Professional Documents

Culture Documents

3bhs201058e01 Rev - Ac800pec Sales Brochure 6

Uploaded by

Ghareeb TalaatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3bhs201058e01 Rev - Ac800pec Sales Brochure 6

Uploaded by

Ghareeb TalaatCopyright:

Available Formats

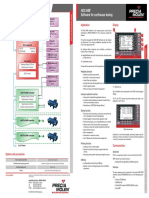

Communication

Process

IT environment

Industrial 31-3 control software

– IEC 611

> 1ms

Slow process I/O

Level 1

Software /Simu link Tools

tion MATLAB

Fast applica

Simulink

I/O Uniit

ps

Simulink

I/O Uniit

– control loochine

The key AC 800PEC capability is high-speed – sta te ma ABB IndustrialIT provides a complete suite

– protection

control application processing, as required in of AC 800PEC engineering tools for all

100 µs - 1 ms

power electronics, for integration into ABB's phases of your automation project – from

Typical cycle time

Level 2

standard ControlIT environment. engineering, installation and commission-

Implementation of the AC 800PEC software on program

ing to operation and maintenance.

lication VHDL

DPRAM

DPRAM

Very fast app ing

three performance levels provides a superb – fast task tim rs

ic and modulato

Configuration access with Control Builder

– pul se log are The ControlIT environment programming

to I/O hardw Fast process I/O

> 25ns

– powerLinkt protection

range of control and communication func- – very fas and service tools are connected directly to

tionality: the controller via Ethernet and RS-232

Level 3

serial links.

Level 1: IndustrialIT integration

OperateIT Process Panel Builder

This level is based on the industry standard

IEC 61131-3 and contains the slow-control,

monitoring, operating, displaying and regis- modulators, pulse logic with associated protec-

tering functions. tive functions, fast analog and binary inputs MATLAB®/ Simulink® and the Real Time

The development of programs in accordance and outputs, etc. It is implemented in the Workshop® (RTW). This requires special skills

FPGA (Field Programmable Gate Array) and that can be acquired by suitable training. ControlIT Control Builder

with the IEC 61131-3 standard is carried out in

the Control Builder M, ABB’s IndustrialIT programmed in VHDL (Very High Speed Alternatively, this part of a project can be

compatible engineering tool. Integrated Circuit Hardware Description assigned to ABB specialists, provided that all

Language). tasks are specified at the beginning of the

Level 2: Fast control software engineering phase.

This level contains the fast control and protec- Engineering workflow The resulting program code is then down- I/O specification

tive functions with cycle times from less than The project-specific high-speed control tasks loaded to the controller by the application MATLAB/Simulink

100 µs to a few milliseconds. and configuration of the AC 800PEC-specific engineer using an Installer Package. The

Fast, time-critical control and I/O tasks are pro- fast I/O are programmed by means of corresponding I/O specification is imported

grammed by means of MATLAB®/Simulink® into the Control Builder M by means of

Software developer Application engineer standard commands.

and integrated into the ControlIT environment

as a Simulink I/O unit. This allows perfect Requirements The application engineer only needs to access PECView

specification

interaction between the high-speed AC 800PEC the ControlIT level to define the standard

Fast control application

core functions and the standard ControlIT programming ControlIT tasks and interfaces (i.e. fieldbus and

(MATLAB/Simulink, FPGA)

software. S800 modules). Applications are created using

Control Builder M, and are then downloaded

Installation Fast control

Level 3: High-speed I/O control package application to the controllers.

(fast control specification

appl. firmware)

This level contains highly time-critical, hard-

ware-specific functions such as pulse-width

Control IT application

ControlIT Control Builder M

programming

(Control Builder M) The AC 800PEC software is managed with

Control Builder M Professional, ABB’s

10 ABB ABB 11

You might also like

- A100A CVR Install ManualDocument72 pagesA100A CVR Install ManualHarry Nuryanto83% (6)

- MPLab Tutorial v1Document45 pagesMPLab Tutorial v1ASIM RIAZNo ratings yet

- 02 20R300 1 C200 Controller Architecture PDFDocument38 pages02 20R300 1 C200 Controller Architecture PDFmiraNo ratings yet

- IEE61850 For Intelligent SubstationsDocument5 pagesIEE61850 For Intelligent Substationsk_arindam1No ratings yet

- Aircraft Landing Gear SystemDocument12 pagesAircraft Landing Gear SystemPaul Pipi OkonkwoNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Mapping Security Frameworks To Your Critical Assets - A Focus On NIST & Regional Frameworks - 17 DecDocument28 pagesMapping Security Frameworks To Your Critical Assets - A Focus On NIST & Regional Frameworks - 17 DecDr. Puk Khanthap100% (1)

- Section3 Vendors List July 2018Document12 pagesSection3 Vendors List July 2018JAGUAR GAMINGNo ratings yet

- Isa Iec 624Document45 pagesIsa Iec 624Aristóteles Terceiro NetoNo ratings yet

- SicarDocument103 pagesSicarenrique campos100% (3)

- Protect - MNS Motor Management INSUM: Technical InformationDocument53 pagesProtect - MNS Motor Management INSUM: Technical InformationAbhijith Sreevalsam100% (1)

- Istoria CMM (In Engleza) PDFDocument20 pagesIstoria CMM (In Engleza) PDF26110100% (1)

- NOA - NAMUR Open ArchitectureDocument5 pagesNOA - NAMUR Open ArchitectureudhaiiNo ratings yet

- Mitsubishi IQ F PLCDocument192 pagesMitsubishi IQ F PLCChi Nguyen NgocNo ratings yet

- Understanding SCADAs Modbus ProtocolDocument32 pagesUnderstanding SCADAs Modbus ProtocolCTKuoNo ratings yet

- Sicam Pas: Automation For Energy SystemsDocument8 pagesSicam Pas: Automation For Energy SystemsSerge RinaudoNo ratings yet

- AN INTERIM GUIDE ON Standard BOQ Section 1 Roadworks JKRDocument165 pagesAN INTERIM GUIDE ON Standard BOQ Section 1 Roadworks JKRekia_my100% (2)

- S01. Introduction To Integration of Industrial Processes PDFDocument29 pagesS01. Introduction To Integration of Industrial Processes PDFEnrique KawataNo ratings yet

- Introduction DCS System r1Document44 pagesIntroduction DCS System r1jalilNo ratings yet

- Simatic Pcs 7: Performance You TrustDocument42 pagesSimatic Pcs 7: Performance You TrustAhmed KhairiNo ratings yet

- AC 800PEC Sales BrochureDocument12 pagesAC 800PEC Sales BrochureMohd Lutfi MahaliNo ratings yet

- 5 Valmet Valimaki 18112015Document12 pages5 Valmet Valimaki 18112015Rio YuwandiNo ratings yet

- Modularity and Architecture of PLC-based Software PDFDocument18 pagesModularity and Architecture of PLC-based Software PDFGTutorNo ratings yet

- Parallel Pumps Bench,: Computer Controlled Series/ With SCADA PBSPCDocument16 pagesParallel Pumps Bench,: Computer Controlled Series/ With SCADA PBSPCDaniel VergaraNo ratings yet

- Public 1541807902 Chapter-14b-Io-LinkDocument19 pagesPublic 1541807902 Chapter-14b-Io-LinkFoaad HawarNo ratings yet

- Solution-Brief Locamation EN v2Document4 pagesSolution-Brief Locamation EN v2JYOTHEESWARA NAIDUNo ratings yet

- Enterprise Environment Monitoring System Management SoftwareDocument1 pageEnterprise Environment Monitoring System Management SoftwareblegedesNo ratings yet

- Building Energy Data InsightsDocument22 pagesBuilding Energy Data InsightsjgnmoqjidncpobeimuNo ratings yet

- Automate Your Substations with SICAM PASDocument8 pagesAutomate Your Substations with SICAM PASPontasNo ratings yet

- MELSEC iQ-F Series PDFDocument192 pagesMELSEC iQ-F Series PDFedu126121No ratings yet

- Automation Studio P7 Brochure English HighDocument28 pagesAutomation Studio P7 Brochure English HighraviwppNo ratings yet

- 1MRK500016-BEN en PYRAMID Substation AutomationDocument16 pages1MRK500016-BEN en PYRAMID Substation Automationleonardo_melo_costaNo ratings yet

- Automation Studio E6 Educational EditionDocument12 pagesAutomation Studio E6 Educational EditionPS LinnNo ratings yet

- 2VAA005093 HR D en Series Control and IO Lo-Res BrochureDocument7 pages2VAA005093 HR D en Series Control and IO Lo-Res BrochureJulioNo ratings yet

- C200 Controller Rack ArchitectureDocument54 pagesC200 Controller Rack ArchitectureFathima MinishaNo ratings yet

- 02 Rudi Both Connected PlantDocument21 pages02 Rudi Both Connected PlantLenkoNo ratings yet

- GP-Pro ex-basic trainingDocument244 pagesGP-Pro ex-basic trainingDAJIMMANZ TVNo ratings yet

- J131 UNITROL® 1010 / 1020 Service and Commissioning TrainingDocument3 pagesJ131 UNITROL® 1010 / 1020 Service and Commissioning TrainingHernan NarezoNo ratings yet

- Bu30a05c10 01enDocument2 pagesBu30a05c10 01enAmit MishraNo ratings yet

- LNA08111 eDocument72 pagesLNA08111 eAdonai BinghimanNo ratings yet

- Germany: Manufacturer /brand Image Notable Feature Available Models Country of OriginDocument7 pagesGermany: Manufacturer /brand Image Notable Feature Available Models Country of OriginAngelNo ratings yet

- In-System Programmability Guidelines For MAX II Devices: Operating ConditionsDocument12 pagesIn-System Programmability Guidelines For MAX II Devices: Operating ConditionsThong ChanNo ratings yet

- I400 WBF Software For Continuous DosingDocument2 pagesI400 WBF Software For Continuous Dosingsudhansu8beheraNo ratings yet

- PLC TrainerDocument32 pagesPLC TrainermahderNo ratings yet

- Taauc: Computer Controlled Automobile With SCADADocument16 pagesTaauc: Computer Controlled Automobile With SCADABeshir Heyru MohammedNo ratings yet

- Computer Controlled 1.5 kW Steam Power Plant with SCADA and PID ControlDocument13 pagesComputer Controlled 1.5 kW Steam Power Plant with SCADA and PID ControlVu NghiaNo ratings yet

- The Benchmark in Controls - Technical HighlightsDocument16 pagesThe Benchmark in Controls - Technical HighlightsNAYEEM100% (1)

- Panel F 74 800 - PrintDocument14 pagesPanel F 74 800 - PrintELECTRICFIRE PERU SACNo ratings yet

- Study of Automation Systems (PLCs) in Process IndustriesDocument84 pagesStudy of Automation Systems (PLCs) in Process IndustriesHanut MathurNo ratings yet

- SICK PerformanceDisc 2013 - ENDocument2 pagesSICK PerformanceDisc 2013 - ENMichal KopcekNo ratings yet

- EcoStruxure For Data Center (BMS & EPMS)Document32 pagesEcoStruxure For Data Center (BMS & EPMS)Yoga SamNo ratings yet

- Open Protocol System Architecture Provides Third Party IntegrationDocument23 pagesOpen Protocol System Architecture Provides Third Party IntegrationIbrahim AntarNo ratings yet

- Industrial Process AutomationDocument16 pagesIndustrial Process Automationwalid bouzayaniNo ratings yet

- Mitsubishi iQ-F-FX Series Selection GuideDocument82 pagesMitsubishi iQ-F-FX Series Selection GuideNhậtQuangNguyễnNo ratings yet

- Healthcare Intelligent Building Management System - Reference ArchitectureDocument1 pageHealthcare Intelligent Building Management System - Reference Architectureexplorer2No ratings yet

- Machine Vision System For Total Quality Control of SMT Electronic CardsDocument5 pagesMachine Vision System For Total Quality Control of SMT Electronic Cardsapi-3706534No ratings yet

- Cyber Security Issues of Critical Components For Industrial Control SystemDocument6 pagesCyber Security Issues of Critical Components For Industrial Control SystemjermNo ratings yet

- Basic PLC Training Material - Part2Document50 pagesBasic PLC Training Material - Part2ruchikaporwal2018No ratings yet

- TDS Profile Catalog TDSDocument28 pagesTDS Profile Catalog TDSวิระศักดิ์ วัตถุNo ratings yet

- Automated Process Control Through Programmable Logic Controller (PLC) For National Economic DevelopmentDocument9 pagesAutomated Process Control Through Programmable Logic Controller (PLC) For National Economic DevelopmentZamfirMarianNo ratings yet

- Yokogawa Centum CS3000Document43 pagesYokogawa Centum CS3000Hammad AshrafNo ratings yet

- Industrial 16-Port Managed Ethernet Switch With 16x10/100Base-T (X)Document4 pagesIndustrial 16-Port Managed Ethernet Switch With 16x10/100Base-T (X)oring2012No ratings yet

- MMS 4.0 - Station 1Document22 pagesMMS 4.0 - Station 1Edgardo MoyanoNo ratings yet

- CC-Link ThuongDocument83 pagesCC-Link Thuongtoàn vũ vănNo ratings yet

- Establishment of A Control Philosophy For The Pebble Bed Modular Reactor FJE Laubscher, HA GrobbelaarDocument6 pagesEstablishment of A Control Philosophy For The Pebble Bed Modular Reactor FJE Laubscher, HA GrobbelaarMuhammad TaufikNo ratings yet

- AI-Based Methods in Practical Fault Location of Medium Voltage Distribution FeedersDocument6 pagesAI-Based Methods in Practical Fault Location of Medium Voltage Distribution FeedersRichard 'strezz' TariganNo ratings yet

- Check Your ECDIS Uses Latest IHO S-52 StandardsDocument4 pagesCheck Your ECDIS Uses Latest IHO S-52 StandardsgongaxNo ratings yet

- Material Science LEDDocument10 pagesMaterial Science LEDIndhujaNo ratings yet

- Limpet Mine Imaging Sonar (LIMIS) : 1013 NE 40thDocument9 pagesLimpet Mine Imaging Sonar (LIMIS) : 1013 NE 40thJamesNo ratings yet

- Tecnotest Analizador Gases Dignostico Stargas Family898 495 enDocument12 pagesTecnotest Analizador Gases Dignostico Stargas Family898 495 ennewslemNo ratings yet

- Symmetry 13 02195Document20 pagesSymmetry 13 02195sonNo ratings yet

- Computer Science Competence Based Syllabus Final Printing VersionDocument130 pagesComputer Science Competence Based Syllabus Final Printing Versionapi-323248884100% (1)

- Geografía de Venezuela 3er Año: 10-11 / 60 Share Save LikeDocument3 pagesGeografía de Venezuela 3er Año: 10-11 / 60 Share Save Likeorlando garciaNo ratings yet

- Vapt 381 RFPDocument54 pagesVapt 381 RFPRashid KamalNo ratings yet

- Pan Card Slip PrintDocument1 pagePan Card Slip PrintHimalay PratapNo ratings yet

- IEC 62040-2 Uninterruptible Power Systems (Ups) - Part 2: Electromagnetic Compatibility (EMC) Requirements Interpretation Sheet 1Document3 pagesIEC 62040-2 Uninterruptible Power Systems (Ups) - Part 2: Electromagnetic Compatibility (EMC) Requirements Interpretation Sheet 1Agfagf212No ratings yet

- The Impact of Digital Advertising On Consumer Purchase DecisionsDocument11 pagesThe Impact of Digital Advertising On Consumer Purchase DecisionsyusufNo ratings yet

- Install Pfsense+luscaDocument36 pagesInstall Pfsense+luscaBisul AsuNo ratings yet

- Mba Ii Semester Assignment (Batch 2018-20) : SpecificationsDocument6 pagesMba Ii Semester Assignment (Batch 2018-20) : Specificationsakshara pradeepNo ratings yet

- Thermo Fluids Ime-241L Lab Report: Prof. DR Salman Habib Hassan Ali Butt 2017-IM-39Document19 pagesThermo Fluids Ime-241L Lab Report: Prof. DR Salman Habib Hassan Ali Butt 2017-IM-39Mahrukh ChaudharyNo ratings yet

- Combivert: Instruction Manual Power Supply Unit R5-C V1.1Document28 pagesCombivert: Instruction Manual Power Supply Unit R5-C V1.1ade izuanNo ratings yet

- Experience Integrated Production Modeling-Digital-OilfieldDocument2 pagesExperience Integrated Production Modeling-Digital-OilfieldabdounouNo ratings yet

- PLC Laboratory Exercise 2Document14 pagesPLC Laboratory Exercise 2Earl Patrick EugenioNo ratings yet

- INTERMEC EasyCoder PC4 Parts ListDocument30 pagesINTERMEC EasyCoder PC4 Parts ListC LNo ratings yet

- Aveva Intouch Access Anywhere Secure Gateway Administrator ManualDocument46 pagesAveva Intouch Access Anywhere Secure Gateway Administrator Manualel misNo ratings yet

- V3435SQ - SQ Programming and Front Cover ManualDocument16 pagesV3435SQ - SQ Programming and Front Cover ManualFaba FacturaNo ratings yet

- Pcs Fca140 Leaflet Interactiveonline enDocument4 pagesPcs Fca140 Leaflet Interactiveonline enLyonelNo ratings yet

- Câmera T5Pro USER MANUALDocument144 pagesCâmera T5Pro USER MANUALFamília CoelhoNo ratings yet

- Development With WebLogic Server 12c and MavenDocument50 pagesDevelopment With WebLogic Server 12c and MavenWilson VerardiNo ratings yet

- Lebanese International University School of EngineeringDocument9 pagesLebanese International University School of EngineeringMohamad AyoubNo ratings yet