Masterys Gp4: UPS From 10 To 160 kVA / KWDocument14 pagesMasterys Gp4: UPS From 10 To 160 kVA / KWmarwanNo ratings yet

- Route 10Document4 pagesRoute 10Afidhu JumaNo ratings yet

- Faro Laser Scanner Focus 150Document2 pagesFaro Laser Scanner Focus 150malchukNo ratings yet

- An Appetizing New Product: Franeo 800Document2 pagesAn Appetizing New Product: Franeo 800Thi Huyen Trang VuNo ratings yet

- EAL-5000 Datasheet en CS6 V01M05Y2021 Outline-CompressedDocument6 pagesEAL-5000 Datasheet en CS6 V01M05Y2021 Outline-CompressedAnkur BhattNo ratings yet

- HOERBIGER Develops Friction Linings for Any ApplicationDocument5 pagesHOERBIGER Develops Friction Linings for Any ApplicationR KathirasanNo ratings yet

- Aeroflex RTS Capabilities Overview v10 PDFDocument2 pagesAeroflex RTS Capabilities Overview v10 PDFcavemusicNo ratings yet

- I1Pro Spectrophotometer: Feature Comparison of New I1pro 3 Plus Vs I1pro 2Document2 pagesI1Pro Spectrophotometer: Feature Comparison of New I1pro 3 Plus Vs I1pro 2Adrian YapNo ratings yet

- 01 OpticsDocument29 pages01 OpticsAkistNo ratings yet

- Absolute Arm and Accessories: Product CatalogueDocument92 pagesAbsolute Arm and Accessories: Product CatalogueTomás ManzanoNo ratings yet

- Vulcain 90DM4Document4 pagesVulcain 90DM4Paky PakicNo ratings yet

- Dimension HPI Industrial AFM Brochure BRUKERDocument8 pagesDimension HPI Industrial AFM Brochure BRUKERamy liu :3No ratings yet

- IMM BR IR en PDFDocument13 pagesIMM BR IR en PDFEliasNo ratings yet

- UCS Compact O Level BroDocument8 pagesUCS Compact O Level BroKuruvila GeorgeNo ratings yet

- Precision Locators - Optimized Precision For Your UtilityDocument8 pagesPrecision Locators - Optimized Precision For Your Utilityrashid kNo ratings yet

- An Introduction to Ruckus Wireless: Simply Better Wi-Fi Through InnovationDocument26 pagesAn Introduction to Ruckus Wireless: Simply Better Wi-Fi Through InnovationbaluvelpNo ratings yet

- The Truly Portable Metrology-Grade 3D Scanners: SolutionsDocument3 pagesThe Truly Portable Metrology-Grade 3D Scanners: SolutionsKhairul Rizal Zainal BadriNo ratings yet

- Faro Freestyle 3dx - BrochureDocument2 pagesFaro Freestyle 3dx - BrochureFélix Luis Ramos VilaróNo ratings yet

- Sugar NIR Brochure ENDocument9 pagesSugar NIR Brochure ENArif SumonNo ratings yet

- KAESER MOBILAIR General CatalogueDocument7 pagesKAESER MOBILAIR General CatalogueVietnam UMacNo ratings yet

- Industrial Wire Screens CatalogueDocument15 pagesIndustrial Wire Screens Catalogueos ozNo ratings yet

- SS IndentronDocument7 pagesSS IndentronDouglas AguilarNo ratings yet

- DUKANE INFINITY-X1 Datasheet FINALDocument2 pagesDUKANE INFINITY-X1 Datasheet FINALAlexis De la fontaineNo ratings yet

- Absolute Arm: Usability - Versatility - Productivity - by DesignDocument32 pagesAbsolute Arm: Usability - Versatility - Productivity - by DesignFernando Moreira da silvaNo ratings yet

- LDocument8 pagesLVyktor GonzalezNo ratings yet

- Foundry Master ProDocument6 pagesFoundry Master ProIdham SsiNo ratings yet

- Spectrolab m12 enDocument8 pagesSpectrolab m12 enBHAART PANCHAL100% (1)

- GyroData - Surveyor X 4 09 v7Document2 pagesGyroData - Surveyor X 4 09 v7Zakhar__6769No ratings yet

- Manual Book IonScan 600Document2 pagesManual Book IonScan 600Yayasan Swara Kukilo25% (4)

- SERVOPRO MultiExact 4100 1Document9 pagesSERVOPRO MultiExact 4100 1JHON JAIRO RAMOS FLOREZNo ratings yet

- D70-D700M - Brochure - ENGDocument6 pagesD70-D700M - Brochure - ENGNguyen binhNo ratings yet

- FibeerSX 5000 LaserMarker Catalog - CompressedDocument9 pagesFibeerSX 5000 LaserMarker Catalog - CompressedIlea VladNo ratings yet

- Sites Can SeriesDocument6 pagesSites Can SeriesNam DoNo ratings yet

- DR 600 (English - Brochure)Document16 pagesDR 600 (English - Brochure)1994mjncNo ratings yet

- Hexagon MI Arm Absolute Arm Brochure A4 enDocument36 pagesHexagon MI Arm Absolute Arm Brochure A4 enLong PhamNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

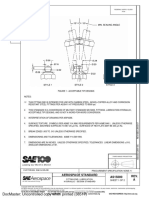

- SAE ARP 908C Torque Hose TubeDocument3 pagesSAE ARP 908C Torque Hose TubeAndr EkmeNo ratings yet

- SAE ARP 908C Torque Hose TubeDocument3 pagesSAE ARP 908C Torque Hose TubeAndr EkmeNo ratings yet

- Sae As 5202a 2005-05-25Document3 pagesSae As 5202a 2005-05-25Andr EkmeNo ratings yet

- Nas 6704Document7 pagesNas 6704Konelek AeroNo ratings yet

- SAE As 1290A Hydro SymbolsDocument63 pagesSAE As 1290A Hydro SymbolsAndr EkmeNo ratings yet

- Sae As 8879D 2004-08-09Document25 pagesSae As 8879D 2004-08-09Andr EkmeNo ratings yet

- NSA 8203 FluorosiliconeDocument9 pagesNSA 8203 FluorosiliconeAndr EkmeNo ratings yet

- DIN9003-3 Bending Radii AlluminiumDocument4 pagesDIN9003-3 Bending Radii AlluminiumAndr EkmeNo ratings yet

- SAE As 8660 Silicone CompoundDocument18 pagesSAE As 8660 Silicone CompoundAndr EkmeNo ratings yet

- NSA 5059 Self Locking NutDocument5 pagesNSA 5059 Self Locking NutAndr EkmeNo ratings yet

- Sae As 33649a 2005-08Document4 pagesSae As 33649a 2005-08Andr EkmeNo ratings yet

- SAE AS 15000A Grease Nipple TipsDocument2 pagesSAE AS 15000A Grease Nipple TipsAndr EkmeNo ratings yet

- MS17334PDocument2 pagesMS17334PAndr EkmeNo ratings yet

- DIN9118 Rivet HolesDocument3 pagesDIN9118 Rivet HolesAndr EkmeNo ratings yet

- NSA 5060 NutDocument5 pagesNSA 5060 NutAndr EkmeNo ratings yet

- NSA 5355 Tab WasherDocument2 pagesNSA 5355 Tab WasherAndr EkmeNo ratings yet

- Nsa 8054 1996-02 yDocument18 pagesNsa 8054 1996-02 yAndr EkmeNo ratings yet

- MS28105DDocument2 pagesMS28105DAndr EkmeNo ratings yet

- Ms17334p Notice 1Document1 pageMs17334p Notice 1Andr EkmeNo ratings yet

- MS28105D Notice-1Document1 pageMS28105D Notice-1Andr EkmeNo ratings yet

- MS25187B Notice-2Document1 pageMS25187B Notice-2Andr EkmeNo ratings yet

- Aurum Investment CapitalDocument3 pagesAurum Investment CapitalAndr EkmeNo ratings yet

- MS17334P Notice-2Document1 pageMS17334P Notice-2Andr EkmeNo ratings yet

- MS16995HDocument9 pagesMS16995HAndr EkmeNo ratings yet

- Om 810600mu R1Document2 pagesOm 810600mu R1Andr EkmeNo ratings yet

- MS28105CDocument3 pagesMS28105CAndr EkmeNo ratings yet

- MS16995GDocument6 pagesMS16995GAndr EkmeNo ratings yet

- Powermax105 SYNC EMF DatasheetDocument2 pagesPowermax105 SYNC EMF DatasheetAndr EkmeNo ratings yet

- Fuel Management - ECA Briefing, 2022 FinalDocument9 pagesFuel Management - ECA Briefing, 2022 FinalAndr EkmeNo ratings yet

- Dls-Dali Lighting Controls SystemDocument2 pagesDls-Dali Lighting Controls SystemAnonymous XYAPaxjbYNo ratings yet

- Accurax linear motor axis with high efficiency iron-core linear motorsDocument14 pagesAccurax linear motor axis with high efficiency iron-core linear motorsdiarjohn9979No ratings yet

- Cheap 12V To 220V InverterDocument3 pagesCheap 12V To 220V InverterAnaar KaliNo ratings yet

- Output Module 22 120 Safety-Related OutputDocument4 pagesOutput Module 22 120 Safety-Related OutputGilberto Alejandro Tun BritoNo ratings yet

- Dell Power Edge R510 ManualDocument17 pagesDell Power Edge R510 ManualstereokidNo ratings yet

- AirControl 1 Maintenance and Operating ManualDocument16 pagesAirControl 1 Maintenance and Operating ManualJunaid AhmedNo ratings yet

- PS500X/PS501X/PS600X/PS501W/ PS600W DLP Projector: User GuideDocument90 pagesPS500X/PS501X/PS600X/PS501W/ PS600W DLP Projector: User GuideVictor P HuamanNo ratings yet

- Wineland Ion TrapDocument30 pagesWineland Ion TrapKhoranaNo ratings yet

- Tape EQDocument4 pagesTape EQdomlashNo ratings yet

- Pioneer DEH-P510UB 5100UB 5150UB 5190UBDocument79 pagesPioneer DEH-P510UB 5100UB 5150UB 5190UBastrid28hNo ratings yet

- Combinada Convencional 8000 Serie 8040 Equipamento Electrico para Ford, Alfa Romeo, Fiat y Mercedes BenzDocument5 pagesCombinada Convencional 8000 Serie 8040 Equipamento Electrico para Ford, Alfa Romeo, Fiat y Mercedes BenzRamón ManglesNo ratings yet

- AllahgholiPour Zahra PDFDocument160 pagesAllahgholiPour Zahra PDFAnand ReddyNo ratings yet

- Efficient Multi Controller for Hitachi CompressorsDocument6 pagesEfficient Multi Controller for Hitachi CompressorsDikaAnindyajatiNo ratings yet

- RDK 131Document24 pagesRDK 131Zoran NesicNo ratings yet

- Panel Dual Polarized Antenna: Technical Data Sheet APX906515L-CT0Document4 pagesPanel Dual Polarized Antenna: Technical Data Sheet APX906515L-CT0sukanganulhoNo ratings yet

- 5583Document27 pages5583Sanurus IndecoraNo ratings yet

- Group 3 Electrical Circuit OperationDocument14 pagesGroup 3 Electrical Circuit OperationTrần Quang ThuậnNo ratings yet

- Chapter-2 Circuit BreakersDocument25 pagesChapter-2 Circuit Breakersyeheyis abebeNo ratings yet

- Circuit Breaker Siemns 110kVDocument116 pagesCircuit Breaker Siemns 110kVzeljkoradaNo ratings yet

- Lecture04 Dynamic CharacteristicsDocument27 pagesLecture04 Dynamic CharacteristicsAhmad Sulaiman Ahmad TajuddinNo ratings yet

- User Manual: HGM6100U Series Automatic Control ControllersDocument39 pagesUser Manual: HGM6100U Series Automatic Control ControllersMohamed R KhamissNo ratings yet

- Turck Foundation Fieldbus JunctionsDocument33 pagesTurck Foundation Fieldbus JunctionsJose NavarreteNo ratings yet

- Pressure-Controlled Pumps CascadeDocument2 pagesPressure-Controlled Pumps Cascadecc_bauNo ratings yet

- Xxgpu65-16 16-TV VDocument1 pageXxgpu65-16 16-TV VИмяNo ratings yet

- Technical Specifications Lifting and TransportDocument1 pageTechnical Specifications Lifting and TransportObet Ralo NautikaNo ratings yet

- Computer SCience Xi Mini MockDocument2 pagesComputer SCience Xi Mini MockMuhammad Usman MunirNo ratings yet

- Electrical Wiring Diagram Books PDFDocument109 pagesElectrical Wiring Diagram Books PDFHillaryNo ratings yet

- VM SssssssDocument18 pagesVM Ssssssskalin3169899No ratings yet

- H-Series Power Module Service Manual UPS 09162004Document35 pagesH-Series Power Module Service Manual UPS 09162004UlisesGómez100% (1)

- Technical Requirements for Power TransformersDocument24 pagesTechnical Requirements for Power Transformersni60No ratings yet