Professional Documents

Culture Documents

Final - Data Sheet Copper Clad Steel Conductor - Opt

Uploaded by

Ruchir Bhoglekar0 ratings0% found this document useful (0 votes)

5 views5 pagesOriginal Title

Final - Data sheet copper clad steel conductor_opt

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views5 pagesFinal - Data Sheet Copper Clad Steel Conductor - Opt

Uploaded by

Ruchir BhoglekarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

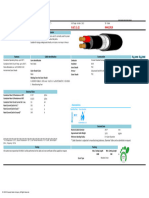

Cable Description 40% COPPERWELD®COPPER CLAD STEEL 19

STRANDS OF 5 AWG (.1819”) LOW CARBON

ANNEALED

Cable Specifications ASTM B910-10 – Standard Specification for

Annealed Copper-Clad Steel Wire

ASTM B228-11 – Standard Specification for

Concentric-Lay-Stranded Copper-Clad Steel

Conductors

Catalog Number 19#5

PHYSICAL DATA Diameter of Individual 4.62 (0.1819) mm (inch)

Wires

Number of Wires 19

Overall diameter 23.1 (0.91) mm (inch)

Cross Section of Area 318.6 (628.9) mm2 (kcmil)

Linear Weight 2660 (1788) kg/km (lb/1000 ft)

Minimum Break Load 76.7 (17246) kN (lbf)

ELECTRICAL DATA Max. Conductor DC 0.14 (0.0427) Ω/km (Ω/1000 ft)

Resistance at 20⁰C

Conductivity 40 %

When selecting a conductor for a ground grid,it must meet the maximum fault current for the identified

duration and meet a minimum breaking load as required by the substation design (typically 5,000

pounds).The key to properly sizing copper clad steel wire is the actual fault current requirement. Often

copper is physically oversized to gain the physical strength needed in the application. With Copper clad, the

physical strength is inherent to the product so theprimary consideration electrical Table 2 below compares

the ampacity ratings of copper and Copper clad Steel Wire which allows the user to visually select the Copper

clad equivalent. Forexample:

Requirements: The equivalent to 4/0 copper per the IEEE Fusing Chart is 19#940%.A typical maximum fault

current for a distribution substation is ~18 kA at 30 cycles

Cable Description 40% COPPERWELD®COPPER CLAD STEEL 7

STRANDS OF 5 AWG (.1819”) LOW CARBON

ANNEALED

Cable Specifications ASTM B910-10 – Standard Specification for

Annealed Copper-Clad Steel Wire

ASTM B228-11 – Standard Specification for

Concentric-Lay-Stranded Copper-Clad Steel

Conductors

Catalog Number 7#5

PHYSICAL DATA Diameter of Individual 4.62 (0.1819) mm (inch)

Wires

Number of Wires 7

Overall diameter 13.86 (0.546) mm (inch)

Cross Section of Area 117.4 (231.6) mm2 (kcmil)

Linear Weight 974.8 (655) kg/km (lb/1000 ft)

Minimum Break Load 28.26 (6354) kN (lbf)

ELECTRICAL DATA Max. Conductor DC 0.14 (0.044) Ω/km (Ω/1000 ft)

Resistance at 20⁰C

Conductivity 40 %

When selecting a conductor for a ground grid, it must meet the maximum fault current for the identified

duration and meet a minimum breaking load as required by the substation design (typically 5,000 pounds). The

key to properly sizing copper clad steel wire is the actual fault current requirement. Often copper is physically

oversized to gain the physical strength needed in the application. With Copperclad,the physical strength is

inherent to the products of the primary consideration electrical Table 2 below compares the ampacity ratings

of copper and Copper clad Steel Wire which allows the user to visually select the Copper clad equivalent.

Forexample:

Requirements: The equivalent to 4/0 copper per the IEEE Fusing Chart is 19#940%.A typical maximum fault

current for a distribution substation is ~18 kA at 30 cycles

Cable Description 40% COPPERWELD®COPPER CLAD STEEL 19

STRANDS OF 7 AWG (.1443”) LOW CARBON

ANNEALED

Cable Specifications ASTM B910-10 – Standard Specification for

Annealed Copper-Clad Steel Wire

ASTM B228-11 – Standard Specification for

Concentric-Lay-Stranded Copper-Clad Steel

Conductors

Catalog Number 19#7

PHYSICAL DATA Diameter of Individual 3.67 (0.1443) mm (inch)

Wires

Number of Wires 19

Overall diameter 18.33 (0.722) mm (inch)

Cross Section of Area 200.5 (395.6) mm2 (kcmil)

Linear Weight 1671.7 (1123.3) kg/km (lb/1000 ft)

Minimum Break Load 48.27 (10853) kN (lbf)

ELECTRICAL DATA Max. Conductor DC 0.2224 (0.0678) Ω/km (Ω/1000 ft)

Resistance at 20⁰C

Conductivity 40 %

When selecting a conductor for a ground grid, it must meet the maximum fault current for the identified duration

and meet a minimum breaking load as required by the substation design (typically 5,000 pounds). The key to

properly sizing copper clad steel wire is the actual fault current requirement. Often copper is physically oversized

to gain the physical strength needed in the application. With Copperclad,the physical strength is inherent to the

products of the primary consideration electrical Table 2 below compares the ampacity ratings of copper and

Copper clad Steel Wire which allows the user to visually select the Copper clad equivalent. Forexample:

Requirements: The equivalent to 4/0 copper per the IEEE Fusing Chart is 19#940%.A typical maximum fault

current for a distribution substation is ~18 kA at 30 cycles

Cable Description 40% COPPERWELD®COPPER CLAD STEEL 7

STRANDS OF 7 AWG (.1443”) LOW CARBON

ANNEALED

Cable Specifications ASTM B910-10 – Standard Specification for

Annealed Copper-Clad Steel Wire

ASTM B228-11 – Standard Specification for

Concentric-Lay-Stranded Copper-Clad Steel

Conductors

Catalog Number 7#7

PHYSICAL DATA Diameter of Individual 3.67 (0.1443) mm (inch)

Wires

Number of Wires 7

Overall diameter 11.0 (0.433) mm (inch)

Cross Section of Area 73.9 (145.8) mm2 (kcmil)

Linear Weight 613.5 (412.2) kg/km (lb/1000 ft)

Minimum Break Load 17.78 (3998) kN (lbf)

ELECTRICAL DATA Max. Conductor DC 0.60 (0.183) Ω/km (Ω/1000 ft)

Resistance at 20⁰C

Conductivity 40 %

When selecting a conductor for a ground grid, it must meet the maximum fault current for the identified duration

and meet a minimum breaking load as required by the substation design (typically 5,000 pounds). The key to

properly sizing copper clad steel wire is the actual fault current requirement. Often copper is physically oversized

to gain the physical strength needed in the application. With Copperclad,the physical strength is inherent to the

products of the primary consideration electrical Table 2 below compares the ampacity ratings of copper and

Copper clad Steel Wire which allows the user to visually select the Copper clad equivalent. Forexample:

Requirements: The equivalent to 4/0 copper per the IEEE Fusing Chart is 19#940%.A typical maximum fault

current for a distribution substation is ~18 kA at 30 cycles

You might also like

- Material Datasheets for Fire Resistant CablesDocument74 pagesMaterial Datasheets for Fire Resistant Cablesabdowais0% (1)

- 10 TMSS 05 R1Document11 pages10 TMSS 05 R1Omar HijaziNo ratings yet

- Flipkart vs Amazon comparison studyDocument6 pagesFlipkart vs Amazon comparison studysunnyNo ratings yet

- Vol2 TL-S11-19 3626Document133 pagesVol2 TL-S11-19 3626cantigiNo ratings yet

- Dno-6282-OPGW 12 HILOS PDFDocument2 pagesDno-6282-OPGW 12 HILOS PDFCristyan Marcelo Rosero ChingalNo ratings yet

- 10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R0Document11 pages10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R0m3eenNo ratings yet

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- B 172 - 01 - Qje3mi1sruqDocument5 pagesB 172 - 01 - Qje3mi1sruqCarlos LiceaNo ratings yet

- TS PHIIR Part4Document104 pagesTS PHIIR Part4purechemcabledeptNo ratings yet

- AMENDMENT 2 (500 KV) (Rev2, Apr2016)Document7 pagesAMENDMENT 2 (500 KV) (Rev2, Apr2016)Jed SrisuthumNo ratings yet

- ACSR Rail ZTTDocument6 pagesACSR Rail ZTTAntony Cesar Caballero IbarraNo ratings yet

- 10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2Document11 pages10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2m3eenNo ratings yet

- Theft Deterrent Composite CableDocument8 pagesTheft Deterrent Composite Cablepatitay036817No ratings yet

- A12 Appendix 12 Technical ScheduleDocument79 pagesA12 Appendix 12 Technical Scheduleanon_31581079No ratings yet

- IndianDocument15 pagesIndiansajjad_pirzadaNo ratings yet

- F Opt Opgwdno 6417-1Document5 pagesF Opt Opgwdno 6417-1gercubNo ratings yet

- M0471285F 7 No 8 40 CCSDocument1 pageM0471285F 7 No 8 40 CCSAnonymous S29FwnFNo ratings yet

- Catalogue of CCS Zhenglan ChinaDocument14 pagesCatalogue of CCS Zhenglan ChinagestordecomprasNo ratings yet

- GTP-04 08 2022Document11 pagesGTP-04 08 2022Bhagawati Prasad SharmaNo ratings yet

- 10-Tmss-07-Substation Grounding Materials-R0Document17 pages10-Tmss-07-Substation Grounding Materials-R0m3eenNo ratings yet

- Acsr SpecsDocument1 pageAcsr SpecsPanda NoirNo ratings yet

- Xlpe Insulated Cables Need Power ConnectDocument32 pagesXlpe Insulated Cables Need Power ConnectTesfahun GirmaNo ratings yet

- ZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Document5 pagesZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Benjamin SalinasNo ratings yet

- NFC 1kv ABC 2&4c16 Ees CableDocument5 pagesNFC 1kv ABC 2&4c16 Ees CableazzouzimedNo ratings yet

- Acsr Panther ConductorDocument17 pagesAcsr Panther ConductorRam Dhani Yadav100% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- Astm A787 PDFDocument6 pagesAstm A787 PDFumeshNo ratings yet

- ACSR AWG/kcmil: DescriptionDocument2 pagesACSR AWG/kcmil: DescriptionRey AlvarezNo ratings yet

- Jumper Cable Spec 14-16 PDFDocument3 pagesJumper Cable Spec 14-16 PDFRAMESH KUMARNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- Technology Department Technical Data Sheet Low Voltage Power CableDocument2 pagesTechnology Department Technical Data Sheet Low Voltage Power CableMuhammad ShahidNo ratings yet

- Opgw Fiber Spec Dno 91391Document5 pagesOpgw Fiber Spec Dno 91391carlos diazNo ratings yet

- Technical Specification: Aluminum Conductors, Aluminum Clad Steel Reinforced (ACSR/AS-Drake (795MCM) )Document5 pagesTechnical Specification: Aluminum Conductors, Aluminum Clad Steel Reinforced (ACSR/AS-Drake (795MCM) )alfredoNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- 2 5px3cywystrfrlsDocument2 pages2 5px3cywystrfrlsKrish0% (1)

- BCC.12103150Document1 pageBCC.12103150sashtiNo ratings yet

- Annex 1 Tech Spec Accc Drake Htls ConductorDocument28 pagesAnnex 1 Tech Spec Accc Drake Htls Conductorelsayed100% (1)

- Acsr Zebra ConductorDocument17 pagesAcsr Zebra ConductorRam Dhani YadavNo ratings yet

- Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors (AAC/TW)Document4 pagesShaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors (AAC/TW)islamakthamNo ratings yet

- ACSR ConductorDocument13 pagesACSR ConductorHrshiya SharmaNo ratings yet

- Martin Zhu: Technical SpecificationDocument5 pagesMartin Zhu: Technical SpecificationalfredoNo ratings yet

- MV Power CablesDocument2 pagesMV Power CablesQC ĐNNo ratings yet

- Norway OPGW DUAL TUBE 96 G.652D-13.9mm 26042018Document5 pagesNorway OPGW DUAL TUBE 96 G.652D-13.9mm 26042018satyam_scribdNo ratings yet

- Overhead ConductorsDocument46 pagesOverhead Conductorsمحمد كهرباءNo ratings yet

- TDS-Solar CableDocument1 pageTDS-Solar CableJaks JaksNo ratings yet

- PBT Opgw CableDocument7 pagesPBT Opgw CableChristian CastroNo ratings yet

- Transmission Materials Standard Specification OverviewDocument0 pagesTransmission Materials Standard Specification OverviewhasanmnhNo ratings yet

- Hangzhou Easy Electric Wire Spec SheetsDocument4 pagesHangzhou Easy Electric Wire Spec SheetsErnesto Antonio Astorga FloresNo ratings yet

- Grounding ElectrodesDocument19 pagesGrounding ElectrodesNgocHoanTranNo ratings yet

- Technical Offer CR Italy 1437 22 V7Document1 pageTechnical Offer CR Italy 1437 22 V7NabeelNo ratings yet

- GTMETRPSOD XX X X - 2018v2Document4 pagesGTMETRPSOD XX X X - 2018v2Stone123456789No ratings yet

- Technical Report For ACFR ConductorDocument6 pagesTechnical Report For ACFR ConductorDejanNo ratings yet

- 400PX3 5caywyxlpeDocument2 pages400PX3 5caywyxlpeAnonymous SDeSP1No ratings yet

- Specs ZTT TACSR AW 410 PDFDocument5 pagesSpecs ZTT TACSR AW 410 PDFVictor DoyoganNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- Technical Specification of 55Sqmm 100Sqmm AAACDocument14 pagesTechnical Specification of 55Sqmm 100Sqmm AAACMurtuzaNo ratings yet

- 24 Fiber OPGW ANDES PDFDocument7 pages24 Fiber OPGW ANDES PDFMAN TNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Utilization of Fluff From Reception To BurnerDocument28 pagesUtilization of Fluff From Reception To BurnerfylakyaNo ratings yet

- Maslows TheoryDocument9 pagesMaslows TheoryPratik ThakkarNo ratings yet

- Economic Valuation of Cultural HeritageDocument331 pagesEconomic Valuation of Cultural Heritageaval_176466258No ratings yet

- Tugas Kelompok Pend.b.asing 3Document5 pagesTugas Kelompok Pend.b.asing 3Akun YoutubeNo ratings yet

- 2001 BagDocument557 pages2001 BagSheshu KNo ratings yet

- Creating and Opening WorkbooksDocument20 pagesCreating and Opening WorkbooksCon SiosonNo ratings yet

- Group7 Sula Wine IBDocument16 pagesGroup7 Sula Wine IBFenny ShahNo ratings yet

- Swelab User ManualDocument2 pagesSwelab User Manualhayder FadelNo ratings yet

- Vari-Green Motor: Start Saving NowDocument4 pagesVari-Green Motor: Start Saving NowRandy HawkinsNo ratings yet

- Yard FacilitiesDocument30 pagesYard FacilitiesYgandranNo ratings yet

- PDFDocument21 pagesPDFClarice Ilustre GuintibanoNo ratings yet

- MT Dbp-hcp-1000 Series ManualDocument54 pagesMT Dbp-hcp-1000 Series ManualNguyễn Thế PhongNo ratings yet

- New Position Performance Evaluation FormDocument4 pagesNew Position Performance Evaluation FormRomero SanvisionairNo ratings yet

- 5 Basic Model of PorterDocument6 pages5 Basic Model of PorterJahanvi PandyaNo ratings yet

- Topic 2Document9 pagesTopic 2swathi thotaNo ratings yet

- Unit 1.3 Practice TestDocument16 pagesUnit 1.3 Practice TestYoann DanionNo ratings yet

- MEC-004 TMA: Harrod-Domar Model and Golden Age EquilibriumDocument11 pagesMEC-004 TMA: Harrod-Domar Model and Golden Age EquilibriumnitikanehiNo ratings yet

- Airport EngineeringDocument48 pagesAirport Engineeringmounika markaNo ratings yet

- Assign Controlling Areas and Company Codes for Optimal Cost AccountingDocument4 pagesAssign Controlling Areas and Company Codes for Optimal Cost Accountingatsc68No ratings yet

- Dangerous Goods Hazmat Material Training Cat-10Document24 pagesDangerous Goods Hazmat Material Training Cat-10Claudio GonzalezNo ratings yet

- Product Specifications Product Specifications: SBNHH SBNHH - 1D45C 1D45C - SR SRDocument6 pagesProduct Specifications Product Specifications: SBNHH SBNHH - 1D45C 1D45C - SR SRjorgeerestrepoNo ratings yet

- When To Replace Your Ropes: Asme B30.30 Ropes For Details On The Requirements For Inspection and Removal CriteriaDocument2 pagesWhen To Replace Your Ropes: Asme B30.30 Ropes For Details On The Requirements For Inspection and Removal CriteriaMike PoseidonNo ratings yet

- Berges 7,5KWDocument66 pagesBerges 7,5KWGabriel CasNo ratings yet

- Sample Whistle Blower PolicyDocument2 pagesSample Whistle Blower Policy4geniecivilNo ratings yet

- Welcome To All of You..: Nilima DasDocument16 pagesWelcome To All of You..: Nilima DasSteven GarciaNo ratings yet

- KS 94 DatasheetDocument8 pagesKS 94 Datasheetbaananou nizarNo ratings yet

- Unit 13Document28 pagesUnit 13Tinh NguyenNo ratings yet

- TARPfinal PDFDocument28 pagesTARPfinal PDFRakesh ReddyNo ratings yet

- Bibicoff Ic Resume 2022 09 For WebsiteDocument3 pagesBibicoff Ic Resume 2022 09 For Websiteapi-633250343No ratings yet