Professional Documents

Culture Documents

04 - Section 3 - Flowcharts (E)

Uploaded by

Mutiara Puspahati CripstyaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 - Section 3 - Flowcharts (E)

Uploaded by

Mutiara Puspahati CripstyaniCopyright:

Available Formats

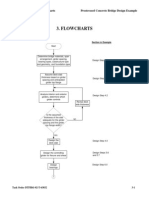

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

3. FLOWCHARTS

Main Design Steps

Section in Example

Start

Determine bridge materials, span

arrangement, girder spacing,

Design Step 2.0

bearing types, substructure type

and geometry, and foundation type

Assume deck slab

thickness based on girder

Design Step 4.2

spacing and anticipated

girder top flange

Analyze interior and exterior

Design Step 4.2

girders, determine which

girder controls

Revise deck

slab thickness

Is the assumed

thickness of the slab

NO

adequate for the girder

spacing and the girder

top flange width?

YES

Design the Design Step 4.0

deck slab

Design the controlling Design Steps 5.6

girder for flexure and shear and 5.7

Design Design Step 6.0

bearings

Task Order DTFH61-02-T-63032 3-1

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Main Design Steps (cont.)

Section in Example

1

Design integral

abutments Design Step 7.1

Design intermediate

pier and foundation Design Step 7.2

End

Task Order DTFH61-02-T-63032 3-2

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Deck Slab Design

Section in Example

Start

Assume a deck slab

thickness based on Design Step 4.2

girder spacing and width

of girder top flange

Determine the location of the

critical section for negative

Design Step 4.6

moment based on the girder

top flange width (S4.6.2.1.6)

Determine live load

positive and negative Design Step 4.7

moments (A4)

Determine dead load Design Steps 4.8

positive and negative and 4.9

moment

Determine factored

Design Step 4.8

moments (S3.4)

Design main

reinforcement for

flexure (S5.7.3)

Determine longitudinal

distribution reinforcement Design Step 4.12

(S9.7.3.2)

Task Order DTFH61-02-T-63032 3-3

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Deck Slab Design (cont.)

Section in Example

1

For Slabs on Continuous Beams:

Steel beam - Determine area of longitudinal reinforcement in the

deck in negative moment regions of the girders (S6.10.3.7)

Concrete Simple Spans Made Continuous for Live Load -

Determine the longitudinal slab reinforcement at intermediate

pier areas during the design of the girders (S5.14.1.2.7b)

Determine strip width for overhang (S4.6.2.1.3)

Design Step 4.10

or where applicable, use S3.6.1.3.4

Determine railing load

resistance and rail moment

resistance at its base (S13.3)

Design overhang reinforcement for

vehicular collision with railing + DL

(Case 1 and Case 2 of SA13.4.1)

Determine factored moments

from DL + LL on the overhang

(Case 3 of SA13.4.1)

Design overhang

reinforcement for DL + LL

Determine the controlling case

for overhang reinforcement,

Case 1, Case 2 or Case 3

Detail

Design Step 4.11

reinforcement

End

Task Order DTFH61-02-T-63032 3-4

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

General Superstructure Design

(Notice that only major steps are presented in this flowchart. More detailed flowcharts of the

design steps follow this flowchart)

Section in Example

Start

Assume girder size

based on span and Design Step 2.0

girder spacing

Determine noncomposite dead load

(girder, haunch and deck slab) for the Design Step 5.2

interior and exterior girders

Determine composite dead load (railings,

Design Step 5.2

utilities, and future wearing surface) for

the interior and exterior girders

Determine LL distribution

Design Step 5.1

factors for the interior and

exterior girders

Determine unfactored Design Step 5.3

and factored force effects

Determine the controlling girder

(interior or exterior) and continue

the design for this girder

Task Order DTFH61-02-T-63032 3-5

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

General Superstructure Design (cont.)

Section in Example

1

Determine long-term and

short-term prestressing Design Step 5.4

force losses

Design for flexure under

Design Step 5.6

Service Limit State

Design for flexure under

Strength Limit State

Design for shear under

Design Step 5.7

Strength Limit State

Check longitudinal reinforcement

for additional forces from shear

Did the girder

pass all design Select a different

checks and the calculations NO girder size or

indicate the selected girder size change strand

leads to an economical arrangement

design?

YES

End

Task Order DTFH61-02-T-63032 3-6

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Live Load Distribution Factor Calculations

Section in Example

Start

Determine the type of cross-

Design Step 5.1

section, Table S4.6.2.2.1-1

Determine the Kg Design Step 5.1.3

factor (S4.6.2.2.1)

For skewed bridges, determine

the skew correction factor for

moment (if allowed by the Design Step 5.1.6

owner) (S4.6.2.2.2e) and for

shear (S4.6.2.2.3c)

Determine LL distribution factors

for moment for the interior girder

Design Step 5.1.5

under single lane and multi-lane

loading (S4.6.2.2.2b)

Determine LL distribution factor

for shear for the interior girder

Design Step 5.1.7

under single lane and multi-lane

loading (S4.6.2.2.3a)

Apply the skew

Design Step 5.1.8

correction factor

Task Order DTFH61-02-T-63032 3-7

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Live Load Distribution Factor Calculations (cont.)

Section in Example

1

Determine the controlling

(larger) distribution factors Design Step 5.1.9

for moment and shear for

the interior girder

Divide the single lane distribution factors by the multiple presence

factor for one lane loaded,1.2, to determine the fatigue distribution

factors (Notice that fatigue is not an issue for conventional P/S

girders. This step is provided here to have a complete general

reference for distribution factor calculations.)

Repeat the calculations for

the exterior girder using

Design Step 5.1.10

S4.6.2.2.2d for moment

and S4.6.2.2.3b for shear

Additional check for the

exterior girder for bridges Design Step 5.1.15

with rigidly connected girders

End

Task Order DTFH61-02-T-63032 3-8

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Creep and Shrinkage Calculations

Section in Example

Start

Calculate the creep coefficient, ψ(t, ti),

for the beam at infinite time according Design Step C1.2

to S5.4.2.3.2.

Calculate the creep coefficient, ψ(t,ti), in the

Design Step C1.3

beam at the time the slab is cast according

to S5.4.2.3.2.

Calculate the prestressed Design Step C1.4

end slope, θ.

Calculate the prestressed

Design Step C1.5

creep fixed end actions

Calculate dead load creep

fixed end actions Design Step C1.6

Determine creep

Design Step C1.7

final effects

Task Order DTFH61-02-T-63032 3-9

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Creep and Shrinkage Calculations (cont.)

Section in Example

Calculate shrinkage strain in beam at Design Step C2.1

infinite time according to S5.4.2.3.3.

Calculate shrinkage strain in the beam at Design Step C2.2

the time the slab is cast (S5.4.2.3.3).

Calculate the shrinkage strain in the slab at Design Step C2.3

infinite time (S5.4.2.3.3).

Calculate the shrinkage Design Step C2.5

driving end moment, Ms

Analyze the beam for the Design Step C2.6

shrinkage fixed end actions

Calculate the correction Design Step C2.7

factor for shrinkage

Calculate the shrinkage Design Step C2.8

final moments

End

Task Order DTFH61-02-T-63032 3-10

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Prestressing Losses Calculations

Section in Example

Start

Determine the stress limit

immediately prior to transfer in

Design Step 5.4.2

the prestressing strands for the

prestressing steel used (S5.9.3)

Determine Instantaneous Losses

(S5.9.5.2) for pretensioned Design Step 5.4.3

members, only Elastic Shortening

(S5.9.5.2.3a) is considered

Will the lump

Lump Sum sum method or the refined Refined

method for time-dependent

losses be used?

Determine the Determine

lump sum time- shrinkage loss Design Step 5.4.6.1

dependent losses (S5.9.5.4.2)

(S5.9.5.3)

Determine

1 creep loss Design Step 5.4.6.2

(S5.9.5.4.3)

Task Order DTFH61-02-T-63032 3-11

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Prestressing Losses Calculations (cont.)

Section in Example

1 2

Determine relaxation Determine losses due

loss at transfer to relaxation after Design Step 5.4.6.3

(S5.9.5.4.4b) transfer (S5.9.5.4.4c)

Determine time-dependent Determine total time-dependent

losses after transfer as the total Design Step 5.4.7

losses after transfer by adding creep,

time-dependent losses minus shrinkage and relaxation losses

relaxation losses at transfer

Determine stress in strands

immediately after transfer as Design Step 5.4.4

the stress prior to transfer

minus instantaneous losses

Determine final stress in strands as

stress immediately prior to transfer minus

Design Step 5.4.8

sum of instantaneous loss and time-

dependent losses after transfer

End

Task Order DTFH61-02-T-63032 3-12

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Flexural Design

Section in Example

Start

Design controlling girder

(interior)

Determine compression and

Design Step 5.6.1.1

tension stress limits at transfer

Determine final compression

Design Step 5.6.2.1

and tension stress limits

Calculate initial service moment

stress in the top and bottom of Design Step 5.6.1.2

the prestressed girder

Calculate final service

moment stress in the top Design Step 5.6.2.2

and bottom of the

prestressed girder

Select a different

girder size or change

strand arrangement

Are service

NO

stresses within

stress limits?

YES

1 2

Task Order DTFH61-02-T-63032 3-13

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Flexural Design (cont.)

Section in Example

1 2

Design the longitudinal Design Step 5.6.3

steel at top of girder

Calculate factored flexural Design Step 5.6.4

resistance, Mr, at points of

maximum moment

(S5.7.3.1)

Check the nominal Select a different

capacity versus the NG girder size or

maximum applied change strand

factored moment arrangement

OK

Check the maximum Select a different

and minimum NG girder size or Design Step 5.6.4.1

reinforcement change strand and 5.6.4.2

(S5.7.3.3.2) arrangement

OK

Check negative moment

connection at

Design Step 5.6.5.1

intermediate pier

Task Order DTFH61-02-T-63032 3-14

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Flexural Design (cont.)

Section in Example

3

Check moment capacity versus

the maximum applied factored Design Step 5.6.5.1

moment at the critical location

for negative moment.

Check service crack control

in negative moment region Design Step 5.6.5.1

(S5.5.2)

Check positive moment

Design Step 5.6.5.2

connection at intermediate pier

Check fatigue in prestressed steel

(S5.5.3) (Notice that for conventional Design Step 5.6.6

prestressed beams, fatigue does not

need to be checked)

Calculate required camber in

the beams to determine Design Step 5.6.7.1

bearing seat elevations

Determine the Design Step 5.6.7.2

haunch thickness

Calculate required camber

in the beams to determine Design Step 5.6.7.3

probable sag in bridge

Task Order DTFH61-02-T-63032 3-15

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Flexural Design (cont.)

Section in Example

4

Optional live load

Design Step 5.6.8

deflection check

(S2.5.2.6.2)

End

Task Order DTFH61-02-T-63032 3-16

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Shear Design – Alternative 1, Assumed Angle

Section in Example

Start

Determine bv and dv Design Step 5.7.2.1

Eq. S5.8.2.9

Calculate Vp

Calculate shear stress

Design Step 5.7.2.2

ratio, vu/f'c

If the section is within the

transfer length of any

Design Step 5.7.2.5

strands, calculate the

average effective value of fpo

If the section is within the

development length of any

Design Step 5.7.2.5

reinforcing bars, calculate the

effective value of As

Assume value of shear

Design Step 5.7.2.5

crack inclination angle θ

Calculate εx using Eq.

S5.8.3.4.2-1

1 2

Task Order DTFH61-02-T-63032 3-17

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Shear Design – Alternative 1, Assumed Angle (cont.)

1 2 Section in Example

Is assumed value of

θ greater than the value NO Use the value last

determined based on determined for θ

calculated εx?

YES

Is assumed value of YES

θ too conservative, i.e.,

too high?

NO

Determine transverse

reinforcement to ensure Design Step 5.7.2.5

Vu <= φVn Eq. S5.8.3.3

Check minimum and

maximum transverse Design Step 5.7.2.3

reinforcement requirements and 5.7.2.4

S5.8.2.5 and S5.8.2.7

Can longitudinal

reinforcement resist NO

required tension? Design Step 5.7.6

Eq. S5.8.3.5

YES

3 4 5 6

Task Order DTFH61-02-T-63032 3-18

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Shear Design – Alternative 1, Assumed Angle (cont.)

3 4 Section in Example

Check bursting resistance

Design Step 5.7.4

(S5.10.10.1)

Can you use excess

YES shear capacity to reduce

the longitudinal steel

requirements in

Eq. S5.8.3.5-1?

Choose values of θ and β

corresponding to larger εx,

Table S5.8.3.4.2-1 NO

5

Provide additional

6 longitudinal reinforcement

Check confinement

Design Step 5.7.5

reinforcement (S5.10.10.2)

Check horizontal shear at

interface between beam Design Step 5.7.7

and deck (S5.8.4)

End

Task Order DTFH61-02-T-63032 3-19

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Shear Design – Alternative 2, Assumed Strain x

Section in Example

Start

Determine bv and dv Design Step 5.7.2.1

Eq. S5.8.2.9

Calculate Vp

Calculate shear stress Design Step 5.7.2.2

ratio, vu/f'c

If the section is within the

transfer length of any

Design Step 5.7.2.5

strands, calculate the

average effective value of fpo

If the section is within the

development length of any

Design Step 5.7.2.5

reinforcing bars, calculate the

effective value of As

Assume value of εx and take θ

and β from corresponding cell of

Table S5.8.3.4.2-1

Calculate εx using Eq. Design Step 5.7.2.5

S5.8.3.4.2-1

2 1 3

Task Order DTFH61-02-T-63032 3-20

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Shear Design – Alternative 2, Assumed Strain x (cont.)

2 1 3 Section in Example

NO Is calculated εx less than

assumed value?

YES

Is assumed value of YES

θ too conservative, i.e.,

too high?

NO

Determine transverse

reinforcement to ensure Design Step 5.7.2.5

Vu <= φVn Eq. S5.8.3.3

Check minimum and

maximum transverse Design Step 5.7.2.3

reinforcement requirements and 5.7.2.4

S5.8.2.5 and S5.8.2.7

Can longitudinal

reinforcement resist NO

required tension? Design Step 5.7.6

Eq. S5.8.3.5

YES

4 5 6 7

Task Order DTFH61-02-T-63032 3-21

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Shear Design – Alternative 2, Assumed Strain x (cont.)

4 5 Section in Example

Check bursting resistance Design Step 5.7.4

(S5.10.10.1)

Can you use excess

YES shear capacity to reduce

the longitudinal steel

requirements in

Eq. S5.8.3.5-1?

Choose values of θ and β

corresponding to larger εx,

Table S5.8.3.4.2-1 NO

6

Provide additional

7 longitudinal reinforcement

Check confinement Design Step 5.7.5

reinforcement (S5.10.10.2)

Check horizontal shear at

interface between beam Design Step 5.7.7

and deck (S5.8.4)

End

Task Order DTFH61-02-T-63032 3-22

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design – Method A (Reference Only)

Section in Example

Start

Determine movements and

loads at pier support (S14.4)

Calculate required plan area

based on compressive stress

limit (S14.7.6.3.2)

Determine dimensions L and W of the

bearing, W is taken to be slightly less than

the width of the girder bottom flange

(S14.7.5.1)

Determine the shape factor for steel-

reinforced elastomeric bearings

according to S14.7.5.1

Determine material

properties (S14.7.6.2)

Check compressive stress. Determine the

maximum allowed shape factor using total load

and live load stresses for the assumed plan area

(S14.7.6.3.2)

Assume elastomer layer

maximum thickness and

number of layers

Task Order DTFH61-02-T-63032 3-23

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design – Method A (Reference Only) (cont.)

1 Section in Example

Recalculate the

shape factor

Determine maximum stress associated

with the load conditions inducing the

maximum rotation (S14.7.6.3.5)

Check stability of the

elastomeric bearing

(S14.7.6.3.6)

Reinforcement for steel-reinforced

elastomeric bearings is designed

according to S14.7.5.3.7

Change plan

Did bearing pass all NO dimensions, number

checks? of layers, and/or

thickness of layers

YES

Check if the bearing needs to

be secured against horizontal

movement (S14.7.6.4)

End

Task Order DTFH61-02-T-63032 3-24

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design – Method B

Section in Example

Start

Determine movements and

Design Step 6.1

loads at pier support (S14.4)

Calculate required plan area

of the elastomeric pad based

Design Step 6.1.1

on compressive stress limit

(S14.7.5.3.2)

Determine dimensions L and W of the

bearing, W is taken to be slightly less Design Step 6.1.1

than the width of the girder bottom flange

(S14.7.5.1)

Determine material

properties (S14.7.5.2)

Check compressive stress. Determine the

maximum allowed shape factor using total load

Design Step 6.1.2.1

and live load stresses for the assumed plan

area (S14.7.5.3.2)

Calculate maximum

elastomer interior layer Design Step 6.1.2.1

thickness, hri. (S14.7.5.1)

Task Order DTFH61-02-T-63032 3-25

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Steel-Reinforced Elastomeric Bearing Design – Method B (cont.)

1 Section in Example

Recalculate the shape factor

Design Step 6.1.2.1

(S14.7.5.1)

Check compressive deflection

if there is a deck joint at the Design Step 6.1.2.2

bearing location (S14.7.5.3.3)

Check shear deformation Design Step 6.1.2.3

(S14.7.5.3.4)

Check combined compression

Design Step 6.1.2.4

and rotation (S14.7.5.3.5)

Check stability of elastomeric

Design Step 6.1.2.5

bearings (S14.7.5.3.6)

Change plan

Did bearing pass NO dimensions, number

all checks? of layers, and/or

thickness of layers

YES

Determine steel reinforcement

Design Step 6.1.2.6

thickness, hs (S14.7.5.3.7)

End

Task Order DTFH61-02-T-63032 3-26

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

SUBSTRUCTURE

Integral Abutment Design

Section in Example

Start

Generate applied dead

Design Step 7.1.1

load and live load for the

abutment components.

Determine controlling limit state.

Factor the loads according to Table Design Step 7.1.2

S3.4.1-1 to be applied for pile design

Check pile compressive resistance

(S6.15 and S6.9.2). Determine number Design Step 7.1.3.1

of piles and corresponding spacing.

Design pile cap reinforcement.

Design Step 7.1.4

Check flexure and shear.

Check the flexure and shear

Design Step 7.1.4.1

resistance of the backwall.

Design wingwall Design Step 7.1.5

Design approach

Design Step 7.1.6

slab for flexure

End

Task Order DTFH61-02-T-63032 3-27

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Intermediate Bent Design

Section in Example

Start

Generate the loads

Design Step 7.2.1

applied to the intermediate

bent components.

Determine maximum loads

transferred from the superstructure

Analyze the pier cap. Determine the

locations of maximum positive moment, Design Step 7.2.2

negative moment and shear

Design flexural and shear

reinforcement in the pier cap

Check limits of reinforcement

(S5.7.3.3)

Check flexural

reinforcement

distribution (S5.7.3.4)

Check minimum temperature

Design Step 7.2.2.4

and shrinkage steel (S5.10.8)

Task Order DTFH61-02-T-63032 3-28

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Intermediate Bent Design (cont.)

1 Section in Example

Check skin reinforcement in

components where de Design Step 7.2.2.5

exceeds 3.0 ft. (S5.7.3.4)

Design the columns. Determine

the maximum moments and Design Step 7.2.3

shears in the column

Check limits for reinforcement in

compression members (S5.7.4.2)

Develop the column

interaction curve

Check slenderness provisions for

Design Step 7.2.3.1

concrete columns (S5.7.4.3)

Determine transverse

reinforcement for a compressive Design Step 7.2.3.2

member (S5.10.6)

Design the footing. Determine

applied moments and shears Design Step 7.2.4

transmitted from the columns

Task Order DTFH61-02-T-63032 3-29

Design Step 3 – Design Flowcharts Prestressed Concrete Bridge Design Example

Intermediate Bent Design (cont.)

2 Section in Example

Check flexural resistance Design Step 7.2.4.1

(S5.7.3.2)

Check maximum and minimum

Design Step 7.2.4.2

reinforcement (S5.7.3.3)

Check distribution of reinforcement for

Design Step 7.2.4.3

cracking in the concrete (S5.7.3.4)

Design footing for maximum shear in the

longitudinal and transverse directions (one-way Design Step 7.2.4.4

shear and punching (two-way) shear)

Foundation soil resistance at the

Design Step 7.2.4.5

Strength Limit State (S10.6.3)

End

Task Order DTFH61-02-T-63032 3-30

You might also like

- Design Flowcharts for Prestressed Concrete BridgeDocument30 pagesDesign Flowcharts for Prestressed Concrete BridgeNamelezz ShadowwNo ratings yet

- Precast Concrete Floors in Steel Framed Buildings: June 2018Document24 pagesPrecast Concrete Floors in Steel Framed Buildings: June 2018amarjeetsinghNo ratings yet

- Two-Way Floor Design Example: ForewordDocument32 pagesTwo-Way Floor Design Example: ForewordTan ChingNo ratings yet

- LRFD Design ExampleDocument698 pagesLRFD Design ExampleCesar RomeroNo ratings yet

- Column Supported Two-Way Post-Tensioned Floor Interenational Version TN460-SIDocument30 pagesColumn Supported Two-Way Post-Tensioned Floor Interenational Version TN460-SIKhuất Trần ThanhNo ratings yet

- SW Design ManualDocument81 pagesSW Design ManualChester SmithNo ratings yet

- Structural Design: Presented by Mohd Khairy Burhanudin Prepared by Ir. Mohammad Soffi MD NohDocument7 pagesStructural Design: Presented by Mohd Khairy Burhanudin Prepared by Ir. Mohammad Soffi MD Nohfuad haziqNo ratings yet

- RC Frame Structural Modelling in Real3DDocument25 pagesRC Frame Structural Modelling in Real3DBlack Fist ZepHyRNo ratings yet

- SWD Aci 318 14Document74 pagesSWD Aci 318 14Wilson Villalobos100% (1)

- SWD Csa A23.3 14 PDFDocument81 pagesSWD Csa A23.3 14 PDFJose L MexiaNo ratings yet

- SWD Aci 318 14Document81 pagesSWD Aci 318 14Mukhlish AkhatarNo ratings yet

- Contoh Soal Psikotes Kerja Dan Kunci JawabanDocument74 pagesContoh Soal Psikotes Kerja Dan Kunci JawabanYulia RimadaniNo ratings yet

- Shear Wall Design-ACI-318-14Document30 pagesShear Wall Design-ACI-318-14Christian ReedNo ratings yet

- Shear Wall Design ManualDocument70 pagesShear Wall Design ManualRupesh MaharjanNo ratings yet

- SWD NZS 3101 2006 PDFDocument74 pagesSWD NZS 3101 2006 PDFsamir_ssh7151No ratings yet

- Shear Wall Design ManualDocument75 pagesShear Wall Design ManualALEX GALICINAONo ratings yet

- ShearWallDesign Manual2016Document82 pagesShearWallDesign Manual2016Alfia BanoNo ratings yet

- SWD Aci 318 11Document75 pagesSWD Aci 318 11mdkmlNo ratings yet

- SWD-ACI-318-11Document75 pagesSWD-ACI-318-11AngusNo ratings yet

- RC Concrete GuideDocument139 pagesRC Concrete GuideSeptimiu100% (1)

- The Column's Base Plate: Design InformationDocument2 pagesThe Column's Base Plate: Design Informationمختار ابراهيمNo ratings yet

- Pile Cap ShearDocument280 pagesPile Cap ShearbrainspeareNo ratings yet

- CFD Csa A23.3 14Document89 pagesCFD Csa A23.3 14lee100% (2)

- CH 4 Beam DesignDocument42 pagesCH 4 Beam Design秦瑋駿No ratings yet

- Analysis and Design of Deck Slab Bridge (IRC)Document6 pagesAnalysis and Design of Deck Slab Bridge (IRC)Rey Balza TornoNo ratings yet

- CFD Csa A23.3 14 PDFDocument89 pagesCFD Csa A23.3 14 PDFSumanth67% (3)

- Shear Wall Design Manual: Mexican RCDF 2004Document73 pagesShear Wall Design Manual: Mexican RCDF 2004Nyein ZawNo ratings yet

- Understanding Engineering DocumentsDocument20 pagesUnderstanding Engineering DocumentsJose Arthur AbellaNo ratings yet

- Sap2000 - V19 NTC-2008Document83 pagesSap2000 - V19 NTC-2008uhkefor52100% (1)

- Bridge Substructure Analysis & DesignDocument193 pagesBridge Substructure Analysis & Designamit457392% (12)

- CSI - Concrete Frame Design Manual As Per CSA-A23.3-04Document95 pagesCSI - Concrete Frame Design Manual As Per CSA-A23.3-04Jason ToraldeNo ratings yet

- Post-Tensioned Beam Design Step-by-Step CalculationDocument30 pagesPost-Tensioned Beam Design Step-by-Step CalculationLau Kim HwaNo ratings yet

- Bent Design - LRFD Design of California BridgesDocument87 pagesBent Design - LRFD Design of California Bridgessongkk100% (1)

- Computer Aided Design of Pile Foundations For River Bridges: A DissertationDocument70 pagesComputer Aided Design of Pile Foundations For River Bridges: A Dissertationdhan singhNo ratings yet

- SWD-ACI-530-11Document58 pagesSWD-ACI-530-11AngusNo ratings yet

- (.K Igi : Dcsign Concepts A T D Detailing SlabsDocument48 pages(.K Igi : Dcsign Concepts A T D Detailing SlabsKosygin LeishangthemNo ratings yet

- SWD Ec 2 2004Document88 pagesSWD Ec 2 2004dalton wongNo ratings yet

- FST L 11Document42 pagesFST L 11Shivangi MishraNo ratings yet

- Steel Frame Design Manual: Italian NTC 2008Document99 pagesSteel Frame Design Manual: Italian NTC 2008Angel VargasNo ratings yet

- 2 What Is The Cantilever WorksDocument34 pages2 What Is The Cantilever WorksAye ZarniNo ratings yet

- BS 8110 ETAbsDocument63 pagesBS 8110 ETAbsnabnaj100% (1)

- Post-Installed Rebar Guide Technical Information ASSET DOC LOC 7210535Document69 pagesPost-Installed Rebar Guide Technical Information ASSET DOC LOC 7210535kyleNo ratings yet

- Steel Frame Design Manual: Italian NTC 2008Document96 pagesSteel Frame Design Manual: Italian NTC 2008Haytham ZaghloulNo ratings yet

- Block of 4 Flats Calculation Report 2Document152 pagesBlock of 4 Flats Calculation Report 2Isaac JosephNo ratings yet

- Design and check of reinforced concrete according to EurocodesDocument4 pagesDesign and check of reinforced concrete according to EurocodesMuscadin MakensonNo ratings yet

- FinalReport - Bridge ProjectDocument302 pagesFinalReport - Bridge ProjectMohamed GamalNo ratings yet

- Concrete Frame Design Manual: CSA A23.3-14Document76 pagesConcrete Frame Design Manual: CSA A23.3-14Angel Vargas100% (2)

- 2010 04 13 Revisions For SDC 15 FinalDocument52 pages2010 04 13 Revisions For SDC 15 FinalsaraviadNo ratings yet

- CBD Aisc 360 16Document98 pagesCBD Aisc 360 16Angel Vargas100% (1)

- Guidelines Code and Standard of Tunnel LinningDocument49 pagesGuidelines Code and Standard of Tunnel LinningChristin UrginoNo ratings yet

- CFD Aci 318 14 - 1Document15 pagesCFD Aci 318 14 - 1tailieuxaydung2019100% (1)

- CBD Aisc 360 10Document79 pagesCBD Aisc 360 10Angel VargasNo ratings yet

- E Man 005Document267 pagesE Man 005chgstructuralNo ratings yet

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesFrom EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesRating: 3.5 out of 5 stars3.5/5 (13)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- PST Es e - PST SL e - en A4 PDFDocument14 pagesPST Es e - PST SL e - en A4 PDFMutiara Puspahati CripstyaniNo ratings yet

- Subgrade ModulusDocument1 pageSubgrade ModulusMutiara Puspahati CripstyaniNo ratings yet

- PST Es e - PST SL e - en A4 PDFDocument14 pagesPST Es e - PST SL e - en A4 PDFMutiara Puspahati CripstyaniNo ratings yet

- Pore Clogging IngredientsDocument1 pagePore Clogging IngredientsMutiara Puspahati CripstyaniNo ratings yet

- General Chiller Catalogue EPCEN07-400 - Catalogues - EnglishDocument48 pagesGeneral Chiller Catalogue EPCEN07-400 - Catalogues - EnglishMutiara Puspahati CripstyaniNo ratings yet

- Direct Stiffness MethodDocument14 pagesDirect Stiffness MethodMutiara Puspahati CripstyaniNo ratings yet

- H VDocument2 pagesH VMutiara Puspahati CripstyaniNo ratings yet

- GoldenAdviceSeries BookDocument10 pagesGoldenAdviceSeries BookMutiara Puspahati CripstyaniNo ratings yet

- SINRe MDocument12 pagesSINRe MMutiara Puspahati CripstyaniNo ratings yet

- Faults in Indonesia PDFDocument20 pagesFaults in Indonesia PDFMutiara Puspahati CripstyaniNo ratings yet

- 3rd ICEEDM - 2016 - Bali-1 PDFDocument2 pages3rd ICEEDM - 2016 - Bali-1 PDFMutiara Puspahati CripstyaniNo ratings yet

- French PDFDocument226 pagesFrench PDFbiroutiNo ratings yet

- Manifacturing LineDocument10 pagesManifacturing Lineismet mehmeti100% (1)

- DESIGN OF CONCRETE STRUCTURES IIDocument100 pagesDESIGN OF CONCRETE STRUCTURES IIMd. Abdullah Al ArafatNo ratings yet

- Real Fire and Fire ModelingDocument14 pagesReal Fire and Fire ModelingmareNo ratings yet

- Errors in The Construction Site and How To Avoid ThemDocument6 pagesErrors in The Construction Site and How To Avoid ThemAriana CabellonNo ratings yet

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDocument33 pagesEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇No ratings yet

- Bondek 2BS-Latest PDFDocument52 pagesBondek 2BS-Latest PDFminnNo ratings yet

- Handouts-Concrete Common Field ProblemsDocument20 pagesHandouts-Concrete Common Field ProblemsAndresPeresNo ratings yet

- D9 AngsanaDocument46 pagesD9 AngsanaRachel IngramNo ratings yet

- Demonstrate teamwork in IBS scoring for a construction drawingDocument7 pagesDemonstrate teamwork in IBS scoring for a construction drawingNuratiqah SharifahNo ratings yet

- Lect2 - 1 11 2011 PDFDocument62 pagesLect2 - 1 11 2011 PDFgendadeyu552625100% (1)

- Reinforced Concrete Design II - ACI 318: Design of Hollow Block and Ribbed SlabsDocument37 pagesReinforced Concrete Design II - ACI 318: Design of Hollow Block and Ribbed Slabsmedo eidNo ratings yet

- Doka Formwork EngineeringDocument148 pagesDoka Formwork EngineeringLim Yew Kwang100% (1)

- Early Age Thermal and Shrinkage CracksDocument15 pagesEarly Age Thermal and Shrinkage Cracksgonzalez_m_aNo ratings yet

- DDM Design of Two Way Floor SlabsDocument43 pagesDDM Design of Two Way Floor SlabssabirfurqanNo ratings yet

- WCS 8034Document8 pagesWCS 8034Sani Oghang PekanNo ratings yet

- Tanjay 5 VariationDocument20 pagesTanjay 5 VariationJet ArcaNo ratings yet

- Supercast PVC : Centrally and Externally Placed PVC WaterstopsDocument4 pagesSupercast PVC : Centrally and Externally Placed PVC WaterstopsmystrophanNo ratings yet

- Basement Construction Method StatementDocument14 pagesBasement Construction Method StatementJinxian XuNo ratings yet

- 12 Steps Construction ProcessDocument2 pages12 Steps Construction ProcessBienvenida Ycoy MontenegroNo ratings yet

- Methodical Approach To Repair BuildingsDocument12 pagesMethodical Approach To Repair BuildingsSri vaishnavaNo ratings yet

- The Safe Handling Transportation and Erection of Precast ConcreteDocument45 pagesThe Safe Handling Transportation and Erection of Precast Concreteespanolal100% (3)

- Direct Design Method - FinalDocument52 pagesDirect Design Method - Finalpatrik gan100% (1)

- Modular Balcony Connectors Provide Thermal Break SolutionDocument2 pagesModular Balcony Connectors Provide Thermal Break SolutionCarolina CordeiroNo ratings yet

- Bebot 1Document9 pagesBebot 1Luna RonquilloNo ratings yet

- Status Rfi Pie Rack & Sleeper.Document20 pagesStatus Rfi Pie Rack & Sleeper.Kurnia AryadiNo ratings yet

- ACI 201.1R Guide To Conducting A Visual Inspection of Concrete in ServiceDocument19 pagesACI 201.1R Guide To Conducting A Visual Inspection of Concrete in ServiceRenato Rocha100% (1)

- Flat SlabDocument31 pagesFlat SlabAnjani Kumar SinghNo ratings yet

- Structural Design Report of Residential BuildingDocument39 pagesStructural Design Report of Residential BuildinghamiNo ratings yet

- KDS 14 20 01 콘크리트구조 설계 (강도설계법) 일반사항Document56 pagesKDS 14 20 01 콘크리트구조 설계 (강도설계법) 일반사항poit0987No ratings yet

- Concrete Pavement Characteristics & BehaviorDocument22 pagesConcrete Pavement Characteristics & BehaviorRuel B. Ramos Jr.No ratings yet