Professional Documents

Culture Documents

BS-EN-ISO-2560-SMAW Consumable

Uploaded by

airul6Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS-EN-ISO-2560-SMAW Consumable

Uploaded by

airul6Copyright:

Available Formats

EN ISO 2560 – B

EXAMPLE:

ISO 2560 – B – E55 18-N2 A U H5

the number of this International Standard, classification by tensile

ISO 2560-B:

strength and 27 J impact energy

E: covered electrode/man

electrode/manual

ual metal arc welding (see 4.1)

55: tensile strength (see Table 1B)

basic iron powder coating suitable for a.c. and d.c. (+), in all positions

18:

except vertical down (see Table 4B)

-N2: 1% Ni as the principale alloying element (see Table 3B)

A: as welded

supplemental impact requirement

requirement of 47 J at the basic 27 J impact test

U:

temperature

H5: hydrogen content (see table 7)

Table 1B

Minimum tensile strength

Symbol 2

N/mm

43 430

49 490

55 550

57 570

Table 7 Hydrogen content

Symbol max.

ml/100g of deposited weld metal

H5 5

H10 10

H15 15

EN ISO 2560 – B

Table 3B Table 4B

Chemical composition

Alloy Principal alloy Nominal Type of Welding Type of

Symbol a

symbol element(s) level covering positions current

mas. %

No

b

symbol, -1 Mn 1 03 rutile basic all AC and DC(±)

ali –P1

-1M3 Mo 0,5 10 cellulosic all DC(+)

Mn 1,5

-3M2 11 cellulosic all AC and DC(+)

Mo 0,4

Mn 1,5 b

-3M3 12 rutile all AC and DC(-)

Mo 0,5

b

-N1 Ni 0,5 13 rutile all AC and DC(±)

rutile + iron b

-N2 Ni 1 14 all AC and DC(±)

powder

b

-N3 Ni 1,5 15 basic all DC (+)

Mn 1,5 b

-3N3 16 basic all AC and DC(+)

Ni 1,5

basic + iron b

-N5 Ni 2,5 18 all AC and DC(+)

powder

b

-N7 Ni 3,5 19 Ilmenit all AC and DC(±)

-N13 Ni 6,5 20 iron oxide PA, PB AC and DC(-)

Ni 1 rutile + iron

-N2M3 24 PA, PB AC and DC(±)

Mo 0,5 powder

Ni 0,5 iron oxide +

-NC 27 PA, PB AC and DC(-)

Cu 0,4 iron powder

Cr 0,5 basic + iron

-CC 28 PA,PB,PC AC and DC(+)

Cu 0,4 powder

Ni 0,2

Manufacturer’s

-NCC Cr 0,6 40 not specified

recommendations

Cu 0,5

Ni 0,6

-NCC1 Cr 0,6 48 basic all AC and DC(+)

Cu 0,5

Ni 0,3

NOTE A description of the characteristic of each

each of the types of

-NCC2 Cr 0,2 covering is given in annex C

Cu 0,5

a

-G Any other agreed composition Positions are defined in ISO 6947. PA = flat,flat, PB =horizontal

vertical fillet, PC = horizontal, PG = vertical down

b

All positions may or may not include vertical downdown welding.

This shall be specified ini n the manufacturer’s trade literature.

You might also like

- AISC Formulas 2010 PDFDocument13 pagesAISC Formulas 2010 PDFsrikanth.iitkgp100% (1)

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- API Index ListDocument18 pagesAPI Index ListRaja Ahsan AzanNo ratings yet

- Wet VentingDocument36 pagesWet VentingMac Shaik100% (2)

- Corrosion (All)Document59 pagesCorrosion (All)trongstaNo ratings yet

- Welding Electrode Classifications Wallchart PDFDocument1 pageWelding Electrode Classifications Wallchart PDFask101No ratings yet

- Site Engineers Manual PDFDocument3 pagesSite Engineers Manual PDFFahadNo ratings yet

- 3 - SELECTION OF WELDING ELECTRODES - StudentDocument15 pages3 - SELECTION OF WELDING ELECTRODES - Studentrazlan ghazaliNo ratings yet

- EN Iso 2560 - BDocument2 pagesEN Iso 2560 - Bimupathan100% (1)

- Norms Overview.: Pipeline ConstructionDocument3 pagesNorms Overview.: Pipeline ConstructionRjeb mohamedNo ratings yet

- Window Shutters by Shutter SmartDocument18 pagesWindow Shutters by Shutter SmartViken OhenasianNo ratings yet

- BS Iso 21940-1-2019Document40 pagesBS Iso 21940-1-2019airul6100% (2)

- Lubrication Systems - Application & Installation Guide - Lebw4957Document50 pagesLubrication Systems - Application & Installation Guide - Lebw4957aledolz100% (2)

- Saes J 902Document32 pagesSaes J 902Mudabbir HussainNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Technical Manual Schoeck Isokorb (5185) 2016-02-10Document158 pagesTechnical Manual Schoeck Isokorb (5185) 2016-02-10ing urbanNo ratings yet

- SMAW InstructionDocument20 pagesSMAW InstructionSun Sun100% (1)

- Colour Codes For PipingDocument24 pagesColour Codes For PipingYusufNo ratings yet

- Pipe Sizing Formula & Velocity ReferenceDocument3 pagesPipe Sizing Formula & Velocity ReferenceJayakrishnan RadhakrishnanNo ratings yet

- MSDS Pickling Nikko Steel StaincleanDocument5 pagesMSDS Pickling Nikko Steel Staincleanairul691% (11)

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10207farshid KarpasandNo ratings yet

- BÖHLER Ti 52 NG T-FD (Diamondspark 31 NG) : Flux Cored Wire, Seamless, Self-Shielded, UnalloyedDocument1 pageBÖHLER Ti 52 NG T-FD (Diamondspark 31 NG) : Flux Cored Wire, Seamless, Self-Shielded, UnalloyedbrayanNo ratings yet

- HK Si4501bdy 4101260Document15 pagesHK Si4501bdy 4101260Sahid Cota CamachoNo ratings yet

- Datasheet For Steel Grades Specialsteel X6Crnimob17-12-2Document3 pagesDatasheet For Steel Grades Specialsteel X6Crnimob17-12-2axis inspection solutionsNo ratings yet

- Extruded Outlet HeaderDocument2 pagesExtruded Outlet Headermario salazarNo ratings yet

- Indura Em12k-H400Document2 pagesIndura Em12k-H400Rodrigo CarizNo ratings yet

- FICHA Técnica Weld 71T-1 PDFDocument2 pagesFICHA Técnica Weld 71T-1 PDFCarlos Padilla67% (3)

- E-EMM 3122-9-Corrosion and Protection (N)Document13 pagesE-EMM 3122-9-Corrosion and Protection (N)KHAIRUL NASHRAN BIN ANUAR / UPMNo ratings yet

- Section 16 Welding ConsumablesDocument15 pagesSection 16 Welding ConsumablesTahar DabbarNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- TL431, A, B Series, NCV431A Programmable Precision ReferencesDocument19 pagesTL431, A, B Series, NCV431A Programmable Precision ReferencesMarcos E. CuevasNo ratings yet

- OK Tigrod 12.60: Tig Rods (Gtaw) Mild Steel RodsDocument1 pageOK Tigrod 12.60: Tig Rods (Gtaw) Mild Steel RodssankuNo ratings yet

- OK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsDocument1 pageOK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsHusam AhmedNo ratings yet

- Bavaria en BA-TIG 347siDocument1 pageBavaria en BA-TIG 347sicocoNo ratings yet

- Steel Reinforcement For Concrete - BS 8666:2005: Shape CodeDocument8 pagesSteel Reinforcement For Concrete - BS 8666:2005: Shape CodeDeependraNo ratings yet

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- @bohring Bot09 Assignment # EMI & AC Eng@HeyitsyashXDDocument71 pages@bohring Bot09 Assignment # EMI & AC Eng@HeyitsyashXDi.anupamalokNo ratings yet

- Able 1-Chemical Composition of Material Used, WT%: Elements Base Materials Inconel C-22 Undiluted Filler MaterialsDocument5 pagesAble 1-Chemical Composition of Material Used, WT%: Elements Base Materials Inconel C-22 Undiluted Filler MaterialsSayiram GNo ratings yet

- Kiswel K-309LTDocument1 pageKiswel K-309LTOmer IkhlasNo ratings yet

- Datasheet For Steel Grades Specialsteel 0Cr18Ni9Document3 pagesDatasheet For Steel Grades Specialsteel 0Cr18Ni9Umar AslamNo ratings yet

- Bohler Inconel 625 UTP A 6222 Mo-3Document1 pageBohler Inconel 625 UTP A 6222 Mo-3JORAMNo ratings yet

- en - GB FactSheet - Main 01Document1 pageen - GB FactSheet - Main 01ronaldb322No ratings yet

- European Steel and Alloy Grades: About Us EN 10120Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10120farshid KarpasandNo ratings yet

- European Steel and Alloy Grades: 11mnni5-3 (1.6212)Document2 pagesEuropean Steel and Alloy Grades: 11mnni5-3 (1.6212)farshid KarpasandNo ratings yet

- HTPC Project 2Document26 pagesHTPC Project 2JephinSJohnNo ratings yet

- European Steel and Alloy Grades: About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10207farshid KarpasandNo ratings yet

- Format Guideline For Progress ReportDocument4 pagesFormat Guideline For Progress ReportMohammad_Ismai_3096No ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- European Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)Document2 pagesEuropean Steel and Alloy Grades: Nicr22Fe18Mo (Dubl) (2.4665)farshid KarpasandNo ratings yet

- MMBD4148 DatasheetDocument3 pagesMMBD4148 DatasheetJose WadeNo ratings yet

- OK Tigrod NiCu-7Document1 pageOK Tigrod NiCu-7Ali VarmazyarNo ratings yet

- Bas 70Document1 pageBas 70Ricardo UrioNo ratings yet

- DIODO SCHOTTKY - Bat54 - Series - Wte PDFDocument5 pagesDIODO SCHOTTKY - Bat54 - Series - Wte PDFAntonio C MangifestaNo ratings yet

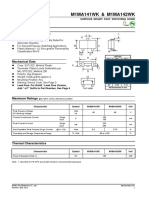

- M T M1ma141wkDocument4 pagesM T M1ma141wkRenick SchumacherNo ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- ch18 MSW15 Corrosion PDFDocument41 pagesch18 MSW15 Corrosion PDFMiralda SyakirahNo ratings yet

- Steel P235TR2Document2 pagesSteel P235TR2Moulham ShahinNo ratings yet

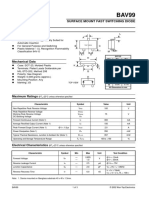

- Features: Surface Mount Fast Switching DiodeDocument4 pagesFeatures: Surface Mount Fast Switching DiodeDe faNo ratings yet

- 14CrMoV6 9 DatasheetDocument3 pages14CrMoV6 9 DatasheetDhurusha GovenderNo ratings yet

- AISI Inco 713 Nickel Alloys - Chemical Composition & Other Alloy PropertiesDocument4 pagesAISI Inco 713 Nickel Alloys - Chemical Composition & Other Alloy PropertiesNovindra Ades WNo ratings yet

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroNo ratings yet

- FSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFDocument2 pagesFSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFJ. BangjakNo ratings yet

- Si4501BDY: Vishay SiliconixDocument14 pagesSi4501BDY: Vishay SiliconixAndré RegisNo ratings yet

- Application of Electrolytic Cells Lesson 11Document24 pagesApplication of Electrolytic Cells Lesson 11Rosmaini MohamadNo ratings yet

- Exp - 1 - PN JUNCTION ZENER DiodeDocument13 pagesExp - 1 - PN JUNCTION ZENER DiodekishorebabNo ratings yet

- Fluxofil 51Document1 pageFluxofil 51ThermalsprayNo ratings yet

- Electricity WorkbookDocument5 pagesElectricity WorkbookLeevan BarrattNo ratings yet

- En 760Document1 pageEn 760chitje100% (2)

- SS41Document3 pagesSS41Danifarrel NurhafizNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- Lect 2Document47 pagesLect 2Azeem AshrafNo ratings yet

- Electrical and Electronic Principles 3 Checkbook: The Checkbook SeriesFrom EverandElectrical and Electronic Principles 3 Checkbook: The Checkbook SeriesNo ratings yet

- En 302194Document15 pagesEn 302194airul6No ratings yet

- En 303276Document31 pagesEn 303276airul6No ratings yet

- En 303098-2Document16 pagesEn 303098-2airul6No ratings yet

- Ts 103863Document23 pagesTs 103863airul6No ratings yet

- Iso 2553Document62 pagesIso 2553airul6No ratings yet

- Surface Sensor SDocument8 pagesSurface Sensor SPrabath De SilvaNo ratings yet

- CSV Working OnDocument168 pagesCSV Working Onsameerkurvey100% (1)

- Overboard Valve: Straight, Flanged EndsDocument1 pageOverboard Valve: Straight, Flanged Endsadvantage025No ratings yet

- Caracol Ekam Usaid CeepcoDocument92 pagesCaracol Ekam Usaid CeepcoUtchu JarawasNo ratings yet

- Upvc and Hdpe ComparisionDocument6 pagesUpvc and Hdpe ComparisionZamir AhmadNo ratings yet

- Tallest Wooden Building in WorldDocument7 pagesTallest Wooden Building in WorldJawad AdsNo ratings yet

- Vectus PPRC Pipes and FittingsDocument13 pagesVectus PPRC Pipes and FittingsVeera CompressorNo ratings yet

- Fly Ash FTIRDocument14 pagesFly Ash FTIRpriyaNo ratings yet

- Filtration Pump Pressure Head Loss CalculationDocument19 pagesFiltration Pump Pressure Head Loss CalculationKalai MNo ratings yet

- تصنيع ومعالجة المواد المركبةDocument32 pagesتصنيع ومعالجة المواد المركبةadel1hammiaNo ratings yet

- Expansion Tank Design Guide, How To Size and Select An Expansion Tank For A Chilled Water System PDFDocument33 pagesExpansion Tank Design Guide, How To Size and Select An Expansion Tank For A Chilled Water System PDFOm Parkash SharmaNo ratings yet

- Dyce/C/Bsl Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No Dycecbsl-02-2021-22 ClosingDocument18 pagesDyce/C/Bsl Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No Dycecbsl-02-2021-22 ClosingMitali JainNo ratings yet

- Astm D7116-16Document4 pagesAstm D7116-16Safiullah KhanNo ratings yet

- Soil Physics: The Solid Phase: Nature and Behavior of ClayDocument23 pagesSoil Physics: The Solid Phase: Nature and Behavior of ClayAndrae GenusNo ratings yet

- SERVICES - Assignment 1Document4 pagesSERVICES - Assignment 1Shiwangi NagoriNo ratings yet

- Assign 3 Bridge Deck DesignDocument1 pageAssign 3 Bridge Deck DesignRodain NajjarNo ratings yet

- Screenshot 2022-10-22 at 2.47.38 PMDocument3 pagesScreenshot 2022-10-22 at 2.47.38 PMARUN KUMARNo ratings yet

- Rar 803: Architectural Structures Module-1 Analysis and Design of Roof Trusses (Steel) PART-1Document6 pagesRar 803: Architectural Structures Module-1 Analysis and Design of Roof Trusses (Steel) PART-1AshutoshNo ratings yet

- 2015 Comfortstar Catalog PDFDocument44 pages2015 Comfortstar Catalog PDFAndres RiveraNo ratings yet

- Jawalakhel Handicraft Center Pvt. LTD.: Structural Analysis and Design ReportDocument32 pagesJawalakhel Handicraft Center Pvt. LTD.: Structural Analysis and Design ReportSandip BudhathokiNo ratings yet