Professional Documents

Culture Documents

PTC305C Series: Vishay Cera-Mite

Uploaded by

ref.mtu.533Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTC305C Series: Vishay Cera-Mite

Uploaded by

ref.mtu.533Copyright:

Available Formats

PTC305C Series

www.vishay.com

Vishay Cera-Mite

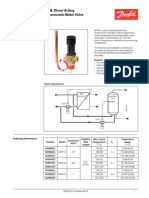

PTC Thermistors Motor Start Packages

FEATURES

• Large diameter ceramic pellets for high starting

current

• Various package sizes for optimum inrush

current and switching time

• Rugged mechanical construction for reliable long life

operation

• UL approved packages

• Plastic case mold UL 94 V-0 approved

• Adapted accessories for easy mounting

• Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

QUICK REFERENCE DATA

PARAMETER VALUE UNIT

Resistance value at 25 °C 15 to 75 APPLICATIONS

Tolerance on resistance value ± 30 % • Single phase motor start assist in

Maximum current ratings 6 to 36 ARMS - Refrigerator systems

Switching temperature 110 to 120 °C - Air-conditioning systems

Switching times (typical) 0.25 to 1.0 s - Heat-pumps

Maximum voltage rating 410, 500 VRMS - Small compressors

Operating temperature range -10 to +80 °C

Storage temperature range -25 to +105 °C

PTC MOTOR START SELECTION CHART

MAX.

SWITCH CURRENT COMPRESSOR COMPRESSOR

VISHAY CERA-MITE CASE RDYN () R25 () VOLTAGE

TIME RATING RANGE RANGE

PART NUMBER STYLE ± 20 % ± 30 % RATING

t (s) at 230 V (ARMS) (BTU 000) (HP)

(VRMS)

PTC305C20 C 25 35 0.25 10 410 10 to 28 0.75 to 2.0

PTC305C21 C 35 50 0.35 8 410 8 to 18 0.5 to 1.5

PTC305C22 C 50 75 0.50 6 410 5 to 12 0.25 to 1.0

PTC305C19 B 20 30 0.50 18 500 20 to 50 1.5 to 4.0

PTC305C12 B 25 40 0.60 15 500 18 to 42 1.5 to 3.5

PTC305C2 B 50 85 1.00 12 500 10 to 25 1.0 to 2.5

PTC305C9 A 10 15 0.50 36 500 28 to 68 3.0 to 7.0

PTC305C11 A 12.5 20 0.60 30 500 28 to 62 3.0 to 6.0

PTC305C1 A 25 42.5 1.00 24 500 14 to 36 1.5 to 3.5

PTC MOTOR START ACCESSORY SELECTION CHART

ACCESSORY

DESCRIPTION

PART NUMBER

PTCAUX36-520M Round mounting bracket for case style C

PTCAUX36-520H Round mounting bracket for case style A and B

PTCAUX7-36-5C U-shaped mounting bracket for case style B

PTCAUX7-36-4C U-shaped mounting bracket for case style A

PTCAUX50-1278 Jumper wire for case style A

Revision: 11-Sep-15 1 Document Number: 23086

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

PTC305C Series

www.vishay.com

Vishay Cera-Mite

ECONOMICAL SOLID STATE TORQUE ASSIST FOR HEAT PUMPS, ROOM AIR, COMMERCIAL AND

RESIDENTIAL AIR CONDITIONING AND REFRIGERATION SYSTEMS

Positive Temperature Coefficient Themistors (PTC) have Safety Agency Recognition

been used for many years in millions of HVAC applications Vishay Cera-Mite motor start PTC thermistors are

to provide starting torque assistance to Permanent Split recognized by Underwriter Laboratories file E97640 in

Capacitor (PSC) single phase compressor motors. accordance with standard for controllers and refrigeration

Sizes are available to cover the full range of 120 V/240 V components UL 873 or UL 60730; and Canadian Standard

PSC compressor motors. C22.2 No. 24. All packages and accessories are

RoHS-compliant.

RELATIVE COMPARISON OF VARIOUS MOTOR STARTING METHODS

Three methods have historically been employed to generate The importance of each category is dependent upon the

starting torque for PSC motors. All are well-proven motor application and industry sector.

technologies and may be compared relative to one another In general, if the PTC starter produces sufficient starting

based upon categories shown below. torque, it is considered the simplest and most economical

choice.

Table 1

MECHANICAL ELECTRICAL FINANCIAL

STARTING EASE SENSITIVE

PANEL ACCELERATION ACCELERATION RESET INVENTORY

METHOD TO EMI/RFI PURCHASED

OF SPACE TORQUE (SWITCH) TIME TECHNOLOGY MIX RELIABILITY

MOUNTING GENERATED COST

WIRING REQUIRED PRODUCED TIME REQUIRED REQUIRED

DIRECTION

Simple 3 min to

PTC starter Lowest No Lowest Fixed No Solid State Lowest Highest Lowest

2 wire 5 min

Start cap

Moderate

with PTC 2 min to

2 wire or Medium Yes Medium Fixed No Solid State Medium Medium Medium

acting as a 5 min

3 wire

current relay

Start cap

Difficult Variable

used with Electro

4 wire or Highest Yes Highest based on None Yes Highest Lowest Highest

potential or Mechanical

5 wire motor speed

current relay

SIMPLIFIED PTC STARTING DIAGRAM

Start Sequence Restart

When starting the compressor, contactor (M) closes; the It is important to provide time between motor starts to allow

PTC, which is at low resistance, provides starting current to the PTC to cool to near its initial temperature. This time is

the motor’s auxiliary winding. After time delay (t), the current usually 3 min to 5 min and is determined by the thermostat

passing through the PTC causes it to heat and “switch” to a (THERM) or separate time-delay relay (TR). Attempts to

very high resistance. At this point the motor is up to speed restart in less time may be successful depending on

and the run capacitor (CR) determines the current in the compressor equalization, line voltage, temperature, and

auxiliary winding. The PTC remains hot and at high other conditions. If the motor were to stall in a locked-rotor

resistance as long as voltage remains on the circuit. When state, overload device (PD or TS) would open the line and a

contactor (M) opens, shutting off voltage to the compressor, further time delay would occur until the motor overload is

the PTC cools to its initial low resistance and is again ready reset. Motor start PTCs are applied to compressors having

to provide torque assist on the next startup. means to equalize pressure during shutdown.

Fig T-2 TYPICAL PTC CHARACTERISTICS

L1 PD AS A MOTOR START DEVICE

M Protective PSC Fig T-3

THERM TS MOTOR

Device CURRENT

Internal 10 000 10.0

Motor MAIN

TR

PTC Resistance ()

PTC Current (ARMS)

M Winding

Overtemp

AC Line Switch 1000 1.0

120 or 240 Optional OFF

VOLTS AC Time Delay TR CR AUX.

Relay

M

100 Switch Time (t) 0.1

Protective

Device M PTC RESISTANCE

L2

Low Voltage Control Transformers Not Shown 10 0.01

50 100 150

PTC Temperature °C

Revision: 11-Sep-15 2 Document Number: 23086

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

PTC305C Series

www.vishay.com

Vishay Cera-Mite

START AND ACCELERATION TORQUES SINGLE PHASE PSC HIGH EFFICIENCY COMPRESSORS

The use of a PTC start assist insures sufficient acceleration

torque to overcome not only breakaway friction, but also

parasitic asynchronous torques associated with the 5th and

100

7th motor harmonics or lamination slot harmonics. A1 Full Load max.

A2 Operating Point Torque

Acceleration Time Considerations

Percent Rated Speed

75

The time to accelerate a rotating machine is:

2 2

RPM x WK lb ft

accelerating time (s) = -------------------------------------------------------------------------- 50

average torque lb ft x 308 B1 B2

average torque = curve B - curve A

25

1. If (curve B - curve A) is zero or less, the motor may stall. 5th

Possible Region of

2. In calculating torque available from curve B, allowance 7th

Harmonic Torques

should be made for cusps in the torque curve due to 0 Slot

100 200

harmonics. The time needed to accelerate from rest to Cold Breakaway Torque Percent Rated Torque

1/2 speed is critical, as the average torque available in

this region is limited. Select a PTC with sufficient CURVE A1 CURVE A2 CURVE B1 CURVE B2

Torque req’d Torque req’d Motor speed Motor speed

switching time (t) to accelerate the compressor. to accelerate to accelerate versus torque versus torque

unloaded compressor at with run cap with run cap

3. Scroll and rotary compressors may have less breakaway compressor partial differential only and PTCR

torque than shown. pressure

4. A compressor with no equalization may require over

100 % starting torque and time as long as several

seconds. PTC starters not recommended.

CONSIDERATIONS FOR CURRENT IN PTC APPROXIMATE EQUIVALENT CIRCUIT PSC MOTOR

AT ZERO SPEED

HP x 746

I L run = ---------------------------------- x I L start I L run Fig. T-5

V M x pf x eff

Line Voltage V M

For running conditions: L1 L2

IL

If V aux = V M then I M and I aux = -------

2 IL IM RM (1) XM (1)

IL VM VM I aux

If V aux V M then I aux = ------- x ------------ and Z aux = ---------- Ic

2 V aux I aux

C

For the greatest starting torque, PTC should be chosen Raux Xaux

PTC

to make:

V M x I M = V aux x I aux . In many cases the auxiliary Vaux

IR

Volt-Amperes are limited to about 50 % of the main winding

Volt-Amperes to get 50 % to 70 % rated torque. * R and X are total of stator and rotor

Then at start, with PTC in series:

Fig T-6

Z' aux = R +Z

PTC aux Simplified voltage diagram of the PSC motor at operating

VM speed.

I Rstart through PTC = ------------

Z aux Note

VM 1 (1) I (auxiliary current) leads I (main current) by 80° to 90° when C

A M

I Cstart through Run Cap = -------; X C = ------------- (run capacitor) is chosen for balanced operation at 3/4 to full

XC 2fC

load. Line Power Factor = sine 2

I aux start = I +I VM

R start C start

If Zaux is low impedance, less than 10 % of RPTC Applied

Voltage

VM (1)

then it can be ignored and IPTC at start = ---------------- xC

R PTCR = IA

=V

C IM

C

This closely approximates the condition for motors over 1/2 V PT IA (1)

VA

HP

Revision: 11-Sep-15 3 Document Number: 23086

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

PTC305C Series

www.vishay.com

Vishay Cera-Mite

EFFECT OF PTC RESISTANCE ON STARTING TORQUE OF PSC MOTORS

Table 2

MOTOR HP LOCKED ROTOR TORQUE WITH STARTING TORQUE WITH RUN CAP AND PTC (% RATED TORQUE) (SEE B)

(TABLE 4) RUN CAP ONLY % RATED TORQUE RESISTANCE (RDYN)

(NOTE 7) (SEE A) 50 25 20 12.5 10

0.5 25 % to 35 % 70 % to 100 % 80 % to 100 % NA NA NA

1 25 % to 35 % 50 % to 70 % 70 % to 100 % NA NA NA

2 20 % to 30 % 40 % to 60 % 60 % to 90 % 70 % to 100 % 70 % to 100 % 80 % to 100 %

3.5 20 % to 30 % NA 40 % to 60 % 50 % to 85 % 60 % to 90 % 70 % to 100 %

5 15 % to 25 % NA NA 40 % to 60 % 50 % to 75 % 60 % to 90 %

6.5 15 % to 25 % NA NA NA 40 % to 70 % 50 % to 80 %

A. Rated torque is the torque at full speed rated load. B. Figure T-4 shows effect of using PTC to increase starting

It is calculated as: torque. For reciprocating compressors, it is advised to

HP x 5250

Torque lb - ft = ---------------------------- choose a resistance value that gives at least 50 % rated

RPM torque at locked rotor. Scroll and rotary compressors

The range shown includes both normal slip and high may require less torque.

efficiency low slip motors. Starting torque varies as:

(Line Voltage)2

TYPICAL PTC CURRENT VS. TIME SHOWING DEFINITION OF RDYN AND SWITCH TIME (t)

Fig T-7

RDYN

Peak OSCILLOSCOPE Time (t) KM (130 °C - T0)

Current

SHUNT

V2PTC

M = PTC mass (g)

T0 = PTC temp at time 0

IPTC

ERMS K = 0.75 J/g/°C

(Normalized)

230 VRMS PTC

IPTC (ARMS)

R DYN =

IPTC max.

20 % Peak

Current Switch Time (t)

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Motor PTC Switchout

Contactor

Closes Time to Switch (s)

START CAPACITOR REPLACEMENT STARTING CURRENT APPROXIMATION BASED

Capacitor Starting Comparison ON

1

Some PSC motors have historically been started with a X C = -------------

2fC

capacitor and relay. To deliver the same starting current as

a start capacitor, a PTC resistance is available for Table 3

approximately equal ohms. Table 3 can be used for

START CAPACITOR PTC VALUE

conversion.

50 μF 50

Even though the start current may be the same, the start

75 μF 37.5

torques may differ depending on the motor design.The PTC

has a fixed time built in. The start capacitor will stay in the 100 μF 25

circuit until a relay switches it out. The longer time provided 125 μF 20

by the capacitor and relay may be needed on applications 200 μF 12.5

where equalization is not present or adequate reset time is 250 μF 10

not available.

Revision: 11-Sep-15 4 Document Number: 23086

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

PTC305C Series

www.vishay.com

Vishay Cera-Mite

PTC SELECTION

• Choosing the best PTC for an application is a simple not harm the motor, but may not be optimum with regards

matter. See Table 4 and Table 2. Vishay Cera-Mite PTCs to acceleration dynamics, or power dissipation

are available in three case sizes (A, B, and C) • The PTC is generally self protecting when applied within

• Table 4 indicates the correct case size for the application. the voltage and current ratings

Table 2 shows how to choose the correct resistance value • All PTC305C Series starters and accessories are

• Using a device too small or resistance too high will give RoHS compliant

inadequate starting performance. An oversize device will

Table 4

PTC MOTOR START SELECTION CHART

VISHAY SWITCH COMPRESSOR

RESISTANCE () (3) CURRENT MAX. VOLTAGE AVG. POWER

CERA-MITE CASE TIME (4) RANGE (8)

RATING (5) RATING (6) DISSIPATION (7)

PART STYLE (2) RDYN R25 (t) s

(ARMS) (VRMS) (W) BTU (000) HP

NUMBER (2) ± 20 % ± 30 % AT 230 V

PTC305C20 (1) C 25 35 0.25 10 410 3.5 10 to 28 0.75 to 2.0

PTC305C21 C 35 50 0.35 8 410 3.5 8 to 18 0.5 to 1.5

PTC305C22 (1) C 50 75 0.50 6 410 3.5 5 to 12 0.25 to 1.0

PTC305C19 (1) B 20 30 0.50 18 500 7 20 to 50 1.5 to 4.0

PTC305C12 (1) B 25 40 0.60 15 500 7 18 to 42 1.5 to 3.5

PTC305C2 B 50 85 1.00 12 500 7 10 to 25 1.0 to 2.5

PTC305C9 (1) A 10 15 0.50 36 500 9 28 to 68 3.0 to 7.0

PTC305C11 A 12.5 20 0.60 30 500 9 28 to 62 3.0 to 6.0

PTC305C1 (1) A 25 42.5 1.00 24 500 9 14 to 36 1.5 to 3.5

UL File E97640

Notes

(1) Preferred values.

(2) Part number is stamped on the device for UL recognition. The customer part number can also include 1 or 3 character alpha-numeric suffix

to designate specific customer marking and accessory furnished. The suffix is not marked on the part. Certified outline drawing and

complete part number will be furnished on request for specific applications.(Example: PTC305C19K01.) Mounting brackets and other

accessories are to be ordered separately.

(3) RDYN is nominal resistance equal to U/I when 230 V, 50 Hz/60 Hz is applied (see Fig T-7). This resistance determines current and maximum

starting torque at the moment of application of voltage to the motor and can be measured with an oscilloscope.

For receiving inspection or routine trouble shooting, the DC resistance at 25 °C (R25) as measured with an ohmmeter is approximately 50 %

greater. For example: PTC305C20 measured with an ohmmeter would be 35 ± 30 % tolerance.

(4) Resistance values are duplicated in several case sizes (i.e.: PTC305C20, C12, and C1) to provide longer switch time (t) and higher current

ratings (see Fig. T-7). Larger parts may be needed for more difficult starting conditions (voltage or temperature) or may be used for

accelerating fans against back pressure.

(5) Maximum current in the PTC is determined by

Maximum Line Voltage

-------------------------------------------------------------

Minimum R DYN

Motor auxiliary winding impedance is usually small compared to PTC resistance, and does not materially affect PTC current.

Current in PTC is a percentage of the full motor inrush (locked rotor) current; usually 30 % to 50 % (see Fig T-5).

(6) In application, the maximum voltage is the voltage that appears across the run capacitor at rated speed, high line, light load. This is not the

applied line voltage (see Fig T-6).

THESE DEVICES ARE INTENDED FOR APPLICATION ON 240 VOLT LINES OR SYSTEMS WITH MAXIMUM LINE VOLTAGE UP TO 265

V. The PTC305C20, 21 and 22 are also used on 120 V systems where the motor is designed to use same run capacitor and PTC as equivalent

230 V compressor.

(7) This is the power used to keep the PTC switched in a high impedance state under full load running conditions at typical ambient

temperature.

(8) BTU and horsepower ranges are for reference only. PTC may be applied outside those ranges as long as maximum voltage and maximum

current are not exceeded. Scroll and rotary compressors may require less starting assistance allowing use of smaller devices.

Revision: 11-Sep-15 5 Document Number: 23086

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

PTC305C Series

www.vishay.com

Vishay Cera-Mite

DIMENSIONS FOR PTC MOTOR START DEVICES in inches (millimeters)

• PACKAGED MOTOR START PTCS ARE OFFERED IN THREE DIFFERENT CASE SIZES TO

ACCOMMODATE THE RANGE OF PSC COMPRESSOR MOTORS SERVED

Case Style C

SAP ORDERING PART NUMBER

Case Style C is a 2-terminal single pellet device with current

carrying capacity up to 10 A. For proper mounting a bracket CASE C MOUNTING BRACKET

has to be ordered separately. PTC305C20

PTC305C21 PTCAUX36-520M (Round)

PTC305C22

Fig T-8 0.609

0.975

(24.75)

0.329

(8.35)

1.780 (15.45) 1.025 0.358

(45.2) 0.641 (26.05) (9.10)

max. (16.30)

Weld 0.25 0.135

Projection (2) (6.35) 0.140 DIA.

Typ. (3.50

0.050 (1.25) HT. TYP. ± 0.07)

0.175 (4.45) WD. TYP. Round Bracket - Spring Steel Phosphate &

Oil Finish. Accepts #6 Sheet Metal Screw

0.810 0.200 0.920 0.298 (7.55)

(20.6) (5.1) (23.35) 0.328 (8.35) 0.579

0.880 max. 0.980 (14.7)

(22.4) (24.90) 0.609

(15.5)

Case Style B

SAP ORDERING PART NUMBER

Case Style B is a 2-terminal single pellet unit with current

carrying capacity up to 18 A. For proper mounting a CASE B MOUNTING BRACKET

U shaped or round bracket has to be ordered separately. PTC305C2

PTCAUX7-36-5C (U-shaped)

PTC305C12

PTCAUX36-520H (Round)

PTC305C19

Fig T-9 1.475

(37.45)

1.525

(38.75)

0.550

0.213 (13.95)

0.15 (3.81) OD x 0.055 (1.4) HT 0.223 DIA. 0.110 (2.8) Nail Pierce 0.580

2.37 (60.2) max. (5.54 ± 0.13) 0.120 (3.05) Ref. (14.75) 0.135 DIA.

Weld 0.25 4 places 0.140

Projection (3) (6.35) (3.50

0.050 (1.27) HT. Typ. Typ. 0.990 1.490 ± 0.07)

(25.1) (37.8)

0.175 (4.45) WD. Typ. 0.650 1.010

(16.5) (25.7) 1.510

max. (38.4)

1.05 (26.7)

1.430 (36.3) 0.298

1.344 0.20 1.50 1.530 (38.9) 1.44 (7.55) 0.579

0.25 (6.35) max. (34.1) (5.1) (26.7) 0.328 (14.7)

2 places 1.406 Typ. (38.1) max. (8.35) 0.609

(35.9) max. (15.5)

Steel U-Bracket - Accepts #8 Sheet Metal Screw

Round Bracket - Spring Steel Phosphate &

Oil Finish. Accepts #6 Sheet Metal Screw

Case Style A

SAP ORDERING PART NUMBER

Case Style A is a 3-terminal device that incorporates two

pellets to be connected in parallel, resulting in lower MOUNTING

CASE A WIRE JUMPER

resistance values and current carrying capacity up to 36 A. BRACKET

For proper mounting a U shaped or round bracket has to be PTC305C1 PTCAUX7-36-4C

(U-shaped) PTCAUX50-1278

ordered separately. To connect the two PTC pellets in PTC305C9 (9.75" (248) Long

parallel, a jumper wire can be ordered separately. PTCAUX36-520H 105 °C wire)

PTC305C11 (Round)

Fig T-10 1.475

(37.45)

0.550 1.525 0.135 DIA.

0.185 DIA. (13.95) (37.75) 0.140

5.25 (133.5) max. 0.25 0.190 0.110 (2.8) Nail Pierce 0.580 (3.50 ± 0.07)

(6.35) (4.75 ± 0.08) 0.120 (3.05) Ref. (14.75)

2.75 (69.9) max. Typ.

(to end of Q.C.)

0.15 (3.8) OD 0.990 1.490

0.20 (5.1) Typ. (25.1) (37.85)

x 0.055 (1.4) HT 1.010 1.510

4 Places (25.7) (38.35)

1.590* 1.05

(40.4) (26.7)

1.690 0.298

(43.0) (7.55) 0.579

1.44 0.328 (14.7)

0.650 (36.6) (8.35) 0.609

0.25 (6.35) 1.716 * Installed Dimension max.

Weld (16.5) (15.5)

max. (43.6) 1.50 max.

Projection (2) Round Bracket - Spring Steel Phosphate & Oil Finish.

3 Places 1.781 0.050 (1.27) HT. Typ.

(38.1)

max.

Steel U-Bracket - Accepts #8 Sheet Metal Screw

(45.4) 0.175 (4.45) WD. Typ. Accepts #6 Sheet Metal Screw

OPERATING TEMPERATURE CONNECTION DIAGRAMS

Under normal operation, the ceramic pellet inside the case PTC Thermistors Motor Start units are connected directly

can reach a temperature of 150 °C. The plastic case material across the PSC motor’s “run” capacitor. Case style A is a

has been recognized by UL for operation up to this 3-terminal device and uses an external jumper wire to

temperature. The actual temperature on the outside of the connect the two internal pellets in parallel. A special

case will be approximately 100 °C while the motor is “piggyback” terminal on the jumper wire provides for two

running. An appropriate mounting location and 105 °C, connections on one side of the A-style case.

600 V wiring are recommended. Fig T-11 Fig T-12

Motor Run Motor Run

Cap Cap

A Style B & C Style

3-Terminal Case 2-Terminal Case

Revision: 11-Sep-15 6 Document Number: 23086

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

PTC305C Series

www.vishay.com

Vishay Cera-Mite

VISHAY CERA-MITE MOTOR START FEATURES

ADVANCED CERAMIC ENGINEERING FOR HVAC

Vishay Cera-Mite’s capability in large diameter ceramic

pellets, unique formulations tailored to motor starting, and

heavy duty electrode systems, have been developed and

proven with the cooperation of HVAC industry experts over

a period of more than 30 years.

INHERENT PERFORMANCE

Large diameter pellets make possible low resistance start

devices needed to match torque requirements of high

efficiency compressor motors.

Various package sizes offer selection of timing intervals,

providing optimum switching time without dependence on

sensing speed, counter EMF, or current.

RUGGED MECHANICAL CONSTRUCTION

Vishay Cera-Mite PTC cases are molded from a UL 94 V-0

high temperature, engineered plastic/glass composite.

Heavy duty aluminum contact plates and stainless steel

force springs are scaled to the pellet sizes and current

ratings to insure no internal arcing and to enhance quick

reset time.

Unbreakable metal mounting brackets, sold separately,

attach securely with a single screw. The “U” - brackets

developed by Vishay Cera-Mite feature lower power

consumption and greater reliability by maximizing case to

ground thermal impedance.

SIMPLE AND ECONOMICAL

A solid state device requiring only 2 quick connect wires and

one bracket screw to install. Compared to the alternative

start capacitor and relay, PTC start devices save several

wires, occupy less panel space, mount more easily, and

cost less.

OUTSTANDING RELIABILITY

Over a twenty year period, with an installed base of millions

of Vishay Cera-Mite PTC start devices, experience has

demonstrated reliability at 1.0 FIT or less. Users have

benefited from very low warranty expense.

RESTART CONSIDERATIONS

A properly sized PTC will provide adequate starting current and starting time with a cool down time of 3 min to 5 min,

coordinating perfectly with standard “off delay” equalization timers restart characteristics of the three case sizes are shown.

Fig T-13 Fig T-14 Fig T-15

CASE STYLE C CASE STYLE B CASE STYLE A

100 100 100

Cold Cold

Cold Start

Start Start

75 75 75

5 Min Cooling

% Initial 50 50 50

Current

3 Min 3 Min

5 Min Coolin g Cooling

3 Min Cooling 5 Min Cooling

Cooling 25

25 25

0 0 0

0 0.2 0.4 0.6 0.8 0 0.2 0.4 0.6 0.8 1.0 0 0.2 0.4 0.6 0.8 1.0 1.2

Time (s) Time (s) Time (s)

Revision: 11-Sep-15 7 Document Number: 23086

For technical questions, contact: ceramitesupport@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as Halogen-Free follow Halogen-Free

requirements as per JEDEC JS709A standards. Please note that some Vishay documentation may still make reference

to the IEC 61249-2-21 definition. We confirm that all the products identified as being compliant to IEC 61249-2-21

conform to JEDEC JS709A standards.

Revision: 02-Oct-12 1 Document Number: 91000

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Smart Grid TechnologyDocument43 pagesSmart Grid Technologyarnav LakshkarNo ratings yet

- Usp Description and SolubilityDocument1 pageUsp Description and SolubilityvafaashkNo ratings yet

- Datasheet ThermistorDocument5 pagesDatasheet ThermistorwaniabuNo ratings yet

- 240Wp HHV Solar DATASHEETDocument1 page240Wp HHV Solar DATASHEETsugunec2013No ratings yet

- 2020-Plastim-Product-Catalog - Resistencias - 1Document7 pages2020-Plastim-Product-Catalog - Resistencias - 1Joel Alevxandr OsorttoNo ratings yet

- PTCTLDocument4 pagesPTCTLinfo.wenamericaNo ratings yet

- Raychem DS Eu1381 QTVR enDocument3 pagesRaychem DS Eu1381 QTVR enTrung Trinh BaoNo ratings yet

- 200706-PD-Overview-for Distributor TrainingDocument96 pages200706-PD-Overview-for Distributor TrainingChester Dalitso MwanzaNo ratings yet

- ASTM PVC Corrosion Coupon Racks v1.0Document1 pageASTM PVC Corrosion Coupon Racks v1.0Naranyu JantarawongsaNo ratings yet

- HOTSTART Bulletin Y Cord Part Numbers 120115Document2 pagesHOTSTART Bulletin Y Cord Part Numbers 120115adeleng2025No ratings yet

- 200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CDocument9 pages200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CselocaNo ratings yet

- Vishay Bccomponents: FeaturesDocument16 pagesVishay Bccomponents: FeaturesPetrutStefanVartolomeiNo ratings yet

- Etr4 11 ADocument4 pagesEtr4 11 AMathiasNo ratings yet

- PTC Thermistors As Heating Elements: Disk Shaped, 12 VDocument9 pagesPTC Thermistors As Heating Elements: Disk Shaped, 12 VCezaryCezasNo ratings yet

- Type Veot and VeosDocument8 pagesType Veot and VeosMahmoud WalyNo ratings yet

- Type Veot and VeosDocument8 pagesType Veot and VeosBalu M100% (1)

- E211.21 Usl Catalogo Tpi Veot-Veos TrenchDocument8 pagesE211.21 Usl Catalogo Tpi Veot-Veos TrenchMario Eduardo Najera RamosNo ratings yet

- Thermistor DatasheetDocument8 pagesThermistor DatasheetWeb BrowserNo ratings yet

- Catalogo de Calentadores Imc700Document52 pagesCatalogo de Calentadores Imc700PieroNo ratings yet

- 700HRM12TA17Document3 pages700HRM12TA17ittg ittgNo ratings yet

- Reset Table FussesDocument1 pageReset Table FussesCarlos OrtizNo ratings yet

- TT Control 600P 220SDocument4 pagesTT Control 600P 220Snanda09lvNo ratings yet

- CAT#450R5-SCR Power RegulatorDocument10 pagesCAT#450R5-SCR Power RegulatorGarlapati TrinadhNo ratings yet

- Dutymax HDSR Brochure PDFDocument7 pagesDutymax HDSR Brochure PDFGaith Ghaleb SharabatiNo ratings yet

- Vs-30Bq100Pbf: Vishay High Power ProductsDocument7 pagesVs-30Bq100Pbf: Vishay High Power ProductspatopickNo ratings yet

- Catalogue - 71-T8 (Rev06)Document7 pagesCatalogue - 71-T8 (Rev06)Suntech Testing Limited STLNo ratings yet

- 01 SAF CatalogDocument95 pages01 SAF Catalogcheveresan123100% (1)

- SMT Current Sense Transformers: A Í Püééí A Í PüééíDocument9 pagesSMT Current Sense Transformers: A Í Püééí A Í PüééíAENo ratings yet

- UK Conductive Heater RangeDocument4 pagesUK Conductive Heater RangeAnonymous zwSP5gvNo ratings yet

- Watlow Power Switching DevicesDocument38 pagesWatlow Power Switching DevicesEliasNo ratings yet

- HeatingDocument10 pagesHeatingNisar AhmedNo ratings yet

- PTC Air HeaterDocument10 pagesPTC Air HeaterandreNo ratings yet

- Product Data: Convertible Air Handlers 1-1/2 - 5 TonDocument28 pagesProduct Data: Convertible Air Handlers 1-1/2 - 5 TonJonathan CapraNo ratings yet

- TCLT100. Series Optocoupler, Phototransistor Output, SOP-4L, Long Mini-Flat PackageDocument10 pagesTCLT100. Series Optocoupler, Phototransistor Output, SOP-4L, Long Mini-Flat PackageHưng HQNo ratings yet

- PTC MotorStarting Disk LPCDocument9 pagesPTC MotorStarting Disk LPCOswaldo CriolloNo ratings yet

- Cs T 240 User ManualDocument3 pagesCs T 240 User ManualTien NguyenNo ratings yet

- Thermostat HousingDocument2 pagesThermostat HousingCrespo JorgeNo ratings yet

- Ultramax Range: Technical Data SheetDocument2 pagesUltramax Range: Technical Data Sheetsofiane aliNo ratings yet

- Aluminum Gravity Die Casting Cost Reducing PTC Stirring ProcessDocument20 pagesAluminum Gravity Die Casting Cost Reducing PTC Stirring ProcessAjoy RajNo ratings yet

- Siemens Motor StarterDocument72 pagesSiemens Motor StarterRitesh ChaudharyNo ratings yet

- Informacion TransferenciaDocument4 pagesInformacion TransferenciaHector Lizardo AndinoNo ratings yet

- Danfoss TermostatoDocument4 pagesDanfoss TermostatoEdgar Poma MedinaNo ratings yet

- 0859 Solid State Relays Data SheetDocument23 pages0859 Solid State Relays Data SheetglennandlynneNo ratings yet

- Data+Sheet+Ntc 5d5Document5 pagesData+Sheet+Ntc 5d5rafael penaNo ratings yet

- 02 - 202-203 DC ContactorDocument2 pages02 - 202-203 DC Contactorshailesh284No ratings yet

- RTI PTC Thermistor CatalogDocument20 pagesRTI PTC Thermistor Cataloghenrycervantes4No ratings yet

- Solid State Relays Interface Relays: Technical CatalogueDocument35 pagesSolid State Relays Interface Relays: Technical CatalogueHisham AllamNo ratings yet

- Vibration and Temperature Monitoring Solutions PDFDocument34 pagesVibration and Temperature Monitoring Solutions PDFyana sopian hidayatNo ratings yet

- PVM (X) Series: Vertical Multistage PumpsDocument9 pagesPVM (X) Series: Vertical Multistage PumpsDiego MorenoNo ratings yet

- NTC SiemensDocument164 pagesNTC Siemenskipkoech_rotichNo ratings yet

- SDT S 105LMRDocument2 pagesSDT S 105LMReaherreramNo ratings yet

- DC Saffro en TN230015Document1 pageDC Saffro en TN230015Abderramen AbdelmouhssinNo ratings yet

- MLV Automotive Series: SMD VaristorsDocument5 pagesMLV Automotive Series: SMD VaristorsIgor PNo ratings yet

- Specification Sheet: Density Measurement of Petroleum Products by Hydrometer MethodDocument9 pagesSpecification Sheet: Density Measurement of Petroleum Products by Hydrometer Methodh8pb8jzyhgNo ratings yet

- Csti Csto Catalog 2020Document2 pagesCsti Csto Catalog 2020Sói CaNo ratings yet

- Peltier CoolerDocument2 pagesPeltier CoolerDagang ManNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Youth Camp Registration Form-2022Document1 pageYouth Camp Registration Form-2022FlerkNo ratings yet

- ANG DELAVEGA FinalPositionPaperDocument6 pagesANG DELAVEGA FinalPositionPaperZane IbalaNo ratings yet

- Presentation AcetanilideDocument22 pagesPresentation AcetanilideNovitasarii JufriNo ratings yet

- MSDS DowthermDocument4 pagesMSDS DowthermfebriantabbyNo ratings yet

- Rectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Document4 pagesRectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Lintas LtiNo ratings yet

- OPTCL-Fin-Bhw-12Document51 pagesOPTCL-Fin-Bhw-12Bimal Kumar DashNo ratings yet

- Indoor Air Quality Standard Procedures - 2014 RevDocument12 pagesIndoor Air Quality Standard Procedures - 2014 RevFioriAmeliaHathawayNo ratings yet

- Management of DredgedExcavated SedimentDocument17 pagesManagement of DredgedExcavated SedimentMan Ho LamNo ratings yet

- Project ReportDocument14 pagesProject ReportNoah100% (7)

- Conquest CXAX Air-to-Water Heat PumpDocument6 pagesConquest CXAX Air-to-Water Heat PumpAlexandre LopesNo ratings yet

- Matters Signified by The Sublord of 11th Cusp in KP SystemDocument2 pagesMatters Signified by The Sublord of 11th Cusp in KP SystemHarry HartNo ratings yet

- SAT Practice Test 10 - College BoardDocument34 pagesSAT Practice Test 10 - College BoardAdissaya BEAM S.No ratings yet

- Discrete Wavelet TransformDocument10 pagesDiscrete Wavelet TransformVigneshInfotechNo ratings yet

- Lima Indiana Oil FieldDocument32 pagesLima Indiana Oil FieldCHARLES PATULAYNo ratings yet

- Solar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power GeneratorDocument4 pagesSolar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power Generatorluis fernandoNo ratings yet

- Birla MEEP Op ManualDocument43 pagesBirla MEEP Op ManualAshok ChettiyarNo ratings yet

- The 10 Most Famousfilipino Artists and Their MasterworksDocument3 pagesThe 10 Most Famousfilipino Artists and Their MasterworksGina MagtibayNo ratings yet

- English2 Q2 Summative Assessment 4 2Document4 pagesEnglish2 Q2 Summative Assessment 4 2ALNIE PANGANIBANNo ratings yet

- 9A02502 Transmission of Electric PowerDocument6 pages9A02502 Transmission of Electric PowersivabharathamurthyNo ratings yet

- Synthesis Essay Coming To Grips With GenesisDocument11 pagesSynthesis Essay Coming To Grips With Genesisapi-259381516No ratings yet

- Resume: Satyam KumarDocument3 pagesResume: Satyam KumarEr Satyam Kumar KrantiNo ratings yet

- Esterification Oil of WintergreenDocument8 pagesEsterification Oil of WintergreenMaria MahusayNo ratings yet

- The History of AstrologyDocument36 pagesThe History of AstrologyDharani Dharendra DasNo ratings yet

- Contoh CV / Daftar Riwayat HidupDocument2 pagesContoh CV / Daftar Riwayat HiduprusmansyahNo ratings yet

- Haldex-Barnes 2-Stage Pump For Log SplittersDocument2 pagesHaldex-Barnes 2-Stage Pump For Log SplittersPer Akkamaan AgessonNo ratings yet

- Veronte Autopilot Kit DatasheetDocument2 pagesVeronte Autopilot Kit DatasheetEkmedzicNo ratings yet

- Terminals of Ecm: E3 E4 E5 E6Document2 pagesTerminals of Ecm: E3 E4 E5 E6jeremih alhegn100% (1)

- BIO 201 Chapter 11 LectureDocument34 pagesBIO 201 Chapter 11 LectureDrPearcyNo ratings yet