Professional Documents

Culture Documents

Technical Fiche Profile H65 Rev 13

Uploaded by

Satendra ThakurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Fiche Profile H65 Rev 13

Uploaded by

Satendra ThakurCopyright:

Available Formats

TECHNICAL FICHE Rev.

13

PROFILE H 65 of 17/06/2015

Page 1 of 2

The technical fiche of standard profile height 6,5 mm describes synthetically the main technical

characteristics of the product deducible from the drawings and the technical specifications of the suppliers.

Specifications of raw materials (UNI EN 485-2)

ALLOY STATE THICKNESS Rm Rp A5% A50 %

3003 H 28 190 160 2

0,20 0,45

3005 H18 0,25 0,28 210 ÷ 250 190 3

3005 H24* 0,31 0,39 170 ÷ 225 130 12

3005 H22* 0,35 145 ÷195 110 8

3005 H26* 0,31 195 ÷ 240 160 9

3105 H26 0,31 0,45 200 180 3

Tolerance on the thickness + 0,01 mm Legend:

Rm = unit breaking load in traction

* Material used in the production of bendable Rp = yield load

profile. A = elongation per cent

Composition of raw material (UNI EN 573-3)

ALLOY 3003

other other

Si Fe Cu Mn Mg Cr Zn Ti cad. tot. Al

0,6 0,70 0,05 ÷ 0,20 1,0 ÷ 1,5 -- -- 0,10 -- 0,05 0,15 rest

LEGA 3005

other other

Si Fe Cu Mn Mg Cr Zn Ti cad. tot. Al

0,60 0,70 0,30 1,0 ÷ 1,5 0,20 ÷ 0,60 0,10 0,25 0,10 0,05 0,15 rest

LEGA 3105

other other

Si Fe Cu Mn Mg Cr Zn Ti cad. tot. Al

0.60 0,70 0,05 ÷ 0,20 1,0 ÷ 1,5 -- -- 0,10 -- 0,05 0,15 rest

Specifications of the finished product

Tolerance on the wideness + 0,1 mm

Tolerance on the height + 0,1 mm

Tolerance on the length - 5 mm / + 10 mm

Check on the welding Test with penetrating liquid (0 points/m)

Check ultrasounds in line (Eddy Sensor)

Fogging test and volatile content According to part “C” and “G” of the rules UNI 1279-6 (0%)

Residual greases Test for the difference of weight after the degreasing

(< 5 mg/m)

Permeability of holes Test with flow meter (171 + 26 l/m)

Painting (if made) Paintings 100% polyester (thickness 20 -24 μm)

Painting on the side is 2.5 mm + 1 mm

Oxidation (if made) According to the type of colour thickness between 1- 5 μm

TECHNICAL FICHE Rev. 13

PROFILE H 65 of 17/06/2015

Page 2 of 2

C

H

Welding

Thickness

L

Thickness Thickness Thickness Thickness Thickness

L H C

Profile ± 0,01 mm ± 0,01 mm ± 0,01 mm ± 0,01 mm ± 0,01 mm

± 0,1 mm ± 0,1 mm ± 0,2 mm

Standard Std light Bendable Bend. thicker Bend. light

A040 4.00 6.50 4.50 0.28 -- -- -- --

A055 5,50 6,50 4,60 0,28 0.25 0,35 0.39 --

A075 7,50 6,50 5,10 0,28 0.25 0,35 0.39 0.31

A085 8,50 6,50 5,10 0,28 0.25 0,35 0.39 0.31

A095 9,50 6,50 5,10 0,28 0.25 0,35 0.39 0.31

A105 10.50 6.50 5.10 0.28 0.25 0.35 0.39 0.31

A115 11,50 6,50 5,10 0,28 0.25 0,35 0.39 0.31

A125 12.50 6.50 5.10 0.31 0.28 0.35 0.39 0.31

A135 13,50 6,50 5,10 0,31 0.28 0,35 0.39 0.31

A145 14,50 6,50 5,10 0,31 0,28 0,35 0.39 0.31

A155 15,50 6,50 5,10 0,31 0,28 0,35 0.39 0.31

A165 16,50 6,50 5,10 0,31 0,28 0,35 0.39 0.31

A175 17,50 6,50 5,10 0,31 0,28 0,35 0.39 0.31

A195 19,50 6,50 5,10 0,31 0,28 0,35 0.39 0.31

A215 21,50 6,50 5,10 0,39 -- 0,39 0.45 --

A235 23,50 6,50 5,10 0,39 -- 0,39 0.45 --

A255 25,40 6,50 5,10 0.45 -- 0,45 -- --

A265 26.50 6,50 5,10 0.45 -- 0,45 -- --

For painted spacers, outside dimensions are oversized of a level variable between 12 and 20 μ

For anodized spacers, outside dimensions are oversized of a level variable between 3 and 5 μ

Dimensions and tolerances

Quality aspects

2.1 Quality management

ALU-PRO is certified according to UNI EN ISO 9001:2008

2.2 Test of the product

Processes and routines are established to secure the quality of the delivered material. During production the spacer are constantly

monitored through a planning check. Data will be available for a period of 5 years.

2.3 Quality agreement

ALU-PRO fulfil the requirements of EN 1279-6 annex A. Specific quality agreement can be made to reduce inspection and test of

incoming material according to EN 1279-6 part 5.2.6.

Customer focus and warranty

To secure the performance of the spacer, the stock conditions must be acceptable. Broken packaging, high humidity and variations in

temperature will have an effect on the spacer surface. It is recommended to check out these specific points.

On all aluminium spacer bars, ALU-PRO offers a 5 year product warranty. The warranty covers free exchange of spacers in case of a

defect. The spacers must have been stored, installed and used according to present norms and technical standards.

You might also like

- Specifications of Raw Materials: Technical Fiche Profile H 65Document3 pagesSpecifications of Raw Materials: Technical Fiche Profile H 65RigoRuizNo ratings yet

- GB 700 88Document5 pagesGB 700 88trungNo ratings yet

- AS 3678 STEEL GRADE 350Document3 pagesAS 3678 STEEL GRADE 350gsoaresrj80No ratings yet

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Document6 pagesINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezNo ratings yet

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- General Catalouge OldDocument186 pagesGeneral Catalouge Oldlifib23970No ratings yet

- CHIYODA WELDING PRODUCTS Combination Welding and Cutting Torches GuideDocument13 pagesCHIYODA WELDING PRODUCTS Combination Welding and Cutting Torches Guideandi permanaNo ratings yet

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- Instrumentation Tubing ENDocument5 pagesInstrumentation Tubing ENLuis CasasNo ratings yet

- CuNi18Zn20 M18 CDocument3 pagesCuNi18Zn20 M18 CJORDAN JUNOR ELLANo ratings yet

- Specification For Galvanized Steel: Raw Material SpecificationsDocument2 pagesSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNo ratings yet

- Seamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsDocument2 pagesSeamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsWiryanto DewobrotoNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- g250 1Document2 pagesg250 1kiata2201No ratings yet

- Sabater Fundimol Catalog p22 23Document2 pagesSabater Fundimol Catalog p22 23Pep VasilevaNo ratings yet

- Nedal Aluminium BV Alloy Data Sheet for EN-AW 6060 Extrusion AlloyDocument1 pageNedal Aluminium BV Alloy Data Sheet for EN-AW 6060 Extrusion Alloyankur panwarNo ratings yet

- Fittings and TolerancesDocument31 pagesFittings and TolerancesVinay GautamNo ratings yet

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- ASTM A672 Grade CC 60 EFW Pipe SuppliersDocument4 pagesASTM A672 Grade CC 60 EFW Pipe SuppliersRELIABLE PIPES & TUBESNo ratings yet

- Solid Bronze Bearing: Technical DataDocument6 pagesSolid Bronze Bearing: Technical DatadangminhNo ratings yet

- Hallite 15 rod seal designDocument2 pagesHallite 15 rod seal designNal FivefivetwooneNo ratings yet

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Document5 pagesDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNo ratings yet

- Medium Strength Extrusion Alloy Data SheetDocument1 pageMedium Strength Extrusion Alloy Data Sheetankur panwarNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- Commercial-Purity Aluminium1050Document1 pageCommercial-Purity Aluminium1050SiyabulelaNo ratings yet

- Non Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% MinimumDocument1 pageNon Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% Minimumprivate 2No ratings yet

- Commercial Purity Aluminium1050Document1 pageCommercial Purity Aluminium1050HermanNo ratings yet

- Web Datasheet b4.1Document3 pagesWeb Datasheet b4.1Reza Khatibi NasabNo ratings yet

- Sticle Prismatice Indicatori NivelDocument2 pagesSticle Prismatice Indicatori NivelGeorge TanasaNo ratings yet

- 066 enDocument2 pages066 enlesonspkNo ratings yet

- Tubes Sicam PDFDocument28 pagesTubes Sicam PDFDobrica PetrovicNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- Aps Bluescope Asnzs3678 G250 PlateDocument2 pagesAps Bluescope Asnzs3678 G250 PlateMuhammad Adam PratamaNo ratings yet

- CW50MMDocument96 pagesCW50MMപോൾ വീട്ടിൽ ബീനോയ്No ratings yet

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGDocument2 pagesKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGBiaizidi Abbou SamirNo ratings yet

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- Metal Coated HSLA Steels, EN10346:2015Document3 pagesMetal Coated HSLA Steels, EN10346:2015ronakguptaNo ratings yet

- ALUMINIUM ALLOYS FOR EXTRUDED PROFILESDocument19 pagesALUMINIUM ALLOYS FOR EXTRUDED PROFILESDon JonesNo ratings yet

- T 753 PG 199-202 PDFDocument4 pagesT 753 PG 199-202 PDFJossimar PerezNo ratings yet

- Standard Tolerance Guide Sheet: Rubber MouldingDocument1 pageStandard Tolerance Guide Sheet: Rubber MouldingMarcos Antonio RossiNo ratings yet

- 1050 Data Sheet: Chemical CompositionDocument1 page1050 Data Sheet: Chemical CompositionMiguel Angel Rocca HuaytaNo ratings yet

- CORUS Celsius 355 Hollow SectionsDocument24 pagesCORUS Celsius 355 Hollow SectionsPaul HardingNo ratings yet

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Document1 pageMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinNo ratings yet

- STANDARD - ASTM A653 - Brief DescriptionDocument7 pagesSTANDARD - ASTM A653 - Brief DescriptionSeyong ParkNo ratings yet

- Vortex 70Document92 pagesVortex 70MajazNo ratings yet

- Hallite t58Document6 pagesHallite t58ShaneNo ratings yet

- Montana 120Document84 pagesMontana 120Abdul BasithNo ratings yet

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- DIN 17174 SEAMLESS STEEL TUBES FOR LOW TEMP USEDocument7 pagesDIN 17174 SEAMLESS STEEL TUBES FOR LOW TEMP USEdjmattmNo ratings yet

- TB-62mm - V1 Rev2Document84 pagesTB-62mm - V1 Rev2Mohsin KhanNo ratings yet

- Aisi 9254 - Spring SteelDocument2 pagesAisi 9254 - Spring SteelSergio100% (1)

- Compare S355J2+N, St52-3, Fe510DDocument4 pagesCompare S355J2+N, St52-3, Fe510DGANESHNo ratings yet

- En 10305 en 10296Document4 pagesEn 10305 en 10296Siti Zaleha HmlonNo ratings yet

- S-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDDocument6 pagesS-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDSergio AlejandroNo ratings yet

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 pagesAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamNo ratings yet

- CORSON (C7025) : Cu-Ni-Si ALLOYDocument2 pagesCORSON (C7025) : Cu-Ni-Si ALLOYstrip1No ratings yet

- Thyssenkrupp s355jr Product Information Precision Steel en PDFDocument2 pagesThyssenkrupp s355jr Product Information Precision Steel en PDFjackcan501No ratings yet

- Sliding TB 105mmDocument42 pagesSliding TB 105mmSaud AffanNo ratings yet

- Iust v9n3p1 enDocument16 pagesIust v9n3p1 enSatendra ThakurNo ratings yet

- Chemical composition limits for steel gradesDocument8 pagesChemical composition limits for steel gradesrobin regoNo ratings yet

- IATF16949 ExovDocument59 pagesIATF16949 Exovhappy441No ratings yet

- Industris P.O 31307Document7 pagesIndustris P.O 31307Satendra ThakurNo ratings yet

- Thyssenkrupp Materials (UK) LTD Aluminium Alloy 6082: Material Data SheetDocument2 pagesThyssenkrupp Materials (UK) LTD Aluminium Alloy 6082: Material Data SheetSatendra ThakurNo ratings yet

- TDS YIEH 6082 PlateDocument4 pagesTDS YIEH 6082 PlateSatendra ThakurNo ratings yet

- Metals 12 01326 v2Document17 pagesMetals 12 01326 v2Satendra ThakurNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- EN AW-6082 Data Sheet: High Strength Aluminum Alloy for Structural ApplicationsDocument1 pageEN AW-6082 Data Sheet: High Strength Aluminum Alloy for Structural ApplicationsemilasanovskiNo ratings yet

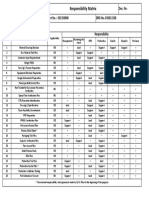

- Responsibility Matrix: Doc. No-Part Name: CUP Part No.: 501350000 DRG No.-035011538 Customer ResponsibilityDocument1 pageResponsibility Matrix: Doc. No-Part Name: CUP Part No.: 501350000 DRG No.-035011538 Customer ResponsibilitySatendra ThakurNo ratings yet

- Grey Cast Iron CompositionDocument6 pagesGrey Cast Iron CompositionSatendra ThakurNo ratings yet

- Grey IronDocument1 pageGrey IronSatendra ThakurNo ratings yet

- 431 Martensitic Stainless Steel BarDocument4 pages431 Martensitic Stainless Steel BarKrishnanNo ratings yet

- Ductile Iron Check ValveDocument1 pageDuctile Iron Check ValveSatendra ThakurNo ratings yet

- Anodisation PDFDocument12 pagesAnodisation PDFprasannaNo ratings yet

- 46 Heat SinksDocument41 pages46 Heat SinksDhanus KodiNo ratings yet

- How To Store Hydraulic Cylinders - SafelyDocument2 pagesHow To Store Hydraulic Cylinders - Safelyankesh_ghoghariNo ratings yet

- Goodway Machine Corp.Document20 pagesGoodway Machine Corp.mihovcaNo ratings yet

- Displacement and Double Decomposition ReactionDocument22 pagesDisplacement and Double Decomposition ReactionSaksham GuptaNo ratings yet

- Set8ans 12Document9 pagesSet8ans 12WalerNo ratings yet

- Tippmann Industrial Products Sewing MachineDocument16 pagesTippmann Industrial Products Sewing MachinePeter DavidsonNo ratings yet

- Ash Handling SystemDocument25 pagesAsh Handling Systemgpeck0012763No ratings yet

- A 249Document1 pageA 249AnuranjanNo ratings yet

- Vertical Subsystems and Rigid Frame AnalysisDocument20 pagesVertical Subsystems and Rigid Frame Analysisarif_rubinNo ratings yet

- Nanotechnology PPT R22Document35 pagesNanotechnology PPT R22keerthi goratiNo ratings yet

- Refining HB 2000 For CD RomDocument10 pagesRefining HB 2000 For CD RomCarlos Alberto Ubillas AlcaldeNo ratings yet

- CONCENTRATION AND DILUTION CALCULATIONSDocument32 pagesCONCENTRATION AND DILUTION CALCULATIONSRaja Mohan Gopalakrishnan100% (2)

- Nitoflor FC550Document4 pagesNitoflor FC550Venkata Raju KalidindiNo ratings yet

- Polymer Processing With Super Critical Fluids by SG KazarianDocument24 pagesPolymer Processing With Super Critical Fluids by SG KazarianLia NashNo ratings yet

- 89-1501 Air Carbon Arc GougingDocument36 pages89-1501 Air Carbon Arc GougingdevakimdNo ratings yet

- Cutler Hammer Residential ATS Switch ManualDocument24 pagesCutler Hammer Residential ATS Switch ManualjacksmarineNo ratings yet

- Hexavalent Chromium PresentationDocument58 pagesHexavalent Chromium PresentationGuru SamyNo ratings yet

- Maharashtra Jeevan Pradhikaran Schedule of Rates 2018-19Document3 pagesMaharashtra Jeevan Pradhikaran Schedule of Rates 2018-19tatyarao6538No ratings yet

- CS Steel Pipe Selection GuideDocument40 pagesCS Steel Pipe Selection GuideImran HussainNo ratings yet

- Past Midterm ExamDocument12 pagesPast Midterm Examrony16novNo ratings yet

- Cement Industry - Maihar Cement (Birla Gold)Document13 pagesCement Industry - Maihar Cement (Birla Gold)Gaurav Kumar100% (2)

- BCA Publication "Making Good & Finishing"Document14 pagesBCA Publication "Making Good & Finishing"MisterphylNo ratings yet

- ETPDocument25 pagesETPAnkurNo ratings yet

- How To Design Concrete Structures Using Eurocode 2 PDFDocument83 pagesHow To Design Concrete Structures Using Eurocode 2 PDFbarbiesmilez100% (1)

- Straw Reinforced Unfired Clay BricksDocument54 pagesStraw Reinforced Unfired Clay BricksHayana M UNo ratings yet

- Ready Mix ConcreteDocument28 pagesReady Mix ConcreteLance Sabu100% (1)

- Altos Loose Tube, Gel-Free Cable: Features and BenefitsDocument3 pagesAltos Loose Tube, Gel-Free Cable: Features and BenefitsSosialNo ratings yet

- Enkadrain: High Performance Drainage Composites Product OverviewDocument12 pagesEnkadrain: High Performance Drainage Composites Product Overviewahmedmido14No ratings yet

- Ba00194cen 1413 PDFDocument120 pagesBa00194cen 1413 PDFJohnny PaloozaNo ratings yet

- Commercial Desalination Products Powered by Renewable EnergyDocument28 pagesCommercial Desalination Products Powered by Renewable EnergyCognosferaNo ratings yet