Professional Documents

Culture Documents

Powermax105 SYNC EMF Datasheet

Uploaded by

Andr EkmeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Powermax105 SYNC EMF Datasheet

Uploaded by

Andr EkmeCopyright:

Available Formats

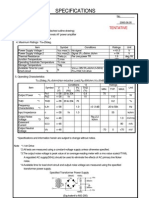

MODEL – Plasma Cutting System

Electromagnetic Field (EMF) Measurements ES3791

Introduction

Electric and magnetic fields are often referred to as “electromagnetic fields,” or EMF. The EMF generated by

Hypertherm plasma arc cutting equipment is not significant when operated and installed according to Hypertherm’s

instructions to minimize EMF.

How Do I Minimize EMF Exposure?

Failure to follow these instructions will increase EMF:

• Cut with the lowest current setting necessary for the application and quality of the cut.

• Never coil a torch cable or work lead around your body.

• Do not place your body between the torch cable and work lead.

• Route cables together on the same side of your body.

• Route the torch cable and work lead close together. If possible, secure them together with tape or cable ties.

• Connect the work cable to the workpiece as close to the cutting zone as practical.

• Keep the cutting power source and cables as far away from you as practical.

European EMF Directive (2013/35/EU amending 2008/46/EC & 2004/40/EC )

The European Commission published Directive 2013/35/EU on the minimum health and safety requirements regarding

the exposure of workers to the risks arising from physical agents such as electromagnetic fields (EMF). The new feature

of the EMF Directive effective July 2016 is the requirement that employers must assess the risk separately for each

workplace. Risk assessment of electromagnetic fields in the workplace (including measurements or calculations, if

necessary) should be carried out. Where applicable, special attention shall be paid to workers at particular risks

(pregnant, living with implanted medical devices. The employer shall consider updating the risk assessment and the

prevention measures if workers report transient symptoms in relation to their sensory/neural system. Health

surveillance shall be carried out by the employer and the findings preserved.

Hypertherm EMF measurements

Measurements were taken per EN50444 figure A.1 and IEC 62822-2 figures 7, 11, and 15 as shown below.

MODEL – Plasma Cutting System

Electromagnetic Field (EMF) Measurements ES3791

IEC 62822-2 IEC 62822-2 EN50444 Date

Power Measurement

Ambient

Source Meter used Range Hand/Thigh Head/Trunk 20 cm Taken

(µT)

Model

3 cm (µT) 10 cm (µT) (µT)

1Hz – 18-Mar-21

Narda ELT-400 400KHz 6.645 79.62 45.24 12.36

Powermax

30Hz - 18-Mar-21

105 SYNC

Narda ELT-400 400KHz 1.466 49.85 23.99 8.8

Omega HHG-23 DC 0 1210 470 100 18-Mar-21

Notes:

1. The above data was measured for reference only in Hypertherm’s R&D lab environment over multiple

days with other equipment running in the lab.

2. The positioning of the measurement equipment used results in variation of measurements.

3. The AC component was measured with the Narda ELT-400 and the DC component was measured with

the Omega HHG-23.

4. Non-thermal effects due to electric fields per IEC 62822-1:2016 4.3 complies because the welding

equipment is designed in accordance with IEC 60974-1.

5. There are no contact currents per IEC 62822-1:2016 4.4

6. Non-thermal effects of output current ripple per IEC 62822-1:2016 4.5 is exempt because the ripple

current for the above products is less the 100A peak to peak.

7. Thermal effects per IEC 62822-1:2016 4.6 are exempt because the ripple current for the above

products is less then 300A peak to peak.

Revision Date Section History Change

1 4-November-2016 - Initial Release

You might also like

- HF B8H Prod Edited - V2Document42 pagesHF B8H Prod Edited - V2Carlos CrisostomoNo ratings yet

- Esm 100Document4 pagesEsm 100Pedro Bernardo PortoNo ratings yet

- Narda Emr Series - ManualDocument139 pagesNarda Emr Series - Manualrab tagNo ratings yet

- Emf 839 ManualDocument28 pagesEmf 839 ManualCarlos CrisostomoNo ratings yet

- EMF-819 Electromagnetic PollutionDocument2 pagesEMF-819 Electromagnetic PollutionLenin SucaNo ratings yet

- EMR Series ManualDocument140 pagesEMR Series ManualPau Dguez.No ratings yet

- SMD ManualDocument8 pagesSMD ManualJose K ManadanNo ratings yet

- Motan 960Document11 pagesMotan 960DgfdghfghFfdhgfhjgNo ratings yet

- MPP Manual - EngDocument23 pagesMPP Manual - EngLý Chính ĐạoNo ratings yet

- Everlight Electronics Co., LTD.: Infrared Remote-Control Receiver ModuleDocument8 pagesEverlight Electronics Co., LTD.: Infrared Remote-Control Receiver ModuleW Percy Huallpa CalizayaNo ratings yet

- ELT400 DataSheetDocument6 pagesELT400 DataSheetscdenizNo ratings yet

- 4422703Document43 pages4422703Zvonko ŠuljakNo ratings yet

- 5042 AppDocument18 pages5042 AppAgustio Sahela BukhariNo ratings yet

- Esm 100 - 07 2005Document4 pagesEsm 100 - 07 2005mahir_dzaficNo ratings yet

- 7.1. Environmental ConditionsDocument20 pages7.1. Environmental Conditionschakrapani vagish chandra pandeyNo ratings yet

- Kew Snap: Instruction ManualDocument24 pagesKew Snap: Instruction ManualClaudio CostaNo ratings yet

- Motorola An 780ADocument6 pagesMotorola An 780ArobinsonsNo ratings yet

- Hornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetDocument2 pagesHornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetInstruTech, Inc.No ratings yet

- 1 Performance DataDocument9 pages1 Performance DataYusep KurniaNo ratings yet

- 9878Document5 pages9878hugoivNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- STM32Document24 pagesSTM32Aditya SrivatsavNo ratings yet

- InnoCare T Service ManualDocument19 pagesInnoCare T Service ManualTony NavaNo ratings yet

- Rapid-Moc Mooring Array Instrumentation: Instrument Types and Specifications TelemetryDocument19 pagesRapid-Moc Mooring Array Instrumentation: Instrument Types and Specifications TelemetryRudra Kumar MishraNo ratings yet

- LAB MANNUA1.Docx Mech s3Document29 pagesLAB MANNUA1.Docx Mech s3SyamjithNo ratings yet

- EHP 200A 11-10-NardaDocument7 pagesEHP 200A 11-10-NardaDrughinsNo ratings yet

- ACCELEROMETERDocument9 pagesACCELEROMETERDHAMO DHARANNo ratings yet

- CM-350C User's ManualDocument31 pagesCM-350C User's Manualeurl.ivmmed.distribNo ratings yet

- Intercomp TL Series Instruction ManualDocument13 pagesIntercomp TL Series Instruction ManualJonny LopezNo ratings yet

- Primus DescriptionDocument92 pagesPrimus Descriptionwizardgrt1No ratings yet

- Elmag 200m Instruction ManualDocument22 pagesElmag 200m Instruction ManualAnand BagadeNo ratings yet

- St6911 Ipt™ Acceleration Vibration Transducer St6917 Ipt™ Velocity Vibration TransducerDocument8 pagesSt6911 Ipt™ Acceleration Vibration Transducer St6917 Ipt™ Velocity Vibration TransducerProcurement PardisanNo ratings yet

- Alsa Excell 400 - User Manual PDFDocument30 pagesAlsa Excell 400 - User Manual PDFSamoel De MeloNo ratings yet

- ESP Operation ManualDocument29 pagesESP Operation ManualNhật TuấnNo ratings yet

- ESP Operation ManualDocument29 pagesESP Operation ManualPrajapati ChandrakantNo ratings yet

- Meter ENGDocument4 pagesMeter ENGDocu CenterNo ratings yet

- UHF Low-Noise Amp, Wide-Band Amp Applications: FeaturesDocument4 pagesUHF Low-Noise Amp, Wide-Band Amp Applications: Featuresmark777markNo ratings yet

- GP2Y0D340K: Distance Measuring Sensor Unit Digital Output (400 MM) TypeDocument9 pagesGP2Y0D340K: Distance Measuring Sensor Unit Digital Output (400 MM) TypeAndac KizilirmakNo ratings yet

- Technical Spec For P-29-2012-13-DLMS & NON-DLMS 11KV BULK & LT BULK DLMS dt.18.02.2013Document59 pagesTechnical Spec For P-29-2012-13-DLMS & NON-DLMS 11KV BULK & LT BULK DLMS dt.18.02.2013Pawan Kumar RaiNo ratings yet

- Kentamed 1e - User Manual - Eng PDFDocument10 pagesKentamed 1e - User Manual - Eng PDFdian33% (3)

- Partial Discharge Basics of MonitoringDocument18 pagesPartial Discharge Basics of Monitoringreza515heiNo ratings yet

- TGS5042 Product Infomation Rev01Document2 pagesTGS5042 Product Infomation Rev01Sahil ChadhaNo ratings yet

- Test Report On SarDocument61 pagesTest Report On SarSorin BotîrlăNo ratings yet

- II. 8 .2 Alat Laboratorium 2Document290 pagesII. 8 .2 Alat Laboratorium 2085270710307No ratings yet

- AS064-ILST-NDHHDD Version 2 - NTC DAS Hub Hardware Design Document - SignedDocument17 pagesAS064-ILST-NDHHDD Version 2 - NTC DAS Hub Hardware Design Document - SignedrasyidinabNo ratings yet

- Invitation of Fresh Budgetary Quotes Aug 10 Final DocumentDocument6 pagesInvitation of Fresh Budgetary Quotes Aug 10 Final DocumentDeepak Kumar SinghNo ratings yet

- Thyristor Power Controller: B DI1002 V1.0 Manual/Operating InstructionsDocument12 pagesThyristor Power Controller: B DI1002 V1.0 Manual/Operating InstructionsZaini DalimusNo ratings yet

- For Low Noise Audio Amplifier Applications and Recommended For The First Stages of MC Head AmplifiersDocument4 pagesFor Low Noise Audio Amplifier Applications and Recommended For The First Stages of MC Head Amplifierslu1agpNo ratings yet

- STK442 110Document4 pagesSTK442 110Ivan AsimovNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Power Electronics Applied to Industrial Systems and Transports, Volume 4: Electromagnetic CompatibilityFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 4: Electromagnetic CompatibilityNo ratings yet

- Hall-Effect Sensors: Theory and ApplicationFrom EverandHall-Effect Sensors: Theory and ApplicationRating: 5 out of 5 stars5/5 (1)

- FARO Quantum M Tech SheetDocument2 pagesFARO Quantum M Tech SheetAndr EkmeNo ratings yet

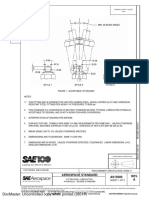

- SAE As 1290A Hydro SymbolsDocument63 pagesSAE As 1290A Hydro SymbolsAndr EkmeNo ratings yet

- Sae As 5202a 2005-05-25Document3 pagesSae As 5202a 2005-05-25Andr EkmeNo ratings yet

- SAE As 8660 Silicone CompoundDocument18 pagesSAE As 8660 Silicone CompoundAndr EkmeNo ratings yet

- DIN9118 Rivet HolesDocument3 pagesDIN9118 Rivet HolesAndr EkmeNo ratings yet

- DIN9003-3 Bending Radii AlluminiumDocument4 pagesDIN9003-3 Bending Radii AlluminiumAndr EkmeNo ratings yet

- Sae As 33649a 2005-08Document4 pagesSae As 33649a 2005-08Andr EkmeNo ratings yet

- SAE AS 15000A Grease Nipple TipsDocument2 pagesSAE AS 15000A Grease Nipple TipsAndr EkmeNo ratings yet

- MS28105DDocument2 pagesMS28105DAndr EkmeNo ratings yet

- NSA 8203 FluorosiliconeDocument9 pagesNSA 8203 FluorosiliconeAndr EkmeNo ratings yet

- MS17334PDocument2 pagesMS17334PAndr EkmeNo ratings yet

- Fuel Management - ECA Briefing, 2022 FinalDocument9 pagesFuel Management - ECA Briefing, 2022 FinalAndr EkmeNo ratings yet

- MS16995HDocument9 pagesMS16995HAndr EkmeNo ratings yet

- Free Online Auto Repair Manualhbydr PDFDocument1 pageFree Online Auto Repair Manualhbydr PDFcoachtable3No ratings yet

- Mechanical Behaviour of Materials Questions PART 1Document3 pagesMechanical Behaviour of Materials Questions PART 1Sachi Dhanandam100% (2)

- NIPM - TA For Self & OthersDocument9 pagesNIPM - TA For Self & OthersNabi RasoolNo ratings yet

- Applied Partial Differential Equations - J. David Logan-1998Document2 pagesApplied Partial Differential Equations - J. David Logan-1998Jeremy Mac LeanNo ratings yet

- List of Documents ISO 45001 Documentation Toolkit enDocument2 pagesList of Documents ISO 45001 Documentation Toolkit enCiciaSalatin100% (1)

- 3º Congresso Brasileiro de Túneis e Estruturas Subterrâneas Seminário Internacional "South American Tunnelling - SAT 2012"Document7 pages3º Congresso Brasileiro de Túneis e Estruturas Subterrâneas Seminário Internacional "South American Tunnelling - SAT 2012"MapeixNo ratings yet

- Performance Task 2 Practical ResearchDocument5 pagesPerformance Task 2 Practical Researchmaeca mae gloriosoNo ratings yet

- Iap Feb IssueDocument86 pagesIap Feb IssueDhanya PillaiNo ratings yet

- Family Safety HandbookDocument12 pagesFamily Safety HandbookAdib_dokterNo ratings yet

- Subsurface Investigation For Foundations - Code of Practice: Indian StandardDocument52 pagesSubsurface Investigation For Foundations - Code of Practice: Indian StandardBodhraj singh solanki50% (2)

- Ohio Tools For Watershed Stewardship in The Chippewa Creek WatershedDocument30 pagesOhio Tools For Watershed Stewardship in The Chippewa Creek WatershedFree Rain Garden ManualsNo ratings yet

- D375A-6 Cooling SystemDocument26 pagesD375A-6 Cooling Systemalcowo100% (3)

- Bible - To Love, Honor and Vacuum PDFDocument9 pagesBible - To Love, Honor and Vacuum PDFDiana ArunNo ratings yet

- Series QCT and QCB Cylinders With Integrated Guide: Double-Acting, Magnetic Piston, Guided Ø 20, 25, 32, 40, 50, 63 MMDocument5 pagesSeries QCT and QCB Cylinders With Integrated Guide: Double-Acting, Magnetic Piston, Guided Ø 20, 25, 32, 40, 50, 63 MMVanesaNo ratings yet

- Rosoka General 2015Document20 pagesRosoka General 2015swTechieNo ratings yet

- CMT Electronic Heated ViscometerDocument1 pageCMT Electronic Heated ViscometerIBRAHIM ALMANLANo ratings yet

- Solutions: Homework 2 Biomedical Signal, Systems and Control (BME 580.222)Document5 pagesSolutions: Homework 2 Biomedical Signal, Systems and Control (BME 580.222)JoJa JoJaNo ratings yet

- International Classi Fication of Retinopathy of Prematurity, Third EditionDocument18 pagesInternational Classi Fication of Retinopathy of Prematurity, Third EditionRameshNo ratings yet

- Technology Can Provide Much-Needed SupportDocument3 pagesTechnology Can Provide Much-Needed SupportPaz MoscosoNo ratings yet

- Practical Advice For Pure Land Practitioners - HuijingDocument16 pagesPractical Advice For Pure Land Practitioners - HuijingHerbert Edgar WyndhamNo ratings yet

- Maternal Child Nursing Care Canada 2nd Perry Test BankDocument8 pagesMaternal Child Nursing Care Canada 2nd Perry Test Banksonyaaaq0% (1)

- Leadership and FollowershipDocument10 pagesLeadership and FollowershipLawrence ConananNo ratings yet

- Technovate Refrigeración y Aire AcondicionadoDocument34 pagesTechnovate Refrigeración y Aire Acondicionadojpg60No ratings yet

- IBIG 04 04 Equity Value Enterprise Value Metrics MultiplesDocument95 pagesIBIG 04 04 Equity Value Enterprise Value Metrics MultiplesGabriel La MottaNo ratings yet

- Technical Requirements For Medical DevicesDocument11 pagesTechnical Requirements For Medical DeviceshelloNo ratings yet

- BC AppNote 005Document6 pagesBC AppNote 005David CheNo ratings yet

- SS ZG653 (RL1.2) : Software Architecture: BITS PilaniDocument12 pagesSS ZG653 (RL1.2) : Software Architecture: BITS PilaniAditya AggarwalNo ratings yet

- Manualesj. Ge319 Ee3-1Document1 pageManualesj. Ge319 Ee3-1gabriel gabuyaNo ratings yet

- Fernandez - Aalbers - Financialization and Housing - 2016Document18 pagesFernandez - Aalbers - Financialization and Housing - 2016AndreaNo ratings yet

- Akram M Zepeda S J 2015-2 PDFDocument17 pagesAkram M Zepeda S J 2015-2 PDFsheyla_liwanagNo ratings yet