Professional Documents

Culture Documents

Data Sheet OMI-2 - Optical Machine Interface

Data Sheet OMI-2 - Optical Machine Interface

Uploaded by

ruiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet OMI-2 - Optical Machine Interface

Data Sheet OMI-2 - Optical Machine Interface

Uploaded by

ruiCopyright:

Available Formats

Data sheet

H-2000-2205-01-A

OMI-2 - optical machine interface

The OMI-2 is a combined optical receiver/interface, which conveys and processes

signals between an inspection probe and the CNC machine control

1 2 3 4 5

OMI-2 with

mounting

bracket

OMP60

CNC 6

machine

control 7

8

FEATURES OMI-2 STATUS LEDs

● Modulation transmission for improved rejection Visual indication of system status is provided by LEDs.

of optical interference. 1. LED (Yellow) - START signal status.

Lit when a start signal is transmitted to the probe.

● Compatible with Renishaw machine probes that

use modulated transmission. 2. LED (Red) - Low battery life.

● Toughened glass window. Lit when probe battery voltage falls below a set level.

● Sealed to IPX8 for machine tool environment. 3. LED (red, green) - Probe status.

Lit when OMI-2 is powered.

● Internal range selection:

Green - Probe seated.

Reception (RX) 50% or 100%

Red - Probe triggered or an error has occurred.

Transmission (TX) 50% or 100%

Both factory set to 100% 4. LED (red, blue, violet, yellow) - Error.

Indicates transmission error condition

● User configurable inputs:

e.g. optical beam obstructed / probe out of optical

Machine start Machine control M code command

range / probe switched off / battery exhausted.

(level / pulsed).

Auto start Start signal at one second intervals. Red - Signal from probe has either failed or

has stopped.

● User configurable outputs:

Blue - A second modulated signal is being received.

Probe status 1. SSR. N/O / N/C (level / pulsed).

Yellow - Interference or weak probe signal is being

Probe status 2a. 5 V isolated driven skip received.

(level / pulsed).

Violet - Interference or a weak probe signal has

Probe status 2b. Driven at power supply voltage caused the trigger instant to be delayed.

(level / pulsed).

5. LED (red, yellow, green) - Signal condition.

Error SSR. N/O / N/C.

Signal condition received from probe.

Low battery SSR. N/O / N/C. Red - There is no signal from probe.

OMI-2 OPTIMUM POSITION SETTING Yellow - Signal received from probe is either too

To assist finding the optimum position for the OMI-2 weak or interference is present.

during system installation, signal condition received Green - The condition of signal received from

is indicated on the red / yellow / green LED (item 5). probe is good.

WARNING 6. Sealing gland.

If two systems are operating in close proximity, take care 7. Conduit.

to ensure that signals transmitted from the OMP on one 8. Cable.

machine, are not received by the OMI-2 on the other

machine, and vice versa.

The OMI-2 may have to be shielded from direct light sources.

Renishaw plc T +44 (0)1453 524524

New Mills, Wotton-under-Edge, F +44 (0)1453 524901

Gloucestershire GL12 8JR E uk@renishaw.com

United Kingdom www.renishaw.com

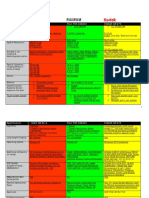

Installation Wiring diagram

dimensions mm (ins)

(with the output groupings shown)

84 (3.30) 46.7 (1.84)

Turquoise

40 (1.57) 40 (1.57) Probe status 1

Turquoise/black (SSR)

OMI-2 Violet

Low battery

40 (1.57)

Violet/black (SSR)

Green

Error

Green/black (SSR)

45 (1.77)

White

63 (2.48)

+ve

Machine

Brown start input

–ve

5V

Driver Yellow

Signal Probe status 2a

(5 V isolated

Grey

Return driven skip)

Driver

16 (0.63) Orange Probe status 2b (driven at

power supply voltage)

Mounting bracket 12 to 30 V Red

allows OMI-2 directional setting Power supply

0V Black

(12 to 30 V)

19 (0.75)

25 25

Green/yellow

(0.98) (0.98) Screen

Machine ground (star point)

38 (1.50)

Cable installation

3 holes Ø6.4 (0.25) 3 grip protrusions ● Install OMI-2 with cable exiting from

100.5 (3.95) lower side for good coolant run off.

2.0 ● Cable entry to the OMI-2 is sealed with

(0.08)

45 (1.77) (0.98) (1.18)

a gland.

30

● Cable protection against physical damage

should be provided by flexible conduit.

25

Adjustable 6 x paired holes ● Route the cable away from potential

setting Ø5.3 (Ø0.20) sources of electro magnetic interference.

permit OMI-2

mounting ● Maintain screen through cable joins.

in alternative

● Cable specification

orientation

2.0 (0.08) 45 (1.77) 45° Polyurethane Ø7.5 (Ø0.29) 13 core

90 (3.54) screened cable, each core 18 x 0.1

Standard lengths 8 m (26 ft) or 15 m (49 ft).

Parts list - Please quote the Part No. when ordering equipment

Type Part No. Description

OMI-2 A-5191-0049 OMI-2 with 8 m (26 ft) cable, magnetic label, tool kit and User’s guide.

OMI-2 A-5191-0050 OMI-2 with 15 m (49 ft) cable, magnetic label, tool kit and User’s guide.

Mounting bracket A-2033-0830 Mounting bracket complete with fixing screws, washers and nuts.

Conduit kit A-4113-0306 Conduit kit with 1 m (3.28 ft) of polyurethane conduit and bulkhead connector

(a clearance hole for M 16 thread is required).

Window A-5191-0019 Comprising window assembly with ‘O’ ring, 3 x stainless steel M3 x 14 mm long

replacement kit screws, 3 x stainless steel M3 x 5 mm long screws and 2.5 mm hexagon wrench.

Tool kit A-5191-0300 2.5mm hex wrench, 4 mm hex wrench, 14 x ferrules,

*H-2000-2205-01*

2 x M5 screws, 2 x M5 washers and 2 x M5 nuts.

User’s guide H-2000-5233 OMI-2 Installation and user’s guide.

For worldwide contact details please visit our web site at www.renishaw.com/contact

© 2005 Renishaw plc Renishaw reserves the right to change specifications without notice Issued 03.05 Part no. H-2000-2205-01-A

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Automated Water Billing SystemDocument47 pagesAutomated Water Billing SystemTame PcAddict89% (27)

- Radar InfoDocument4 pagesRadar InfoJose Norton DoriaNo ratings yet

- Guia Prof LPDocument136 pagesGuia Prof LPJose Norton DoriaNo ratings yet

- Altivar 312 - ATV312H075N4Document4 pagesAltivar 312 - ATV312H075N4Jose Norton Doria100% (1)

- 1FT7044 1AF71 1CH1 Datasheet enDocument1 page1FT7044 1AF71 1CH1 Datasheet enJose Norton DoriaNo ratings yet

- 6gk7 343 1ex30 0xe0 Simatic Net CP Industrial Ethernet CP 343 1 Siemens ManualDocument6 pages6gk7 343 1ex30 0xe0 Simatic Net CP Industrial Ethernet CP 343 1 Siemens ManualJose Norton DoriaNo ratings yet

- Data Sheet: PNP Darlington TransistorDocument7 pagesData Sheet: PNP Darlington TransistorJose Norton DoriaNo ratings yet

- Huawei GPON HG8247H WithRouter v2 PDFDocument4 pagesHuawei GPON HG8247H WithRouter v2 PDFJose Norton DoriaNo ratings yet

- 2013varistors CatalogueDocument32 pages2013varistors CatalogueJose Norton DoriaNo ratings yet

- Audi RNSDocument4 pagesAudi RNSJose Norton DoriaNo ratings yet

- NNSD 698 SDocument40 pagesNNSD 698 SAnonymous 2GVabYh40W100% (1)

- Msi MS-10581Document44 pagesMsi MS-10581Captain444No ratings yet

- Manual Panasonic Sa He70 enDocument20 pagesManual Panasonic Sa He70 enItzel MartínezNo ratings yet

- 15A04601 Microprocessors & MicrocontrollersDocument1 page15A04601 Microprocessors & Microcontrollers17BF1A04L7 kalyanNo ratings yet

- Tle Css - Grade 10: Let Us DiscoverDocument7 pagesTle Css - Grade 10: Let Us DiscoverKentJosephEspinosaPaluaNo ratings yet

- Installshield Updates and PatchesDocument11 pagesInstallshield Updates and PatchesLuis Agustin Suaña JalaNo ratings yet

- Servlets File UploadingDocument4 pagesServlets File UploadingAnonymous GQ6TmqNo ratings yet

- Bassi MVD V11 EngDocument4 pagesBassi MVD V11 EngmohammedNo ratings yet

- Tutorial Ip 2 Win EnglishDocument25 pagesTutorial Ip 2 Win EnglishGarry Zein0% (1)

- Explain The Meaning of A Mechtronic SystemDocument8 pagesExplain The Meaning of A Mechtronic Systemross bennettNo ratings yet

- FilterSense, Manual, EM 30T v2.02, Installation and OperatingDocument34 pagesFilterSense, Manual, EM 30T v2.02, Installation and OperatingcanchaneNo ratings yet

- PADS Layout TipsDocument5 pagesPADS Layout TipsAvala LokeshNo ratings yet

- Linux Command Reference: File Commands System InfoDocument1 pageLinux Command Reference: File Commands System InfosamNo ratings yet

- Partes FRYMASTER Freidora H50.explodata PDFDocument44 pagesPartes FRYMASTER Freidora H50.explodata PDFLuminita SirghiNo ratings yet

- Jetty 9 New FeaturesDocument32 pagesJetty 9 New FeaturesgirglNo ratings yet

- 111 310 - Falk Orange Peel Coupling Guards - CatalogDocument28 pages111 310 - Falk Orange Peel Coupling Guards - CatalogNickNo ratings yet

- Group 1: Cruz, Marvi Ned Xigrid Garcia, Claira Lauryn Pagkaliwangan, Prescious Palad, Kathleen GinmerDocument41 pagesGroup 1: Cruz, Marvi Ned Xigrid Garcia, Claira Lauryn Pagkaliwangan, Prescious Palad, Kathleen GinmerAngel JuanNo ratings yet

- Megaraid Sas 9260-4I, Sas 9260-8I, and Sas 9260De-8I Raid ControllersDocument4 pagesMegaraid Sas 9260-4I, Sas 9260-8I, and Sas 9260De-8I Raid ControllersDimitri GutiérrezNo ratings yet

- Fire Alarm Address Check ListDocument11 pagesFire Alarm Address Check ListRa ArNo ratings yet

- M-DAC Service Manual - 20120710Document29 pagesM-DAC Service Manual - 20120710DRF254No ratings yet

- Washing Machine: Technical InformationDocument72 pagesWashing Machine: Technical Informationugano529510No ratings yet

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNo ratings yet

- Assignment OracleDocument4 pagesAssignment OracleKyle Austin PabustanNo ratings yet

- FileDocument37 pagesFilelgelectronicNo ratings yet

- Lexf4913 01 Emcp 3 1 PDFDocument2 pagesLexf4913 01 Emcp 3 1 PDFAhmedNo ratings yet

- Huawei ERAN6 0 KPI IntroductionDocument57 pagesHuawei ERAN6 0 KPI IntroductionPedro_1976100% (2)

- MPS ManualDocument90 pagesMPS ManualjoseadrianoNo ratings yet

- NormalizationDocument33 pagesNormalizationGerson Cebrero BelenNo ratings yet

- Chapter 01 - Introduction To SmartFormsDocument42 pagesChapter 01 - Introduction To SmartFormstopankajNo ratings yet