Professional Documents

Culture Documents

Page 270

Page 270

Uploaded by

tito3007Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Page 270

Page 270

Uploaded by

tito3007Copyright:

Available Formats

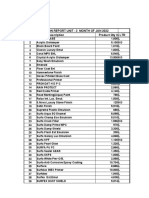

PC BOARD MAKING CHEMICALS, ACCESSORIES

NEGATIVE ACTING LIQUID NEGATIVE RESIST DEVELOPER

PHOTO RESIST

A liquid, spray-on coating in its own spray bottle. This developer will develop the ER-71

When a coated board is exposed to UV light, it is Negative Acting Resist; resist areas not

then developed in the ER-8 liquid developer. A hardened via UV light are dissolved

remaining etch resist will protect the copper from away. UV hardened areas remain to

an etchant bath, thus producing your circuit. resist the etchant.

Negative acting. Coats approx. 1700 sq. inches.

May be flow coated or brushed.

4 oz. Bottle (Includes Sprayer)-No. ER-71

16 oz. Can Developer-No. ER-8

PC BOARD ETCHING SOLUTION

(LIQUID FERRIC CHLORIDE)

This Ferric Chloride is one of the most DRY CONCENTRATE ETCHANT

popular and safest etching materials for (FERRIC CHLORIDE)

copper clad boards available. A quart of

etching solution will etch approximately

960 square inches of PC board. Ferric Chloride is the best choice for etch-

Caution: use only with plastic or glass ing copper PC boards. Datak supplies

trays FeCl in a dry, powder form and the user

must add it to water to make the etching

solutions. The 1/4 lb. package produces 1 pint which will etch

approx. 200 sq. inches of standard copper board.

12-2038 Quart (32 oz)

1/4 lb. FeCl etchant powder-No. ER-3

1 lb. FeCl etchant powder-No. ER-21

12-2039 Gallon (128 oz) 2 lb. FeCl etchant powder-No. ER-22

TINNIT TM

TIN PLATE

Tinnit TM will plate a copper clad board with a bright tin plate

approx. .0004” thick. Enhances solderability, resists oxidation. Also use

POWER ETCH PUMP

on card edge contact fingers. Supplied as a dry concentrate; just add The etch pump and distributor tubing may be used to accelerate

water. One pint plates up to 600 sq. inches of copper. May be used to etching and free you from some of the constant agitating of the etch

plate some other metals such as brass, bronze, iron; anything more solution. Bubbles provide both agitatation and also some oxygen

active than tin. which inhances the process

Plating is complete in about 10 minutes in a fresh solution.

Tinnit TM is supplied as a dry mixture with indefinite shelf life.

When mixed with water, the solution has

approximately a 2 month life.

TINNIT 1 Pint Size - No. ER-18

TINNIT 1/2 Gallon Size - No. ER-181

TINNIT TM

KIT Etch Pump Set - No. ER-12

This handy kit contains package of No. ER-18 Tinnit

(sufficient to make 1 pint and plating 600 sq. in. of cop-

per), plastic tray (8” x 6” x 2”), 16 oz. plastic bottle for

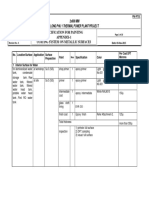

DATAK SYSTEM INSTRUCTION MANUAL

storing tinnit between uses and tool for handling P.C.

board during tinning process. A manual that gives detailed instructions for

most of the Datak PC board making prod-

ucts including: NEG-FAST film, Negative

No.12-800 Photo Resist, Presensitized PC Boards,

TinnitTM Tin Plating, Etching. A complete

guide for PC board making via DATAK

products.

No. 12-760A

270

You might also like

- Midi Drum Kit - 1: TEACH-IN 2008Document85 pagesMidi Drum Kit - 1: TEACH-IN 2008carl12No ratings yet

- A Textbook Organic Chemistry - CompressedDocument1,224 pagesA Textbook Organic Chemistry - CompressedEJ CUBERNo ratings yet

- 05-Humble Homemade Hifi - HATT MK-VIIIDocument9 pages05-Humble Homemade Hifi - HATT MK-VIIIjns0110No ratings yet

- Glass StructureDocument116 pagesGlass StructureArion Dan67% (3)

- Weathering and ErosionDocument49 pagesWeathering and Erosionjoshua.brussell100% (25)

- 1002 - EPE Bounty Treasure HunterDocument7 pages1002 - EPE Bounty Treasure HunterLaurentiu IacobNo ratings yet

- Sacrificial Anode Cathodic ProtectionDocument8 pagesSacrificial Anode Cathodic Protectionnero daunaxilNo ratings yet

- Standard System 2015 7th EditDocument130 pagesStandard System 2015 7th EditLisa Shenton100% (2)

- Isolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CDocument2 pagesIsolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CMark JosephNo ratings yet

- Crude Distillation Unit & Vacuum Distillation UnitDocument10 pagesCrude Distillation Unit & Vacuum Distillation Unitsenthilkumarbt100% (1)

- MDSP Diag 1Document3 pagesMDSP Diag 1Tyron RebellonNo ratings yet

- Obturation Tech FinalDocument143 pagesObturation Tech FinalFrancis Prathyusha100% (2)

- Expt Nichem Boren: Preliminary Data SheetDocument16 pagesExpt Nichem Boren: Preliminary Data Sheetshortfilms babaNo ratings yet

- PC Materials: Caig Cleaners, Chemicals & CoatingsDocument2 pagesPC Materials: Caig Cleaners, Chemicals & CoatingsbeemasundarNo ratings yet

- Prototyping Flyer WebDocument3 pagesPrototyping Flyer WebZoltars ButtNo ratings yet

- ILERTENNA English Manual PDFDocument20 pagesILERTENNA English Manual PDFJernej BattistaNo ratings yet

- Equinox II11 ADocument5 pagesEquinox II11 AMaulana AdiNo ratings yet

- Classic Pedal Kit: Assembly InstructionsDocument12 pagesClassic Pedal Kit: Assembly InstructionslanoimageNo ratings yet

- AcSim V12Document3 pagesAcSim V12carlosNo ratings yet

- Sprayable Syntactic Materials: Radius Compound Coring/Bulk Print BlockerDocument1 pageSprayable Syntactic Materials: Radius Compound Coring/Bulk Print BlockerjohnNo ratings yet

- Catalog 201204072062Document1 pageCatalog 201204072062tito3007No ratings yet

- Od67 10Document3 pagesOd67 10kascelNo ratings yet

- Jenny Greenteeth V1.1: Weird Chorus /putchbend / Ringmod Based On Merlin Blencowe 'S CircuitDocument4 pagesJenny Greenteeth V1.1: Weird Chorus /putchbend / Ringmod Based On Merlin Blencowe 'S CircuitcrackintheshatNo ratings yet

- Optimum Anode-to-Cathode Speed: Copper XHB 5305Document2 pagesOptimum Anode-to-Cathode Speed: Copper XHB 5305Roger Mendoza CaceresNo ratings yet

- U Boot V15Document4 pagesU Boot V15Mattia Terri TerrandoNo ratings yet

- Valv e Tizer V15bDocument6 pagesValv e Tizer V15bVince WaldonNo ratings yet

- Distortion - Based On The JHS® Andy Timmons™Document4 pagesDistortion - Based On The JHS® Andy Timmons™ZalNo ratings yet

- Turnabout Jhs Andy TimosDocument4 pagesTurnabout Jhs Andy TimosbufalmacoNo ratings yet

- Dr. Phil. V1.1aDocument5 pagesDr. Phil. V1.1acrackintheshatNo ratings yet

- Fosroc Products and UsesDocument4 pagesFosroc Products and UsesMaheshNo ratings yet

- Amtech Inv Handout Rev 1115 PDFDocument2 pagesAmtech Inv Handout Rev 1115 PDFTom TomNo ratings yet

- Cygnus DocumentationDocument12 pagesCygnus DocumentationARITOSOUL341No ratings yet

- Condor V1.1c: Runoffgroove's Famous Cabinet SimulatorDocument4 pagesCondor V1.1c: Runoffgroove's Famous Cabinet SimulatorGeko7No ratings yet

- Tipos de Uninoes en Materiale de Fibra de VidrioDocument2 pagesTipos de Uninoes en Materiale de Fibra de VidrioANTONIO PEREIRANo ratings yet

- Component List: Buy Extras Item Name Required NumberDocument6 pagesComponent List: Buy Extras Item Name Required NumbermjovicaNo ratings yet

- Boss Ce-2 Chorus PlanosDocument12 pagesBoss Ce-2 Chorus Planosprofugo2807No ratings yet

- Lexan Thermoclear Technical ManualDocument26 pagesLexan Thermoclear Technical ManualPavo PerkovićNo ratings yet

- Monthly Reports 2022Document31 pagesMonthly Reports 2022Anonymous sFDTzxBGNo ratings yet

- Ic Packaging/Intro: - Ics Are at The Core of A Modern Digital System - Many Systems Fit Entirely On A Single Ic (Soc)Document34 pagesIc Packaging/Intro: - Ics Are at The Core of A Modern Digital System - Many Systems Fit Entirely On A Single Ic (Soc)mohammed zubairNo ratings yet

- Horndog: Based On The Experimentalist Anonymous Bit CrusherDocument4 pagesHorndog: Based On The Experimentalist Anonymous Bit CrusherSimon RubinNo ratings yet

- Blues Crusher SchematicDocument28 pagesBlues Crusher Schematiczeus maxNo ratings yet

- E-Brite 2.0 Ag RTP: Non-Cyanide Alkaline Silver PlatingDocument4 pagesE-Brite 2.0 Ag RTP: Non-Cyanide Alkaline Silver PlatingUsman ali CheemaNo ratings yet

- Tempest: Friedman BE-OD / Dirty ShirleyDocument11 pagesTempest: Friedman BE-OD / Dirty ShirleyAle MontoyaNo ratings yet

- 10W HF Amp20191212Document16 pages10W HF Amp20191212ffwwfNo ratings yet

- Properties and Applications of Panasonic Ecool R-1787Document4 pagesProperties and Applications of Panasonic Ecool R-1787jackNo ratings yet

- Hatt-Se: The HATT Special Edition - A High-End Mini MonitorDocument6 pagesHatt-Se: The HATT Special Edition - A High-End Mini Monitorjns0110No ratings yet

- Specification For Painting Appendix-1 Coating System On Metallic SurfacesDocument18 pagesSpecification For Painting Appendix-1 Coating System On Metallic SurfacesLy Thanh HaNo ratings yet

- Fan Coil UnitDocument16 pagesFan Coil UnitSivarajkumar GanesanNo ratings yet

- Hvac Accessory CatalogDocument19 pagesHvac Accessory Catalogmakmak9No ratings yet

- Understanding The Nelco N8000 Cyanate Ester EpoxyDocument4 pagesUnderstanding The Nelco N8000 Cyanate Ester EpoxyjackNo ratings yet

- ITC BenefitsDocument2 pagesITC BenefitsLuz SmithNo ratings yet

- 22-000XXX RE Siniloan, Laguna (Vertical Drop, Termination, Testing and Activation of 15 Cameras, DVR, HDD, Monitor and UPS)Document20 pages22-000XXX RE Siniloan, Laguna (Vertical Drop, Termination, Testing and Activation of 15 Cameras, DVR, HDD, Monitor and UPS)Ralph Jason JacintoNo ratings yet

- Cornish CC-1-GC-1Document12 pagesCornish CC-1-GC-1Tanker BorysNo ratings yet

- HIT RE 100 Adhesive Anchor Product Data 1353047Document46 pagesHIT RE 100 Adhesive Anchor Product Data 1353047Daniel ChangNo ratings yet

- VFE TractorBeamDocument10 pagesVFE TractorBeamantonio martosNo ratings yet

- TE Connectivity - White Paper - Mounting, Termination, and Cleaning of PCB RelaysDocument2 pagesTE Connectivity - White Paper - Mounting, Termination, and Cleaning of PCB Relaysmthf02No ratings yet

- Nanokeyer Building Instructions PCB Rev d1 PDFDocument35 pagesNanokeyer Building Instructions PCB Rev d1 PDFSreejith SreedharanNo ratings yet

- How 12 Oz Copper PCB Increases Efficiency in Electronic DevicesDocument6 pagesHow 12 Oz Copper PCB Increases Efficiency in Electronic DevicesjackNo ratings yet

- Marco Durathon III Catalog 1986Document20 pagesMarco Durathon III Catalog 1986Alan MastersNo ratings yet

- Spring Reverb MK II BOM - SPRING REVERBDocument1 pageSpring Reverb MK II BOM - SPRING REVERBdreadlock holidayNo ratings yet

- TYCO Dry-Type Sprinklers (DS-1)Document10 pagesTYCO Dry-Type Sprinklers (DS-1)kuraimundNo ratings yet

- Circuitbenders - Phonic Taxidermist Build GuideDocument5 pagesCircuitbenders - Phonic Taxidermist Build GuideLéorNo ratings yet

- Team Repair - NewDocument36 pagesTeam Repair - NewSachin D PatilNo ratings yet

- 01Document4 pages01Jorge ZambranoNo ratings yet

- Compact Disc Manufacturing: From Wikipedia, The Free EncyclopediaDocument6 pagesCompact Disc Manufacturing: From Wikipedia, The Free EncyclopediaJustin CookNo ratings yet

- Diavolino InstruxDocument30 pagesDiavolino InstruxMark LachowitzerNo ratings yet

- Solstice Documentation PDFDocument10 pagesSolstice Documentation PDFIvan RodriguezNo ratings yet

- Reasons For Hot Dip Galvanizing - Galvanising Process - Wedge GalvanizingDocument2 pagesReasons For Hot Dip Galvanizing - Galvanising Process - Wedge GalvanizingluthfibomentNo ratings yet

- Influence of Solidification Rate On Material Properties of Cast Aluminium Alloys Based On Al-Si-Cu and Al-Si-MgDocument12 pagesInfluence of Solidification Rate On Material Properties of Cast Aluminium Alloys Based On Al-Si-Cu and Al-Si-Mgkt rajaNo ratings yet

- DB Sokalan CP5 Nov2006Document2 pagesDB Sokalan CP5 Nov2006salehi.infinity0% (1)

- Missile MaterialsDocument4 pagesMissile Materialsmed turkiNo ratings yet

- Understanding Cut-Off Value and Concentration Limits in CLP Regulation and China GHSDocument39 pagesUnderstanding Cut-Off Value and Concentration Limits in CLP Regulation and China GHSBartosz GrzegorowskiNo ratings yet

- 2016-Review. Oil and Grease Removal From WastewatersDocument102 pages2016-Review. Oil and Grease Removal From WastewatersSilvia Nathalia ContrerasNo ratings yet

- Monitoring of Prestressing Forces in Prestressed CDocument27 pagesMonitoring of Prestressing Forces in Prestressed CSofía Córdoba SáenzNo ratings yet

- Experimental Development of Johnson-Cook Strength Model For Different Carbon Steel Grades and Application For Single Pass Hot RollingDocument11 pagesExperimental Development of Johnson-Cook Strength Model For Different Carbon Steel Grades and Application For Single Pass Hot RollingakhmadmarufnurNo ratings yet

- AA6082 Corrosion Behaviour .,2017Document9 pagesAA6082 Corrosion Behaviour .,2017Ahsan Iqbal AlamgirNo ratings yet

- Chapter 1-INTRODUCTIONSDocument15 pagesChapter 1-INTRODUCTIONSGirman ranaNo ratings yet

- GBidron JMatProcTechDocument16 pagesGBidron JMatProcTechKue DroidNo ratings yet

- Ch04 LectureDocument96 pagesCh04 LectureTsaiBenyanNo ratings yet

- S Y B SC Syllabus 1Document71 pagesS Y B SC Syllabus 1Dr. Mithil Fal DesaiNo ratings yet

- Dieless Wire DrawingDocument16 pagesDieless Wire DrawingRohit GothwalNo ratings yet

- 2530Document4 pages2530pollux23100% (1)

- Bel NotesDocument7 pagesBel NotesUsama JanNo ratings yet

- 2100 2800 Series PDFDocument2 pages2100 2800 Series PDFhendrabudimanNo ratings yet

- 5.4.1 PRACTICAL Student Copy - Chemicla Composition of A Compound 5.4.1Document1 page5.4.1 PRACTICAL Student Copy - Chemicla Composition of A Compound 5.4.1Declan QuinNo ratings yet

- Cambridge Lower Secondary Checkpoint: Science 1113/02Document8 pagesCambridge Lower Secondary Checkpoint: Science 1113/02igloo79No ratings yet

- Sika WT-240 P - PDSDocument3 pagesSika WT-240 P - PDSDavid V. BaltazarNo ratings yet

- St. Joseph'S College of Engineering Department of Chemical Engineering Multiple Choice QuestionsDocument8 pagesSt. Joseph'S College of Engineering Department of Chemical Engineering Multiple Choice QuestionsSurya SuryaNo ratings yet

- Mat Sci Homework 1 Solutions SP2015 PDFDocument3 pagesMat Sci Homework 1 Solutions SP2015 PDFacar1No ratings yet