Professional Documents

Culture Documents

QA-FM-RY-071 Rev.02 Pump Engineering Assesment Report Forms

QA-FM-RY-071 Rev.02 Pump Engineering Assesment Report Forms

Uploaded by

nnonine88Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA-FM-RY-071 Rev.02 Pump Engineering Assesment Report Forms

QA-FM-RY-071 Rev.02 Pump Engineering Assesment Report Forms

Uploaded by

nnonine88Copyright:

Available Formats

PUMP SERVICE INSPECTION REPORT

Job No. วันทีร่ ับ กำหนดส่งวันที่

Type : Submersible Pump Split case Pump Centrifugal Pump Other

Customer : Pump Type - Size

Project Site Serial

Tag No:

Name: No:

Application Q: H: n:

Pumped

Temp: Impeller Ø: Year:

Medium:

Motor/Serial No: Coupling Make Coupling Spacer Length D.O.L. Y-∆

MDE Bearing: V: A: VFD Soft start

MNDE Bearing: Cos φ: Hz: RPM: Power: SF:

Additional Pump Data / ข ้อมูลปั๊ มเพิม

่ เติม:

ทดสอบผ่ำน Name Plate & Pump Photos / ภำพถ่ำย แผ่นป้ ำยเพลท และ ภำพของ Pump

ส่งไปแผนก

เบอร์ลัง

แผนก Mechanic

แผนก Mechanic

แผนกสี

รำยละเอียดกำรซ่อม

Coupling ลึก mm. เสมอ mm. ยาว mm.

Pulley ลึก mm. เสมอ mm. ยาว mm.

Incoming Test (QA) Dis- Assembly (ME) Assembly (ME) Final Test (QA) QC

่ ___________________ ลงชือ

ลงชือ ่ ___________________ ลงชือ

่ ___________________ ลงชือ

่ ___________________ ลงชือ

่ _________________

วันที่ ______/______/______ วันที่ ______/______/______ วันที่ ______/______/______ วันที่ ______/______/______ วันที่ ______/______/_____

เวลำ _________________ น. เวลำ _________________ น. เวลำ _________________ น. เวลำ _________________ น. เวลำ ________________ น.

Effective date : 10/7/2023 QA-FM-RY-059 Rev.03

Pump Engineering Assessment for Outage / Turn-around Executive Planning

SERVICE REPORT Installation Inspection/Check Supervision

Page No.

Diagnosis Maintenance Inspection Commissioning/Test run Modification

Repairing Technical support Training

สรุปผลวิเคราะห์

Customer : Pump Type - Size

Project Site Serial

Tag No:

Name: No:

Application Q: H: n:

Pumped

Temp: Impeller Ø: Year:

Medium:

Motor/Serial No: Coupling Make Coupling Spacer Length D.O.L. Y-∆

MDE Bearing: V: A: VFD Soft start

MNDE Bearing: Cos φ: Hz: RPM: Power: SF:

Author : Date :

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

Pump Engineering Assessment for Outage / Turn-around Executive Planning

SERVICE REPORT Installation Inspection/Check Supervision

Page No.

Diagnosis Maintenance Inspection Commissioning/Test run Modification

Repairing Technical support Training

สรุปผลวิเคราะห์

Customer : Pump Type - Size

Project Site Serial

Tag No:

Name: No:

Application Q: H: n:

Pumped

Temp: Impeller Ø: Year:

Medium:

Motor/Serial No: Coupling Make Coupling Spacer Length D.O.L. Y-∆

MDE Bearing: V: A: VFD Soft start

MNDE Bearing: Cos φ: Hz: RPM: Power: SF:

FFT Spectrum:

Diagnosis:

Author : Date :

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

Pump Engineering Assessment for Outage / Turn-around Executive Planning

SERVICE REPORT Installation Inspection/Check Supervision

Page No.

Trial Running Test Maintenance Inspection Commissioning/Test run Modification

Repairing Technical support Training

ทดสอบการท างาน Pump

Submersible

Customer : Pump Type - Size

Project Site Serial

Tag No:

Name: No:

Application Q: H: n:

Pumped

Temp: Impeller Ø: Year:

Medium:

Motor/Serial No: Coupling Make Coupling Spacer Length D.O.L. Y-∆

MDE Bearing: V: A: VFD Soft start

MNDE Bearing: Cos φ: Hz: RPM: Power: SF:

Time

H (Y)

ISO 10861-7

V (X)

mm/s RMS

POS. 1 - Motor NDE

A

Bearing

°C

Temp

Envelop g's P m/s^2

Displacement µm

dBm

Shock Pulse

dBc

H (Y)

ISO 10861-7

V (X)

mm/s RMS

POS. 2 - Motor DE

A

Bearing

°C

Temp

Envelop g's m/s^2

Displacement µm

dBm

Shock Pulse

dBc

H (Y)

ISO 10861-7

V (X)

mm/s RMS

POS. 3 - Pump DE

A

Bearing

°C

Temp

Envelop g's m/s^2

Displacement µm

dBm

Shock Pulse

dBc

H (Y)

ISO 10861-7

V (X)

mm/s RMS

POS. 4 - Pump NDE

A

Bearing

°C

Temp

Envelop g's m/s^2

Displacement µm

dBm

Shock Pulse

dBc

Author : Date :

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

Pump Engineering Assessment for Outage / Turn-around Executive Planning

SERVICE REPORT Installation Inspection/Check Supervision

Page No.

Trial Running Test Maintenance Inspection Commissioning/Test run Modification

Repairing Technical support Training

ทดสอบการทางาน

Customer : Pump Type - Size

Project Site Serial

Tag No:

Name: No:

Application Q: H: n:

Pumped

Temp: Impeller Ø: Year:

Medium:

Motor/Serial No: Coupling Make Coupling Spacer Length D.O.L. Y-∆

MDE Bearing: V: A: VFD Soft start

MNDE Bearing: Cos φ: Hz: RPM: Power: SF:

Date

Time

Thrust / Lift In

Off Device

Out

Bearing

Cooling ∆T

In

Bearing

Max ∆T = 10 °C

Out

Cooling

∆T

In

Jacket

Out

Cooling

Pump NDE

∆T

Balancing BLOL

Leak Off Deaerator

Line

∆T

In

Mechanical

Max ∆T = 8 °C

Out

Seal Liquid

∆T

Mechanical In

Seal

Out

Cooling /

Heating ∆T

In

Bearing

Max ∆T = 10 °C

Out

Cooling

∆T

In

Jacket

Out

Cooling

Pump DE

∆T

In

Mechanical

Max ∆T = 8 °C

Out

Seal Liquid

∆T

In

Mechanical

Out

Seal Cooling

∆T

Suction Pressure Bar

Discharge Pressure Bar

Balancing Pressure Bar

Differential Pressure Bar

Flow Rate m^3/h

Minimum Flow Rate (As Test) m^3/h Density As Test Kg/m^3 Viscosity As Test

DE: Note:

API Mech. Seal Flushing Plan

NDE:

Author : Date :

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

Pump Engineering Assessment for Outage / Turn-around Executive Planning

ISO 20816-1:2016 Mechanical vibration — Measurement and evaluation of machine vibration

Part 1: General guidelines

ISO 20816-1:2016 establishes general conditions and procedures for the measurement and evaluation of vibration using

measurements made on rotating, non-rotating and non-reciprocating parts of complete machines. It is applicable to

measurements of both absolute and relative radial ...

Zone A: The Vibration of newly commissioned ma chines would normally fall within this Zone.

Zone B: Machines with Vibration within this zone are normally considered acceptable for unrestricted long term Operation.

Zone C: Machines with Vibration within this zone are normally considered unsatisfactory for long-term con tinuous Operation.

Generally, machine may be operated for a limited period in this condition until a suitable opportunity arises for remedial action.

Zone D: Vibration values within this zone are normally considered to be of sufficient severity to Cause dam age to the machine.

Author : Date :

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

Pump Engineering Assessment for Outage / Turn-around Executive Planning

ISO 10816-3 is primarily used to detect vibration in industrial machinery, such as electro motors with a power output of more

than 15 kW and a speed range of more than 500 rpm (120 RPM-15000RPM)on stationary elements such as bearing housings,

utilizing accelerometers or velocity transducers

ISO 20816-3:2022 Mechanical vibration — Measurement and evaluation of machine vibration — Part 3: Industrial machinery

with a power rating above 15 kW and operating speeds between 120 r/min and 30 000 r/min

This first edition of ISO 20816-3 cancels and replaces ISO 7919-3:2009, ISO 7919-3:2009/Amd 1:2017, ISO 10816-3:2009

and ISO 10816-3:2009/Amd 1:2017, which have been merged and editorially revised. A list of all parts in the ISO 20816 series

can be found on the ISO website.

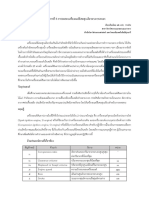

Classification of vibration severity zones for machines of Group 1: Large machines with rated power above 300 kW and

not more than 50 MW; electrical machines with shaft height H ≥ 315 mm

Classification of vibration severity zones for machines of Group 2: Medium-size machines with rated power above 15 kW

up to and including 300 kW; electrical machines with shaft height 160 mm ≤ H < 315 mm

Classification of vibration severity zones for machines of Group 3: Pumps with multivane impeller and with separate

driver (centrifugal, mixed flow or axial flow) with rated power above 15 kW

Classification of vibration severity zones for machines of Group 4: Pumps with multivane impeller and with integrated

driver (centrifugal, mixed flow or axial flow) with rated power above 15 kW

Zone A: The Vibration of newly commissioned ma chines would normally fall within this Zone.

Zone B: Machines with Vibration within this zone are normally considered acceptable for unrestricted long term Operation.

Zone C: Machines with Vibration within this zone are normally considered unsatisfactory for long-term con tinuous Operation.

Generally, machine may be operated for a limited period in this condition until a suitable opportunity arises for remedial action.

Zone D: Vibration values within this zone are normally considered to be of sufficient severity to Cause dam age to the machine.

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

Pump Engineering Assessment for Outage / Turn-around Executive Planning

ISO 10816 - 7 - 2009Mechanical vibration — Evaluation of machine vibration by measurements on non rotating parts Part 7:

Rotodynamic pumps for industrial applications, including measurements on rotating shafts

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

Pump Engineering Assessment for Outage / Turn-around Executive Planning

Effective date : 10/7/2023 QA-FM-RY-071 Rev.01

You might also like

- Pressure Test 001Document2 pagesPressure Test 001Wisüttisäk Peäröön100% (1)

- บัญชีรายชื่อเครื่องจักรและอุปกรณ์: Equipment and Machine ListDocument3 pagesบัญชีรายชื่อเครื่องจักรและอุปกรณ์: Equipment and Machine Listpornnarong tosomNo ratings yet

- FM NM 018แบบประเมิณผลผู้ผลิตรายใหม่Document6 pagesFM NM 018แบบประเมิณผลผู้ผลิตรายใหม่phutthawongdanchai041215No ratings yet

- 4) P-FmeaDocument7 pages4) P-Fmeaphutthawongdanchai041215No ratings yet

- PFMEA - CP-CombiDocument64 pagesPFMEA - CP-CombiwgerbecNo ratings yet

- CNT-N1-RFA-MET-SN-0001 Method Statement For Sleeve InstallationDocument3 pagesCNT-N1-RFA-MET-SN-0001 Method Statement For Sleeve InstallationtadkratukNo ratings yet

- Manipulator Inspection Check ListDocument2 pagesManipulator Inspection Check Listchannarong50% (2)

- SY75C TH 20230601Document2 pagesSY75C TH 20230601nats.nerayaNo ratings yet

- MINUS A5 II (G N23 - 24) - Panasonic - Rev00Document2 pagesMINUS A5 II (G N23 - 24) - Panasonic - Rev00Ptah EngineeringNo ratings yet

- FM-MT-003-00 Equipment Periodical Inspection StandardDocument1 pageFM-MT-003-00 Equipment Periodical Inspection Standardphutthawongdanchai041215No ratings yet

- TSP Precision Steel Tube Manufacturing (Thailand) Co., LTD: Mill Test CertificateDocument5 pagesTSP Precision Steel Tube Manufacturing (Thailand) Co., LTD: Mill Test CertificateAzee TitouNo ratings yet

- Tgi TS 001Document2 pagesTgi TS 001Santi CheewabantherngNo ratings yet

- Turbne Water MeterDocument3 pagesTurbne Water Metersaroat moongwattanaNo ratings yet

- SY215C LC TH 20230601Document2 pagesSY215C LC TH 20230601nats.nerayaNo ratings yet

- Hydraulic Crane Inspection Check ListDocument2 pagesHydraulic Crane Inspection Check ListchannarongNo ratings yet

- โครงการ PDFDocument3 pagesโครงการ PDFSekson JunsukplukNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-10-23T01 - 26 - 29Document6 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-10-23T01 - 26 - 29Tonny DannyNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-15T07 - 01 - 20Document7 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-15T07 - 01 - 20Tonny DannyNo ratings yet

- 120hz 2.2kw Motor CDQC ChinaDocument3 pages120hz 2.2kw Motor CDQC ChinatomsiriNo ratings yet

- SY55C TH 20230601Document2 pagesSY55C TH 20230601nats.nerayaNo ratings yet

- Q7000EL - Control For SaleDocument4 pagesQ7000EL - Control For Saleสุวิด สกิดตลิ่งNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-11-20T01 - 27 - 07Document7 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-11-20T01 - 27 - 07Tonny DannyNo ratings yet

- SY35U TH 20230531Document2 pagesSY35U TH 20230531nats.nerayaNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-09T01 - 45 - 17Document7 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-09T01 - 45 - 17Tonny DannyNo ratings yet

- F Eng 20Document6 pagesF Eng 20Krit Rattana (Mark)No ratings yet

- 16-5) IPP TagDocument1 page16-5) IPP Tagphutthawongdanchai041215No ratings yet

- Daily ReportDocument11 pagesDaily ReportCherdchai nuntariNo ratings yet

- Pricelist Fujielectric PDFDocument62 pagesPricelist Fujielectric PDFNut AssanaiNo ratings yet

- LS Electric - Pricelist - MASTER - V12 - SpreadDocument1 pageLS Electric - Pricelist - MASTER - V12 - SpreadEkanit ChuaykoedNo ratings yet

- CNT-N1-RFA-MET-SN-0001 Method Statement For Sleeve InstallationDocument9 pagesCNT-N1-RFA-MET-SN-0001 Method Statement For Sleeve InstallationtadkratukNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-10-26T06 - 27 - 03Document6 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-10-26T06 - 27 - 03Tonny DannyNo ratings yet

- การเปลี่ยนรอบมอเตอร์ด้วยการเปลี่ยนโพลDocument5 pagesการเปลี่ยนรอบมอเตอร์ด้วยการเปลี่ยนโพลpaween saetaeNo ratings yet

- Sekisui Polymatech (Thailand) Co.,Ltd: Maintenance Monthly Report 2021 Maintenance ReportDocument1 pageSekisui Polymatech (Thailand) Co.,Ltd: Maintenance Monthly Report 2021 Maintenance ReportWanchanaNo ratings yet

- LiftDocument2 pagesLiftฟลุ๊ค ชนะชัยNo ratings yet

- Elevator Inspection Check List 1Document3 pagesElevator Inspection Check List 1channarongNo ratings yet

- การวิเคราะห์คุณภาพน้ำมันDocument4 pagesการวิเคราะห์คุณภาพน้ำมันSanoa100% (1)

- ตารางรายการสรุปงานเปลี่ยนแปลง (PS,FP,FUEL) - Reply-0601022Document3 pagesตารางรายการสรุปงานเปลี่ยนแปลง (PS,FP,FUEL) - Reply-0601022kotechakorn thirdchaiyaphoomNo ratings yet

- Fire Pump No.1 Mantainance ReportDocument2 pagesFire Pump No.1 Mantainance ReportPanisa BanimaNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-09T02 - 25 - 10Document7 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-09T02 - 25 - 10Tonny DannyNo ratings yet

- ปฏิบัติการที่ 5 การทดสอบเครื่องยนต์ดีเซลสูบเดียวDocument8 pagesปฏิบัติการที่ 5 การทดสอบเครื่องยนต์ดีเซลสูบเดียวWatsapon JunpayapNo ratings yet

- Testing Guide 5051Document7 pagesTesting Guide 5051ChaichaloemWaihorNo ratings yet

- Hoist Inspection Check ListDocument3 pagesHoist Inspection Check ListchannarongNo ratings yet

- Catalog แรงสูงDocument68 pagesCatalog แรงสูงKittisak BuakhaoNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-11-15T07 - 59 - 15Document7 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-11-15T07 - 59 - 15Tonny DannyNo ratings yet

- Quotation 1907192 COCO SEA PHUKET TO P'เทอดศักดิ์ D-TOP PHUKETDocument10 pagesQuotation 1907192 COCO SEA PHUKET TO P'เทอดศักดิ์ D-TOP PHUKETtherdsakNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-10-31T01 - 48 - 21Document7 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-10-31T01 - 48 - 21Tonny DannyNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-09T01 - 23 - 30Document7 pagesService Order List SAHACHARTGROUP - DANCHAI - PHU 2023-12-09T01 - 23 - 30Tonny DannyNo ratings yet

- Guideline Vdip by DIgSILENTDocument17 pagesGuideline Vdip by DIgSILENTSomticha PanichNo ratings yet

- VibrationDocument1 pageVibrationRucha TravellerNo ratings yet

- Example - Spec TOR ศูนย์กระจายสินค้าDocument176 pagesExample - Spec TOR ศูนย์กระจายสินค้าchock channel 19No ratings yet

- MCC Chiller Plant Equipment ScheduleDocument16 pagesMCC Chiller Plant Equipment SchedulePojsawat JunsanitNo ratings yet

- PIMODocument30 pagesPIMOsozodaaaNo ratings yet

- Fmea4thedition Master 140821195625 Phpapp01 PDFDocument51 pagesFmea4thedition Master 140821195625 Phpapp01 PDFFaiq Nur ZamanNo ratings yet

- Service Order List SAHACHARTGROUP - DANCHAI.PHU 2023-10-31T02 - 42 - 53-งานที่กำลังดำเนินการDocument7 pagesService Order List SAHACHARTGROUP - DANCHAI.PHU 2023-10-31T02 - 42 - 53-งานที่กำลังดำเนินการTonny DannyNo ratings yet

- Obk 28Document3 pagesObk 28naroechit uchupongamornNo ratings yet

- RSD Quality Report 11Document1 pageRSD Quality Report 11Red Royal CustomNo ratings yet

- SWOTDocument1 pageSWOTPeerasut ChaisrimaneepanNo ratings yet

- Shop Manual Diesel Engine 6M70 EURO3 (ภาษาไทย)Document294 pagesShop Manual Diesel Engine 6M70 EURO3 (ภาษาไทย)Phongphat MasingNo ratings yet

- 2.SPPM 450W-Monocrystaline Monofacial (MIT) - CompressedDocument2 pages2.SPPM 450W-Monocrystaline Monofacial (MIT) - CompressedPawrij SuriyaaroonrojNo ratings yet